HEATMKIT b

Page 4DA

fiTROM

CIRCUIT DESCRIPTION

_ItI4II I IIIIII1I«IIII IIIIIIIIIII•II IIIIIIIIII I »IIIIIIIt•l*II•II111tl1II•li•IIIIIiItIlI*'•<

LEFT CHANNEL PREAMPLIFIER

ai•)i*ii*MIiiiiit•»i iM11)iMivf

IUMII I1IMIHI iII l< Ml

LEFT CHANNEL POWER AMPLIFIER

h-

3

CL

z

:z

-z

:<

-i

:u

AUX

TUNER

XTAL PHONO

:“MAG. PHONO

y

t

VCW

y

6EU7

^I1I1III«fl IIIIIIIIII I IfIIIIIIiIIII*IIII| | I!IIII||IIIAIIIIIIII|I I 1IMIIIIII•IIIIIIIII4I I II*«II•IiXl1191 v1*114111 11 1*11•11

SOURCE

SELECTOR MC

SELE'

IDE 1

CTOR |

VI B1/2 6EU7 TONE CONTROL jV6 6AN6 V7 EL 84

V3 6AU6 NETWORK !1ve EL84 LEFT

"SPEAKER

i•11•i*1111m11*»11111 1 1 1 11111111»111111111111111*

£». I I IIIIIfII II«IIII1II•III III»1II I tI»I»II«»M«I4 I IIIIt I1(ItI•IiIII*IMt

-to

tHAUX

:o.

:z

=uJ TUNER

:z

:z

-<

E5XTAL PHONO

:h

:5

:gMAG. PHONO

-0£

RIGHT CHANNEL PREAMPLIFIER

t

CW V2B 1/2 6EU7

V4 6AU6 [TONE CONTROL

NETWORK

ll lIIIill 1IIIII I*Iit I I I I II IIII IIIt 11II II) II«IM1 I 1

»

RIGHT CHANNEL POWER AMPLIFIER

L| V5 6AN8 |—»|

V9 EL84

V10 EL84 RIGHT

SPEAKER

V2A 1/2 6EU7

11i11>t11111i•111 1 ii i •1111111r111iii i•i«i11111it1 1 1ii11•1 1 ii111

1

11111i1111«) 1111 i t1111111

»

it11ai1111it11•11»iii tiin1111i»11«iia1

1

«1 1 1m1111111i1 1 1111 < 11111111

1

«i

BLOCK DIAGRAM

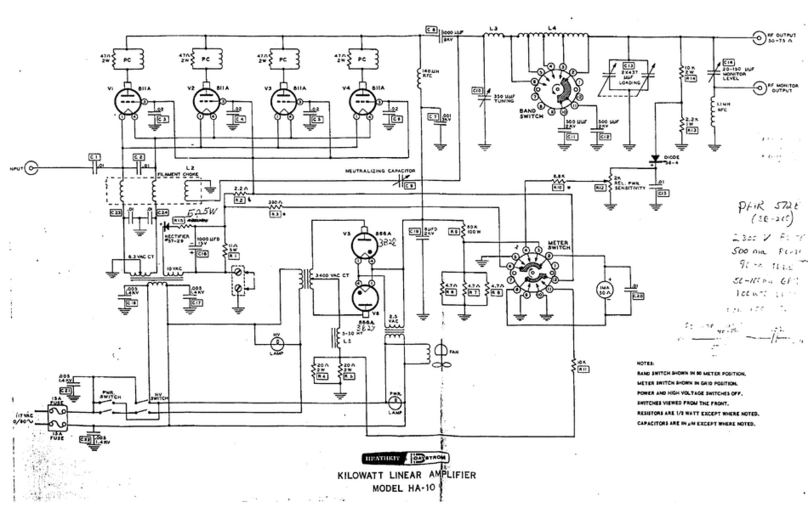

The Model AA-151 Stereo Amplifier has three

basic sections; acommon power supply, the

left channel preamplifier and amplifier, and the

right channel preamplifier and amplifier.

The left and right channel preamplifier and

amplifier circuits are identical, therefore, only

the left channel and power supply circuits will

be discussed. For the purpose of this description,

assume that the SOURCE switch is in the MAG.

PHONO position and that the MODE selector

switch is in the LEFT AMPposition. We suggest

that you frequently refer to the Schematic and

Block Diagrams.

The audio signal presented to the MAG. PHONO

input is applied directly to the grid of tube VIA.

VIA is ahigh-gain, low-noise preamplifier stage.

The amplified signal is coupled from the plate

of VIA through capacitor C5 to the grid of VI B.

Resistors R9 and RIO, along with capacitors

C3, C4 and C6, provide RIAA equalization for

magnetic phono cartridges. VI Bis also ahigh-

gain preamplifier. The amplified signal from its

plate is coupled by capacitor C8 and the VOL-

UME control to the grid of V3.

V3 further increases the amplitude of the sig-

nal. The amplified signal from V3 is fed through

capacitor Cll to the packaged electronic tone

control network. This network consisting of sev-

eral resistors and capacitors, encapsulated in

an insulating material, operate in conjunction

with R20 and R23 to perform the BASS and

TREBLE control functions. The output signal of

the tone control network is applied through the

MODE switch to the grid of V6A.

The signal is again amplified by V6A and is

applied to the grid of V6B, the phase inverter

V6B does not amplify the signal, but applies

the signal in proper phase, to each tube (V7

and V8) in the push-pull amplifier output stage.

The signal from the push-pull output stage is

coupled through audio output transformer T1

to the left channel speaker system.

The power supply uses a5AR4 tube as afull-

wave rectifier. The filter network, consisting

of capacitors C25, C24, C23, and C22, and re-

sistors R36, R35, and R34, removes the 120

cycle ripple from the B+ voltage.