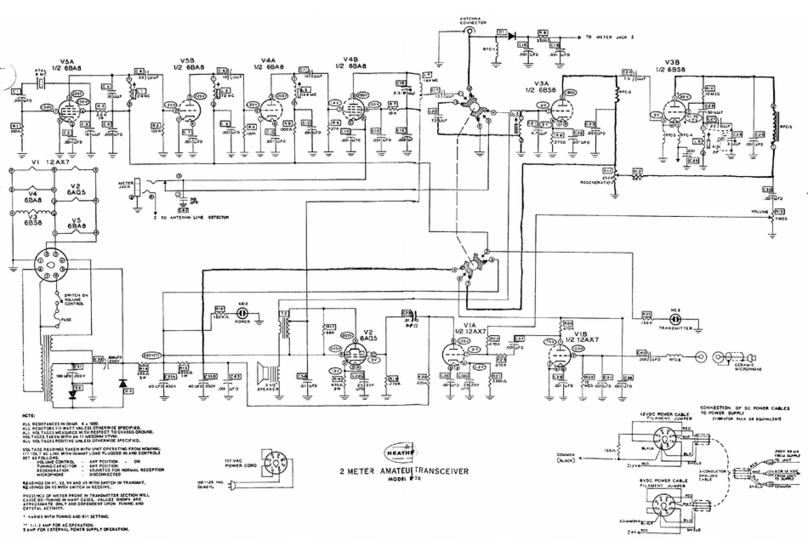

Page 5

If the metering plug is inserted all the way

into the jack, the meter will read final ampli-

fier cathode current, typically in the order of

20-25 ma. The meter plug must be withdrawn

from this position for normal operation once

proper tuneup has been accomplished. The

meter plug in this fully inserted position over-

rides the normal functioning of the transmit -

receive switch and allows final amplifier plate

current to flow regardless of switch position.

With a key plug inserted all the way in the meter

jack, the transmitter may be used on CW if

desired, although considerable "back wave" may

result due to the fact that previous transmitter

stages are running constantly.

For phone operation, modulation is accomplished

by causing the plate and screen voltage source

for V4B to vary at the audio frequency rate

determined by the signal being passed through

the combination modulation -output transfor-

mer (see AUDIO SECTION description).

RECEIVER SECTION

The incoming signal received by the antenna

and arriving at the antenna connector via the

transmission line is supplied to an impedance

matching tap on coil L5, through capacitor C20.

The resultant signal appearing across the broad-

ly tuned circuit consisting of L5 and C21 is fed

to the input of the RF amplifier stage V3A.

The output circuit of the RF amplifier is "im-

pedance coupled" to the cathode circuit of the

superregenerative detector V3B through capac-

itor C24. This arrangement provides consider-

able gain in the RF stage, which does not re-

quire neutralization as the feed point in the

detector circuit is relatively low impedance.

This means of coupling these two stages elimi-

nates the most trying problem in most super-

regenerative detectors in that a condition re-

ferred to as "suck -out" can occur where a

tuned circuit is not properly isolated from the

detector. In other instances where a tuned cir-

cuit (it may be a coil and capacitor combin-

ation or reflected antenna tuning) is closely

coupled, the detector will drop out of oscillation

as detector tuning passes the resonant fre-

quency of the interfering tuned circuit. In

addition to solving the above problem and pro-

viding gain, the RF amplifier also isolates the

antenna from the oscillating detector, mini-

mizing re -radiation from the detector into

the antenna.

The type of detector used is one which pro-

vides the most sensitivity for the number of

components required and is superregenerative.

In a straight regenerative detector, consider-

able sensitivity is achieved by adjusting the

signal feedback of the detector for a near

oscillating condition. In the regenerative cir-

cuit, the more feedback that can be employed

with stable operation short of the detector

actually going into oscillation, the greater will

be the gain.

The superregenerative detector employed here

carries the regenerative principle one step

further in that the detector actually goes in

and out of oscillation at a controlled rate.

In doing such, the detector periodically passes

through the point of maximum gain (just prior

to oscillation) and therefore provides optimum

gain from its circuit. This periodic rate, re-

ferred to as the "quench" frequency, is con-

trolled by the value of RFC5, and associated

components, and is in the vicinity of 20,000

cycles per second; therefore, the quench fre-

quency is inaudible. The detector circuit is

essentially a Colpitts type of oscillator circuit

in which interelectrode tube and stray capac-

ities form the normal feedback path. The detec-

tor cathode and heater are placed above RF

ground by RF chokes RFC3 and RFC4. The

plate circuit is bypassed for RF by C29.

The rear apron mounted 250 Ka linear po-

tentiometer Rh is adjusted for maximum sen-

sitivity by setting the value of B+ voltage at the

detector plate. The receiver configuration is

one of very good sensitivity. Three micro-

volts input will produce near complete quiet-

ing with usable signals extending down to 1/2

microvolt.

AUDIO SECTION

The detected audio signal passes through C30

to the 1 megohm volume control R13. Signal

flow proceeds through the audio mixing resistor

R22 to the grid of the audio driver VIA which is

coupled to the power output stage V2 by capac-

itor C35. The combination modulation -output

transformer T2 provides proper impedance

matching to the speaker with the unit operating

as a receiver. With the transmit -receive switch

in the receive position, no loading of the audio

output occurs at the primary modulation tap

because the cathode circuit of the transmitter

final amplifier is open. During receive, tubes

V5, V4 and section V1B are inoperative.