vizo 24/28

5.1 Installer Testing & Commissioning Tips

•The installer shall instruct the user in the operation

of the boiler, safety devices contained within the

boiler and instruction on how to re-pressurise the

system if the water pressure falls. The installer

should then hand over the instructions with the

Benchmark Logbook that has been completed.

•The user should be instructed to keep the

instructions in a safe place for servicing and future

reference.

•It is important to keep the boiler clear of dust

during the installation. In particular, do not allow

debris to enter the top of the boiler where the flue

connection is made. This may cause the fan outlet

to get blocked or combustion chamber to fill with

debris and will, of course, cause the boiler to fail to

ignite on first ignition. It is recommended that you

check the fan outlet before you light the boiler.

•Before you fit the boiler ensure that the pipe work

that you are installing is connected to the

appropriate connections on the boiler i.e. cold

water pipe to cold water inlet, hot water outlet to

the hot water tap etc.

•Because the boiler is actually operated, at the end

of each production stage, a small amount of water

is retained within the boiler when packed. Please

ensure that you spin the pump rotor manually

before firing the boiler.

•It is important that the boiler must be used in

conjunction with a Heat Line approved flue and all

flue connections are correctly sealed.

•Remember to flush out the system, both cold and

hot, in order to remove the debris from the system.

This should be done particularly where boilers are

being fitted to existing radiator circuits.

•Refer to BS 7593:1992 for the details to clean

DHW and Central heating system.

•This boiler has been factory set and does not

require any adjustments to the gas valve or fan

speed.

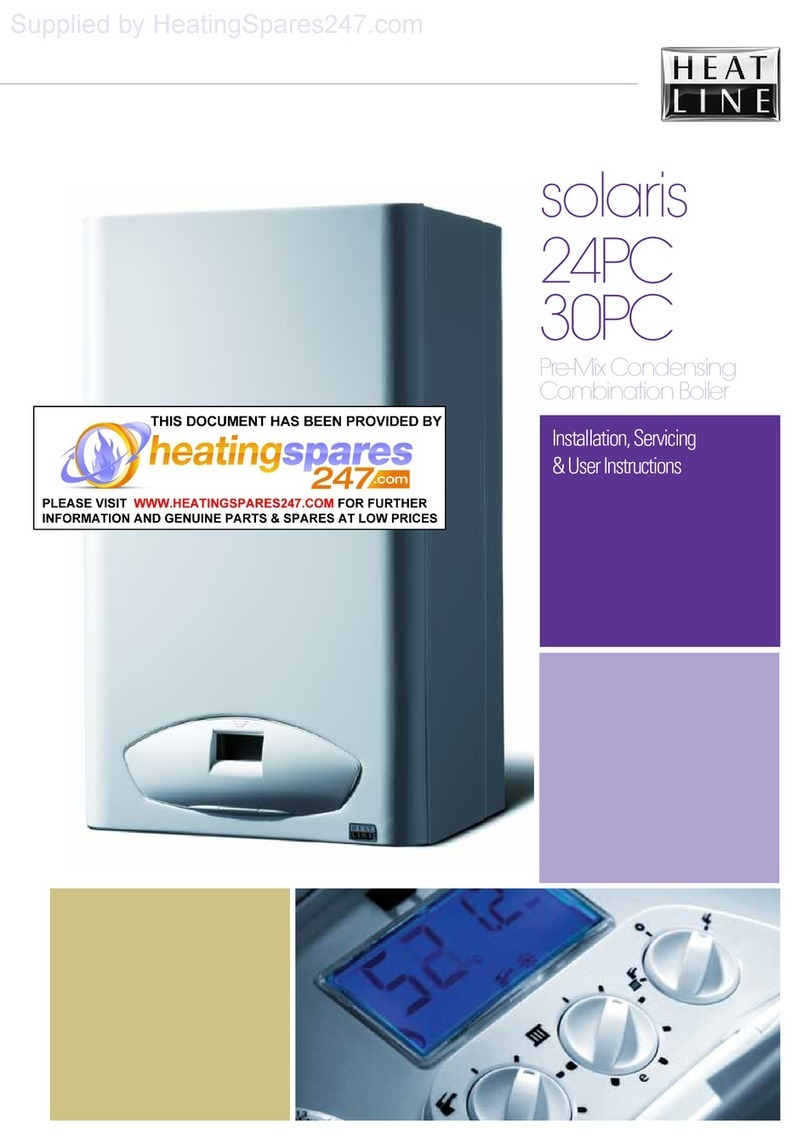

•Remember to release the small cap on top of the

auto air purge device on the pump, 1 turn, before

filling. This will ensure that air is removed as the

system fills.

•Do not use the pressure relief valve as a means

of flushing the system, please use the valve below

the pump. Discharging water from the system from

the pressure relief valve may allow water to seep

after you have left the job, causing the boiler to

lose pressure and debris to collect on the seating.

•The boiler is fitted with inlet filters both on the

cold water inlet and the central heating return. If

you are unable to obtain hot water at the faucet it is

likely that the cold water inlet valve filter has

become blocked, whilst blockage of the filter on

central heating return valve will cause the heater to

lock out at the overheat thermostat as the water

flow is reduced.

•If you are able to obtain hot water but not heating

it is also advisable to check the clock connections

and that the room thermostat and time clock are

calling for heat.

•Remember that after hot water draw off there is a

45 sec delay before the heating will fire up if No.3

dipswitch is in the OFF position, see fig 19 on

page 21

•When commissioning the boiler check the inlet

pressure is at 20mbar and burner pressure against

the Technical data on page 5.

•Note an anti-cycle delay time can be set up to a

maximum of 255 seconds by adjusting

potentiometer 2 as described in section 15.5 on

page 21.

If you experience any problems please refer to the

installation and commissioning guidelines within the

boiler instruction manual. If necessary, please contact

Heat Line

TM

Service Enquiries, in the UK, for further

advice and assistance on 0870 777 8318, in Ireland

call 01 466 4664.

NOTE – FOR INSTALLERS:

REMEMBER IT IS A LEGAL REQUIREMENT

TO COMPLETE THE BENCHMARK CODE OF

PRACTICE LOGBOOK BEFORE LEAVING

THE INSTALLATION.

5. General Installation

09