•The user should be instructed to keep the instructions in a safe place for

servicing and future reference.

•It is important to keep the boiler clear of dust during the installation. In

particular do not allow debris to enter the top of the boiler where the flue

connection is made.

•Before you fit the boiler ensure that the pipe work that you are installing is

connected to the appropriate connections on the boiler i.e. cold water pipe to cold

water inlet hot water outlet to the hot water tap etc. See Figure 1 for detail.

•Please ensure that you spin the pump rotor manually before firing the boiler.

•Remember to thoroughly flush the water circuits after isolating the boiler

Remember to thoroughly flush the water circuits after isolating the boiler Remember to thoroughly flush the water circuits after isolating the boiler

Remember to thoroughly flush the water circuits after isolating the boiler in

in in

in

order to remove any fluxes and debris from them.

order to remove any fluxes and debris from them.order to remove any fluxes and debris from them.

order to remove any fluxes and debris from them. This should be done

This should be done This should be done

This should be done

particularly where boilers are being fitted to existing radiator circuits.

particularly where boilers are being fitted to existing radiator circuits. particularly where boilers are being fitted to existing radiator circuits.

particularly where boilers are being fitted to existing radiator circuits.

•R

RR

Refer to BS 7593:

efer to BS 7593:efer to BS 7593:

efer to BS 7593:2006

20062006

2006 for the details to clean DHW and Central heating system.

for the details to clean DHW and Central heating system. for the details to clean DHW and Central heating system.

for the details to clean DHW and Central heating system.

•This boiler has been factory set

This boiler has been factory set This boiler has been factory set

This boiler has been factory set but adjustment may be required to the Heating

but adjustment may be required to the Heating but adjustment may be required to the Heating

but adjustment may be required to the Heating

input in order to match the heating demand. This can be done using

input in order to match the heating demand. This can be done using input in order to match the heating demand. This can be done using

input in order to match the heating demand. This can be done using

potentiometer R29

potentiometer R29potentiometer R29

potentiometer R29.

..

. See section

See section See section

See section 15 for details.

15 for details. 15 for details.

15 for details.

•To ensure that air is vented from the pump and heat exchanger as the system

fills release the small vent caps (1 turn) of the air vents which are located on top

of the pump and at the top left hand side of the heat exchanger before filling.

•Do not use the pressure relief valve as a means of flushing the system

Do not use the pressure relief valve as a means of flushing the systemDo not use the pressure relief valve as a means of flushing the system

Do not use the pressure relief valve as a means of flushing the system please

use the valve below the pump. Discharging water from the system from the

pressure relief valve may allow debris to collect on the seating allowing water to

weep after you have left the job causing the boiler to lose pressure and shut

down.

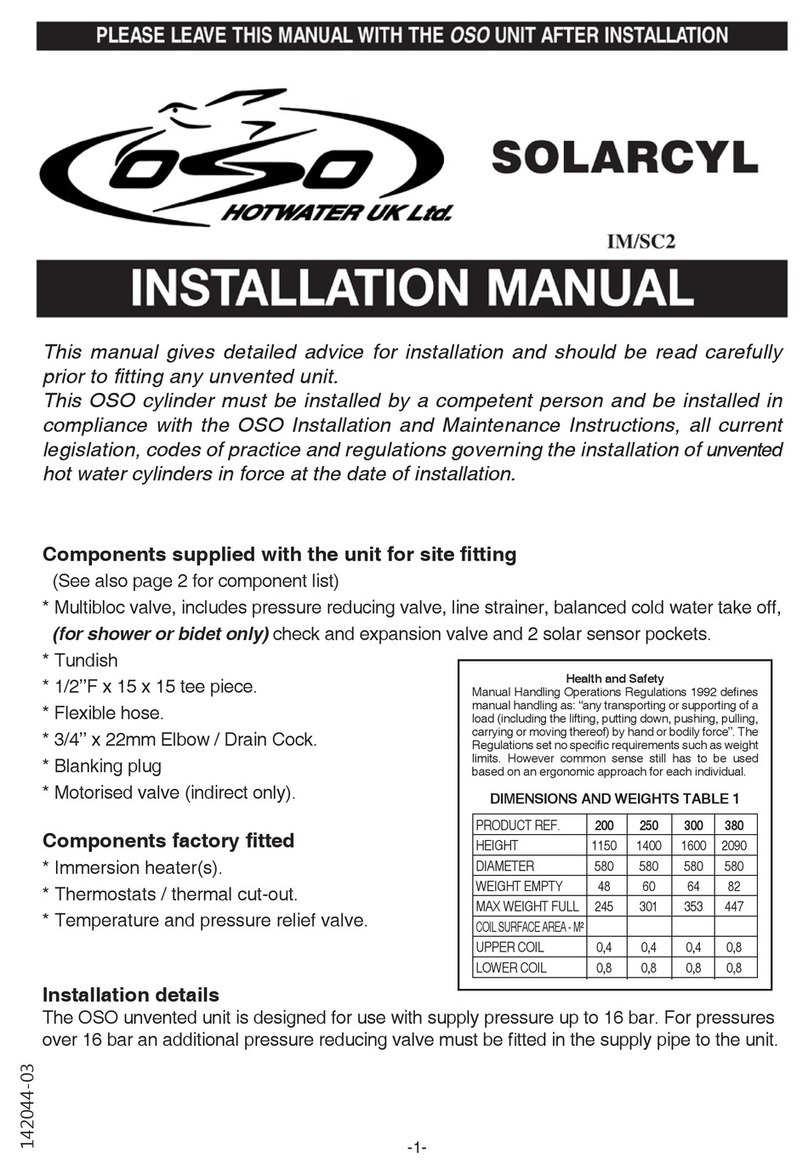

•The boiler is fitted with inlet filters both on the cold water inlet and the central

heating return. If you are unable to obtain hot water at the tap it is likely that the

cold water inlet valve filter has become blocked whilst blockage of the filter on

central heating return valve will cause the heater to lock out at the overheat

thermostat as the water flow is reduced.

•If you are able to obtain hot water but not heating it is also advisable to check the

clock connections and that the room thermostat and time clock are calling for

heat.

•Remember that after hot water draw off there is a 45 sec delay before the

heating will fire up if No.S3 dipswitch is in the OFF position

see fig 22

.

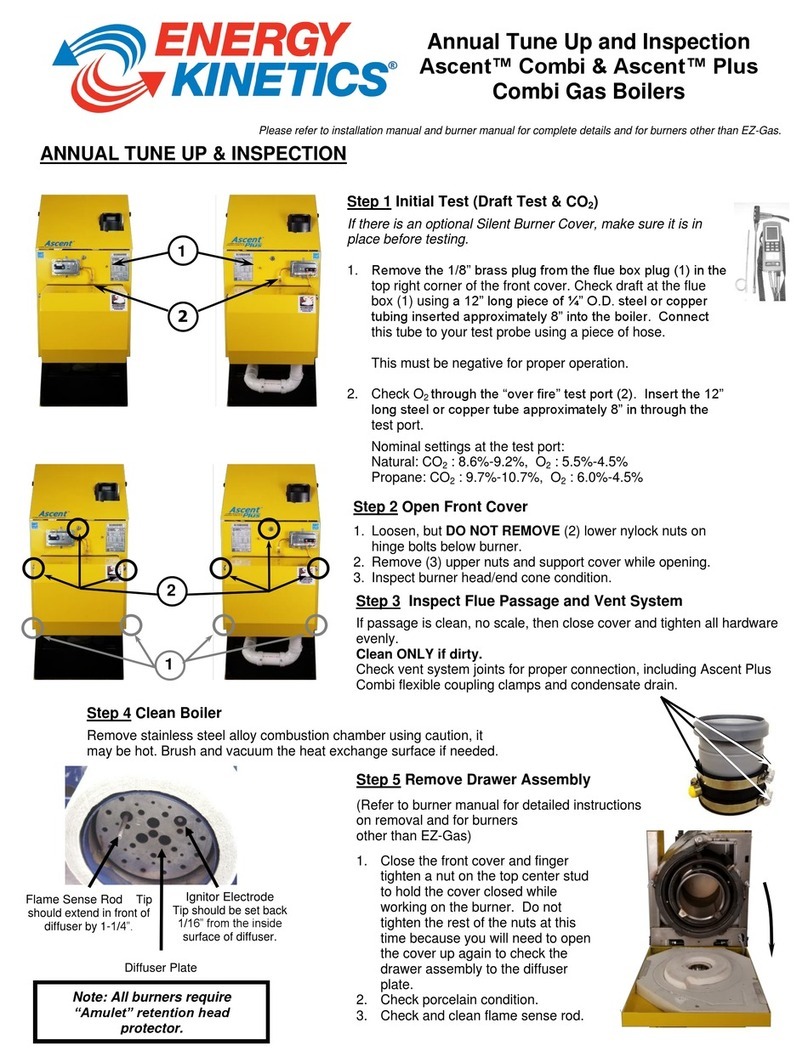

•When commissioning the boiler check the gas inlet pressure is 20mbar (NG) or

37mbar for LPG.

•Note an anti-cycle delay time can be set up to a maximum of 255 seconds by

adjusting potentiometer R28 as described in section

15.1

.

If you experience any problems please refer to the installation and commissioning

guidelines within the boiler instruction manual. If necessary please contact Heat

LineTM Service Enquiries in the UK on 0870 777 8341 for further advice or technical

assistance on 0870 777 8318

0870 777 83180870 777 8318

0870 777 8318.

NOTE

NOTE NOTE

NOTE –

––

– FOR INSTALLERS:

FOR INSTALLERS: FOR INSTALLERS:

FOR INSTALLERS:

REMEMBER IT IS A REQUIREMENT TO COMPLETE THE BENCHMARK CODE OF

REMEMBER IT IS A REQUIREMENT TO COMPLETE THE BENCHMARK CODE OF REMEMBER IT IS A REQUIREMENT TO COMPLETE THE BENCHMARK CODE OF

REMEMBER IT IS A REQUIREMENT TO COMPLETE THE BENCHMARK CODE OF

PRACTICE LOGBOOK BEFORE LEAVING THE INSTALLATION. YOU ARE ALSO

PRACTICE LOGBOOK BEFORE LEAVING THE INSTALLATION. YOU ARE ALSO PRACTICE LOGBOOK BEFORE LEAVING THE INSTALLATION. YOU ARE ALSO

PRACTICE LOGBOOK BEFORE LEAVING THE INSTALLATION. YOU ARE ALSO

REQUIRED TO REGISTER THE INSTALLATION WITH C.O.R.G.I.

REQUIRED TO REGISTER THE INSTALLATION WITH C.O.R.G.I.REQUIRED TO REGISTER THE INSTALLATION WITH C.O.R.G.I.

REQUIRED TO REGISTER THE INSTALLATION WITH C.O.R.G.I. OR YOUR LOCAL

OR YOUR LOCAL OR YOUR LOCAL

OR YOUR LOCAL

AUTHORITY.

AUTHORITY.AUTHORITY.

AUTHORITY.