HeatLink 11500 User manual

Serial Number

Hydraulic

Pressure

Check

HE 152

HE.15274

HE.12488_B © 05/2013 R&D-2

Slim-line Power Press Tool

11500

HeatLink Group Inc.

+1 (800) 661-5332

www.heatlinkgroup.com

L611500 Rev. B

Instruction Manual Pressing Tool

I

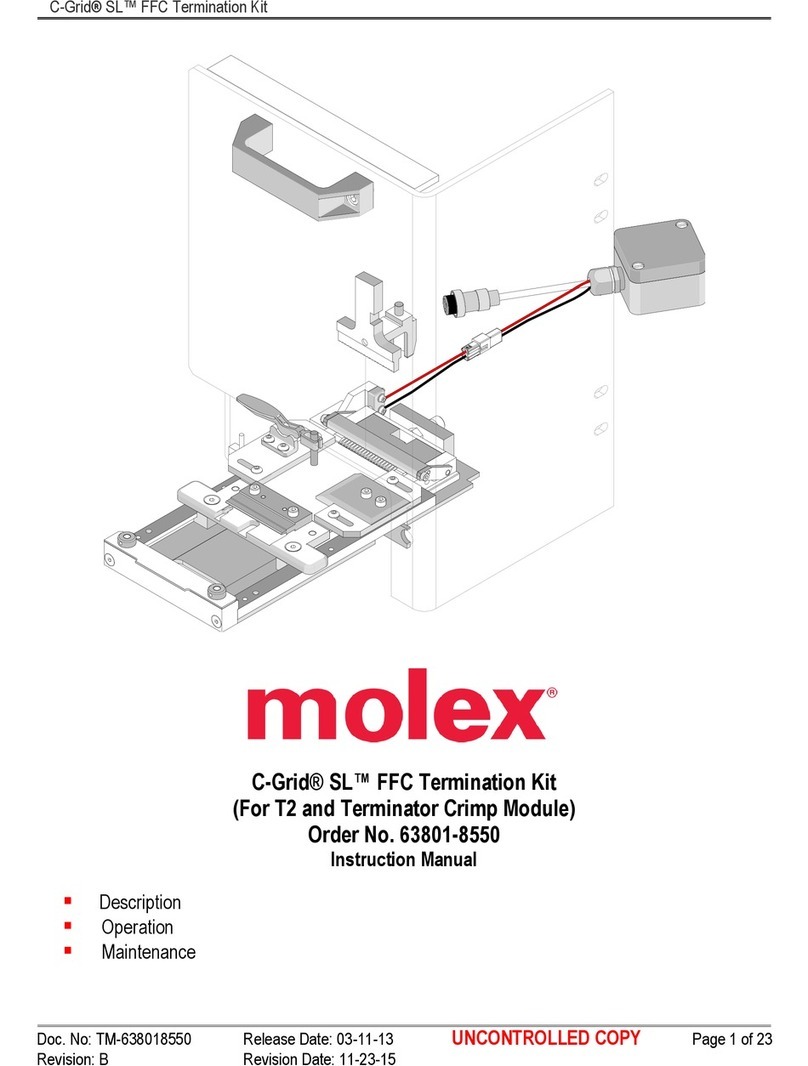

pic. 1

HE 152

HE.15274

Legend p.2

Legend pp.3-4

L611500 Rev. B © 05/2013

11500

15 min.

20 sec/5Hz

page VIII

RESTART

5 Makita BL1815

optionally:

Makita BL1830

9

8

14

7

23

6

Instruction Manual Pressing Tool

II

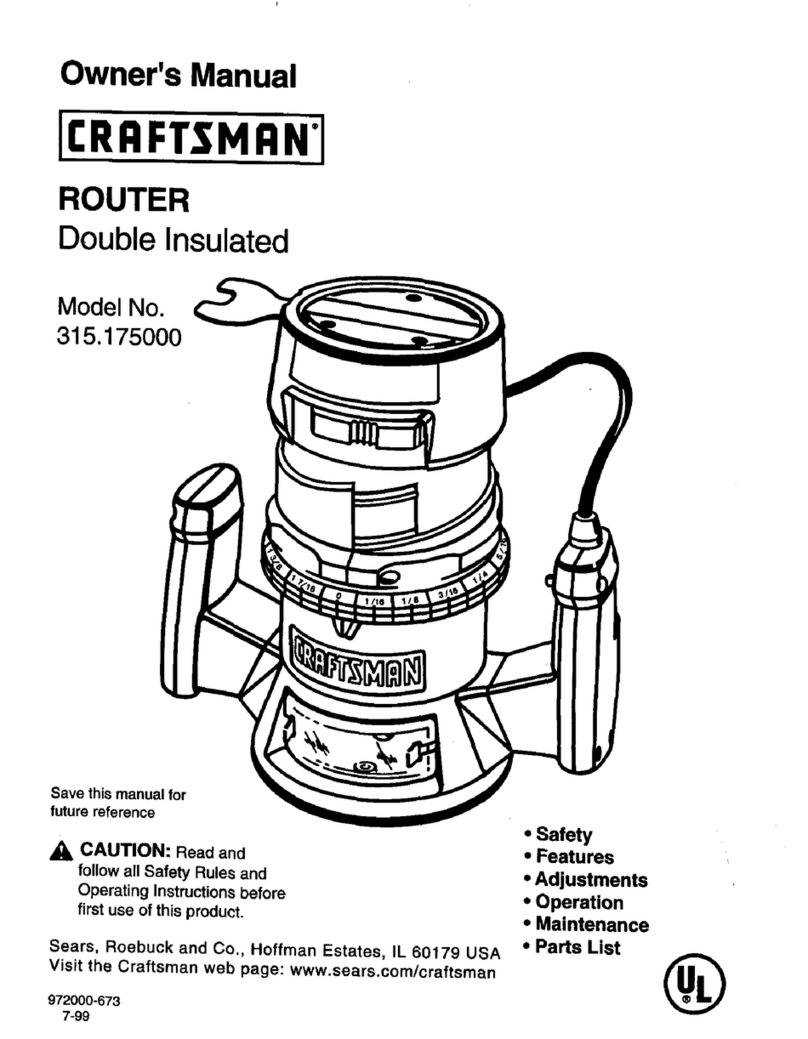

pic. 3

1

2

3

4

5

304711 batch# e.g. 304711

CV datecode e.g. C = 2009; V = July.

142 consecutive# e.g. „142“ = tool # 142

5

pic. 2

11500

Voltage: 18V DC

Thrust: 15 kN

HE.15275

HE.15274

L611500 Rev. B © 05/2013

11500

HE.12486

HeatLink Group Inc.

Head Office

4603E - 13th Street NE

Calgary, AB T2E 6M3-Canada

Instruction Manual Pressing Tool

III

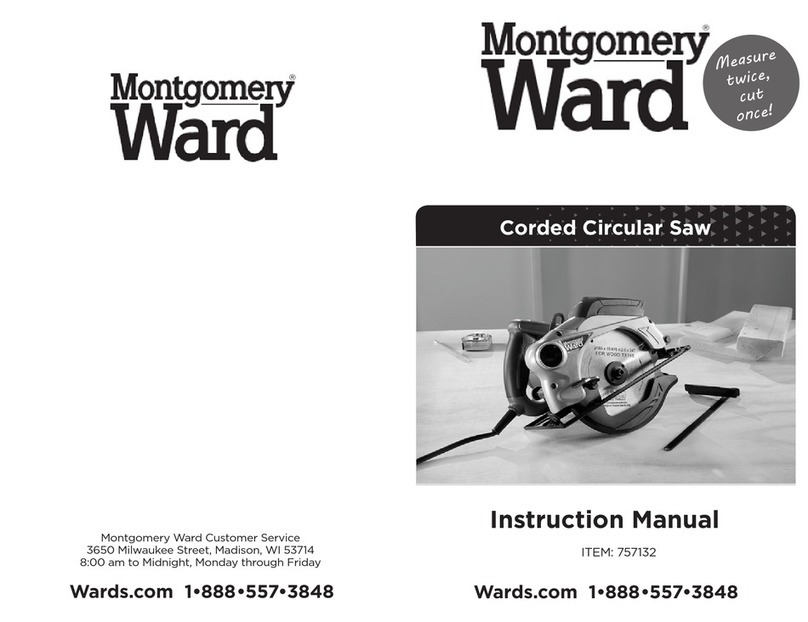

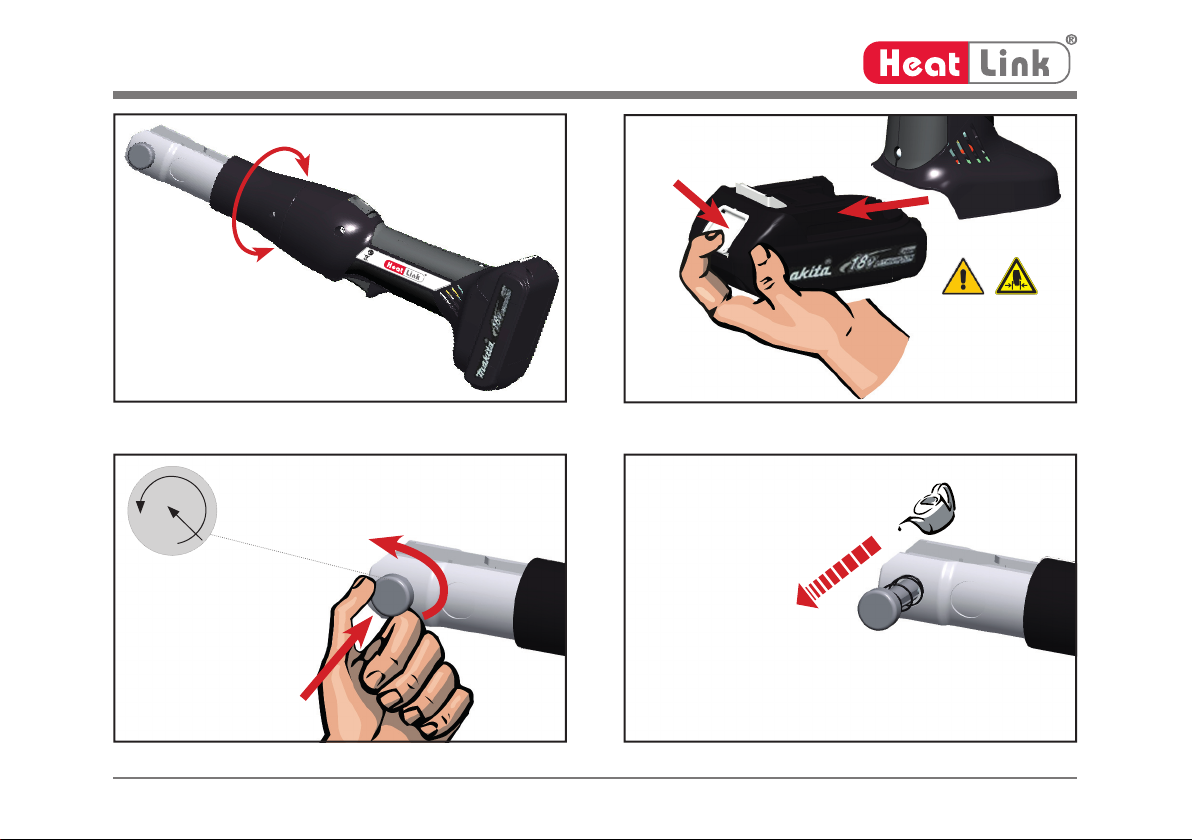

pic. 4 pic. 5

pic. 6 pic. 7 pic. 8

pic. 9 pic. 10

pic. 11

Li-ion

pic. 12

®

#884676B996

#884598C990

pic. 13

L611500 Rev. B © 05/2013

11500

Makita 15 min.

BL1815

optional:

Makita 22 min.

BL1830

CLICK

50 - 104°F

(10 - 40°C)

Instruction Manual Pressing Tool

IV

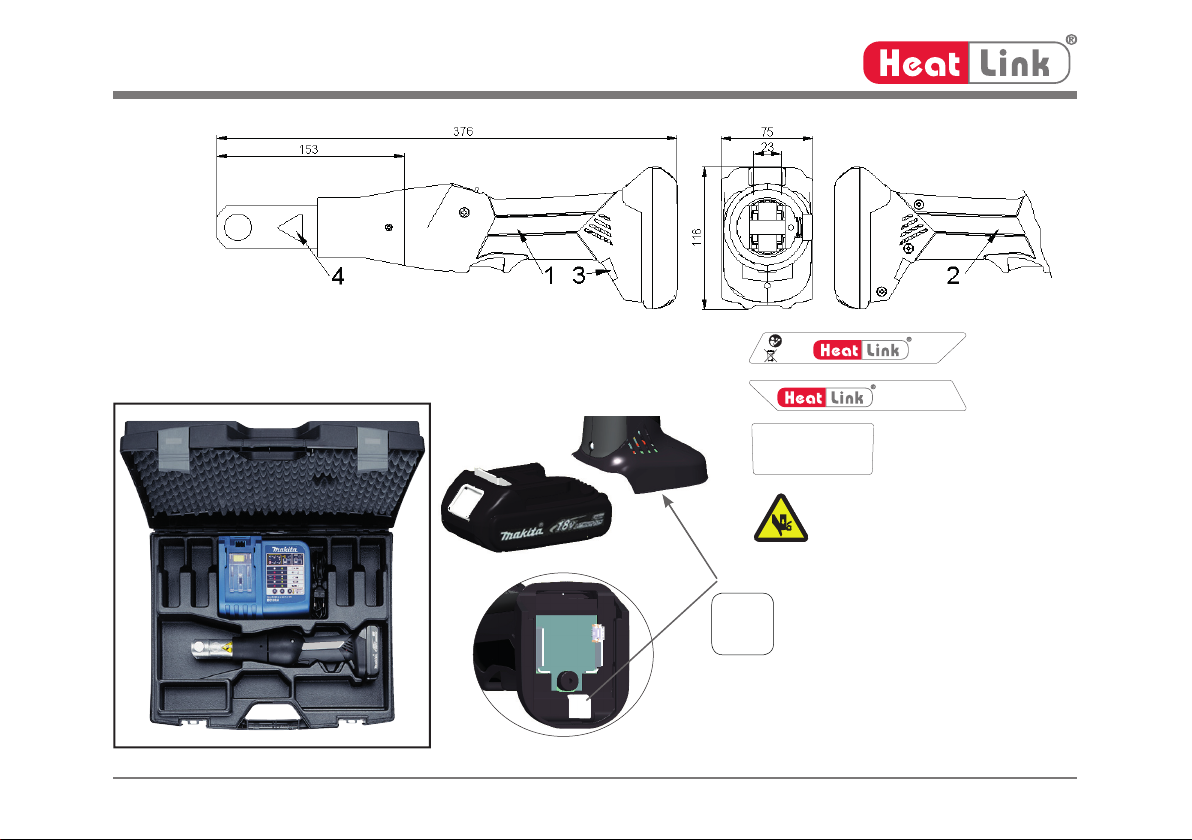

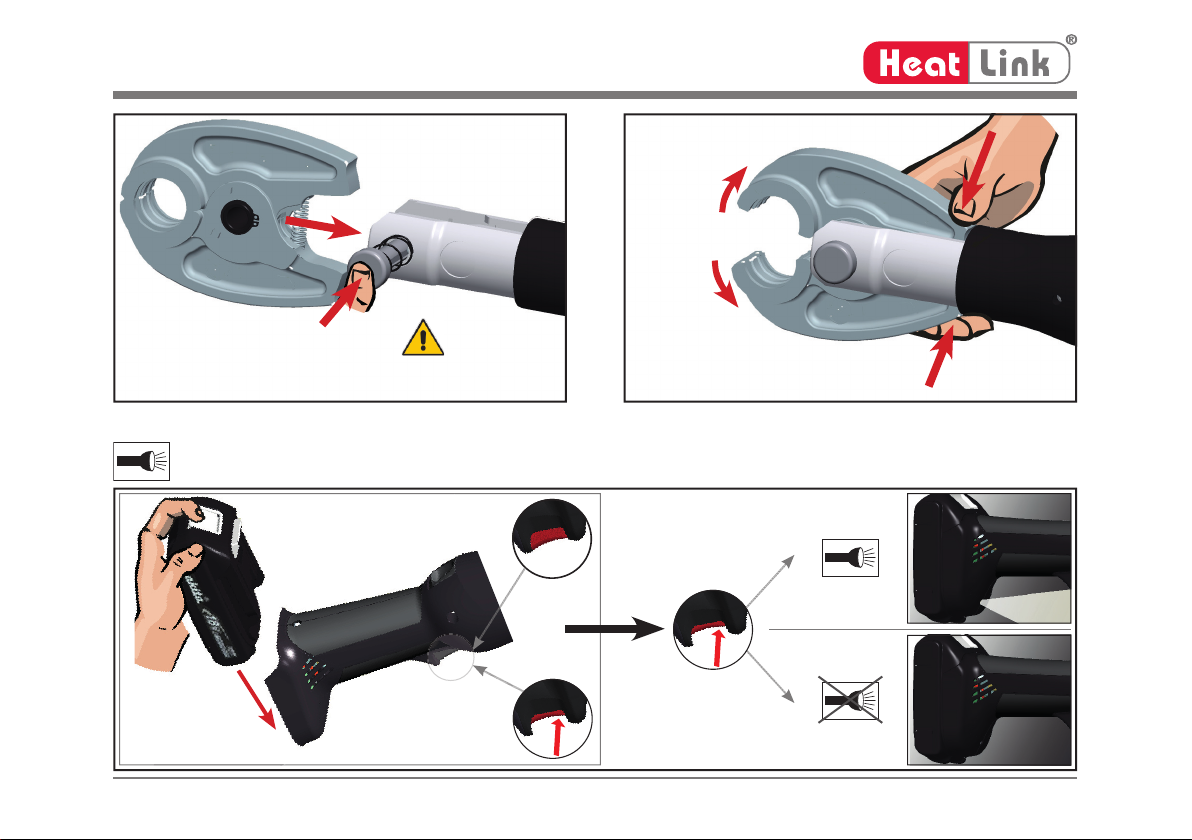

pic. 14 pic.15

1. 2.

350°

pic. 16 pic. 17

45°

1.

2.

OIL

1.

2.

HE.15274

Folie: weiss Druck: farbig

linke Seite, erstellt 10 0

HE.15274

L611500 Rev. B © 05/2013

11500

Instruction Manual Pressing Tool

V

pic. 18 pic. 19

CLICK

1.

2.

on / off

PRESS

PRESS

L611500 Rev. B © 05/2013

11500

Instruction Manual Pressing Tool

VIL611500 Rev. B © 05/2013

11500

Pure

®

Link

Link

Plus

P

u

r

e

®

Link

Link

P

l

u

s

P

u

r

e

®

Link

Link

Pl

u

s

P

ure

®

Link

Link

Plus

Pu

r

e

®

Link

Link

P

l

u

s

Pu

r

e

®

Link

Link

P

l

u

s

Preparation

1. Inspect all components for debris, obstructions, and/or

damage prior to installation.

2.Cut the PEX tubing to length, ensuring a square cut - an

irregular cut may result in a failed connection. For larger

diameter PEX an ABS cutter is recommended.

3. Slide the stainless steel sleeve over the tubing until it is

properly seated.

4. Push the tubing and sleeve onto the fitting or Multiport tee

until it bottoms out on the shoulder.

5. Use the sight hole in the sleeve to verify proper seating

of PEX tubing.

6. Make press as instructions below for 1»2" to 1 1»2".

1»2" to 1 1»2" Press Instructions; Auto Press

{Never press with empty jaws as this will damage the jaws.

{Regularly check tool jaws and sleeve for any abnormalities that

could be an indication of a damaged tool.

{If the Stainless Steel Sleeve is damaged or pressed incorrectly,

ERWKWKH¿WWLQJDQGWKHVOHHYHPXVWEHUHSODFHG

{Never re-use stainless steel press sleeves.

1. Open the jaws and position squarely around the sleeve, then

DOORZWKHMDZVWR¿UPO\JUDVSWKHVOHHYH

LinkPure

®

Link Plus

Instruction Manual Pressing Tool

VIIL611500 Rev. B © 05/2013

11500

2. Squeeze the trigger until the press is complete.

Note: if the red LED flashes or there an audible beep,

consult “Tab. 1.”

3. Open the jaws and remove the tool from the sleeve.

4. Inspect the connection to ensure the tubing is still

properly seated (only PEX is visible in sleeve sight

hole), and the press has been properly formed onto the

sleeve (see diagram for guideline).

Tool jaws imprint "HL" on the sleeve.

An improperly positioned tool may result in a poor

press and a damaged fitting.

Pu

P

u

Pu

Sight

Hole

Improperly

positioned

jaws

PEX

improperly

seated in

sleeve

Pinched Stainless Steel Sleeves

If the stainless steel sleeves are being pinched, the tool jaws

are worn out or damaged and must be replaced.

Example Presses

1»2"3»4"1"

11»4"1

1»2"

Instruction Manual Pressing Tool

VIII

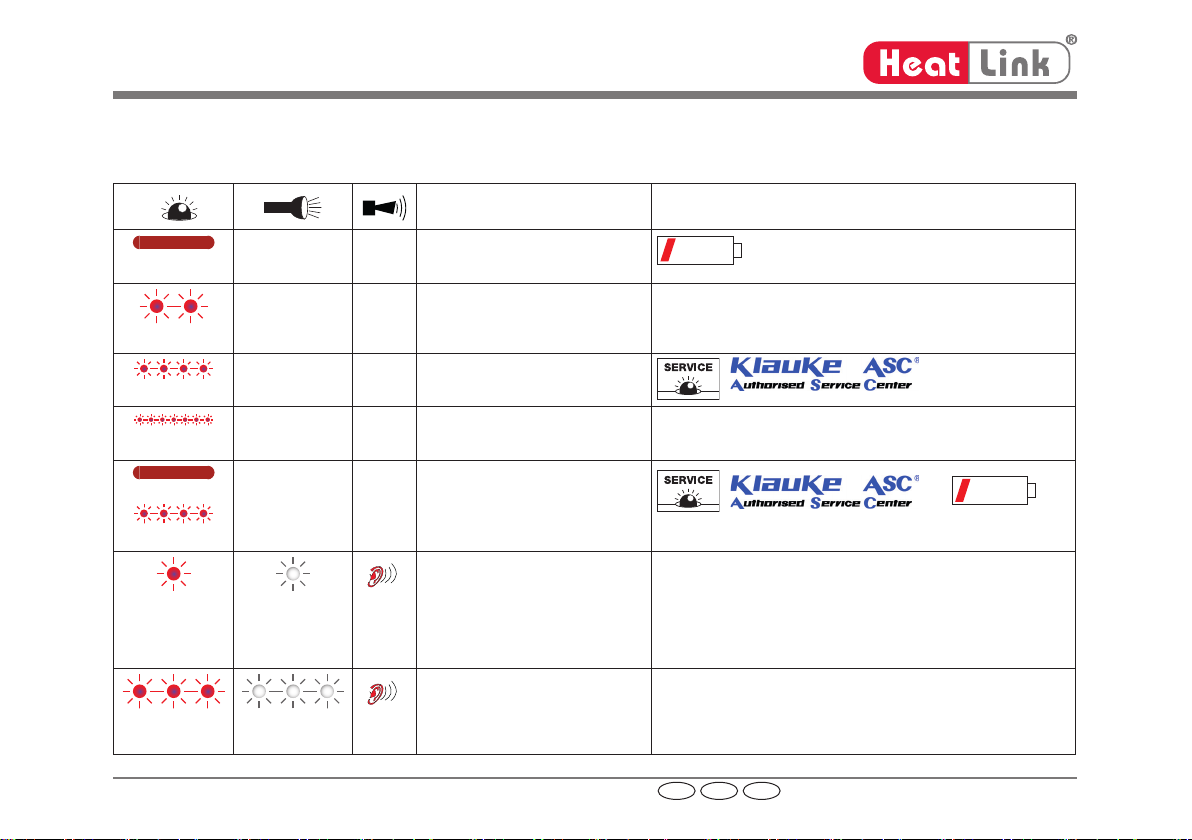

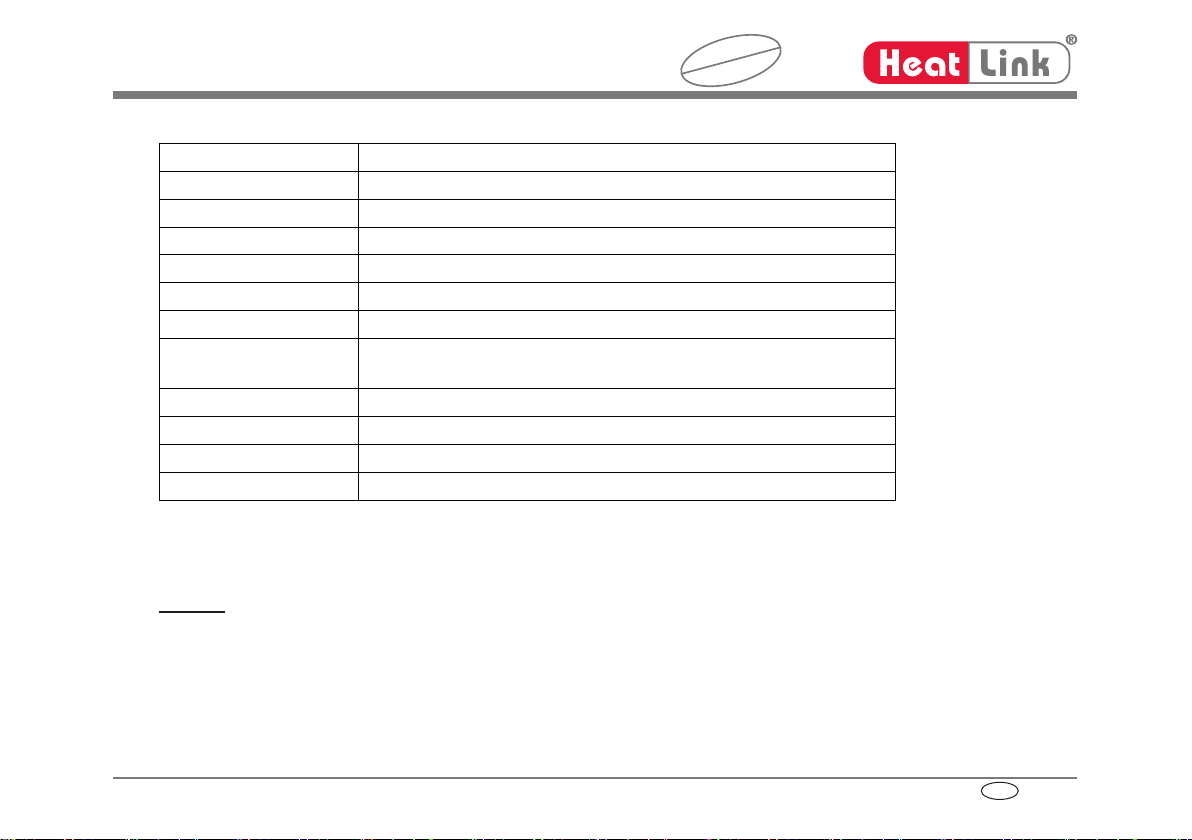

Tab. 1 Visual and Audio Indicator Meanings

Explication des signales acoustiques et visuels

Descripción de las indicaciones del diodo luminoso

When / Quand / cuándo Why / Pourquoi / ¿por qué?

20 sec

after working cycle

après opération de travail

Después del proceso de trabajo

2 x

after inserting the battery

après mise en place de

l’accumulateur

Después de insertar la batería

Self check

autocontrôle

Auto-test

20 sec/2Hz

after working cycle

après opération de travail

Después del proceso de trabajo

20 sec/5Hz

while exceeding the temp. limit

pendant surchauff e

en caso de temperatura excesiva

Unit too hot

outil surchauff é

Herramienta demasiado caliente

20 sec

20 sec/2Hz

after working cycle

après opération de travail

Después del proceso de trabajo

+

1 x 1 x

after working cycle

après opération de travail

Después del proceso de trabajo

Error: the required pressure has not been reached. The operator

has interrupted the pressing cycle manually while the motor was

not running.

Erreur: Pression necessaire pas atteinte. Il s‘agît d‘une interrupti-

on manuelle de la sertissage au moteur arrêté.

Error: No se ha alcanzado la presión necesaria o el operador ha

interrumpido el ciclo a mano mientras el motor ha parado.

3 x 3 x

after working cycle

après opération de travail

Después del proceso de trabajo

Serious Error: The pressure has not been reached while the motor

was running.

Erreur grave: Pression pas atteinte au moteur courant.

Error grave: No se ha alcanzado presión mientras el motor estaba

en marcha

US F Sp

L611500 Rev. B © 05/2013

11500

1

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

Index

1. Introduction

2. Warranty

3. Description of the electro-hydraulic pressing tool

3.1 Description of the components

3.2 Features

3.3 Visual and Audio Indicator Meanings

4. Operating Instructions

4.1 Operation of the tool

4.2 Explanation of the application range

4.3 Service and Maintenance

5. Troubleshooting

6. Technical data

7. Decommissioning/Disposal

Symbols

Safety Warnings

Please do not disregard to avoid injuries and environmental damage

Application Warnings

Please do not disregard to avoid damaging the tool.

1. Introduction

Before using the tool please read the instruction manual carefully.

Use this tool exclusively for its determined use and follow all applicable safety instructions. This instruction manual

should accompany the tool for its entire life span.

The owner has to: • guarantee the availability of the instruction manual for the user and

• make sure, that the user has read and understood the instruction manual.

2

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

2. Warranty

If the tool is operated according to its intended use and the regular maintenance services are observed our war-

ranty is 24 months from the time of delivery. Worn-out parts resulting from regular use are excluded. We reserve

the right to rework the tool in case of a valid warranty claim.

3. Description of the battery operated electro-hydraulic pressing tool

3.1 Description of the components

The hydraulic tool is a hand operated tool and consists of the following components:

Table 2 (see page I, pic.1)

Pos. Description Function

1 Pressing head Working unit to accommodate the pressing jaws

2 Retract slide Slide to open the pressing jaws in case of an error or emergency

3 LED (red) Indicator for battery charge, service Intervals and faults

4 Battery lock Slide to unlock the battery

5 Battery Rechargeable Li-Ion battery 18V

6LED (white) to illuminate the working area

7 Trigger Actuator to start the pressing cycle

8 Jaws Pressing jaws

9 Locking pin Pin with special lock to open/close the pressing head

3

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

3.2 Features

Safety features:

The unit is equipped with a special brake which instantly stops the forward motion of the piston/dies when the trigger

is released.

A white LED illuminates the working space after activating the trigger. It automatically switches off 10 sec. after relea-

sing the trigger. This feature can be deactivated (see page V).

Hydraulic Pressure Check, HPC for short, monitors the oil pressure in the tool’s oil circuit, hence ensuring a conti-

nuous, consistent press quality.

During each pressing cycle, the achieved pressing pressure is determined by a pressure sensor and compared to the

required minimum value. An audible warning signal sounds if the achieved pressure diff ers from the specified working

pressure. The user will know immediately that the fi tting must be checked and repressed or replaced as required.

Functional features:

The hydraulic unit incorporates an automatic retraction which returns the piston into its starting position when the

maximum operating pressure is reached.

A manual retraction allows the user to return the piston into the starting position in case of an incorrect press.

The pressing head can be smoothly turned by 350° around the longitudinal axis in order to gain better access to tight

corners and other diffi cult working areas.

The unit is equipped with a microprocessor (page I, pic. 1.3) which shuts off the motor automatically after the press

is completed, indicates service intervals, checks battery capacity and does a trouble check e.g. informing the user

through audible and visual warning signals about the kind of error.

Power saving function through motor switch-off .

The ergonomically formed compact housing has two important features. The non-slip rubber coated grip area to-

gether with a balanced center of gravity allows fatigue-free working.

All tool functions can be controlled by one trigger. This results in an easy handling and a better grip compared to a

two button operation.

4

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

Li-Ion batteries have neither a memory eff ect nor self-discharge. Even after long periods of non-operation the tool

is always ready to operate. In addition, they have a lower power weight ratio with 50% more capacity and shorter

charging cycles compared to NiMH batteries.

The oil used in our tool is rapidly bio-degradable and non-hazardous to water, and has been received “The Blue

Angel” ecolabel. The oil is suitable for low temperatures and has excellent lubrication characteristics.

At the end of a job a print-out via a USB adapter (not included) can be generated documenting the proper function

of the tool.

3.3 Visual and Audio Indicator Meanings

See page VIII, tab. 1

4. Operating Instructions

4.1 Operation of the tool

The pressing cycle is started by squeezing the trigger (page 1, pic. 1.7). The pressing cycle is characterized by the closing

motion of the jaws. Due to the linear movement of the rollers on the piston the jaws close scissors like.

Attention

The pressing cycle must be completed and the jaws closed to ensure a permanent leak free connection.

Attention

The pressing process can be interrupted at any moment by releasing the trigger.

Attention

This tool is intended for use with HeatLink®PEX tubing, fittings, and stainless steel press sleeves.

Attention

The user has to check by visual means whether the pressing jaws are completely closed.

Attention

If a pressing cycle has been interrupted the fitting has to be either replaced or pressed a second time.

Attention

Do not operate the tool without jaws.

5

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

Attention

For your own safety please observe all local safety regulations.

The user needs to make sure that the pressing jaws are completely closed and that there are no foreign objects (e.g.

plaster or stone fragments) between the pressing jaws.

4.2 Application

This tool is meant for use with HeatLink® stainless steel press sleeves, PEX tubing, and fi ttings.

The unit is not to be restrained in a vise. It is not allowed to use the tool in a stationary application.

The tool is not designed for continuous use. After series of approximately 50 completed presses, let the tool cool

down for 15 min.

Attention

Overly intensive use can cause heat damage to the tool

Attention

During the operation of the built-in electric motor, sparks can occur, which might ignite highly inflammable

or explosive liquids and materials.

Attention

Electric tools must not be operated in pouring rain or under water.

4.3 Service and Maintenance

The reliable operation of the tool is dependent on proper handling and service. To ensure proper presses, this tool

must be mainted and serviced regularly as follows:

1. The electric-hydraulic pressing unit must be cleaned and dried after each use before stored.

2. In order to guarantee reliable operation, the pressing tool should be returned to the manufacturer or one of our Au-

thorized Service Centers (ASCs) after the red LED indicates Service (after 10,000 pressing cycles) or once every

year whichever occurs fi rst.

3. The nuts and bolts, the rollers and their guides as well as the moveable parts of the pressing jaw must be

lightly oiled on a regular basis.

6

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

4. Perform and inspect test presses or have the tool manufacturer check the tool and pressing jaws regularly to en-

sure proper function.

5. Keep the pressing jaws clean. Remove dirt with a brush.

In order to avoid possible malfunctions we off er you a manufacturer service consisting (see ASC) of disassembly,

cleaning, exchange of possibly worn out parts assembly and fi nal inspection. Only a clean and properly functioning

press tool can ensure a leak free connection.

The tool has no user serviceable parts. Only the pressing jaws (page I, pic. 1.8; page III, pic. 13) and battery can

be changed by the user.

Attention

Do not damage the seals of the tool. If the seals are damaged the warranty is null and void.

5. Troubleshooting

a.) Constant fl ashing/indicating of the red LED (page I, pic 1.3) or an audible warning signal.

see table 1. If the issue cannot be resolved return the tool to the nearest Authorized Service Center (see

inside back cover).

b.) The tool is leaking oil.

Return the unit to the manufacturer. Do not open it and damage the seal of the tool.

c.) The red LED fl ashes 3x and simultaneously 3 acoustic warning signals occur (see table 1).

Serious fault! If this fault occurs repeatedly, return the unit to an Authorized Service Center (ASC). Do not

open it and damage the seal of the tool.

In case of a one time occurrence the fi tting has to be replaced or pressed a second time.

7

US

Instruction Manual Pressing Tool

authorised

copy

L611500 Rev. B © 05/2013

11500

6. Technical Data

Type 11500

Weight incl. battery: 3.74 lb (1.7 kg)

Pressing time: 3-4 s

Thrust force (linear): 15 kN min.

Battery voltage: 18 V

Battery capacity: 1.3 Ah Li-Ion (Makita BL1815) or 3.0 Ah Li-Ion (Makita BL1830)

Battery charging time: 15 min. (Makita BL1815) or 22 min. (Makita BL1830)

Presses/charge: approx. 150 presses (1/2”) (Makita BL1815)

approx. 300 presses (1/2”) (Makita BL1830)

Ambient temperature: 14°F to 104°F (-10°C to +40°C)

Hydraulic oil: Rivolta S.B.H. 11

Sound level: < 70 dB (A) at a distance of 3.3 ft (1 m)

Vibrations: < 2.5 m/s²

7. Decommissioning/Disposal

The tool and battery must be disposed of in accordance with local guidelines and regulations.

Remark

This instruction manual can be ordered free of charge. The Part No. is L611500 (HE.12488).

1

F

Mode d´emploi sertisseuse

copy

L611500 Rev. B © 05/2013

11500

Sommaire

1. Introduction

2. Garantie

3. Description de outillage hydraulique

3.1 Description des composants

3.2 Caractéristiques

3.3 Explication des signales acoustiques et visuels

4. Consignes pour un usage conforme

4.1 Utilisation de l‘appareil

4.2 Application

4.3 Service et Maintenance

5. Marche à suivre en cas de panne de la outillage

6. Caractéristiques techniques

7. Mise hors service / Mise au rebut

Symboles

Instructions techniques de sécurité

à respecter impérativement, pour la sécurité des personnes et la protection de l‘environnement.

Instructions techniques d‘utilisation

à respecter impérativement, pour éviter des dommages à l‘appareil.

1. Introduction

Lire attentivement le mode d‘emploi avant la mise en service de votre outillage.

N‘utilisez cet appareil qu‘exclusivement pour l‘usage prévu, en respectant les instructions relatives à la sécurité et à

la prévention des accidents du travail.

L‘exploitant doit • mettre le mode d‘emploi à la disposition de l‘utilisateur et

• s‘assurer que celui-ci ait lu et bien compris son contenu.

2

F

Mode d´emploi sertisseuse

copy

L611500 Rev. B © 05/2013

11500

2. Garantie

La garantie s’élève à 24 mois date de la livraison à condition d’une utilisation de l’outil exclusivement pour son

usage déterminé et d’observation des intervalles des maintenance. Sauf pièces de rechanges qui résultent d’un

usage déterminé. Nous réservons le droit de récupérer le produit.

3. Description de outillage hydraulique

3.1 Description des composants

L’ outillage électro-hydraulique est un appareil conduit manuel qui se compose des éléments suivants:

Tabl. 2 (cf. page I, fig. 1)

Pos. Désignation Fonction

1Tête de sertissage Unité de travail pour le logement des mâchoires de sertissage

2Commutateur de retour Commutateur glissant d‘ouverture des mâchoires de sertissage

en cas d‘anomalie ou d‘arrêt d‘urgence.

3Affi cheur LED (rouge) Indication capacité d’accumulateur, indication Service et erreur d’outil

4Déblocage de l‘accumulateur Commutateur glissant de déblocage de l‘accumulateur

5Accumulateur Accumulateur rechargeable au Li-Ion 18V

6LED (blanche) Pour l’éclairage du local de travail

7Commutateur de marche Déclenchement du sertissage

8Mâchoires de sertissage Mâchoires de sertissage (dépendent du système)

9Boulons de verrouillage Dispositif de verrouillage pour l‘ouverture/fermeture de la tête.

3

F

Mode d´emploi sertisseuse

copy

L611500 Rev. B © 05/2013

11500

3.2 Caractéristiques

Caractéristiques de sécurité

L‘outillage est équipé d‘un dispositif d‘arrêt immédiat qui stoppe instantanément l‘avance dès que le bouton de mar-

che/d´arrêt est lâché.

LED blanche illumine le local de travail en actionnant le commutateur de service et s’éteint après 10 s. Cette fonction

peut être éliminée.

La fonction Hydraulic Pressure Check, abrégée HPC contrôle la pression d’huile directement dans le circuit d’huile

des outils et assure ainsi une qualité uniforme et constante des sertissages.

À chaque cycle de sertissage, la pression atteinte est déterminée au moyen d’un capteur de pression, puis comparée

à la valeur minimale requise. Un signal acoustique et optique paraît lorsque des diff érences par rapport à la pression

de travail déterminée se produisent.

Caractéristiques de fonction

L‘outillage possède une fonction de retour automatique, qui ramène automatiquement les galets d‘entrainement en

position initiale après que la sertisseuse ait atteint sa pression maxi de fonctionnement.

Un retour manuel permet à l’utilisateur de retourner le piston à la position initiale coupage.

La tête peut être tourné de 350° en continu autour de son axe de rotation. Ceci permet le coupage à des endroits

diffi cilement accessibles.

L’outil est équipée d’un système électronique donnant informations importantes sur l’état de la machine, le résultat

de coupage et la capacité de l’accumulateur. L’indication s’eff ectue par diode luminescente ou par un signal acous-

tique.

Fonction d’économie d’énergie grâce à l‘arrêt automatique du moteur en fi n de cycle de sertissage.

Le corps en plastique bi-matière avec insert souple contribue à une sensation de prise agréable et sûre. La position

optimisée du centre de gravité permet en complément un travail durable et sans fatigue.

Toutes fonctions de l’outil s’eff ectuent par moyen d’une commande à bouton unique pour une maniement aisée et

un meilleur appui.

Accus lithium-ions 18V puissants avec une capacité complémentaire de 50% et des délais de charge extrêmement

courts. Ces accumulateurs n’ont pas d’eff et mémoire et auto-décharge électrique.

4

F

Mode d´emploi sertisseuse

copy

L611500 Rev. B © 05/2013

11500

Cet outil travaille avec huiles hydrauliques synthétiques. Ces huiles sont facilement biodégradables et ne présentent

aucun danger pour l’eau.

Fonction d’évaluation par interface optique et adaptateur USB. (Équipement spéciale).

3.3 Explication des signales acoustiques et visuels

Voir page IX, tableau 1

4. Consignes pour un usage conforme

4.1 Utilisation de l‘appareil

Un processus de sertissage se déclenche en actionnant le commutateur de service (page I, fi gure 1.7).

La fermeture des mâchoires signale le commencement du processus de sertissage. Les mâchoires de sertissage se

ferment en forme de ciseaux au moyen des rouleaux d‘entraînement situés sur la barre de piston.

Attention

Effectuer un contrôle visuel à la fin du processus de sertissage pour vérifier si les mâchoires de sertissage

sont entièrement fermées.

Attention

Le cycle de sertissage peut être interrompu à tout instant en relachant la pression exercée sur le bouton de

commande.

Attention

Cet outil est prevu pour utilization avec HeatLink® PEX tube, raccords, et bagues à sertir inoxidables.

Attention

A la fin du cycle de sertissage, il est nécessaire d‘effectuer en plus un contrôle visuel, pour vérifier que les

mâchoires soient bien complètement fermées.

Attention

Les raccords pour lesquels le cycle de sertissage n‘a pas été complètement terminé doivent être démontés,

ou faire l‘objet d‘un nouveau sertissage complet.

Table of contents

Languages:

Other HeatLink Power Tools manuals