4.

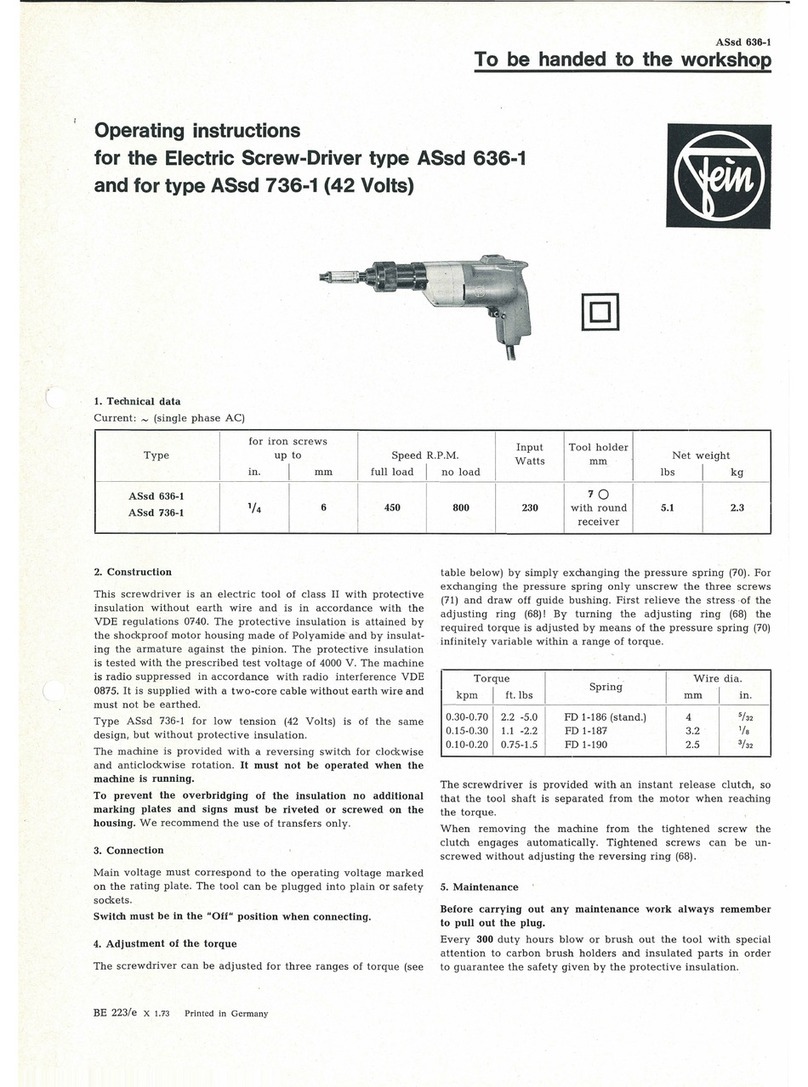

Maintenance

Befo~e

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

Every

100

duty

hours blow

or

brush

out

the

tool

with

special

attention

to

carbon

brush holders

and

insulated

parts

in

order

to

guarantee

the

safety

given

by

the

protective

insulation.

After

checking

the

carbon

brushes

make

sure

th

at

they

move

easily in

their

holder.

They

should be replaced

at

the

latest

when

the

y h

ave

worn

down

to 7

mm

(1/4"). Please,

only

use original

FEIN

carbon

brushes

(Order

Reference

EZ

11-59).

After

fitting

new

brushes,

ru

n

tool

unloaded

for

about

15

minutes

to

allow

brushes

to

bed in.

On

e

pair

of

spare

carbon

brushes will be

found

in

the

cover

of

the handle,

ple

ase,

do

not

forget

to

reorder

them

in

time.

In

order

to

prevent

accidents check cable

at

re

gular intervals.

To

re

place

the

cable take off

the

screws (24, 25),

then

tak

e off

the

hand

le

co

ve

r (20), loosen

the

t

wo

screws (19)

of

the terminal clamp

(1

8)

and

clamp

off

the

cable

from

the

switch (2).

5. Lubrication

We recommend

to

renew

th

e gear grease

af

ter

300

duty

hour

s.

Plea

se

only

u

se

the

Fein special grease

FG

1.

For

ball

bearings which s

hou

ld

be lubricat

ed

afte

r

approx.

900

dut

y hours

we

recommend

our

ball

bearing grease

FK

3.

The

ball

bearings

are

to

be rinsed

in

clean s

olvent

and

packed with

ne

w grease.

The

space

between

inner

and

outer

ring

is

to

be

one

third filled

with

grease

in order that

the

bearings

do

not

overheat.

I Grease tubes I

Contents

Type

of

grease

order

N°

oz

I g

-~~--

-

I

!'&+

fm

gem

JO

Ji

MZ

60-3

/FG

1 I 22

/a

80

I ·FK--s·

for

ball b

ear

in

gs

MZ

60-1/FK

3 1

/a

10 I

":".?.

No

claims can be

entertained

for

damage

du

e

to

negli

ge

nt

mai

nt

e

nanc

e

and

inadequate

lubrication

.

6.

Overhaul

After

900

dut

y hours

the

machine should be completely

dismantled

as described

under

pa

ragraph

7

and

all

parts

should be

thoroughly

cleaned. Rinse ball bea

rin

gs

an

d gears in clean solve

nt

a

nd

pack w

ith

fresh grease as

per

paragraph

5.

Please

be

sure

that

all

electric

parts are

only

cleaned

dry.

7.

Dismantling

The

tool should

only

be taken

apart

by a skilled

wo

rker

.

1.

Unscrew

fillister

head

screw (25)

and

the t

wo

cy

li

ndr

ical screws

(24),

then

take

off

handle

cov

er

(20).

2.

Remove

supply

cable

from

switch, dr

aw

out

switch

and

discon

nect

motor

cable.

After

unscr

ew

ing

the

screws (10)

draw

out

carbon

holder

(5),

un-

sc

re

w screw (4)

and

pull

out

radio interference

capacitor

(3).

3. T

ake

off

cy

lin

drical screws (58

an

d 59), remove

out

er

b

earing

(35)

with

intermedi

at

e bearing (34).

4.

Pull

out

a

rm

ature

(26), unscrew the three screws (

31

)

and

remov

e

armature

dri

ve

(30).

5.

Draw

in

s

ul

ation

ring (15)

out

of

motor

housing (1), unscrew

cy

lin-

drical screws (1

4)

and

remo

ve

pole

housing (12).

Re

-asse

mbl

e

in

re

verse

se

qu

ence.

Please

bear

in

mind

that

existing washers

ar

e

to

be

placed

in

t

he

right

places.

Their

lo

ss

wou

ld

lead

to

dam

age.

8. Repair

and

spare

parts

We recommend

our

Fein Service

Sta

tions

to

ca

rr

y out all

overhaul

and

rep

a

ir

w

or

k quickly a

nd

expe

rtl

y.

Please

quote

Order

Reference

when

ordering

spare

parts

or

send

in

sample

part.

We d

raw

yo

ur

atten

tion

to

the ne

ed

to ca

rry

out

a high

voltage

test

in

accordan

ce

wit

h y

our

local regulations (

or

VDE

regu

lation 0740)

before t

ak

in

g a tool

into

service a

ft

er any

repair

carried

out

by y

our

own

staff.

U

se

U nl

vmsa

l

Gro:'lse

t

ype

Sst

1

l

nsto~

j I

v~i!L/

l

i)-

FG

1

use

sr

~.:te

FG

12

Jofgc

~ring.

/ /

C.

u.

E.

FEI