2230756 rev 1

SOMMAIRE

1. Consignes de sécurité................................................91

2. Batterie .........................................................................91

3. Fusibles.........................................................................91

4. Témoin lumineux.........................................................91

5. Remplacement de la carte de contrôle PCD ...........92

6. Menu de configuration...............................................94

7. Mise à jour logicielle...................................................95

8. Remplacement du capteur de température............96

9. Schéma de câblage ....................................................97

10. Régulateur de pression ..............................................99

11. Réglage de la vanne de démarrage progressif.......99

12. Réglage des régulateurs de pression.......................99

13. Réglage des électrovannes......................................100

14. Numérotation et noms des vérins...........................101

15. Capteurs de fin de course sur les vérins ................101

16. Réglage du capot......................................................102

17. Schéma du circuit pneumatique .............................103

18. Réglage du support intérieur ..................................104

19. Réglage de la hauteur du support extérieur du vérin 4105

20. Remplacement de la tête pivotante sur vérin 4 ....105

21. Capteurs de charriot inductifs.................................105

22. Mesure de contrôle du charriot...............................106

23. Installation du palier-bascule sur le charriot..........106

24. Remplacement de la protection de l'arbre............106

25. Rempacement de la pompe....................................107

26. Installation du moteur du mélangeur.....................118

27. Remplacement de l'arbre d'entraînement.............121

28. Autotest ......................................................................126

29. Réinitialisation aux valeurs d'usine .........................132

INNEHÅLL

1. Säkerhetsföreskrifter.................................................135

2. Batteri..........................................................................135

3. Säkringar ....................................................................135

4. Varningslampa...........................................................135

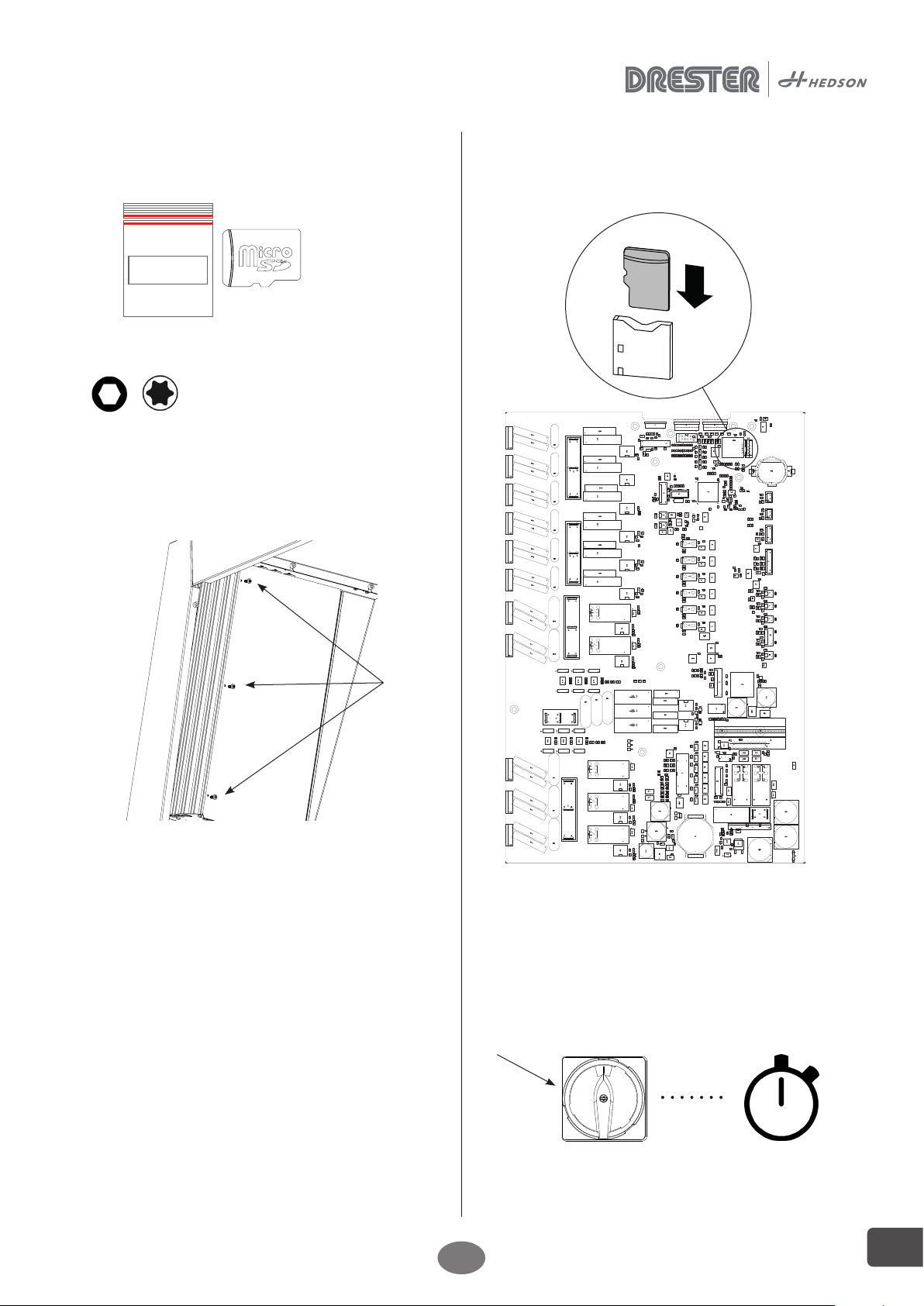

5. Byte av styrkort ..........................................................136

6. Konfigurationsmeny..................................................138

7. Programuppdatering................................................139

8. Byta ut temperatursensorn.......................................140

9. Kopplingsschema......................................................141

10. Tryckvakt.....................................................................143

11. Justering av mjukstartsventilen ...............................143

12. Justering av tryckregulatorerna...............................143

13. Justering av magnetventilerna................................144

14. Cylindrarnas nummer och namn.............................145

15. Cylindrarnas ändlägessensorer...............................145

16. Justera luckan............................................................146

17. Pneumatiskt kopplingsschema................................147

18. Justering av inre vagga ............................................148

19. Justera höjden på cylinder 4 för yttre vagga.........149

20. Byta svänghuvud på cylinder 4 ...............................149

21. Induktiva vagnsensorer ............................................149

22. Kontrollmätning av vagnen......................................150

23. Installation av vagnens gångjärnsförsedda lager .150

24. Byta axelskydd...........................................................150

25. Byta pump..................................................................151

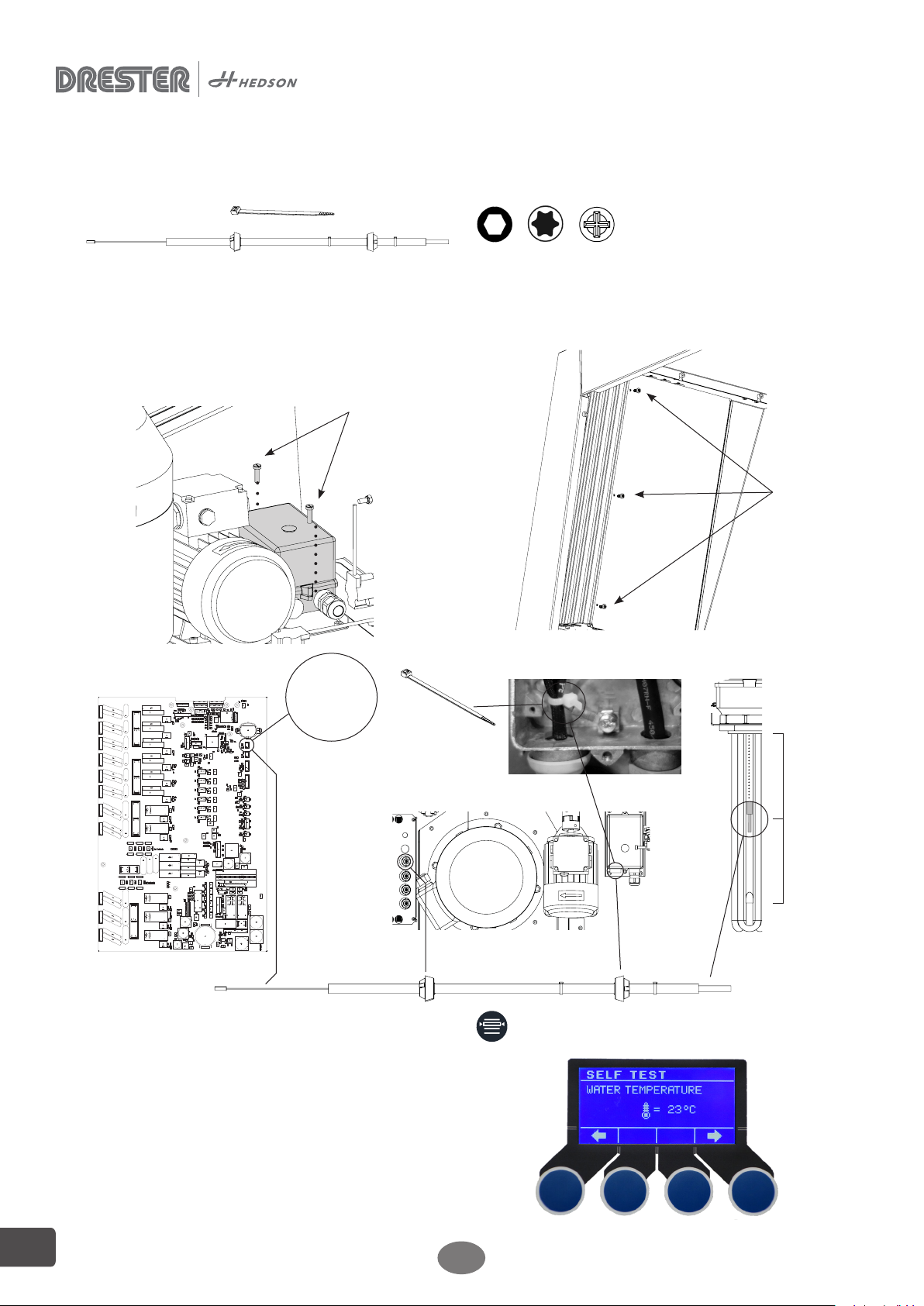

26. Installation av mixermotor........................................162

27. Byta drivaxel...............................................................165

28. Självtest.......................................................................170

29. Fabriksåterställning...................................................176

CONTENT

1. Safety precautions.........................................................3

2. Battery.............................................................................3

3. Fuses ..............................................................................3

4. Warning lamp ................................................................3

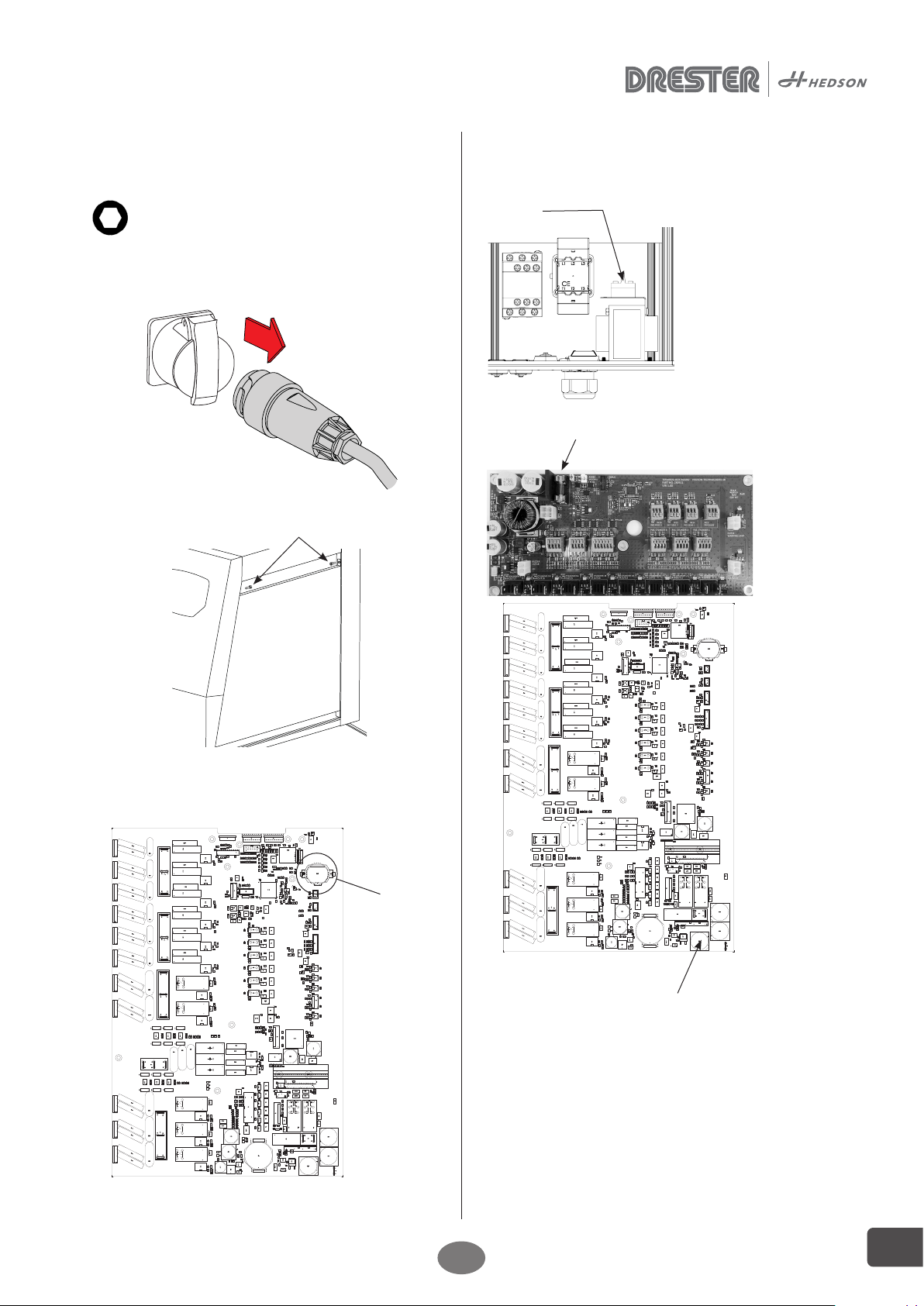

5. Control card PCD replacement................................... 4

6. Configuration menu......................................................6

7. Software update ............................................................7

8. Replacing temperature sensor ....................................8

9. Wiring diagram..............................................................9

10. Pressure governor ......................................................11

11. Adjustment of the soft start valve..............................11

12. Adjustment of the pressure regulators.....................11

13. Adjustment of solenoid valves ..................................12

14. Numbering and names of cylinders .........................13

15. End position sensors on the cylinders......................13

16. Adjust the lid................................................................14

17. Pneumatic circuit diagram..........................................15

18. Adjustment of inside cradle.......................................16

19. Adjust the height of cylinder 4 outside cradle ........17

20. Changing swivel head on cylinder 4.........................17

21. Inductive trolley sensors.............................................17

22. Control measurement of the trolley..........................18

23. Installation of the hinged bearing on the trolley.....18

24. Replacing shaft protection.........................................18

25. Pump replacement......................................................19

26. Mixer motor installation..............................................30

27. Drive shaft replacement .............................................33

28. Self test .........................................................................38

29. Factory reset.................................................................44

INHALT

1. Sicherheitshinweise ....................................................47

2. Batterie .........................................................................47

3. Sicherungen.................................................................47

4. Warnlampe...................................................................47

5. Austauschen der Steuerplatine.................................48

6. Konfigurationsmenü ...................................................50

7. Softwareaktualisierung ...............................................51

8. Austauschen des Temperatursensors.......................52

9. Schaltplan.....................................................................53

10. Druckregler..................................................................55

11. Einstellen des sanftanlaufventils................................55

12. Einstellen der druckregler..........................................55

13. Einstellen von Magnetventilen ..................................56

14. Nummerierung und Namen der Zylinder................57

15. Endlagensensoren auf den zylindern.......................57

16. Einstellen des deckels ................................................58

17. Pneumatischer Schaltplan..........................................59

18. Einstellen des innenträgers........................................60

19. Einstellen der höhe von zylinder 4 am aussenträger61

20. Wechseln des schwenkkopfs an zylinder 4..............61

21. Induktive rollwagensensoren.....................................61

22. Kontrollmessung des rollwagens..............................62

23. Installation des scharierlagers am rollwagen ..........62

24. Austauschen des wellenschutzes..............................62

25. Austausch der pumpe ................................................63

26. Installation des Mischermotors..................................74

27. Austauschen der Antriebswelle.................................77

28. Selbsttest......................................................................82

29. Werkseinstellungen ....................................................88

DE

GB FR

SE