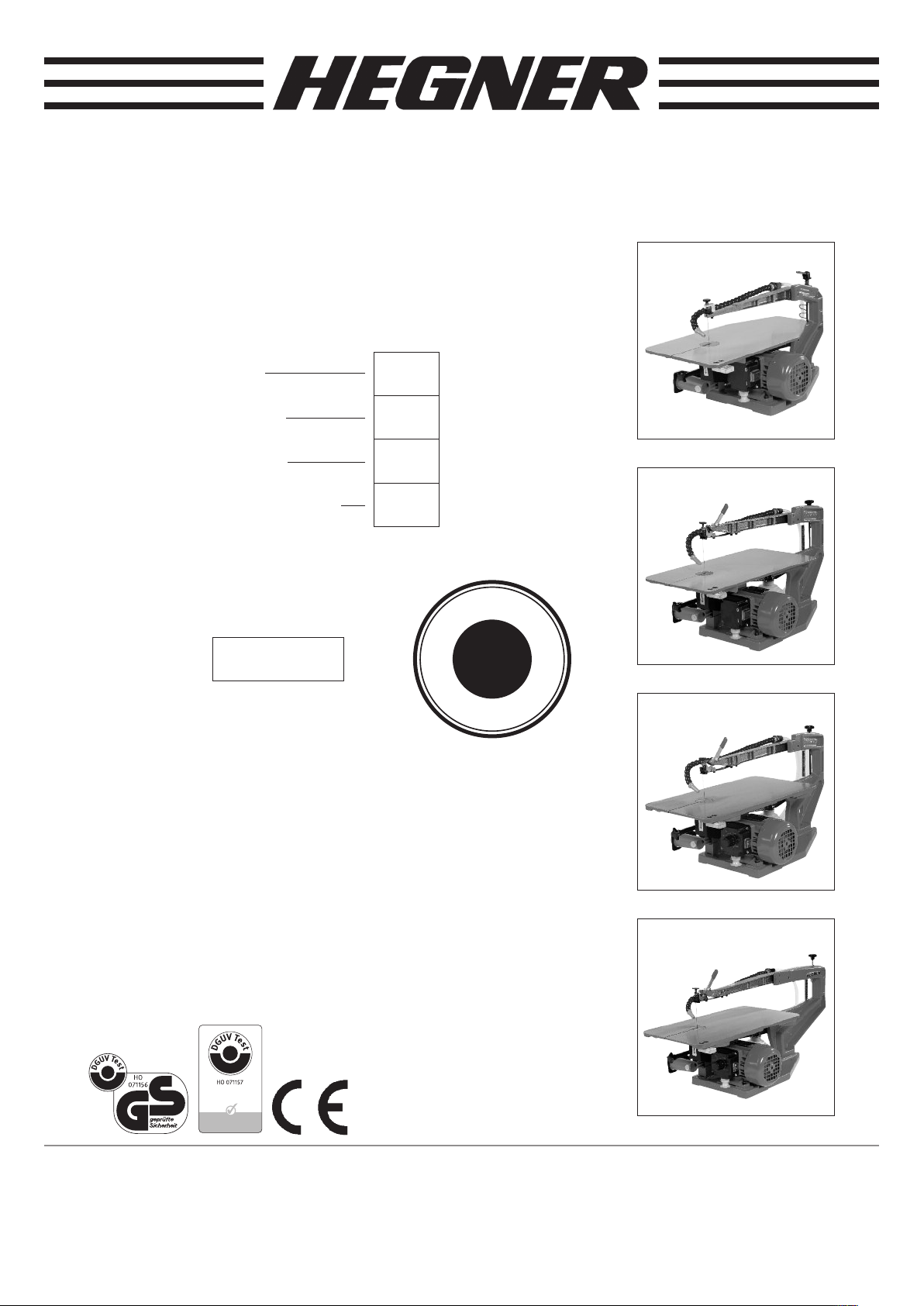

Hegner Multicut-1 User manual

Super- Universal- Fine Cut Saws

riginal operating instructions

Multicut-1

Multicut-2S

Multicut-SE

Multicut-Quick

Serial no.:

Important

In order to prevent the risk of accidents, please

read the operating instructions carefully before

installation and use of the machine.

Always keep these operating instruction

near to the machine.

It is important that these instructions are

always available for reference purposes.

holzstaubgeprü

G

A

R

A

N

T

I

E

G

A

R

A

N

T

I

E

G

U

A

R

A

N

T

E

E

3

J

A

H

R

E

A

N

S

Y

E

A

R

S

*

*Except electronics (1 year)

and wearing parts

EC-Conformity Declaration for

Super-Universal-Fine Cut Saws

Multicut-1

Multicut-2S

Multicut-SE

Multicut-Quick

We declare on our sole responsibility that the product described under

technical data complies with the following conditions:

- 2006/42EC Machine directive

- 2004/108 EC EMC directive

- 2006/95 EC ow voltage directive

The following regulations were applied to the construction and design of the machine.

Harmonised standards:

- EN 12100-1

- EN 12100-2

- EN 294

- EN 349

- EN DIN 61000

- EN 60529

- EN 60204-1

For the machine, a construction test to § 7 of the Machine Safety aw

(GPSG) was performed by the

Trade Association for Wood

Test and Certification Centre in the BG-PRÜFZERT

Vollmoellerstraße 11

70563 Stuttgart

and

GS test certificate number 071156 and

BG test certificate number 071157

were issued.

Hegner Präzisionsmachinen GmbH

upfenstraße 29

78056 VS-Schwenningen

VS-Schwenningen, 12.08.2010

Werner Broghammer

Technical Manager

Preface

Machines: Multicut-1

Multicut-2S

Multicut-SE

Multicut-Quick

are suitable for both professional and private use.

The machines are intended solely for sawing wood,

plastics, NF metals and soft iron with fretsaw blades and

marquetry saw blades with a length of 130 mm.

These operating instructions should provide the necessary

knowledge for installation, commissioning and handling

of the machines.

Furthermore the instructions contain important notes for

your safety when handling the machine, and give tips for

use and repair of faults.

Please read these operating instructions carefully and

in particular note the references and warnings.

Incorrect handling and failure to observe the warning

notes and descriptions in the operating instructions

invalidate any guarantee by the manufacturer of the

machines.

If you have any questions after reading these instructions,

please contact your dealer.

Hegner Präzisionsmaschinen GmbH

Symbols and their Meanings

Text marked with this symbol contains very important

information, including relating to avoidance of health

risks. These texts must be observed.

This symbol points to texts containing comments,

information or tips.

This symbol refers to a chapter, subchapter, page or

diagram. Follow these references to obtain further

information on the current topic.

This point indicates a description of activities which you

must perform.

Wear protective goggles.

Contents:

1.0 Technical data

2.0 Delivery of machine

3.0 Operating instructions

4.0 Proper use

5.0 Safety notes

6.0 Remaining risks

7.0 Unpacking/assembly

8.0 Commissioning/decommissioning

9.0 Changing the saw blade

10.0 Change the saw blade for internal cutting

11.0 Swivelling the table plate

12.0 Adjusting the stroke length

13.0 Extraction connections

14.0 Maintenance/cleaning

15.0 Repair/spare parts

16.0 Type of application

17.0 Selection of speed

18.0 Operating errors and causes

1.0 Technical Data

Multicut-1

Clearance length 365 mm

Clearance height 50 mm

Max. cut height 50 mm

Saw table size 435 x 230 mm, 45º swivel

ength x width 520 x 270 mm

Saw blade stroke 12 and 15 mm

Motor 230 V~, 50 Hz, 100 watt output power

Weight Approx 16 kg net

ength of saw blade 130 mm

Extraction connection Ø 35 mm

Mains fuse 6 A

Multicut-2S and SE

Clearance length 460 mm

Clearance height 65 mm

Max. cut height 65 mm

Saw table size 435 x 230 mm, 45º/12° swivel

ength x width 610 x 280 mm

Saw blade stroke 12 and 19 mm

Motor 230 V~, 50 Hz, 100 watt output power

Weight Approx 19 kg net / 23 kg

ength of saw blade 130 mm

Extraction connection Ø 35 mm

Mains fuse 6 A

Multicut-Quick

Clearance length 560 mm

Clearance height 65 mm

Max. cut height 65 mm

Saw table size 435 x 230 mm, 45º/12° swivel

ength x width 730 x 280 mm

Saw blade stroke 12 and 19 mm

Motor 230 V~, 50 Hz, 100 watt output power

Weight Approx 29 kg net

ength of saw blade 130 mm

Extraction connection Ø 35 mm

Mains fuse 6 A

☞

⇒•

1

1.1 Values for extraction connection

Volume flow for connection Ø 35 mm: 70 m3

Vacuum pressure present

for an air speed of 20 m/s: 1666 Pa.

The dust emissions measured according to the principles

for testing dust emission (workplace-related dust

concentration) from woodworking machines by the Trade

Association for Wood lie clearly below the applicable limit

value o 2,0 mg/m3.

1.2 Noise emission

Measurement conditions:

- prEN 31202 for workplace-related emission values

with the following additions established by TC 142 in

order to obtain an accuracy class of better than 3 dB:

- The ambient correction factor K2A or K3A is < 4 dB.

- The difference between external noise level and the

noise sound pressure level is < 6 dB for each

measurement point.

- K3A is calculated according to appendix A, prEN 31204.

- A square envelope surface with nine measurement

points at a distance of 1 m from the reference surface

was used.

Workpiece: spruce

- Dimensions 150 / 100 / 20 mm (planed all round).

Tool: Fretsaw blade

- Dimensions t = 1.5 mm, b = 1 mm.

- The noise level emitted amounted to:

Sound pressure level at workplace [dB (A)]

Idling: 64.1

Cutting: 74.5

A measurement uncertainty supplement of K = 4 dB (A)

applies to the said emission values.

The values given are emission values and therefore do not

necessarily equate to safe workplace values. Although

there is a correlation between emission and immission

levels, it cannot be reliably deduced whether or not

additional precautionary measures are required. Factors

which can influence the immission level present at the

workplace at any time include the duration of effect, the

nature of the workplace, other noise sources etc., e.g. the

number of machines and other adjacent processes. The

reliable immission level may also vary from country to

country. This information should however enable the user

to make a closer assessment of the risk and danger.

2

2.0 Delivery of machine

• After receiving the machine please check:

- packing for damage (inform carrier immediately in case

of damage).

- completeness of content according to delivery note.

- examine the packing for sundry parts.

3.0 perating instructions

Read the operating instructions precisely before

commissioning and use of the machine. No guarantee

is given in the case of incorrect handling and failure to

follow the operating instructions.

4.0 Proper use

- The machine is designed solely to cut wood, plastics,

NF metal and soft iron using fretsaw blades and

marquetry saw blades with a length of 130 mm.

- Only cut workpieces which are securely supported

and can be guided.

- No further or different use is intended.

- The machine may only be used, fitted and maintained

by people familiar with it and aware of the risks.

- The relevant accident prevention regulations and other

generally acknowledged health and safety rules must be

observed.

- Only original spare parts may be used.

- The manufacturer is not liable for any damage caused

by use of non-original spare parts.

- Changes to the machine or incorrect use of the

machine exclude the manufacturer’s liability for

damage.

5.0 Safety notes

5.1 General safety notes

- Keep unauthorised persons away from the machine.

- Only allow children to work on the machine under

supervision.

- Do not touch any moving parts with fingers.

- Wear protective goggles.

3

5.2 Commissioning

- Check that the voltage on the motor rating plate

corresponds to the voltage from the power source.

- Connect the dust extractor.

⇒ Point 13.0

- Only work in ventilated areas.

5.3 Users

- Read the operating instructions to prevent specific

machine accident risks.

- Never work under the influence of drugs, alcohol or

medication.

- Wear tight fitting clothing and protective goggles.

- Do not wear jewellery when working.

5.4 Before starting work

- Check that the machine is switched off.

⇒ Point 8.3

- Check that the saw blade fitted is suitable for the work.

- Check that the saw blade is clamped tightly.

- Check that all protective devices are fitted.

5.5 During work

- Remove residue and cuttings only when the machine is

switched off.

- On power failure, set the on / off switch to O.

5.6 After work

Switch off the machine and remove the plug.

6.0 Remaining risks

Even on proper use and despite observation of all

relevant safety regulations, because of the design

required for the purpose of the machine, the following

remaining risks can still arise.

- Touching the fretsaw blade.

- Breakage of fretsaw blade.

- Contact with live parts if there is damage to

- terminal box

- capacitor, or

- exposed supply cables.

- Inhalation of dust harmful to health.

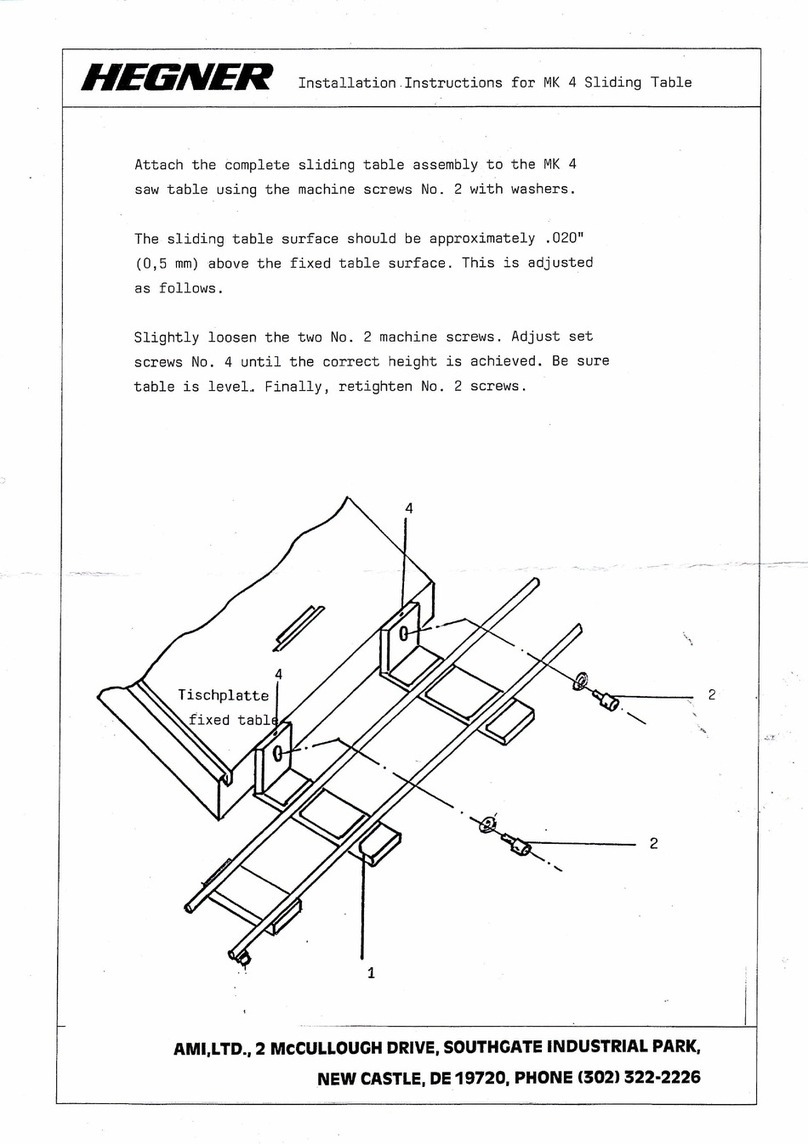

7.0 Unpacking / Assembly

7.1 Unpacking

⇒

Fig. 7-1

• ift the machine out of the packing box as shown.

• Do not lift by the upper swing arm.

7.2 Assembly

⇒ See Fig. 7-2

• Place the machine on a stable vibration free support so

that it can be controlled from the front.

- The height of the support should be adapted to the size

of the operator and depends on whether operation is

performed seated or standing.

• Attach the machine.

- either with 2 wood screws inserted from above through

the two holes (1) in the subframe (or with 2 coach bolts),

- or with 3 M8 bolts screwed from below into the threaded

bore (2) through the machine stand.

7.3 Environment

The location of the machine should be free from

- vibration

- moisture

- free from aggressive gasses and vapours

- free from mineral dust and

- able to be ventilated.

7.4 Electrical installation

The electrical installation of the site must comply with the

relevant regulations and meet the requirements of the

machine.

⇒1. Technical data

• Activate the mains switch so that the machine is

switched off.

⇒ point 8.3 switching off the machine.

• Connect the plug to the socket.

Route the power cable so that

- it does not hinder work

- it does not constitute an obstacle for tripping and

- it is not kinked, crushed or damaged.

4

Fig. 7.1

Fig. 7.2

12

12

2

8.0 Commissioning/Decommissioning

8.1 Commissioning the machine

We assume

- that you have read the previous chapters (in particular

Chapter 5, Safety instructions). If not, please do so and

return to this point.

- that the machine is properly assembled, installed and

connected.

- that all tools or workpieces are removed from the

working area.

- that all parts of the machine are undamaged and

correctly mounted.

• Check whether the saw blade fitted is straight.

A bent saw blade is unusable and must be replaced

with a new one.

⇒9. Changing the saw blade.

8.1.1 Tensioning the saw blade

⇒ Fig. 8-1 and 8-2

• Check that the clamping lever (1) is in the clamping

position.

• Tensing the saw blade using the cross-handled

screw (2) (Multicut 2S / SE / Quick).

On Multicut 1, tighten the saw blade with the clamping

lever (1).

• To do this turn the cross-handled screw or clamping

lever (Multicut 1) clockwise until the saw blade emits

a high note when tapped with the finger.

8.1.2 Releasing the saw blade

⇒Fig. 8-1 and 8-2

• Ensure that the machine is switched off before

releasing the saw blade.

• Release the saw blade by pulling the quick release

lever (1) forward (Multicut SE / Quick).

On Multicut 1, push the clamping lever up.

8.1.3 Connect vacuum cleaner

⇒ Fig. 8-1 and 8-2

• Connect the suction nozzle of the vacuum cleaner to

the opening provided (3).

• Make sure that the protective cover (4) is lifted up

☞

5

Fig. 8-1

Fig. 8-2

Multicut 2S/ SE / Quick

Multicut-1

21

1

34

34

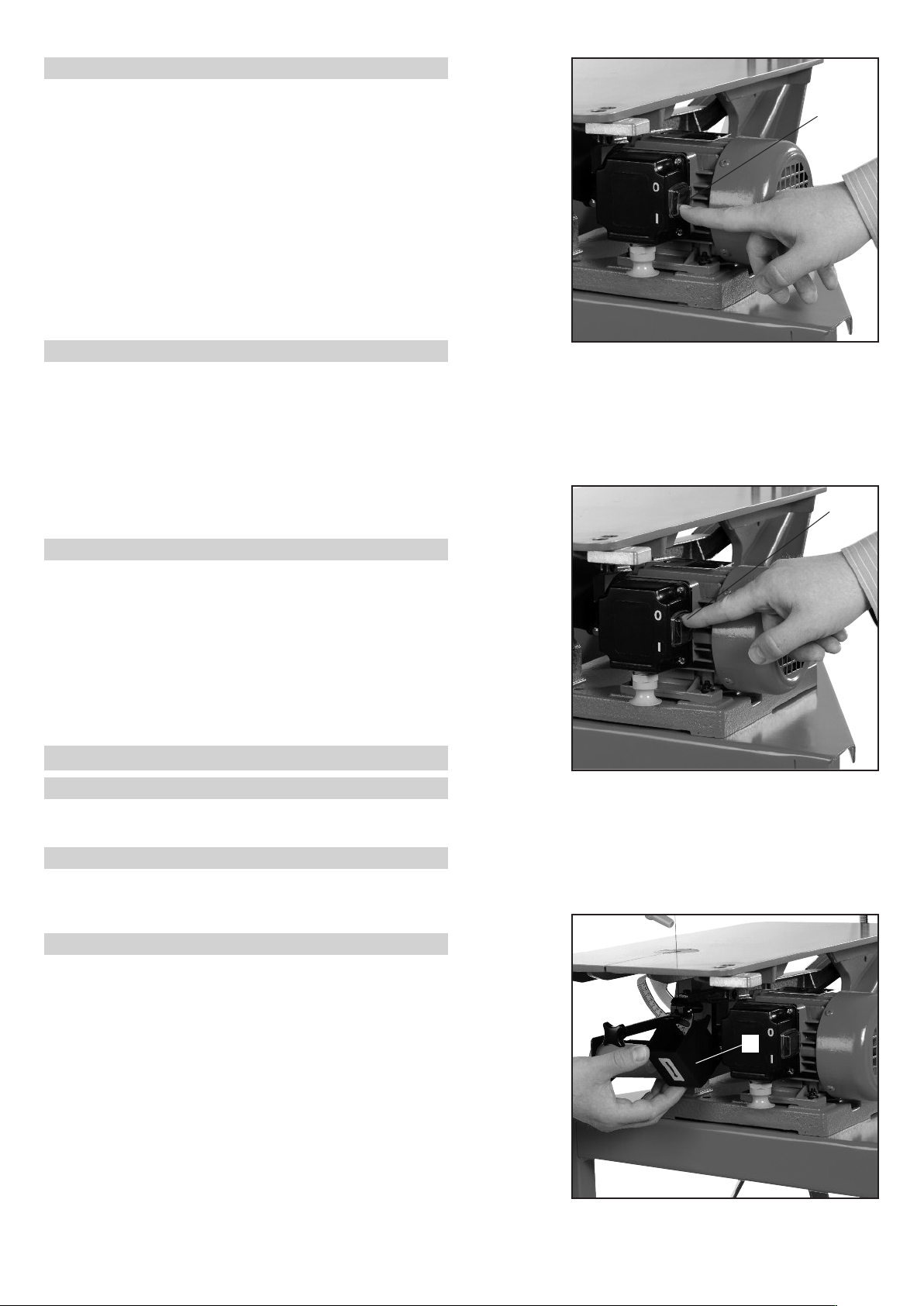

8.2 Switching on the machine

⇒

Fig. 8-3

Warning:

The machine starts to work as soon as it is switched

on.

• First remove all tools, workpieces, residue and

chippings from the working area.

• Connect the plug to the socket and switch the

machine on with the power switch (1) by pressing the

rocker switch down (I).

• Switch on the vacuum cleaner.

8.3 Switching off the machine

(for brief interruptions)

⇒ Fig. 8-4

• Switch off the machine with the power switch (1) by

pressing the rocker switch up (O).

• Switch off the vacuum cleaner.

• Remove all tools, workpieces, residue and chippings

from the working area.

8.4 Decommissioning the machine

(for longer stoppages, change-over, end of work etc.)

•Switch off the machine with the power switch (1) by

pressing the rocker switch up ( ) and remove the

plug from the socket.

• Release the fretsaw blade.

• Remove all workpieces, residue and chippings from the

working area.

9.0 Changing the Saw Blade

9.1 Switch off saw

⇒8.4 Decommissioning the machine.

9.2 Release saw blade

⇒8.1.2 Release saw blade.

Also release the saw blade if the blade is broken.

9.3 Fold protective cover down

⇒ Fig. 9.1

• Fold protective cover (1) down.

• Also remove chippings and residue from the protective

cover.

6

Fig. 8-3

Fig. 8-4

Fig. 9-1

1

1

1

9.4 Remove saw blade from machine

⇒

Fig. 9-2

• Turn the knurled screw up until it only just projects

through the bottom of the saw blade holder.

⇒ Fig. 9-3

• Gently press the upper swing arm down and remove

the saw blade clamp from its holder.

⇒ Fig. 9-4

• Press the clamp retaining spring down slightly and

remove the entire saw blade with clamps from the

machine.

9.5 Remove saw blade from saw blade clamps

⇒ Fig. 9-5

• Place the saw blade clamp in the clamp insert device

at the front right of the saw table.

⇒ Fig. 9-6

• Using the square wrench, open the clamps until you

can remove the saw blade.

9.6 Clamp new saw blade in saw blade clamps

⇒ Fig. 9-5

• ay the new saw blade in the clamps, precisely

centred and straight, with the teeth pointing down to

the right.

• Push the saw blade up to the stop (on the square bolt)

and then retract it approx 1 – 2 mm (so that the bolt

does not twist the blade when it is tightened).

• Clamp the saw blade clamp tightly using the square

wrench.

⇒ Fig. 9-7

• Clamp the other end of the saw blade in the same

way.

⇒ Fig. 9-8

• Ensure that the saw blade ends are clamped centrally.

9.7 Insert saw blade with clamp in machine

⇒ Fig. 9-4

• First insert the lower clamp in the lower swing arm.

• Then insert the upper clamp in the upper swing arm.

⇒ Fig. 9-9

• Turn the upper knurled screw towards the clamp so

that a gap of around 1 mm exists between the clamp

and the bolt.

☞

7

Fig. 9-2 Fig. 9-3

Fig. 9-4 Fig. 9-5

Fig. 9-6 Fig. 9-7

Fig. 9-8 Fig. 9-9

10.0 Changing the saw blade for int. cutting

To make an internal cut in a workpiece with the

machine, the workpiece must have an opening in which

you can insert the saw blade. We recommend using the

special clamp for internal cutting.

10.1 Decommission the machine

⇒ 8.4 Decommissioning the machine.

10.2 Fit the special clamp

⇒ Fig. 10-1

• Attach the special clamp in the upper swing arm and

lock with the knurled screw.

10.3 Insert the workpiece

• Push the saw blade to one side until you can guide

the saw blade through the opening of the workpiece.

10.4 Clamp the saw blade

⇒ Fig. 10-2

• From the front, guide the saw blade into the special

clamp, ensuring that the blade does not bend.

• Close the special clamp by twisting the knurled

aluminium screw.

10.5 Tensioning the saw blade

⇒ 8.1.1 Tensioning the saw blade

• Align the workpiece so that when the machine is

switched on, it cannot be touched by the saw blade

and flung out.

Note: When using the special clamp, the knurled

screw must always be locked in position on the top

arm. This will save time when changing the blade.

11.0 Swivelling the table plate

By adjusting the table plate, you can make angled cuts

up to maximum 45º on workpieces.

11.1 Decommission the saw

⇒ 8.4 Decommissioning the saw.

11.2 Swivel table plate

• Turn the table insert (1) Fig. 11-1-1

• Turn the cross-handled screw (2), Fig. 11-1-2,

around one turn anticlockwise.

• Angle the table plate to the required position and

retighten the cross-handled screw.

☞

☞

☞

8

Fig. 10-1

Fig. 10-2

Fig. 11-1-1

Fig. 11-1-2

1

2

12.0 Adjusting the stroke length

The machine is set by the factory to a long stroke length

which is normally best for most fretsaw work.

For working in extremely thin, light material such as

wood veneer or thin sheets, shortening the stroke may

improve saw control and smoothness. There is less risk

of breaking the thin fretsaw blade.

12.1 Decommission the machine

⇒ 8.4 Decommissioning machine.

12.2 Unscrew protective cover

⇒ Fig. 12-1

• Using the Allen key, unscrew the bolt (1) and remove

the protective plate.

12.3 Lock the cam

⇒ Fig. 12-2

• Push the steel pin (1) into the bore on the cam plate.

12.4 Release the connecting rod

⇒ Fig. 12-3

• With one hand hold the steel pin (1). This prevents

the cam plate turning.

• Using the fork wrench (3) (on Multicut 1, Allen key 3

mm) turn the screw (2) anticlockwise.

12.5 Adjust the stroke length

⇒ Fig. 12-4

• Push the connecting rod (1) aside. Behind this are the

two threaded bores in the shaft of the cam plate.

• For a short saw stroke,

- screw the bolt into the threaded bore closest to the

centre point (3).

- For a long saw stroke, screw the bolt into the threaded

bore further out.

12.6 Clamp the connecting rod

⇒ Fig. 12-5

Before screwing on the connecting rod ensure that the

spacer (1) is fitted.

• When tightening the connecting rod again, secure the

cam plate against twisting with the steel pin.

☞

☞

9

Fig. 12-1

Fig. 12-3

Fig. 12-4

Fig. 12-5

Fig. 12-2

1

1

3

2

1 3 4

1

13.0 Extraction connection

Certain wood types such as chipboards etc.

produce harmful dust emissions during machining.

For this reason the machine must be connected to

a dust extractor. For long and frequent use of the

machine, operating measures must ensure that the

extractor is automatically switched on when the

machine is switched on.

13.1 Connection

⇒ Fig. 13-1

The machine is designed for a standard dust extractor

(vacuum cleaner).

Push the connector of the extractor system into

opening (1) of the connection piece so that it locks.

13.2 Adjust the upper extraction

⇒ Fig. 13-2

• Adjust the upper extraction hose (1) so that it lies on

the workpiece around 5 mm away from the saw blade.

If however you want to work without the extractor, the

cut line can be blown clear by pulling the hose (4) off

the connection piece (5) and inserting it in the pump

base (3).

When the dust extractor is not connected, the

machine may only be used for open air work. In

closed rooms the dust extractor must be connected

(see 13.0 Extraction connection).

14.0 Maintenance / Cleaning

The machine is low maintenance.

Only the upper and lower arm bearings need to be oiled

regularly (approx. every 10 operating hours) with a fine

non-resinous oil (e.g. sewing machine oil).

14.1 Maintenance – oil arm bearings

⇒ Fig. 14-1

• Remove any dust deposits at the lubrication points.

• Using a light oil, oil both arm bearings (1). Apply 3 to

4 drops of oil at the points marked with arrows

(between the swing arm and washer).

The clamping spindle (2) must not be oiled or

greased.

☞

☞

☞

☞

10

Fig. 13-1

Fig. 13-2

Fig. 14-1

1

1

3

1

1

2

4

5

14.2 Maintenance – inspection

• With the machine switched off, carry out a visual

inspection at regular intervals and check the parts

of the machine for damage, above all

- the plug

- the power cable

- the terminal box

• If damage is found in particular to the electrical

equipment, decommission the machine

immediately and arrange for professional repair

with original spare parts.

14.3 Cleaning

- Clean the machine according to the level of dirt.

- No deposits of dust or chippings should form on or in

the machine.

14.3.1 Decommission machine

⇒ 8.4 Decommissioning the machine

14.3.2 Clean the machine

• Clean the machine by extracting the dust with a

vacuum cleaner.

• Remove the side protective cover from time to time

and remove any dust below it.

• Remove sticky deposits with a brush or similar.

• Do not use any

- flammable

- aggressive or

- scouring cleaning agents

• Prevent the penetration of fluid / liquid into the

machine and in particular the electrical parts.

• If however moisture or fluid enters the machine,

do not connect the machine to the power supply.

• In this case contact the dealer or manufacturer.

15.0 Repair / Spare parts

These operating instructions do not contain any repair

instructions. Parts are repaired and / or replaced at

your own risk.

• The following notes must be observed.

15.1 Repair

• Do not repair any (faulty) electrical machine parts.

• These parts must be replaced by original spare

parts from the manufacturer.

• nly the manufacturer or authorised dealer /

specialist with corresponding training (e.g.

electricians) may replace electrical machine parts.

• If incorrect D.I.Y. work is performed on electrical

machine parts, there is a risk of life-threatening

current surges and/or burns.

• The person responsible is liable for all damage or

injury caused in this way.

Faulty or worn machine parts:

- may in principle only be replaced by the manufacturer

/ authorised dealer or specialist with corresponding

training.

- may be replaced by the user with original parts from

the manufacturer if the user has the necessary

mechanical knowledge.

- The person responsible is liable for injury and/or

damage caused by incorrect repair or replacement

work by the user or other unauthorised persons.

If you still wish to repair your machine yourself:

• first disconnect the power switch and remove the plug

from the socket.

☞

☞

11

16.0 Tips for use

16.1 Examples of correct choice of saw blade

⇒ Table on side protection cover of machine

Important:

Blunt saw blades must be replaced. This applies in

particular when cutting iron. Full cutting power and

accuracy is achieved only if the recommended quality of

saw blade is used.

Useful note:

If for economy reasons you wish to continue to use a

blunt saw blade, for example for cutting iron, attach a

smooth support approx. 20 mm thick to the saw table

plate of the machine using twin-sided adhesive tape,

and continue to cut on this. By raising the saw table in

this way you can progressively use up more of the saw

blade.

Working with plastics:

To prevent the material melting when cutting, mask off

the cutting line with plastic adhesive tape.

16.2 Feed pressure

The feed pressure to be exerted on the workpiece must

always be directed obliquely from top to bottom, else

the workpiece may jump. Some workpieces require a

strong feed pressure.

16.3 Stop

In general stops are not used when sawing with

fretsaw blades. Fretsaw blades will move off the

cutting line if the workpiece is force-guided.

Accurate sawing requires:

- a sharp saw blade

- a thin, accurate cutting line

- correctly applied, bright light

16.4 Straight cutting

• Always hold the workpiece at an angle of 1 to 5º (the

angle depends on material, saw blade type and blade

tension).

16.5 Notes on sawing metal

• First deburr metal workpieces to be cut on all sides

and flatten these off carefully so they sit flat.

• Either glue thin or small workpieces (e.g. thin sheets)

onto a 5 mm thick plywood block (using contact

adhesive or twin-sided adhesive film) or place these

between two pieces of plywood and secure against

slipping with pins.

• Then cut the workpiece out together with the plywood

(do not choose sheets that are too thick).

• Use

- fretsaw blade no. 1 to 5 for

- soft NF metals, e.g.

- aluminium (sheet)

- soft copper (sheet)

- soft brass (sheet)

If necessary you can also use metal saw blades

numbers 5 to 9.

• Before sawing, coat the cut line with lubricating oil

(universal oil).

• Use

- metal saw blades nos. 1, 5, 9 or 12 for

- hard NF metals e.g. for

- hard aluminium (sheet)

- hard copper (sheet)

- hard brass (sheet)

- iron (sheet).

• Before sawing, coat the cut line with cutting oil or

paste.

• Despite using saw blades of top quality, depending on

hardness iron will cause greater blade wear.

17.0 Speed selection

(only on motors with electronic speed control)

• In general, low speeds are better if accuracy,

guidance of the saw blade or durability of the saw

blade are important, whereas higher speeds are

generally better for higher working output and reduced

cutting times.

•Thin or fragile materials are best handled at low speeds.

• Extra thick materials or plastics are best handled at

medium or low speeds.

☞

☞

☞

☞

☞

☞

12

13

18.0 perating Mistakes and Causes

Effect

Workpiece catches or

jumps.

Sawblade does not

appear to cut well.

Sawblade pulls out of

clamp.

Sawblade running hot

and burning or tearing.

Hard to follow marked

lines.

Cutting face is bowed.

Cutting face is not

vertical.

Underside of

workpiece splinters.

Cause

To much feed pressure on the workpiece.

Sawblade is in the machine upside down.

Turning a sharper radius than the sawblade

will comfortably allow at the feed speed.

Blunt or wrong sawblade.

Poor quality sawblade.

Insufficient feed pressure.

Clock key screw insufficiently tightened.

Too strong a feed pressure, turning too

quickly in thick timber.

Too fine a sawblade in close grain timber.

Blunt sawblade.

Too strong a feed pressure.

Blunt or incorrect grade of sawblade.

Not enough support on this materials.

Insufficient blade tension.

Blunt sawblade and too strong a

feed pressure.

Too fine a sawblade.

Table top not a 90°- to the blade or table

adjustment screw not tightened.

Wrong type of sawblade.

Worn table insert.

Remedy

Slaken off the pressure. Give the blade time

to cut at its own speed.

Put blade in correctly (see 9.5).

Slow down, ease the sawblade slowly round

tight corners.

Replace with sharp and/or correct sawblade!

Use high quality German sawblades!

Increase feed pressure.

Increase clamping pressure! If the sawblade

continues to pull out - replace clamp.

Reduce feed pressure!

Choose coarser sawblade!

Replace sawblade.

Reduce feed pressure!

Replace sawblade or choose finer blade!

Back thin sheet with a 4 mm plywood or

hardboard sheet.

Increase blade tension!

Replace with new sawblade and decrease

feed pressure!

Utilise a coarser sawblade!

Align table top correctly with a square and

tighten screws!

Utilise reverse tooth sawblades!

Change table insert!

(included with standard accessories)

14

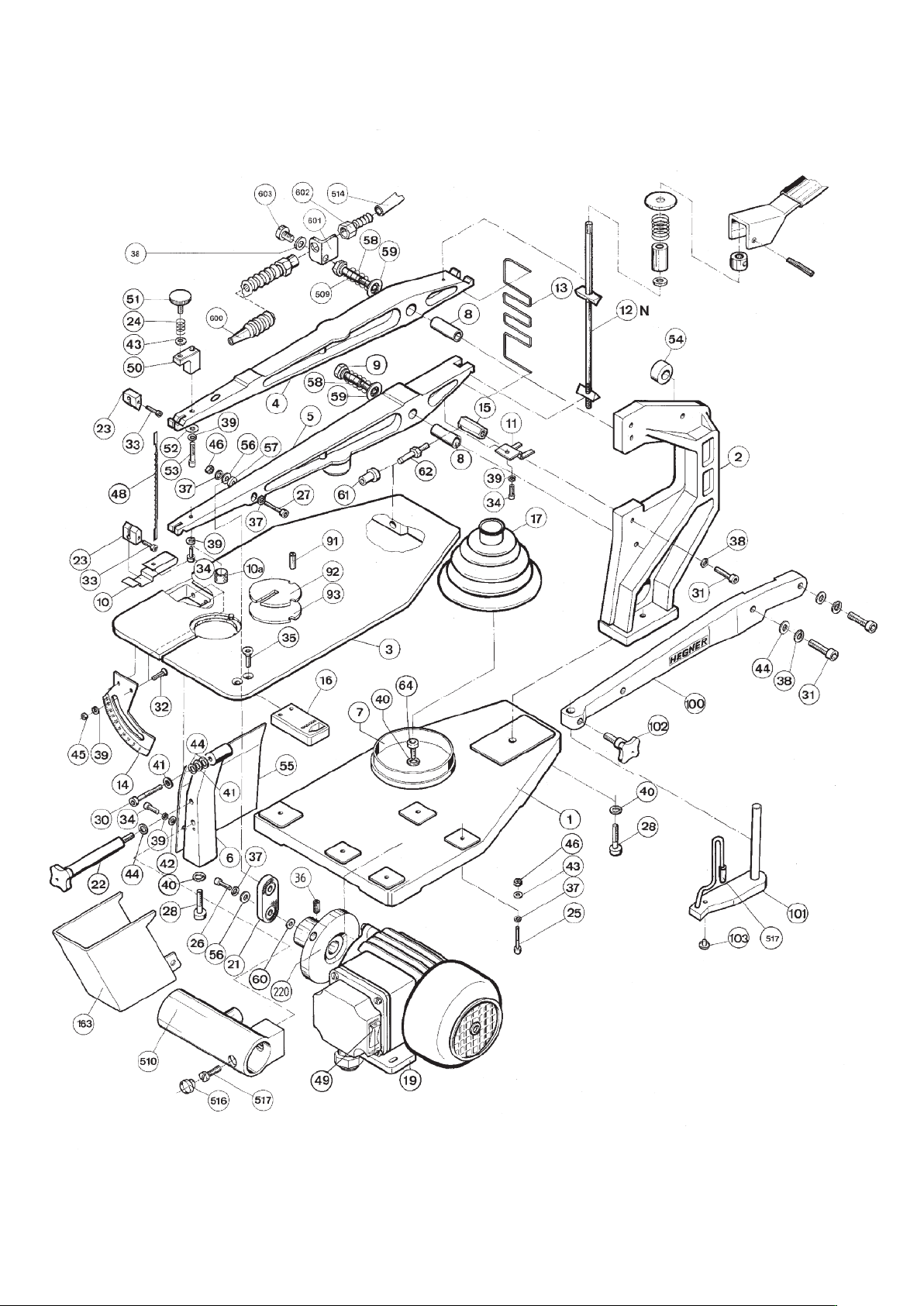

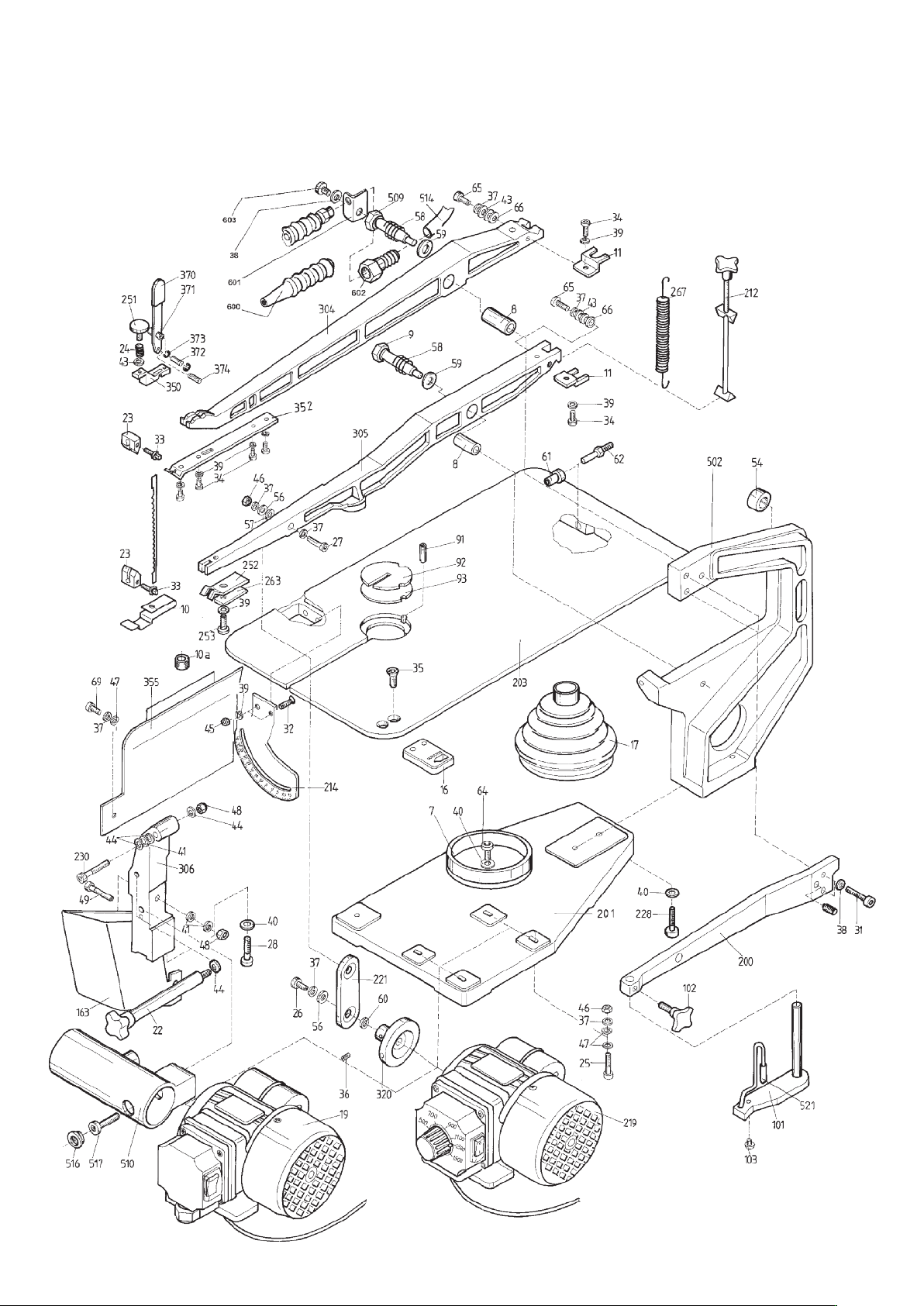

Spare parts

If you require a spare part, simply quote the

number shown in the exploded drawing.

HEGNER Multicut-1

15

HEGNER Multicut-2S

16

HEGNER Multicut-SE

17

HEGNER Multicut-Quick

11/2010

This manual suits for next models

3

Table of contents

Other Hegner Saw manuals

Popular Saw manuals by other brands

woodmizer

woodmizer 1996 LT25 Safety, Setup, Operation & Maintenance Manual

Hyd-Mech

Hyd-Mech H10A Safety and operating instructions

Delta

Delta 20-330 instruction manual

woodmizer

woodmizer LT40 Series Safety, Setup, Operation & Maintenance Manual

Powerplus

Powerplus POWX225 manual

Power Fist

Power Fist J1G-355C owner's manual

Delta

Delta UniSaw 36-L31 instruction manual

Nova gear

Nova gear NG-210 instruction manual

woodmizer

woodmizer LT40L AH Safety, Setup, Operation & Maintenance Manual

woodmizer

woodmizer LT15 AL-KO Safety, Setup, Operation & Maintenance Manual

ESAB

ESAB Aristo 1000 instruction manual

Mac allister

Mac allister MTSP800A manual