Hegwein ZT0 User manual

Inhaltsverzeichnis

Operating Manual

Gas fired igniter

ZT0

©

Hegwein GmbH

Am Boschwerk 7

70469 Stuttgart, Germany

Before first use, read the operating manual!

Tel.: +49 (0)711 13 57 88-0

Fax: +49 (0)711 13 57 88-5

www.hegwein.de

Status: 11-2018

Gas fired igniter ZT0

Contents

- 2 - Status: 11-2018

1General .......................................................3

1.1 Information on the operating manual...........3

1.2 Explanation of symbols................................3

1.3 Liability disclaimer .......................................4

1.4 Copyright protection ....................................5

1.5 Spare parts..................................................5

1.6 Warranty regulations ...................................5

1.7 After-sales service.......................................5

2Safety..........................................................6

2.1 Owner’s responsibility..................................6

2.2 Operating personnel....................................7

2.2.1 Requirements ..............................................7

2.2.2 Unauthorized persons .................................8

2.3 Intended purpose of the equipment.............8

2.4 Personal protective gear..............................9

2.5 Special dangers.........................................10

2.6 Securing against unauthorized switching

use.............................................................13

2.7 Response in case of danger or accident...14

3Transport, packaging and storage ........15

3.1 Safety instructions for transport.................15

3.2 Transport inspection..................................15

3.3 Packaging..................................................16

3.4 Storage conditions.....................................16

4Specifications ..........................................17

4.1 Type designation with type key .................17

4.2 Gas fired igniter .........................................18

4.3 Power head ...............................................19

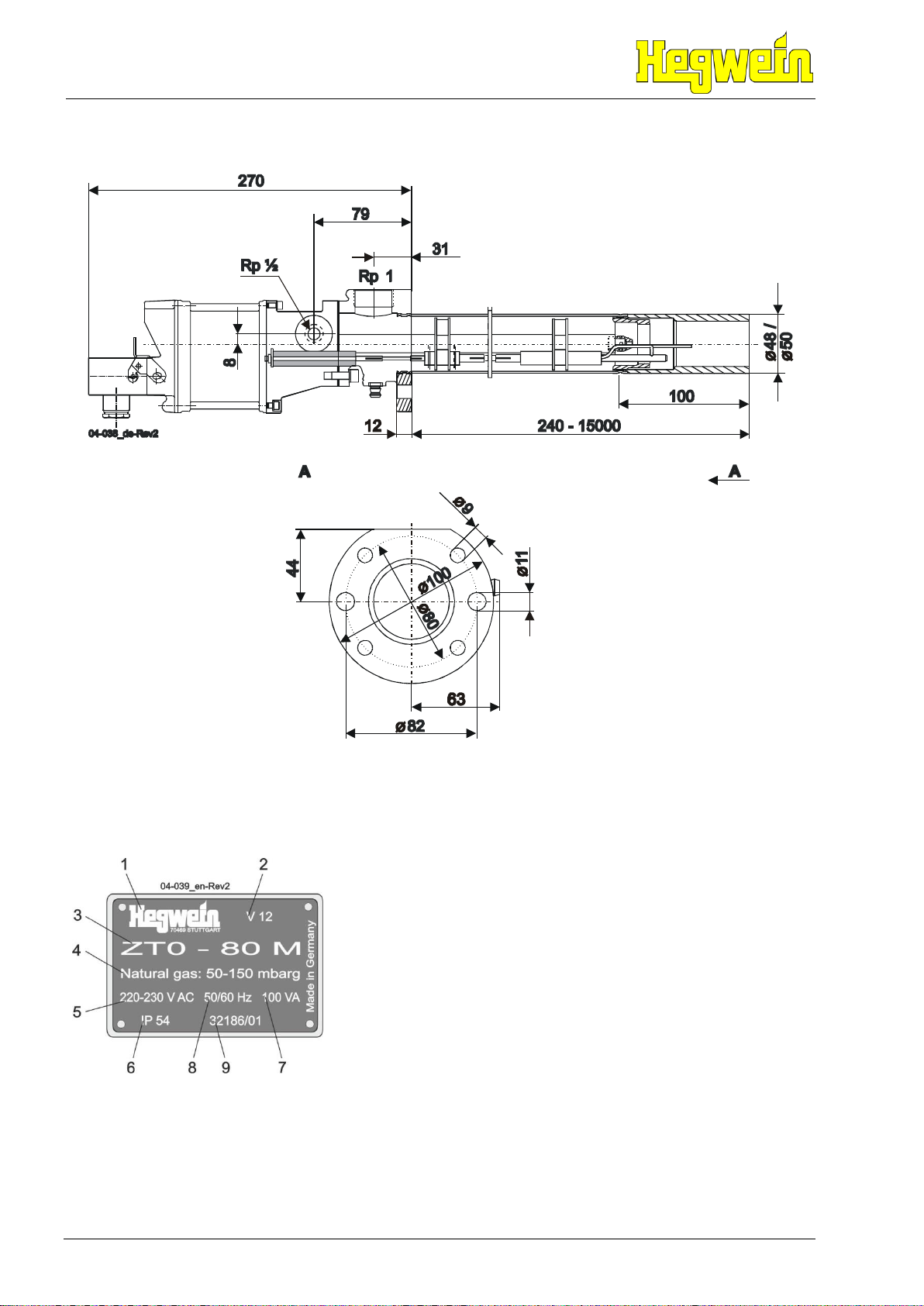

4.4 Dimensional drawing.................................20

4.5 Rating plate ...............................................20

4.6 Service life.................................................21

5Functional characteristics and

structure...................................................22

5.1 Functional characteristics..........................22

5.2 Structure....................................................22

5.3 Flame monitoring.......................................23

5.3.1 Safety time.................................................23

5.4 Gas and air adjusting components

(accessories)............................................. 24

5.5 Electrical wiring versions........................... 25

6Installation and initial commissioning.. 26

6.1 Safety........................................................ 26

6.2 Installation and electrical connection ........ 28

6.3 Electrical function test............................... 32

6.4 Setting the required air volume................. 34

6.5 Setting the required gas volume ............... 35

6.6 Checking the setting result........................ 37

7Operation ................................................. 38

7.1 Safety........................................................ 38

7.2 Operation................................................... 38

8Maintenance ............................................ 39

8.1 Safety........................................................ 39

8.2 Maintenance, general................................ 39

8.3 Conditions for maintenance work.............. 40

8.3.1 Exchanging the outer tube........................ 41

8.3.2 Exchanging the power head...................... 42

8.3.3 Exchanging the final electrode support

ring ............................................................ 43

8.3.4 Exchanging the intermediate support

rings........................................................... 44

8.4 Actions following completed maintenance

work........................................................... 44

9Troubleshooting...................................... 45

9.1 Safety........................................................ 45

9.2 Troubleshooting table................................ 46

10 Dismantling / Disposal............................ 49

10.1 Safety........................................................ 49

10.2 Dismantling................................................ 49

10.3 Disposal..................................................... 50

11 Spare parts list ........................................ 51

11.1 Spare and wearing parts........................... 51

12 Annex ....................................................... 53

12.1 EU Declaration of conformity .................... 53

Gas fired igniter ZT0

General

Status: 11-2018- 3 -

1 General

1.1 Information on the operating manual

This operating manual provides important information on working

with the gas fired igniter. Safe working can only be ensured by

adhering to all the safety remarks and instructions provided.

In addition, the locally applicable accident prevention legislation

and general safety regulations with validity for the place of

operation must be adhered to.

Read through the operating manual carefully before starting any

work. These instructions form a constituent part of the product and

must be kept in the immediate vicinity of the equipment at all times

within easy reach for personnel.

When the gas fired igniter is passed on to third parties, it must

always be accompanied by the operating instructions.

The illustrations in this operating manual are intended to aid

understanding of the content. They are not necessarily true to

scale and may differ slightly in some details from the actual

configuration of the gas fired igniter.

1.2 Explanation of symbols

Warning instructions

Warning instructions are indicated in this operating manual by

symbols. The remarks are introduced by the use of signal words

which indicate the degree of severity of the hazard.

The instructions must be adhered to without fail and acted upon

prudently in order to prevent accidents, personal injury or material

damage.

DANGER!

… denotes a hazardous situation which results in

death or serious injury unless prevented.

WARNING!

… denotes a hazardous situation which could result

in death or serious injury unless prevented.

CAUTION!

… denotes a hazardous situation which could result

in minor or slight injury unless prevented.

NOTE!

… denotes a hazardous situation which could result

in material damage unless prevented.

Gas fired igniter ZT0

General

- 4 - Status: 11-2018

Recommendations

REMARK!

… highlights useful recommendations and

information designed to permit efficient, trouble-

free operation.

Special safety remarks

In order to draw attention to special hazards, the following symbol

is used in conjunction with safety remarks:

DANGER!

Fatal danger due to electrical current!

… denotes a potentially fatal situation due to

electrical current. Failure to adhere to the safety

instructions can give rise to the danger of serious

injury or death.

The work to be performed may only be carried out

by a suitably qualified electrician.

1.3 Liability disclaimer

All instructions and remarks contained in this operating manual are

collated taking into account applicable standards and regulations,

the state of the art and our many years of experience and

expertise.

The manufacturer is consequently unable to accept any liability for

damage caused as a result of:

Failure to adhere to the instructions

Use for any other than the designated purpose

Deployment of untrained personnel

Internally executed modifications or conversion work

Technical modifications

Use of unapproved spare parts

The actual scope of the delivery may differ in some details from the

explanations and illustrations provided here in the case of special

versions, where additional optional features are made use of or

due to the latest technical modifications.

Otherwise, the obligations agreed in the Supply Agreement, the

General Terms and Conditions and the Manufacturer’s Conditions

of Supply and the statutory regulations in force at the time of

conclusion of contract shall be applicable.

Gas fired igniter ZT0

General

Status: 11-2018- 5 -

1.4 Copyright protection

These operating instructions must be treated in confidence. They

are exclusively intended for the persons operating the gas fired

igniter and may not be made available to third parties without the

prior written consent of the manufacturer.

REMARK!

The information, texts, drawings, illustrations and

other representations are protected by copyright

and are subject to industrial property rights.

Utilization for any other than their intended purpose

renders the perpetrator liable to prosecution.

The contents of all or part of these operating instructions may not

be duplicated in any form, nor may they be used and/or

communicated to any third party without the written consent of the

Manufacturer. Any breach of this obligation shall render the

perpetrator liable to compensation of damages, without prejudice

to any further-reaching claims.

1.5 Spare parts

WARNING!

Danger of injury due to the use of incorrect

spare parts!

Incorrect or faulty spare parts can result in

damage, malfunctions or total failure of the

equipment as well as posing a safety hazard.

–Only ever use original spare parts from the

manufacturer.

Order spare parts through your authorized dealer or directly from

the manufacturer. Address: see table of contents cover sheet.

1.6 Warranty regulations

The warranty regulations are provided as a separate document in

the General Terms and Conditions.

1.7 After-sales service

For any technical information, consult our after-sales service.

Information can be obtained through the responsible contact at any

time by phone, fax, e-mail or Internet. For the manufacturer’s

address, see the cover sheet on the table of contents.

Our employees are always interested to receive any new

information or experience arising from application which could be

of use in the further development of our products.

Gas fired igniter ZT0

Safety

- 6 - Status: 11-2018

2 Safety

This section provides an overview of all important safety aspects

for optimum protection of personnel as well as safe, trouble free

operation.

Failure to observe the operating instructions and safety remarks

contained in this manual can cause serious injury.

2.1 Owner’s responsibility

As the gas fired igniter is used commercially, the owner of the gas

fired igniter is obliged to adhere to occupational safety regulations

as well as any other applicable directives, legislation and

standards.

Alongside the occupational safety remarks contained in these

operating instructions, the safety, environmental and accident

prevention regulations governing the field of application of the gas

fired igniter must be adhered to, whereby the following regulations

in particular apply:

The owner must be aware of the valid occupational safety

regulations and also determine any additional potential hazards

arising as a result of the specific working conditions applicable

at the location in which the igniter is used, by performing a risk

assessment. This must be implemented in the form of operating

instructions governing operation of the gas fired igniter.

The owner must test, throughout the service life of the gas fired

igniter, whether the operating instructions drawn up by him still

correspond with the latest revision of the relevant rules and

regulations, and must update these where applicable.

The owner must clearly regulate and define fields of

responsibility for installation, operation, maintenance and

cleaning.

The owner must ensure that all employees involved in working

with the gas fired igniter have read and understood the

operating instructions.

Furthermore, the owner must provide personnel training at

regular intervals and inform staff of potential hazards.

As the owner is also responsible for ensuring that the gas fired

igniter is always in good technical working order the following

requirements additionally apply:

The owner must ensure that maintenance work is performed

regularly.

The owner must regularly check that all safety devices are fully

functional and complete.

The owner must provide the necessary protective gear for

personnel.

Gas fired igniter ZT0

Safety

Status: 11-2018- 7 -

2.2 Operating personnel

2.2.1 Requirements

WARNING!

Danger of injury due to insufficient qualification

Incorrect handling of the equipment can result in

severe personal injury and material damage.

–Only allow activities to be performed by suitably

qualified specialist personnel.

The following qualifications are required for the various fields of

activity:

Qualified personnel

are capable on the basis of their specialist training, knowledge

and experience as well as their knowledge of the applicable

regulations of executing the work assigned to them and of

independently recognizing possible hazards.

Electrical specialists

are capable on the basis of their specialist training, knowledge

and experience as well as their knowledge of the applicable

regulations of working on electrical installations and of

independently recognizing possible hazards.

Electrical specialists have received training specifically for the

work environment in which they are employed and are familiar

with the relevant standards and regulations.

Gas specialists

are capable on the basis of their specialist training, knowledge

and experience as well as their knowledge of the applicable

regulations of working on gas installations and of independently

recognizing possible hazards.

Gas specialists have received training specifically for the work

environment in which they are employed and are familiar with

the relevant standards and regulations.

Only persons who may be expected to perform their task reliably

may be authorized to use the equipment. Persons whose reaction

capacity is impaired, for example due to drugs, alcohol or medicine

use, may not be authorized.

When selecting suitable personnel, observe the age and

profession-specific regulations applicable at the place of use.

Gas fired igniter ZT0

Safety

- 8 - Status: 11-2018

2.2.2 Unauthorized persons

WARNING! Danger for unauthorized persons!

Persons who do not comply with the requirements

described here are not aware of the dangers

inherent in the work area.

–Keep unauthorized persons away from the work

area.

–In case of doubt, approach the person in

question and direct them out of the work area.

–Interrupt work for as long as any unauthorized

person remains in the work area.

2.3 Intended purpose of the equipment

The gas fired igniter is exclusively designed to perform the

intended purpose described here.

The gas fired igniter is a piece of equipment that has to be

integrated into a gas-consuming installation. It must not be

operated without an overriding safety control system.

It is designed for the sole purpose off lighting and

supporting any gas-, oil- or solid fuel fired burner of medium

heat release in industrial furnaces, thermo-processing

plants and boilers.

WARNING!

Danger due to use not in accordance with the

intended purpose!

Any application beyond and/or not in accordance

with the intended purpose of the gas fired igniter

can result in the occurrence of hazardous

situations.

–Only operate the gas fired igniter when in a

mounted condition. Ensure that the combustion

points created by the flame are fitted with a

suitable extraction facility over the exposed flue

gas channel throughout the plant.

–Only operate the gas fired igniter according to

the specifications indicated on the rating plate.

Otherwise, potential danger of personal or

material damage can arise.

–Adhere to all the instructions provided in this

operating manual without fail.

The manufacturer can not be held liable for physical or material

harm caused by misuse of equipment or use for anything other

than its intended purpose.

Gas fired igniter ZT0

Safety

Status: 11-2018- 9 -

2.4 Personal protective gear

Personal protective gear must be worn while working with the

equipment in order to minimize potential health hazards.

Wear the protective gear necessary for performance of the

relevant task at all times while working.

Observe all signs relating to personal protective gear in the

work area.

To be worn at all times

Wear the following for the performance of all work:

Protective work clothing

This comprises tight-fitting work clothes which are resistant to

tearing, have tight-fitting sleeves and no projecting parts. This is

required primarily to protect against burns.

Safety shoes

To protect the feet against heavy falling articles and to prevent

slipping on floors.

Protection helmet

Protection helmets protect the head from falling parts, swinging

loads or bumping it against stationary equipment.

To be worn for special types of

work

When performing special types of work, special safety equipment

is required. This is covered in depth in the individual chapters of

this instruction manual. These types of special protective gear are

described in the following:

Face protection

To protect one’s eyes and face from flames, sparks or embers as

well as hot particles or flue gases.

Protective gloves

To protect one’s hands from rubbing, chafing, puncturing or deeper

injuries and from contact with hot surfaces.

Gas fired igniter ZT0

Safety

- 10 - Status: 11-2018

2.5 Special dangers

Remaining dangers are listed in the section below.

The remarks provided here and the safety instructions in the

subsequent chapters of this operating manual must be observed in

order to reduce the possible risk to health and prevent the

occurrence of dangerous situations.

Incorrect transport

WARNING!

Danger of injury as a result of incorrect

transport!

In the case of incorrect transport, considerable

material damage can occur.

–Note the intrinsic weight of the gas fired igniter

or the components. If necessary, use suitable

hoisting gear.

–From an outer tube length of 3 m use several

lashing points or a suitable hoisting gear with

supports.

–Please mind the centre of gravity.

–Secure the gas fired igniter from dropping down

or falling over.

–Do not stand under the load while lifting or

lowering it and stay out of the danger zone.

Gas fired igniter ZT0

Safety

Status: 11-2018- 11 -

Electrical current

DANGER!

Danger to life due to electrical current!

When touching with current conducting parts, there

is a danger to life. Damage to the insulation or

individual components can have potentially life-

threatening consequences.

–In the event of damage to the insulation of the

power supply, switch off immediately and

arrange for repairs to be carried out.

–Work on the electrical system may only be

carried out by suitably qualified electricians.

–Before starting work, switch off the power

supply and make sure it cannot be inadvertently

switched back on. Observe the 5 safety rules:

–De-energise.

–Secure against reconnection.

–Ascertain de-energised condition.

–Earth and short-circuit.

–Cover or block off adjacent live parts.

–Never bypass or decommission fuses. When

changing fuses, adhere to the correct amperage

and the correct characteristics.

–Only connect the gas fired igniter to the

permitted operating voltage / load according to

the technical data.

–The operator/installer is responsible for

adherence to the permitted environmental

conditions and/or ambient atmosphere in

accordance with the technical data.

–Keep moisture away from live components. This

can create a short circuit.

Electrostatic charge (ESD)

CAUTION!

Damage of electronic components due to

electrostatic discharge (ESD)!

Electronic components become steadily smaller

and more complex. This also increases the

susceptibility to electrostatic discharging.

–Take measures to protect the components

against electrostatic discharge.

–Take measures to prevent static charging of the

human body.

Gas fired igniter ZT0

Safety

- 12 - Status: 11-2018

Highly inflammable materials

WARNING!

Danger of burns due to flammable materials!

Highly flammable materials, liquids or gases can

catch fire and cause serious to fatal injuries.

–Do not smoke in the danger area and in the

close vicinity. Do not use any naked flames or

ignition sources.

–Keep a fire extinguisher on hand.

–Report suspicious substances, liquids or gases

immediately to the responsible officer.

–In case of fire, stop work immediately. Leave

the danger area until the all-clear is given.

Hot surfaces

CAUTION!

Danger of burns due to hot surfaces!

Contact with hot components can cause burns.

–When carrying out any work near hot

components, always wear protective work

clothing and safety gloves.

–Before performing any work, ensure that all

components have cooled to ambient

temperature.

Sharp edges and pointed corners

CAUTION!

Danger of injury on edges and corners!

Sharp edges and pointed corners can cause

chafing of the skin and cuts.

–Take particular care when performing work near

to sharp edges and pointed corners.

–In unsure, wear safety gloves.

Special environmental influences

NOTE!

Danger of damage due to special

environmental influences!

Vibrations affecting the gas fired igniter or welding

work performed in the area of the gas fired igniter

can result in damage.

–In order to prevent damage to the gas fired

igniter, it must not be exposed to any vibrations.

–When carrying out any welding work in the area

of the gas fired igniter, it must be electrically

disconnected and removed.

–Before welding work on the outer tube of the

gas fired igniter can be carried out, this must

first be disconnected from the power head.

Gas fired igniter ZT0

Safety

Status: 11-2018- 13 -

2.6 Securing against unauthorized switching use

DANGER!

Risk of fatal injury due to unauthorized use!

When working in the danger area, there is a risk

that the energy supply could be switched on by an

unauthorized person. This creates a potentially

fatal hazard for persons working in the danger

area.

–Observe the instructions provided on securing

against unauthorized switching back on in the

chapters of this operating manual.

–Always observe the procedure described below

to secure against unauthorized switching back

on.

Switch safeguarded by lock

on: …….. at ……hours

DO NOT SWITCH ON

The lock may only be removed

by: …………………

once steps have been taken to ensure

that no persons are located in the

danger area.

Securing against unauthorized use

1. Switch off the power supply.

2. If possible, secure the switch with a lock and attach a sign in

an easily visible location at the switch.

3. Have the key looked after by the employee named on the

sign.

Switched off

on: …….. at ……hours

DO NOT SWITCH ON

The lock may only be removed

by: …………………

once steps have been taken to ensure

that no persons are located in the

danger area..

4. Should it not be possible to secure a switch using a lock, set

up a sign.

5. Once all the work has been carried out, ensure that there are

no longer any persons located in the danger area.

6. Ensure that all safety devices are installed and are fully

functional.

7. Only then may the sign be removed.

Gas fired igniter ZT0

Safety

- 14 - Status: 11-2018

2.7 Response in case of danger or accident

Preventive actions

Always be prepared for accidents and for fires!

Keep first aid equipment (first aid kit, blankets etc.) and a fire

extinguisher on hand.

Familiarize personnel with accident alarm, first aid and rescue

facilities.

Ensure that access paths for emergency vehicles are kept

unobstructed.

In case of accident: React correctly

Initiate first aid measures.

Evacuate any persons located in the danger area.

Inform those responsible at the incident location.

Alert the emergency medical / fire services.

Clear access paths for emergency vehicles.

Gas fired igniter ZT0

Transport, packaging and storage

Status: 11-2018- 15 -

3 Transport, packaging and storage

3.1 Safety instructions for transport

Incorrect transport

WARNING!

Danger of injury as a result of incorrect

transport!

In the case of incorrect transport, considerable

material damage can occur.

–When unloading packaged items on delivery,

and when transporting within the premises, take

extreme care and observe the symbols and

instructions on the packaging.

–Depending on the length of the product and the

scope of delivery suitable lifting equipment

should be used for unloading. The load capacity

of the lifting equipment should exceed the total

weight of the delivery.

–Please mind the centre of gravity.

–Only use the provided lashing points.

–Do not stand under the load while lifting or

lowering it and stay out of the danger zone.

REMARK!

Extreme vibration or shock may cause damage to

electrical components.

3.2 Transport inspection

Check the delivery on receipt without delay for completeness and

transport damage.

In the case of externally recognizable transport damage, report the

damage immediately, adopting the following procedure:

Only conditionally accept the delivery.

Note the extent of the damage on the transport documents or

on the shipping agent’s delivery note.

Initiate a complaint.

Concealed transport damage must be reported within seven days.

REMARK!

Report any defect immediately it is noticed. Claims

for damages can only be asserted within the

applicable deadlines for the filing of complaints.

Gas fired igniter ZT0

Transport, packaging and storage

- 16 - Status: 11-2018

3.3 Packaging

Packaging

The individual products are packaged in accordance with the

transport conditions expected for the consignment. Exclusively

environmentally friendly materials are used for the packaging.

The packaging should protect the individual components from

transport damage, corrosion and other damage up until such time

as they are assembled. For this reason, do not destroy the

packaging and only remove it shortly before assembly.

Handling packaging materials

If no outline agreement has been reached for packaging, separate

the materials according to type and size, and send for re-use or

recycling.

NOTE!

Environmental damage due to incorrect

disposal!

Packaging materials are valuable raw materials

and in many cases can be reused or usefully

processed and recycled.

–Ensure environmentally responsible disposal of

packaging materials.

–Observe locally applicable disposal regulations.

3.4 Storage conditions

Storage

Store the gas fired igniter and the spare parts under the following

conditions:

Never keep outdoors.

Store in dry, dust-free conditions.

Do not expose to any corrosiv substances.

Avoid any drop in temperature below the dew point.

Protect the gas fired igniter from mechanical damage.

Storage temperature: 0 °C to 60 °C

Relative humidity: max. 60 %

When storing for longer than 3 months, regularly check the

condition of all parts and the packaging. If necessary refresh or

replace the conservation.

REMARK!

The packaging units may come with storage

instructions applicable in addition to the

requirements outlined here. These must be

adhered to.

Gas fired igniter ZT0

Specifications

Status: 11-2018- 17 -

4 Specifications

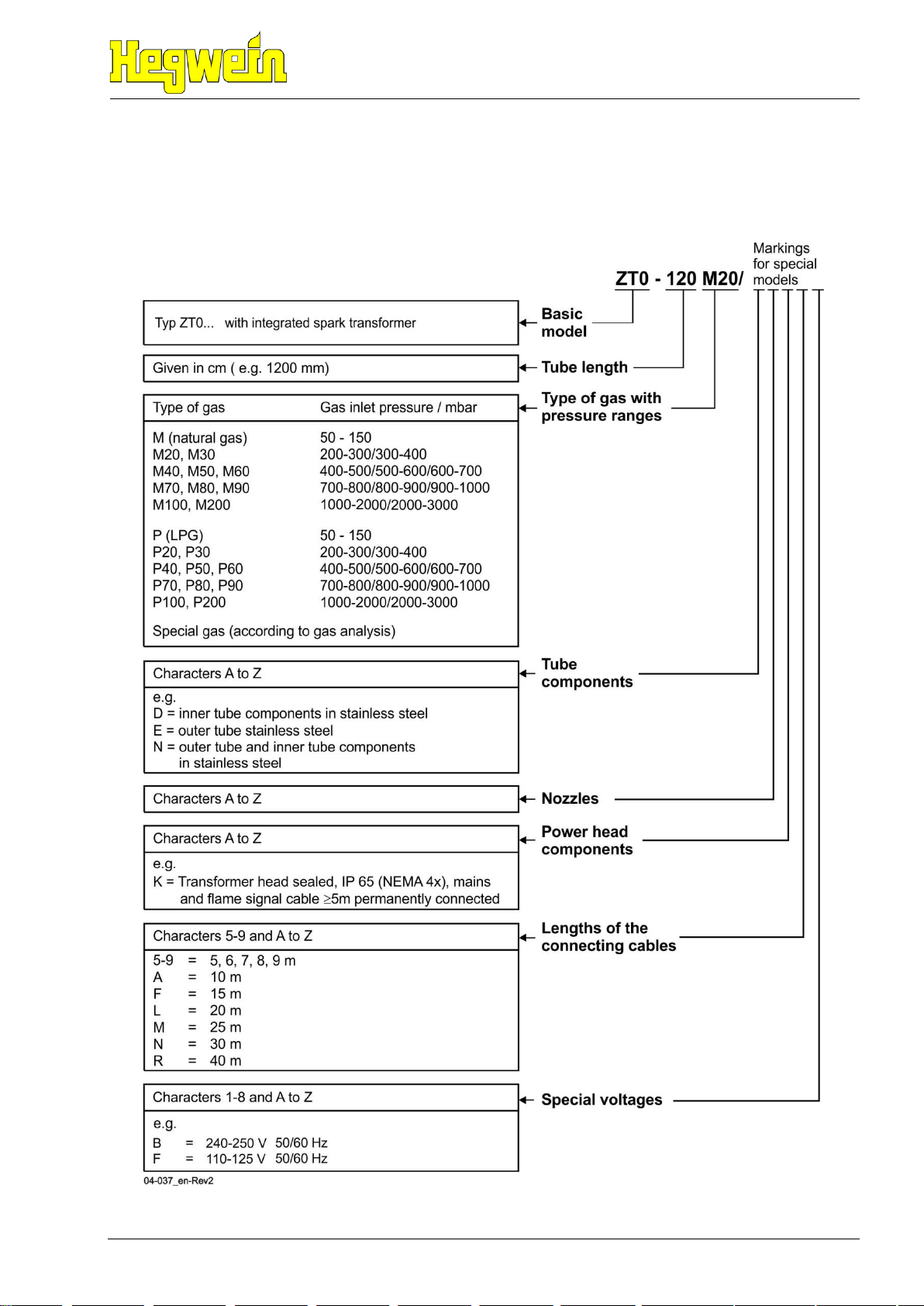

4.1 Type designation with type key

Example of type designations with the most important igniter data:

Fig. 1: Type key

Gas fired igniter ZT0

Specifications

- 18 - Status: 11-2018

4.2 Gas fired igniter

Characteristic

Value

Heat release

max. 120 kW

Flame length (depending on the gas)

max. 600 mm

Outer tube length

in 10 mm increments from –to

240 - 15000 mm

Outer tube diameter

Outer tube length up to 4000 mm

Outer tube length from 4000 mm

dia. 48 mm

dia. 50 mm

For the stainless steel version always dia. 50 mm

Design pressure gas flange

max. 10 bar

Gas port

Rp ½, left or right

Maximum counter pressure in gas fired igniter

housing

200 mbarg overpressure

Air port

Rp 1, rotatable 4 x 90°

Air volume

max. 50 m³/h

Air temperature

max. 80 °C

Relative humidity

max. 70 %

Air quality

free of dust, oil, grease and aerosols

Air coefficient

The remaining air volume must be made available

in the combustion chamber.

0.3 - 0.5

Maximum ambient temperature of the outer tube

see chapter “Installation and electrical connection”

Total weight (depending on scope of delivery)

approx. 2.5 kg power head with mounting flange +

approx. 3.5 kg/m (length of outer tube in cm, as

indicated in the rating plate)

Total dimensions (depending on scope of delivery)

Length of power head with mounting flange (see

dimensional drawing in section 4.4) + outer tube

length (in cm, as indicated in the rating plate)

Gas fired igniter ZT0

Specifications

Status: 11-2018- 19 -

4.3 Power head

Characteristic

Value

Supply voltage of spark transformer

Primary:

220 –230 V AC, 50/60 Hz (standard)

or in accordance with rating plate

Secondary:

5 kV against ground

Protection rating

IP 54 (standard) or

IP 65 (special version)

Connection type

Standard version, IP 54, with plug connection

Electrical connecting plug (10-pin) with 2 cable

glands (M20x1.5) for cable diameter 7 –13 mm;

Line-/screw connection 0.5 - 2.5 mm2

(2.5 mm2only without core cable ends)

Connection type

Special version, IP 65, with 3-core mains cable and

1-core flame signal cable (with shielding)

Permanently sealed mains cable

(wire gauge 1 mm2) and flame signal cable

(wire gauge 1.5 mm2), cable diameter in each case

approx. 7 mm

Power consumption

Spark transformer:

100 VA (fusing 2 A slow blowing, to be fused

externally)

Duty cycle

Spark transformer:

actuation via control unit

15 % duty cycle (cycle duration 3 min. = 100 %)

Primary thermal winding protection.

Ambient temperature

- 30 °C to + 60 °C (condensation must be avoided)

Ambient temperature (special version)

- 30 °C to + 80 °C (condensation must be avoided)

Interconnection

With suitable control units (see chapter “Functional

characteristics and structure”)

Gas fired igniter ZT0

Specifications

- 20 - Status: 11-2018

4.4 Dimensional drawing

Fig. 2: Dimensional drawing, gas fired igniter

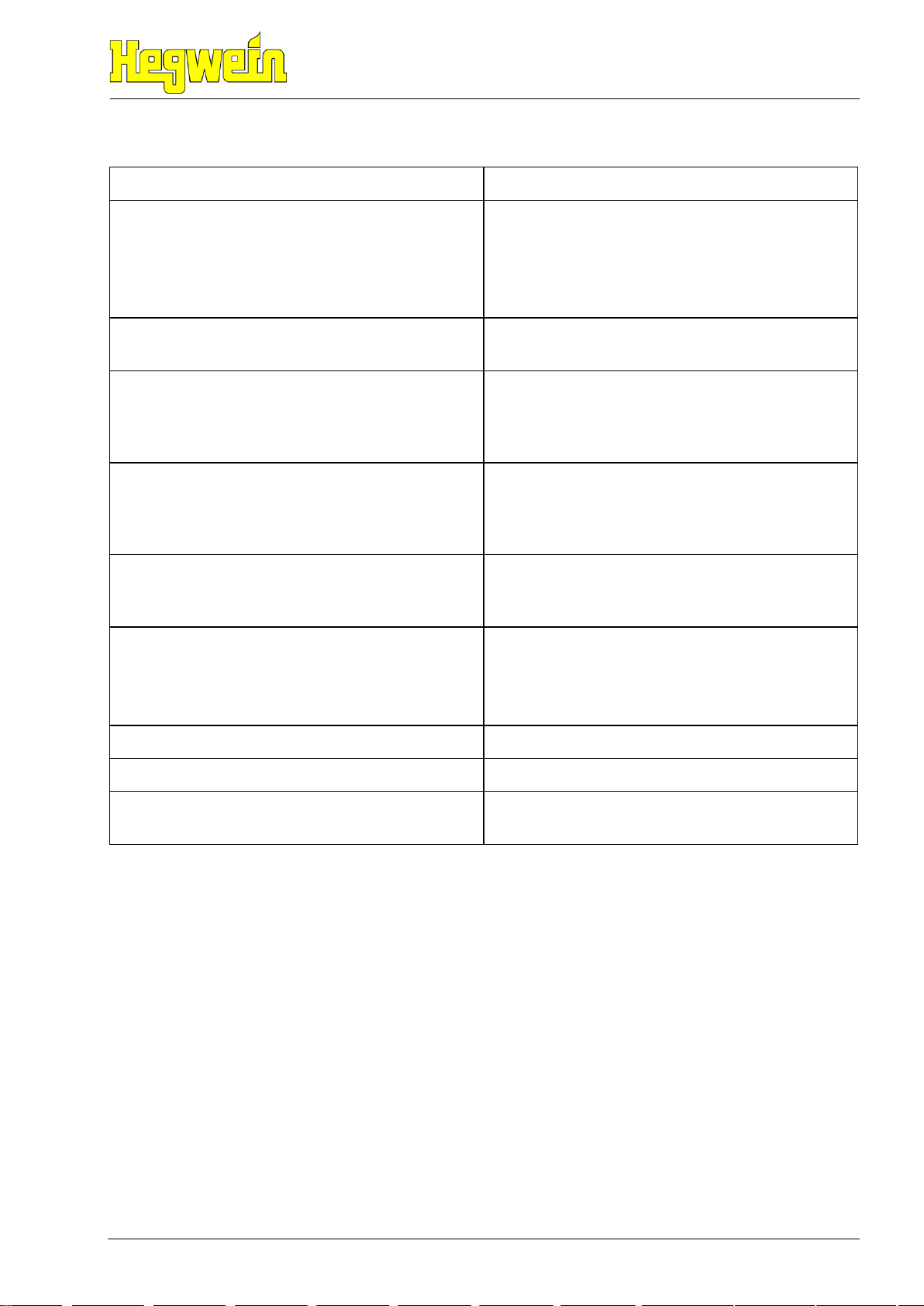

4.5 Rating plate

Fig. 3: Example of rating plate

The rating plate is located on the housing of the power head and

contains the following information:

1 Manufacturer

2 Date of manufacture (Hegwein code)

3 Type

4 Gas type and maximum gas inlet pressure

5 Supply voltage

6 Protection rating

7 Maximum power consumption

8 Frequency

9 Serial number (with consecutive device number)

Table of contents

Popular Burner manuals by other brands

Riello

Riello RLS 160/EV Installation, use and maintenance instructions

Riello

Riello RS 28/M Installation, use and maintenance instructions

True Induction

True Induction TI4B user guide

Riello

Riello RG1RKD Installation, use and maintenance instructions

Weishaupt

Weishaupt WG20 Series manual

Carolina Cooker

Carolina Cooker M116672 owner's guide

AESYS

AESYS TurboFire II Installation, operation and maintenance manual

IKEA

IKEA GRILLSKÄR manual

baltur

baltur TBL 1000 ME Instruction manual for installation, use and maintenance

Riello Burners

Riello Burners P 200 P/G Installation, use and maintenance instructions

WLD-TEC

WLD-TEC powerjet instruction manual

Riello

Riello RDB 3.2 BX 32/50 Installation, use and maintenance instructions