Heico Quell EESeal User manual

Quell Corporation | A HEICO® Company

5639 Jefferson NE Albuquerque, NM 87109 USA

505.243.1423

EESeal@Quell.US

www.eeseal.com

EESeal ® Manual insertion Instructions

for MDM Connectors

Manual Insertion Instructions for MDM Style EESeal®FilterSeals

Warning: The very high density of MDM Style EESeals®and potential cutting action of the MDM connector’s

sockets make the installation more difficult than our standard EESeals®. Quell recommends using the MDM

Insertion Tools over hand insertion. Please follow these instructions carefully and take your time. We

recommend using some magnification the first time or two.

Since this EESeal®is so small, a rubber tool is suggested to assist with installation, and may have been

provided with your order (a pencil eraser from a mechanical pencil will also work).

Begin installation by orienting the EESeal®so the EESeal®blank side face up and match the EESeal’s®shape

with the host connector’s shell.

Important Note: It is imperative that the EESeal®be inserted “right side up” (with the EESeal®logo down and no printing

visible after it is inserted). The MDM connector is symmetrical about the vertical centerline and, thus, if an EESeal®is

incorrectly inserted with the EESeal®logo up, it will not filter the correct pins or will not function properly.

Next, place the EESeal®onto the MDM connector so the MDM sockets and the EESeal®pinholes are roughly

aligned. Now, simply start inserting the EESeal® into the connector shell by pushing down with your thumb

until it rests just over the MDM sockets. Do NOT try to seat it over the sockets with your fingers. First, verify

that the EESeal® is closely aligned with the MDM shell and sockets.

You are now ready to insert the EESeal® onto the tips of the MDM sockets. Use the flat side of the rubber tool,

starting at one end of the connector, to gently work the EESeal® down over just the tips of the sockets – the

sockets should barely poke through each corresponding hole in the EESeal®. You may notice some very minor

slivers of silicone trimmed from the EESeal’s®pinholes during this process, which is normal.

Once it is confirmed that the tip of every MDM socket is just poking through its corresponding hole in the

EESeal®, then the EESeal® can be fully seated by simply using the mating connector to push it to the bottom of

the host connector.

For additional information or to see an instructional video, Visit:

https://eeseal.com/installation-MDM/

Extraction: MDM style EESeals®cannot be extracted without damaging the EESeal®. Use any dull probe to carefully reach under

the inserted EESeal®and slowly work it out. Slowly work it up the shaft of all sockets a little bit at a time, working around the

perimeter. Do not try to pry the EESeal® completely off some sockets when other sockets are still fully seated. Slowly working the

EESeal® out will minimize tearing and make it easier to get it out in one piece without leaving torn sections behind.

Questions?

Please call (505) 243-1423 or

Email EESeal@Quell.us for Assistance

Quell Corporation | A HEICO® Company

5639 Jefferson NE Albuquerque, NM 87109 USA

505.243.1423

EESeal@Quell.US

www.eeseal.com

EESeal

® Insertion Instructions for

Micro-D & MDM Connectors

Overview

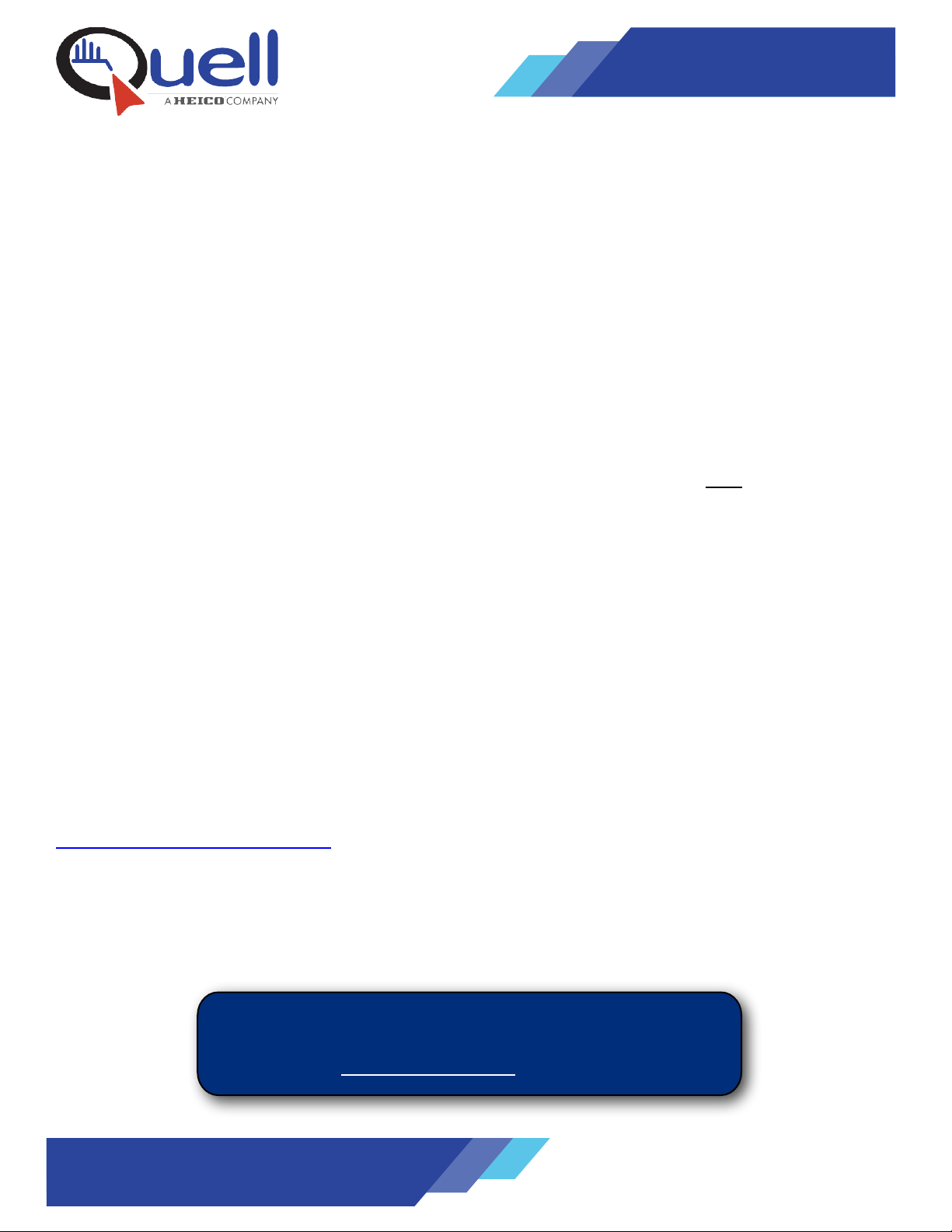

The very high density of MDM Style EESeals® and potential cutting

action of the MDM connector’s sockets make installation by hand

more difficult than our standard EESeals®. As a result, Quell has

developed MDM Installation Tools to ensure that your EESeal® is

installed easily and reliably into your MDM connector. Please follow these

instructions carefully and take your time. We recommend that you watch

the easy-to-follow installation video showing you the easy step by step

instructions. The video can be found on the Quell website at:

https://eeseal.com/installation-MDM/

Step 1 – Insert guide pins into the connector

It is important to orient the guide pins of the MDM Insertion Tool in the

proper direction. Guide pins must be installed into the MDM Insertion

Tool with the chamfered end first. The “flat” side of the guide pin is

designed to rest on the top of the MDM socket during installation.

Insert the guide pins by inserting the MDM insertion tool into your

connector. Squeeze the tool to release the guide pins into the MDM

sockets. Be careful to keep the MDM pins face up to keep the guide

pins in place.

Step 2 – Orient the EESeal®

Arrange the EESeal®so the blank side is up and the side with the

EESeal®logo is down, and the shape of the EESeal®matches up to the

shape of the connector. It is imperative that the EESeal®be inserted “right

side up” (with the EESeal®logo down and no printing visible after it is

inserted). The MDM connector is symmetrical about the vertical centerline

and, thus, if an EESeal®is incorrectly inserted with the EESeal®logo up, it will

not filter the correct pins.

Step 3 - Initial EESeal®placement

Place the EESeal® over the guide pins until the tips of the guide pins

protrude through the holes of the EESeal®. Use the insertion block to

press the EESeal® down over the guide pins. The insertion block helps

to maintain even downward pressure across the EESeal®. The EESeal®

should now be in place just above the rim of the MDM. The insertion

block must be gently removed to avoid pulling the guide pins from the

connector. Slightly rocking the insertion block from side-to-side should

ensure that the guide pins are not hung up in the block. If the guide pins

are pulled from the connector, all guide pins must be reinserted in the

insertion tool with the chamfered end facing the tool, and the insertion process must be started

over.

Press the Insertion

block down

Guide pins protruding

through the EESeal

®

Squeeze

the

insertion

tool

Guide pins

inserted

Quell Corporation | A HEICO® Company

5639 Jefferson NE Albuquerque, NM 87109 USA

505.243.1423

EESeal@Quell.US

www.eeseal.com

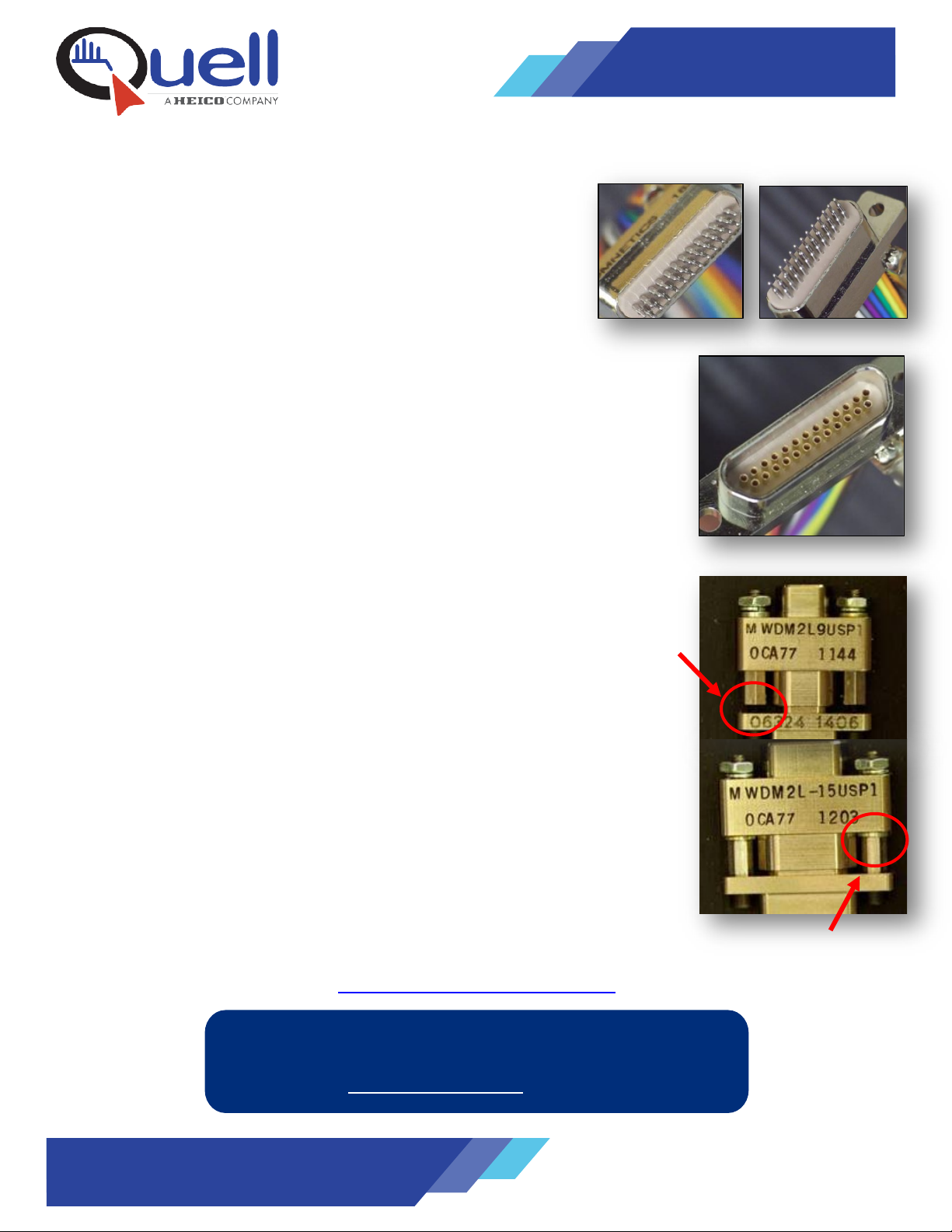

1/32” Washer

Step 4 – Seating the EESeal®

While holding the guide pins in place, gently press the edges of the

EESeal®below the connector rim using your fingernail or a soft

rubber tool. Make sure the edges of the EESeal®are below the

surface of the connector to prevent the EESeal®from rolling up

during final insertion. To complete installation, use the MDM

Insertion tool to seat the EESeal® at the bottom of the connector

and extract the guide pins from the MDM connector and back into

the tool.

Step 5 – Visually Inspect EESeal®

A visual inspection is suggested to ensure your EESeal®has been properly

installed. Under magnification check to see that the edges are properly seated

(not rolled up) and that the wire contacts are tucked down properly. If the

EESeal is not properly seated, the tip of the soft rubber tool may be used to tuck

in any rolled-up edges or exposed wire ends.

Your MDM is now a “Filtered” MDM connector.

Note: Mind the Gap

The presence of an EESeal®between the connectors pair will likely prevent

metal-to-metal contact between the mounting flange and the mounting jack

screws. Although the nominal torque of 2.5-4 in.-lb. is not sufficient to cause any

issues with the EESeal, overtightening the mounting hardware to try to close this

gap, or a severe vibration environment, could potentially damage the EESeal or

the connector.

Accordingly, if a gap is present after properly mating the connectors, a spacing

washer must be added to protect the EESeal®:

•If the connector has an interfacial seal, removing the connector interfacial seal and

adding a 1/64” thick flat washer between the jack screws and the connector

mounting flange will compensate for the thickness of the EESeal®.

•If the connector does not have an interfacial seal or the interfacial seal cannot be

removed, adding a 1/32” thick flat washer between the jack screws and the

connector mounting flange will compensate for the thickness of the EESeal®.

For additional information or to see an instructional video, Visit:

https://eeseal.com/installation-mdm/

Questions?

Please call (505) 243-1423 or

Email EESeal@Quell.us for Assistance

Gap

Edge un-tucked

Edge tucked in

Visually Inspect

Table of contents

Other Heico Cables And Connectors manuals