8

WARNING

!

Installation

• Read and follow ALL safety, use, sizing, installation, and care instructions

and follow all building codes, construction standards, appliance manufac-

turer recommendations and instructions, and applicable ANSI standards.

• Gas connector installation and testing procedures MUST BE performed by

a licensed contractor.

• Installation of the Blue Hose gas connector MUST BE in compliance with

the National Fuel Gas Code (ANSI Z223.1/NFPA 54), Natural Gas and

Propane Installation Code (B149.1), or the International Fuel Gas Code

(IFGC), in addition to all federal, state, and local gas installation codes.

• A restraining device MUST BE connected when a moveable gas appliance

is in service, as required by fuel gas codes and ANSI/CSA product stan-

dards.

• If a gas odor or leak is detected or suspected before, during, or after

installation, IMMEDIATELY turn off the gas supply and have gas lines, gas

connector, fittings, and appliance inspected by professionals.

• DO NOT REUSE. This gas connector and its accessories are intended

for a single installation and should be used on the original appliance at the

original location only. If the appliance is replaced or moved to a location

other than the original kitchen footprint, you MUST replace the gas con-

nector and its accessories.

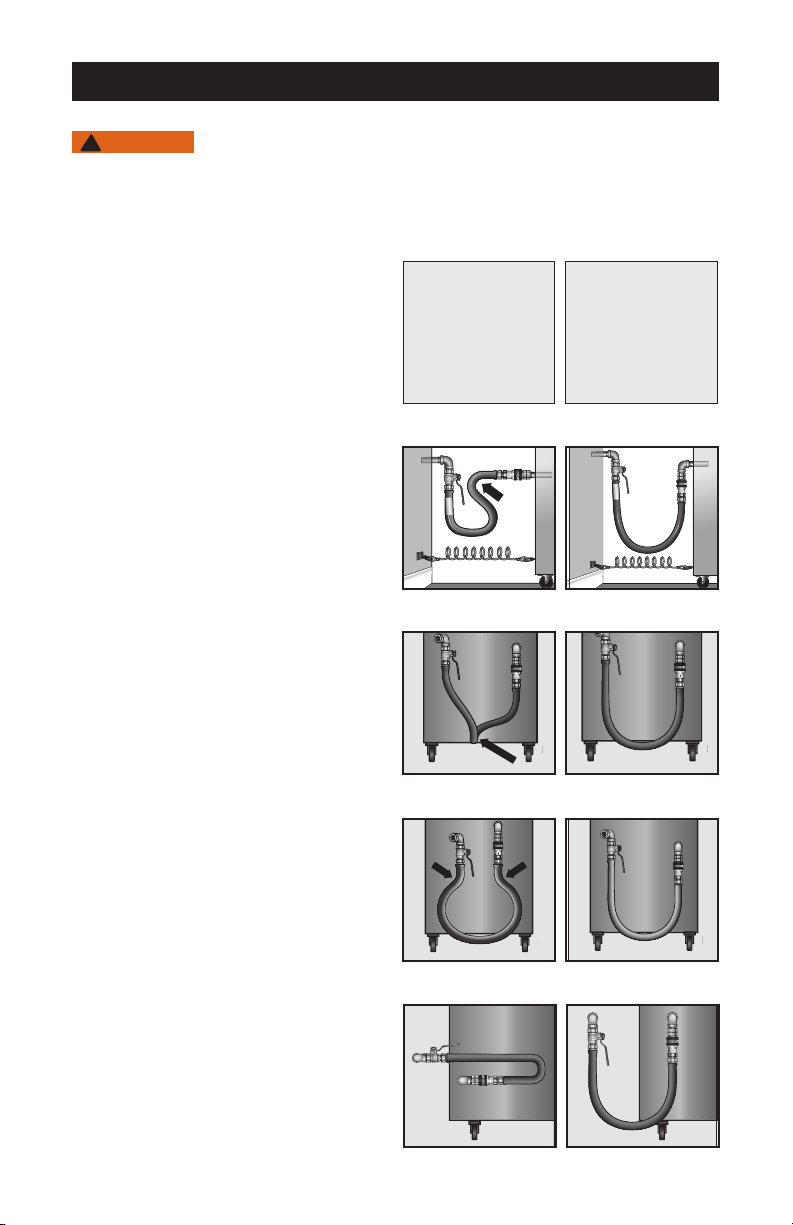

• DO NOT over-extend the gas connector assembly as this can cause dam-

age to the gas connector and/or shorten the life of the connector. Follow all

instructions on the proper movement of the appliance for cleaning, mainte-

nance, or service.

• DO NOT use the gas connector or its accessories if they are damaged in

any way. Discard any damaged items and replace with new items.

• DO NOT run a gas connector through walls, partitions or floors. The gas

connector must always be visible and accessible and should never be

concealed.

• DO NOT install a gas connector in an area where it can come into contact

with wiring, sharp edges, or surfaces that reach temperatures in excess of

230°F (110°C).

• STRONG CLEANING SOLUTIONS OR CHEMICAL SUBSTANCES

SHOULD NOT COME IN CONTACT WITH THE GAS CONNECTOR

OR ACCESSORIES. These may include acids, solvents, fluxes with zinc

chloride, or other chlorinated chemicals. If contact occurs, rinse the gas

connector and/or accessories with water and dry thoroughly with clean

cloths. If there are any signs of damage to the gas connector or accesso-

ries, turn off the gas supply and have the gas line replaced by a profession-

al immediately.

• The final assembly MUST BE tested for leaks. NEVER use an open flame

or other sources of ignition for leak testing purposes and be aware that

some leak test solutions may cause corrosion. RINSE THE INSTALLED

ASSEMBLY WITH WATER AFTER HAVING THE LEAK TEST

PERFORMED. To check the gas supply piping system for leakage, see

National Fuel Gas Code (ANSI Z223.1/NFPA 54), Natural Gas and Propane

Installation Code (B149.1), or the International Fuel Gas Code (IFGC). If an

odor of gas is detected or suspected, turn off the gas to the appliance and

have a licensed contractor identify the leak source and eliminate it.

• DO NOT use the gas connector as an appliance ground. Appliance must

be independently and properly grounded.

• NEVER jump, stand or otherwise place weight on the gas connector,

regardless of whether it is connected or disconnected.

To avoid injury, death, fire, explosion, gas leak, or property damage: