Heinzmann Programmer 2 User manual

Heinzmann GmbH & Co. KG

Engine & Turbine Controls

Am Haselbach 1

D-79677 Schönau (Schwarzwald)

Germany

Phone +49 7673 8208-0

Fax +49 7673 8208-188

www.heinzmann.com

V.A.T. No.: DE145551926

HEINZMANN®

Digital Speed Governors

Hand Held Programmer

Programmer 2

Copyright 2007 by Heinzmann GmbH & Co. KG. All rights reserved. This document may not be reproduced or handed on to third parties.

Manual DG 95 106-e / 07-07

Read this entire manual and all other publications appertaining to the

work to be performed before installing, operating or servicing your

equipment.

Practice all plant and safety instructions and precautions.

Failure to follow instructions may result in personal injury and/or

damage to property.

HEINZMANN will refuse all liability for injury or damage which

results from not following instructions

Please note before commissioning the installation:

Before starting to install any equipment, the installation must have been

switched dead!

Be sure to use cable shieldings and power supply connections meeting

the requirements of the European Directive concerning EMI.

Check the functionality of the existing protection and monitoring

systems.

To prevent damages to the equipment and personal injuries, it is

imperative that the following monitoring and protection systems

have been installed:

Overspeed protection acting independently of the speed governor

Overtemperature protection

HEINZMANN will refuse all liability for damage which results from

missing or insufficiently working overspeed protection

Generator installation will in addition require:

Overcurrent protection

Protection against faulty synchronization due to excessive frequency,

voltage or phase differences

Reverse power protection

Overspeeding can be caused by:

Failure of the voltage supply

Failure of the actuator, the control unit or of any accessory device

Sluggish and blocking linkage

Warning

Danger

Danger

Danger!

High

Voltage

Danger

Electronically controlled injection (MVC) will in addition require

to observe the following:

With Common Rail systems a separate mechanical flow limiter must

be provided for each injector pipe.

With Pump-Pipe-Nozzle (PPN) and Pump Nozzle (PNE) systems fuel

release may be enabled only by the movement of control piston of the

solenoid valve. This is to inhibit fuel from being delivered to the

injection nozzle in case of seizure of the control piston.

The examples, data and any other information in this manual are

intended exclusively as instruction aids and should not be used in any

particular application without independent testing and verification by

the person making the application.

Independent testing and verification are especially important in any

application in which malfunction might result in personal injury or

damage to property.

HEINZMANN make no warranties, express or implied, that the

examples, data, or other information in this volume are free of error,

that they are consistent with industry standards, or that they will meet

the requirements for any particular application.

HEINZMANN expressly disclaim the implied warranties of

merchantability and of fitness for any particular purpose, even if

HEINZMANN have been advised of a particular purpose and even if a

particular purpose is indicated in the manual.

HEINZMANN also disclaim all liability for direct, indirect, incidental

or consequential damages that result from any use of the examples,

data, or other information contained in this manual.

HEINZMANN make no warranties for the conception and engineering

of the technical installation as a whole. This is the responsibility of the

user and of his planning staff and specialists. It is also their

responsibility to verify whether the performance features of our devices

will meet the intended purposes. The user is also responsible for correct

commissioning of the total installation.

Warning

Warning

Danger

Contents

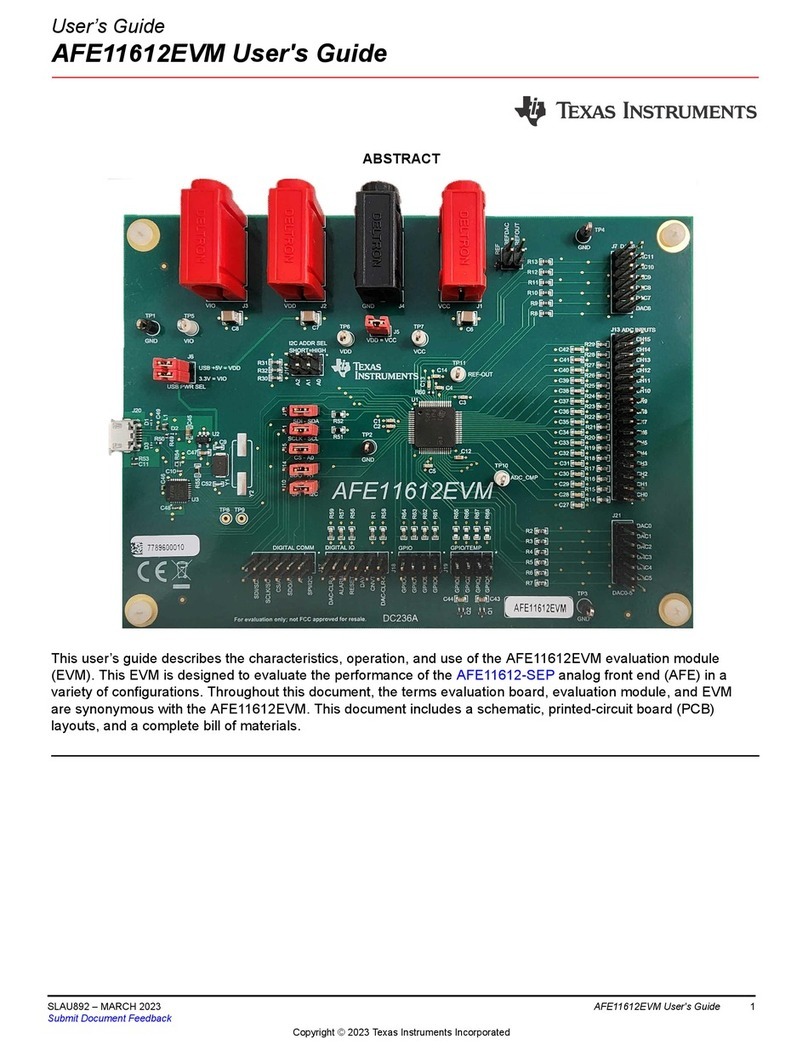

Programmer PG 02

Contents

Page

1 Safety Instructions and Related Symbols ........................................................................... 1

1.1 Basic Safety Measures for Normal Operation................................................................. 2

1.2 Basic Safety Measures for Servicing and Maintenance .................................................. 2

1.3 Before Putting an Installation into Service after Maintenance and Repair Works ......... 3

2 General ................................................................................................................................... 4

2.1 General System Description............................................................................................ 4

2.2 Further Informations........................................................................................................4

2.3 Parameter Lists ................................................................................................................ 6

2.4 Levels .............................................................................................................................. 8

3 Parameterization of HEINZMANN Speed Governors ...................................................... 9

3.1 Possibilities of Parameterization ..................................................................................... 9

3.2 Saving Data ................................................................................................................... 10

3.3 DcDesk 2000 ................................................................................................................. 10

3.4 Parameter Value Ranges................................................................................................ 11

3.5 Activation of Functions ................................................................................................. 12

3.6 Parameterization of Characteristics............................................................................... 12

3.7 Parameterization of Maps.............................................................................................. 13

3.8 Reset of Control Unit..................................................................................................... 14

4 Starting the Engine.............................................................................................................. 15

5 Configuring the Governor with the Hand Held Programmer ........................................ 20

5.1 The Display Panel.......................................................................................................... 21

5.2 The Control Panel.......................................................................................................... 22

5.2.1 The Standard Functions ......................................................................................... 22

5.2.2 The Second Functions............................................................................................ 24

5.2.3 Special Functions................................................................................................... 25

5.2.3.1 Engine Stop .................................................................................................... 25

5.2.3.2 Saving Values in the Governor ...................................................................... 25

5.2.3.3 Data Transfer Governor →Hand Held Programmer→Governor ................ 26

5.2.3.4 Data TransferPC →Hand Held Programmerr →PC .................................... 27

5.2.3.5 Error Memory ................................................................................................ 27

5.2.3.6 Data Blocks .................................................................................................... 27

5.2.3.7 Automatic Adjustment of Actuator................................................................ 28

5.3 Parameter Selection ....................................................................................................... 28

5.3.1 Entering Parameter Numbers................................................................................. 28

5.3.2 Selection by Arrow Keys....................................................................................... 28

Contents

Programmer PG 02

5.4 Changing Values ........................................................................................................... 29

5.4.1 Entering Values ..................................................................................................... 29

5.4.2 Changing Values Directly...................................................................................... 29

5.5 User Masks .................................................................................................................... 30

5.5.1 General................................................................................................................... 30

5.5.2 Activating and Deactivating the User Mask.......................................................... 30

5.5.3 Creating and Deleting User Masks ........................................................................ 30

6 Data Management ............................................................................................................... 31

6.1 Serial Number of Control Unit ...................................................................................... 31

6.2 Identification of Control ................................................................................................ 31

6.3 Identification of PC Programme / Hand Held Programmer .......................................... 32

7 Error Handling.................................................................................................................... 33

7.1 General .......................................................................................................................... 33

7.2 Error Memories ............................................................................................................. 35

7.3 Emergency Shutdown Errors......................................................................................... 35

7.4 Error Parameter List ...................................................................................................... 36

8 Order Specifications for Manuals...................................................................................... 49

1 Safety Instructions and Related Symbols

Programmer PG 02 1

1Safety Instructions and Related Symbols

This publication offers wherever necessary practical safety instructions to indicate inevitable

residual risks when operating the engine. These residual risks imply dangers to

persons

product and engine

environment.

The symbols used in this publication are in the first place intended to direct your attention to

the safety instructions!

This symbol is to indicate that there may exist dangers to the engine, to

the material and to the environment.

This symbol is to indicate that there may exist dangers to persons.

(Danger to life, personal injury).

This symbol is to indicate that there exist particular danger due to

electrical high tension. (Mortal danger).

This symbol does not refer to any safety instructions but offers important notes for

better understanding the functions that are being discussed. They should by all

means be observed and practiced. The respective text is printed in italics.

The primary issue of these safety instructions is to prevent personal injuries!

Whenever some safety instruction is preceded by a warning triangle labelled “Danger” this is

to indicate that it is not possible to definitely exclude the presence of danger to persons,

engine, material and/or environment.

If, however, some safety instruction is preceded by the warning triangle labelled “Caution”

this will indicate that danger of life or personal injury is not involved.

The symbols used in the text do not supersede the safety instructions. So please do not

skip the respective texts but read them thoroughly!

Warning

Dan

g

er

Danger!

High

V

olta

g

e

Note

1 Safety Instructions and Related Symbols

2 Programmer PG 02

In this publication the Table of Contents is preceded by diverse instructions that

among other things serve to ensure safety of operation. It is absolutely imperative

that these hints be read and understood before commissioning or servicing the

installation.

1.1 Basic Safety Measures for Normal Operation

•The installation may be operated only by authorized persons who have been duly

trained and who are fully acquainted with the operating instructions so that they are

capable of working in accordance with them.

•Before turning the installation on please verify and make sure that

- only authorized persons are present within the working range of the engine;

- nobody will be in danger of suffering injuries by starting the engine.

•Before starting the engine always check the installation for visible damages and make

sure it is not put into operation unless it is in perfect condition. On detecting any faults

please inform your superior immediately!

•Before starting the engine remove any unnecessary material and/or objects from the

working range of the installation/engine.

•Before starting the engine check and make sure that all safety devices are working

properly!

1.2 Basic Safety Measures for Servicing and Maintenance

•Before performing any maintenance or repair work make sure the working area of the

engine has been closed to unauthorized persons. Put on a sign warning that

maintenance or repair work is being done.

•Before performing any maintenance or repair work switch off the master switch of the

power supply and secure it by a padlock! The key must be kept by the person

performing the maintenance and repair works.

•Before performing any maintenance and repair work make sure that all parts of engine

to be touched have cooled down to ambient temperature and are dead!

•Refasten loose connections!

•Replace at once any damaged lines and/or cables!

•Keep the cabinet always closed. Access should be permitted only to authorized

persons having a key or tools.

•Never use a water hose to clean cabinets or other casings of electric equipment!

1 Safety Instructions and Related Symbols

Programmer PG 02 3

1.3 Before Putting an Installation into Service after Maintenance and Repair

Works

•Check on all slackened screw connections to have been tightened again!

•Make sure the control linkage has been reattached and all cables have been

reconnected.

•Make sure all safety devices of the installation are in perfect order and are working

properly!

2 General

4Programmer PG 02

2General

2.1 General System Description

The HEINZMANN Digitals Controls are designed as universal speed controls for diesel

engines, gas engines, and other prime movers. In addition to their basic purpose of

controlling speed, these governors are capable of performing a multitude of other tasks and

functions.

At the core of the control unit is a very fast and powerful microprocessor (CPU). The

controller programme itself based on which the microprocessor operates is permanently

stored in a so-called Flash-ROM.

Actual engine speed is measured by a magnetic pickup on the starter gear. For fail-safe

operation, either an additional speed pickup can be installed, or the control can use the

alternator signal from terminal W as a default speed signal. Thus, there will be no

interruption of operation if the first pickup should happen to fail.

Engine speed is set by one or more setpoint adjusters. These adjusters can be designed to

be analogue or digital ones. Further digital inputs permit to switch on functions or to

change over to other functions.

Furthermore, there are various sensors provided to feed the control all the data it needs to

adjust the engine's operating state. As an example, it is possible to have several

temperature and pressure signals transmitted from the engine.

The actuator regulating fuel supply to the engine is driven by a PWM signal. By this, both

two-quadrant actuators (working electrically one way) and four-quadrant actuators

(working electrically both ways) can be driven.

The control generates analogue and digital signals which are used to indicate the engine's

operating conditions or serve other purposes and functions. Communication with other

units is established via a serial interface and a CAN bus.

2.2 Further Informations

This manual contains mainly the description of programming the HEINZMANN governors

with the hand held programmer PG 02. The error handling is also discussed in detail.

2 General

Programmer PG 02 5

The functionality of the software, the speed governing in general, the specifications and

connections of the control electronics, sensors, setpoint adjusters and actuators are

described in detail in the manuals:

Basic Information for Digital Governors Level 6, Manual No.. DG 95 105 - e

Basic Information 2000 for Digital Governors Level 6, Manual No. DG 00 001 - e

Digital Basic System PRIAMOS I, Manual No. DG 93 101 - e

Digital Basic System PRIAMOS II, Manual No. DG 94 111 - e

Digital Basic System PRIAMOS III, Manual No. DG 95 111 - e

Digital Basic System PRIAMOS IV, Manual No. DG 96 004 - e

Digital Basic System PRIAMOS V, Manual No. DG 97 013 - e

Digital Basic System HELENOS I, Manual No. DG 93 102 - e

Digital Basic System HELENOS II, Manual No. DG 95 100 - e

Digital Basic System HELENOS III, Manual No. DG 96 005 - e

Digital Basic System HELENOS IV, Manual No. DG 96 003 - e

Digital Basic System HELENOS V, Manual No. DG 97 014 - e

Dual Fuel Operation, Manual No. DG 97 016 - e

The HEINZMANN Digital Controls are shipped tailored to custom requirements and have

been configured as far as possible at the factory. To execute an order properly it is

absolutely necessary for the customer to complete and return to HEINZMANN the

brochure

Order Information for Digital Controls, Manual No. DG 96 012-e.

The Sensors available from HEINZMANN are described in the manual

Product Overview Sensors, Manual No. E 99 001-e

The functionality of the communication programme DcDesk 2000 is described in the

manual

Operating Instructions Communication Programme DcDesk 2000,

Manual No. DG 00 003-e

2 General

6Programmer PG 02

2.3 Parameter Lists

In developing the HEINZMANN Digital Controls top priority was given to realizing a

combination of universal applicability and high grade functionality. As various adjustable

parameters had to be provided for each individual function, some system was needed to

conveniently organize the great multitude of parameters that would inevitably result from

the numerous functions to be implemented. So for the sake of clarity and easy access, the

parameters have been grouped into four lists.

1.Parameters Parameters used for adjusting the control and the engine

(parameter numbers 1..1999)

2.Measurements Parameters (measuring or monitor values) serving to indicate the

actual states of the control and the engine

(parameter numbers 2000..3999)

3.Functions Parameters used for activating and switching over functions

(parameter numbers 4000..5999)

4.Curves Parameters used for parameterizing characteristic curves and

characteristic maps (parameter numbers 6000..7999)

Each parameter is assigned a number and an abbreviation. The parameter number indicates

which list the parameter belongs to. Within these lists, the parameters are arranged by

groups to facilitate identification and reference for more detailed information.

There are different ways of writing of the parameter names. With older

software-versions all letters of the abbreviation largely written (e.g.

SPEED_RAMP_UP) with the newer versions are used large and lower case

(e.g. SpeedRampUp). Crucially for the function of the parameter is however

the parameter number. This was as far as possible maintained with the

modification of the software.

Note

2 General

Programmer PG 02 7

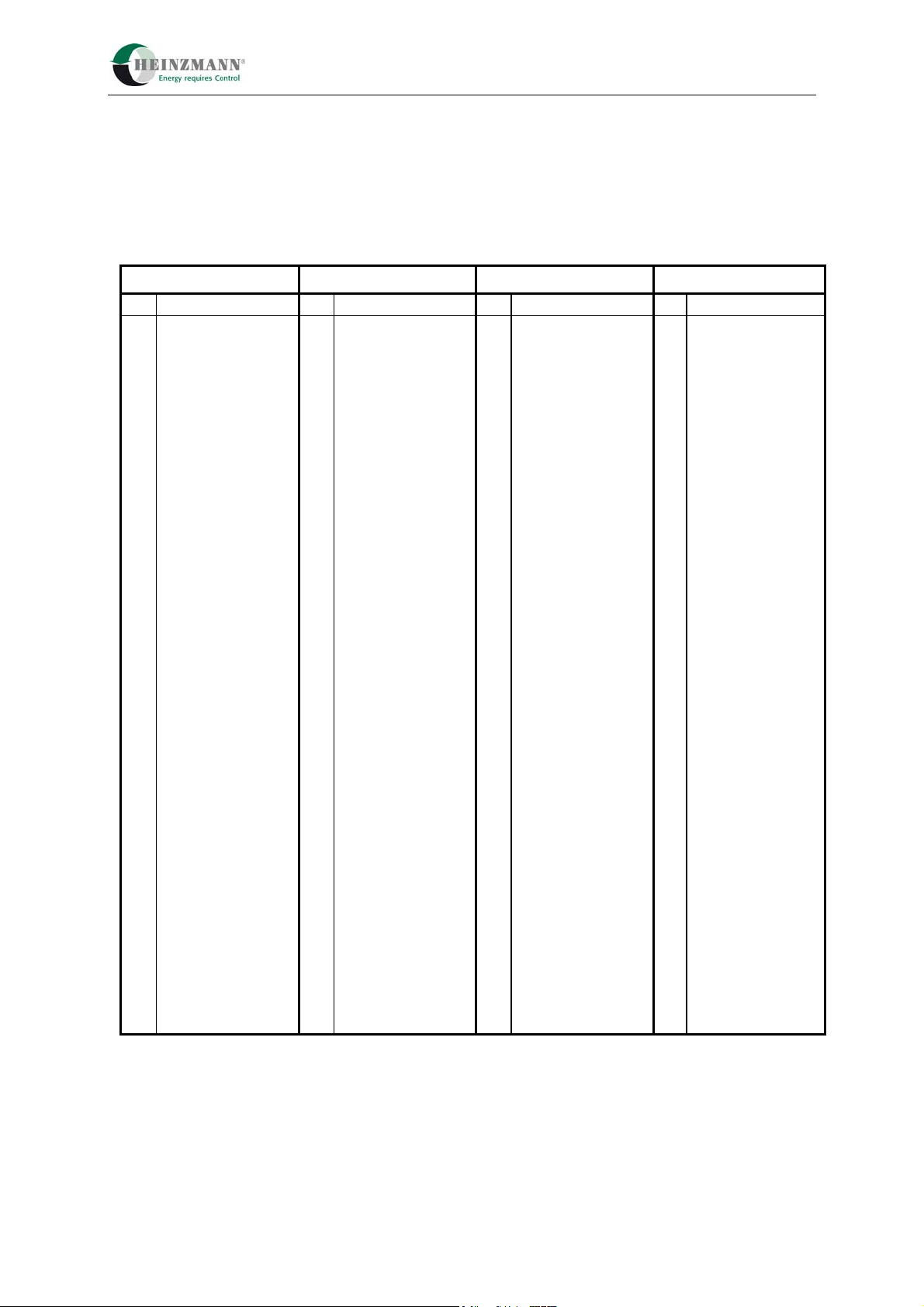

The following overview table shows where the individual parameters are to find.

A detailed parameter list, with which each individual parameter is described, is at the end

of the respective manual with the appropriate software description.

Parameters Measurements Functions Curves

No. Designation No. Designation No. Designation No. Designation

1 Number of Teeth,

Speed

2000 Speed Pickup,

Speed

4000 Speed Pickup,

Speed

6000

100 Stability,

Droop

2100 Stability,

Droop

4100 Stability Map,

Droop

6100 Stability Map

200 Ramp,

Start

2200 4200 Ramp 6200 Stability Map

(Correction Values)

300 Actuator Travel

2300 Actuator Travel

4300 6300

400 CAN

2400 CAN 4400 CAN 6400 Boost Pressure dependent

Fuel and Load Limitation

500 Oil Pressure, Boost

Pressure, Temperature

2500 4500 Oil Pressure, Boost

Pressure, Temperatuer

6500 Oil Pressure Monitoring

600 Excitation Control

2600 Excitation Control 4600 Excitation Control 6600 Excitation Control

700 Limitations

2700 Limitations 4700 Limitations 6700 Speed dependent

Fuel Limitation 1

800 Switch Functions,

Digital Outputs

2800 Switch Functions,

Digital Outputs

4800 Digital Inputs,

Digital Outputs

6800 Speed dependent

Fuel Limitation 2

900 Setpoint Adjusters,

Sensors

2900 Setpoint Adjusters

Sensors

4900 Setpoint Adjusters,

Sensors

6900 Speed Notches

Speed dependent Load

Limitation

1000 Error Handling

3000 Current Errors 5000 Error Handling

7000

1100

3100 Error Memroy 5100 Error Handling

7100

1200 Generator

3200 5200 Generator 7200 Pump Map

5250 Marine

1350 Locomotive

3350 Locomotive 5350 Locomotive 7300

1500 Analogue Inputs

3500 PWM-Inputs,

Analogue Inputs

5500 Channel Type 7500

1600 PWM-Outputs

Analogue Outputs

3600 5600 Analogue Outputs 7600

1700 Positioner

3700 5700 Positioner 7700

1800 Status

3800 Status 5800 7800

1900 Servo Loop,

Feedback

3900 Servo Circuit,

Feedback

5900 Servo Loop,

Feedback

7900 Temperature Sensors

Feedback

Table 1: Parameter Overview

2 General

8Programmer PG 02

2.4 Levels

As it is the Digital Control's primary function to control the operational behaviour of the

engine with regard to speed, power, etc., parameterizing should remain entrusted

exclusively to the engine manufacturer. However, to let also the ultimate customer

participate in the advantages of the Digital Control, the parameters of the HEINZMANN

Digital Control have been classified according to seven levels.

Level 1: Level for the ultimate customer

On this level, it is possible to have the basic operational values (e.g., set

values and current values of speed and injection quantity) and errors

displayed. This level, however, does not allow any manipulation of the

control data or the engine data.

Level 2: Level for the device manufacturer

The device manufacturer can set speeds within the permissible ranges.

Besides, the control's dynamic parameters and the dynamics map may be

modified and power output reduced.

Level 3: Level for the service

With the exception of the most significant engine specific parameters, such as

engine output and boundaries of various characteristic map, all types of

modifications are permitted on this level.

Level 4: Level for the engine manufacturer

On this level, the entire programme as needed to programme the control is

accessible.

Level 5: Level for manufacturers of engines with user-specific software

This level is provided for parameters that are required for customer specific

software modifications or expansions.

Level 6: Level for the control manufacturer

On this level, the control functions may be manipulated directly. Therefore,

access on this level remains restricted to HEINZMANN.

Level 7: Level for development

This level remains reserved for the HEINZMANN development department.

As will have become evident from this survey any superior level is a proper superset of the

previous level, providing upward compatibility. At the end of the software manuals a

detailed list of all parameters together with their respective levels is available. The

maximum level is determined by the diagnostics device used (PC or Hand Held

Programmer) and cannot be changed. There exists, however, the option of reducing the

currently valid level by means of a special menu item of the PC-programme or via the

parameter 1800 Level. Reducing the level is, however, bound to affect the number of

parameters and functions that can be accessed.

3 Parameterization of HEINZMANN Speed Governors

Programmer PG 02 9

3Parameterization of HEINZMANN Speed Governors

3.1 Possibilities of Parameterization

There exist various possibilities of parameterizing HEINZMANN Digital Controls. For

testing and initial commissioning HEINZMANN recommend using the PC software

DcDesk 2000 as a tool for diagnostics and parameterization. DcDesk 2000 can also be

used for servicing purposes where, in addition, the Hand Programmers PG 02 and HP 03

are available.

The below list gives an overview of all available options of parameterization:

Parameterization by HEINZMANN

During final inspection at the factory, the functionability of the control is checked by

means of a test programme. If customer specific operational data is available, the test

programme is executed using those data. When mounted on the engine, it is only the

dynamic values and, if necessary, the fuel quantity limitations and the sensors that

remain to be calibrated.

Parameterization Using the Hand Programmer

Depending on the level, parameterization can be completely conducted using the Hand

Programmers PG 2 or HP 3. These handy devices are particularly suited for

maintenance and servicing.

Parameterization by DcDesk 2000

Using the PC programme DcDesk 2000, it is possible to have several parameters

continuously displayed and accessible to modification. Besides, the PC-programme is

capable of graphically displaying limitation curves, characteristics, etc., and of

adjusting them easily and quickly. The control data can be stored by the PC or

downloaded from the PC to the control. A further advantage of the PC programme is

its ability to visualize measured values (such as speed, injection quantity) as functions

of time or as functions of each other (e.g., actuator position versus speed).

Parameterization with User Masks

Parameterization can always be conducted by means of user masks that are provided

by HEINZMANN or can easily be created by the user himself. A user mask will

display only those parameters that are really needed.

Downloading Data Sets

Once parameterization has been completed for a specific engine type and its

application, the data set can be stored within the Hand Programmer or on a disk. For

future applications of the same type, any such data sets can be readily downloaded to

the new controls.

3 Parameterization of HEINZMANN Speed Governors

10 Programmer PG 02

Check-Out Parameterization

This type of parameterization is performed by the engine manufacturer during the final

bench tests of the engine. By this procedure, the control is tuned to engine

requirements and to ordering specifications.

3.2 Saving Data

On principle, the above mentioned communication programmes and devices will modify

parameters only in the volatile memory of the control unit. Although the control unit will

immediately operate using the new values these modifications will get lost as soon as the

the voltage supply is switched off. In order to permanently save the parameter adjustments

in the control unit a storing command must be given. To execute this command DcDesk

2000 uses the function key F6, whereas the Hand Programmers use the key or menu item

“Save Parameter”, and it is this operation that is meant whenever it is required in this

manual that the parameters be saved.

3.3 DcDesk 2000

The HEINZMANN PC programme DcDesk 2000 serves for adjustment and transmission

of operating data for all digital HEINZMANN systems, and, in particular, for the

PRIAMOS and HELENOS systems. Designed as a Windows programme, it offers all

numerical and graphical features required for testing, initial commissioning and servicing,

and helps with preparing the respective documentation.

DcDesk 2000 also allows to produce hard copy printouts of its screens and of its data

records. The data is recorded in a standard text format for further processing and for

incorporation into reports, etc.

The data set of any connected control unit can be processed, and, at the same time, the

responses to parameter changes can be observed. Even without a control unit connected, it

will be possible to process a parameter set and evaluate the recorded data. Any parameter

set generated that way can later on be downloaded to the control unit.

Any adjustment can be made by directly accessing the respective parameter numbers.

There exist, however, additional windows to simplify adjustment of specific functions and,

particularly, parameterization of characteristics and maps.

Current measurements are displayed numerically and/or graphically. In a separate window,

up to ten freely selectable measuring values can simultaneously be displayed as functions

of time. There is a further window that permits to have nine measurements represented in

dependence of a tenth. All of these records can be logged to be evaluated later on and

eventually printed out.

3 Parameterization of HEINZMANN Speed Governors

Programmer PG 02 11

Any of the characteristics and maps available within the control unit can be displayed two-

or three-dimensionally in separate windows. By this, the profile and shape of any specific

characteristic or map can immediately be viewed. The actual point within the characteristic

or map at which the system is currently operating will be displayed online. To make any

adjustments does not require detailed knowledge of the interrelation between the parameter

numbers and the points of the characteristic or map since a special input section has been

provided offering assistance with regard to the peculiarities of parameterizing

characteristics and maps. This feature will prove very helpful to avoid erroneous input.

DcDesk 2000 is being continuously updated and enhanced by additional functions.

HEINZMANN particularly recommend the use of DcDesk 2000 for testing and initial

commissioning. Similarly, when servicing the system, DcDesk 2000 will prove a great

advantage for diagnosis and trouble shooting.

3.4 Parameter Value Ranges

Each parameter is assigned a particular value range. As there is a multitude of parameters

and functions, there also exists a great number of value ranges. Furthermore, the parameter

value ranges can be viewed by means of the PC or the hand held programmer.

For speed parameters, however, a common value range is provided. As a standard, it is set

to 0..4000 rpm which allows to run engines up to maximum speeds of approx. 3.500..3.600

rpm. There must exist some reserve for overspeed monitoring.

For certain parameters the value ranges cannot be explicitly specified in advance, but must

be communicated to the control by the user. This applies to all parameters indicating

physical measurements such as measurements from pressure or temperature sensors.

Some parameters are assigned a value range that is capable of two states only, viz. 0 or 1.

This type parameters are used to activate or switch over particular functions or to indicate

states of errors or of external switches, etc. Parameters with this value range are confined

to the lists 2 (Measurements) and 3 (Functions).

In that case, state "1" signifies that the respective function is active or that the respective

error has occurred, whereas state "0" signals the function to be inactive resp. that no error

has occurred.

The identifiers of change-over switches or of parameters selecting between two functions

always in clude an Or (e.g.: 2812 SwitchDroop2Or1). The function preceding Or will be

active when the parameter value is = 1 whilst the function after Or will be active when the

parameter value is = 0.

3 Parameterization of HEINZMANN Speed Governors

12 Programmer PG 02

3.5 Activation of Functions

With regard to the activation of functions, the following alternatives are provided:

permanently active: These functions cannot be turned off (e.g., overspeed

monitoring).

parameters: Parameters contained in list 3 enable functions that after being

selected by the user will remain permanently active (e.g., speed

dependend fuel limitation.

switching functions : By means of external switches the control can be instructed to

adopt certain requested operational states that are subject to

frequent changes during operation (e.g., change-over of droop or

limitation curves). The states of the external switches can be

viewed by the parameters that have been assigned the numbers

from 2800 on upward.

3.6 Parameterization of Characteristics

Parameterization of characteristics is done by one and the same procedure. The number of

pairs of variates, however, will be different for different functions. A pair of variates

consists of one x-value and one y-value both with the same index. Intermediary values

between adjacent pairs of variates will be interpolated by the control.

When parameterizing a characteristic, the following instructions must be observed:

The characteristics must always begin with the pair of values indexed 0.

The x-values must be sorted in ascending order.

Each x-value may occur only once.

For unused pairs at the end of the characteristic, the x-variate must be set to the

smallest possible value.

Parameterization of any characteristic does not require all pairs of variates to be assigned a

value. It will suffice to assign values only to as many parameters (beginning with index 0)

as will be needed. Similarly, it will not be necessary that the distances between the base

points (or nodes) be the same.

When the current x-value of any characteristic is below the first base point (supporting

point), the value of the characteristic will be set to the y-value of the first base point

(supporting point), and when it is beyond the last base point, the y-value of this base point

will be used. In other words, the first and last of the y-values will be retained in case the

current x-value is outside the characteristic's domain.

3 Parameterization of HEINZMANN Speed Governors

Programmer PG 02 13

3.7 Parameterization of Maps

Parameterization of maps will always follow the same procedure. The number of base

points, however, will be different for different functions. A supporting point consists of

one x-value and one y-value and the associated z-value. Intermediary values between

adjacent pairs of variates will be interpolated by the control.

When parameterizing a map, the following instructions must be observed:

The x- and y-values must always begin with index 0.

The x- and y-values must be arranged by ascending order.

Each x- and y-value may occur only once.

For unused base points at the end of the map, the x- and y-variates must each be

assigned their respective smallest possible values.

Parameterization of any map does not require all pairs of variates to be assigned a value. It

will suffice to assign values only to as many parameters (beginning with index 0 for the x-

and y-values) as will be needed. Similarly, it will not be necessary that the distances

between the base points be the same.

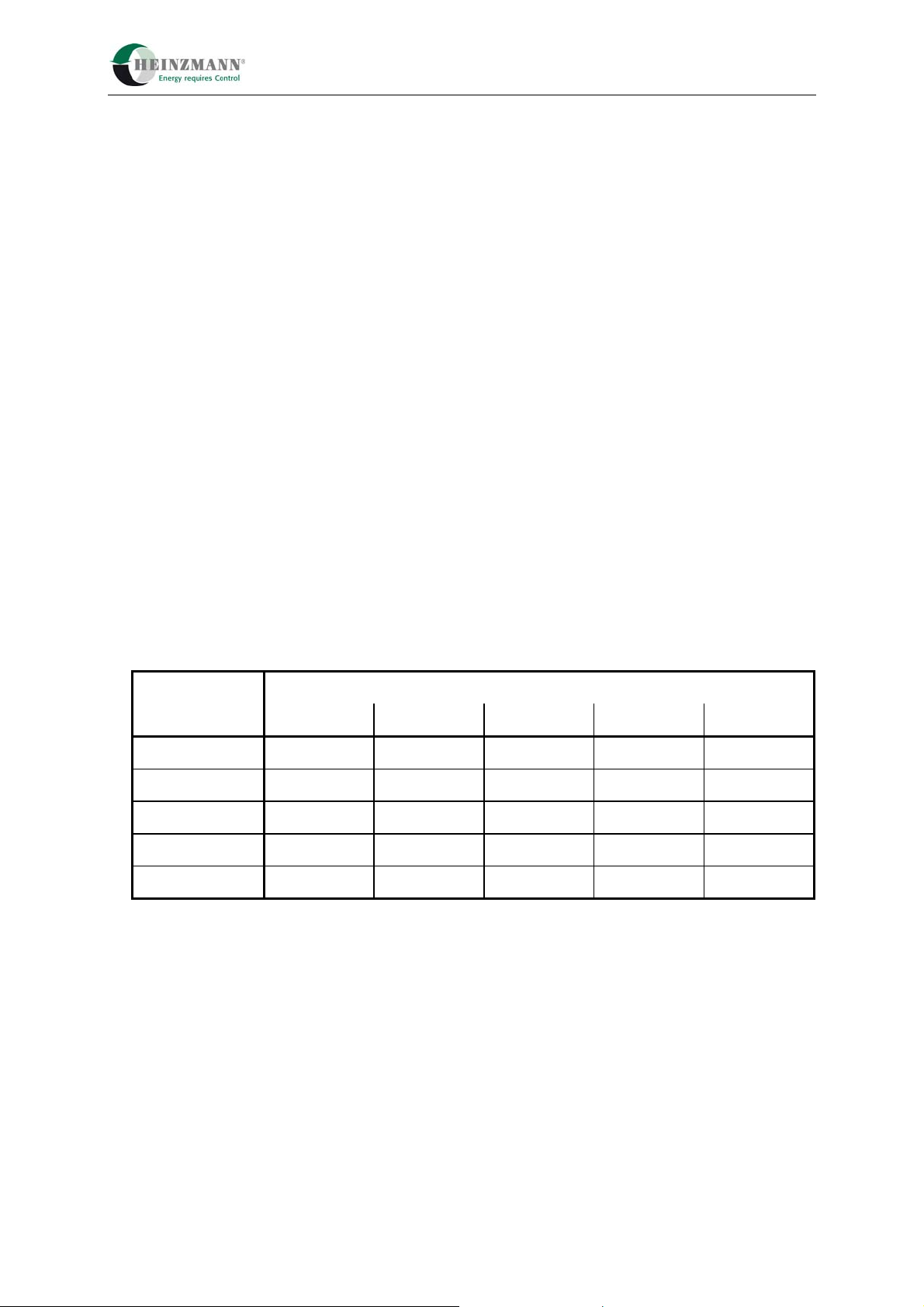

As an illustration of how parameter indexes are assigned to a map, the following example

shows a map table with a domain of 5 times 5 base points:

x-values

y-values x index 0 x index 1 x index 2 x index 3 x index 4

y index 0 z index 0 z index 1 z index 2 z index 3 z index 4

y index 1 z index 5 z index 6 z index 7 z index 8 z index 9

y index 2 z index 10 z index 11 z index 12 z index 13 z index 14

y index 3 z index 15 z index 16 z index 17 z index 18 z index 19

y index 4 z index 20 z index 21 z index 22 z index 23 z index 24

If the current values in direction of the x- and/or y-axes are outside the domain of the map

as defined by the base points, the respective border value of the map will be used instead.

If it should prove necessary to restrict dependence to only one direction this can be

achieved by setting the base points for the other direction to their minimum value. In other

words, if there is functional dependence only in direction of the y-axis, all x index values

are to be set to minimum value. The base points for z will then be those of the series with

x-index 0.

HEINZMANN recommend to use DcDesk 2000 for parameterizing maps and

characteristics as this programme will takes care of all particulars to be paid attention to

and will simplify parameterization considerably. Thus, the above table is included in

3 Parameterization of HEINZMANN Speed Governors

14 Programmer PG 02

DcDesk 2000 in an identical form and offers easy access to any of the base points.

Furthermore, the characteristics and maps can be represented graphically by this tool.

3.8 Reset of Control Unit

A reset is tantamount to powering down the control and restarting it. This can be achieved

by shortly turning off the power supply.

A reset will clear any data that has not been saved in the control's permanent memory. It is,

therefore, imperative that before executing a reset all data be transferred to the control's

permanent memory if this data is to be preserved.

Certain functions of the Digital Control can be activated only following a reset. These are

mostly functions that serve the purpose to put the control into some other operating state,

or parameters that for safety reasons cannot be modified during operation. The parameters

and functions belonging to this category will be explained in detail in the respective

chapters.

A reset has to be executed only with the engine stopped.

Warning

Table of contents