helivol Interceptor 400 User manual

PLEASE READ THROUGH THIS INSTRUCTION

MANUAL CAREFULLY. IT CONTAINS IMPOR-

TANT INSTRUCTIONS AND WARNINGS CON-

CERNING THE ASSEMBLY AND USE OF THIS

MODEL.

www.helivol.com

Specications:

Length: 630mm

Height: 225mm

Main Rotor: 558mm

Tail Rotor: 150mm

Weight: 300g

Flying Weight 580-620g

Motor Gear: Variable

Main Gear: 138T

Hold Rotation Gear: 105T

Tail Gear: 1:9.85:5

INSTRUCTION MANUAL

www.helivol.com

2

IntroductIon..................................2

EssEntIal EquIpmEnt.....................3

BuIld GuIdE..................................5-12

opEratIonal procEdurEs...........13

parts lIst...................................13-14

rotor HEad dIaGram....................15

swasHplatE dIaGram...................16

FramE dIaGram..............................17

FramE assEmBly dIaGram...........18

taIl dIaGram..................................19

lInkaGEs dIaGrams.................20-21

warranty........................................23

The Interceptor 400 is an aerobatic capable

helicopter, offering the performance and y-

ing abilities of 30 - sized nitro helicopter but

within a smaller package.

This is not a toy helicopter. It features a

double-dampened head, belt-driven tail

rotor and aluminium frame. This is a real

helicopter that is more than ready to y any-

where that you can nd a safe landing.

Take care when assembling the Interceptor

400. Incorrectly aligned parts will restrict

the helicopter’s abilities when performing

the extreme aerobatics it has been de-

signed for.

For the latest technical updates or manual

corrections please visit the Helivol website

at www.helivol.com.

warnInG

Strict pre-ight inspections are mandatory

for real aircraft. Although the R/C helicopter

is small and can be own with relative ease,

it does not differ from real aircraft in that if it

were to hit a person or object it could cause

serious damage and/or injury.

If an accident were to occur during opera-

tion the pilot would be held responsible.

Therefore it is recommended that users

possess remote control insurance. Details

on different schemes are available from

your local model shop or online.

Always be sure to inspect the helicopter

before any ight for any signs of damage or

wear. If the helicopter is own in a degrad-

ed condition it is possible for a catastrophic

failure to result.

Immediately replace any part that appears

worn or damaged.

Helivol © Copyright 2009

MADE IN TAIWAN

www.helivol.com

3

Transmitter

Receiver and Servos (3 Collective, 1 Tail)

Gyro

Battery and Charger

Motor

Electronic Speed Controller

Tools:

Pitch Gauge Blade Balancer

Ball Link Pliers Cross Wrench

Allen Wrench

Philips Screwdriver

Box Drive 4mm

Equipment needed:

4

cHoosInG your EquIpmEnt:

The INTERCEPTOR 400 is an impressive

kit helicopter but it requires additional com-

ponents to be operational. You will need

four servos, a radio transmitter and receiver,

a gyro, ESC, motor and lipo battery. We

have carried out substantial tests on various

setups and congurations.

radIo EquIpmEnt

This helicopter requires at minimum a 6CH

transmitter and receiver. It must have the

ability to setup a mechanical mix function on

a 90 degree swashplate. However we rec-

ommend that your radio transmitter also has

the capacity to programme multiple throttle

and pitch curves.

sErVos

We have tested a wide range of servos for

this model. We recommend Acer-Lab A8-

SG. They are fast analogue servos that can

be used with an Alien command. They are

also a perfect t for the frame. Please note

that digital servos can not be used in con-

junction with the Alien Command.

Gyro

You can use any high quality heading hold

gyro with this helicopter. Check compatibil-

ity with your radio equipment.

BattEry

The INTERCEPTOR 400 requires a Lipo

with a capacity of between 1500-2200mAh

and a minimum discharge of 15C for basic

hovering. This helicopter runs on 11.1v (3

Cell’s). Flight time will be between 7-12 min-

utes depending on ight conditions.

The maximum size battery the INTERCEP-

TOR 400 can hold is:

Width: 32.5mm

Height: 28.0mm

Length 104.0mm

Anything larger than this will not t in the

frame and canopy! A well tted battery

makes ying much easier.

motor

We recommend a Acer-Lab Brushless Mo-

tor. This will deliver the power needed to

get the most from the INTERCEPTOR 400

but you can use any motor within the range

2800-3500kv with a suitable pinion.

Esc

We recommend the Acer-Lab 40A. It is

fully programmable and features a double

heatsink, plug and play functionality. It also

boasts a 2 year warranty against defects in

material and workmanship. Any other qual-

ity ESC will also work.

cHarGEr

The battery used for this helicopter will

require a charger for a 3 Cell (11.1V) lipo

battery.

5

Measure the ybar so that is it equal on

both sides of the head. Approx 60mm on

each side.

Thread lock the screws into place then

attach the paddles ensuring that they run

parallel with the head.

BuIld GuIdE:

The INTERCEPTOR 400 is a kit helicopter

this guide covers the INT-401 ARF. In this

section we will take you through the process

to ensure that you correctly assemble your

model. This is a general guide only we rec-

ommend consulting individual component

manuals to ensure correct conguration and

installation. For a complete and thorough

guide on assembly along with videos and

the latest tips and upgrades please visit -

www.helivol.com

assEmBlInG tHE FramE & HEad

The head for the INTERCEPTOR 400

comes assembled in the ARF kit. You need

will need to install the ybar and paddles.

Remove the retaining screw and insert the

ybar.

Place the washer onto the collar of the

main gear. Insert the main shaft through

the frame and into place.

Place the main gear into the frame and

push the shaft through - the washer should

be facing up. Once in place align the holes

in the gear and shaft and t the bolt and nut

use loctite to secure.

Please check that the collar on the main

shaft is secure and correctly holds the head

assembly in place.

skIds

Assemble skids - the uprights with the wider

attachments points are located at the front.

Screw the uprights into place and align the

skid tubes.

6

Align the hole on the end of the boom with

the plastic pin inside the tail rotor assembly.

It will clip into place and hold rm.

Slide the tail push rod holder on to the

boom. Check that the belt is not twisted.

Insert boom into frame aligning the lip with

the groove.

Boom

You will need to feed the belt through the

boom.

We recommend taping the tail push rod to

the belt and then dropping it through the

boom before drawing through the belt after

it.

7

In order to easily place the belt over the

gear it is recommended that you unscrew

the bolt and screws on the boom holder. It

is then possible to push the boom further

into frame.

In order to align the belt correctly - using a

screwdriver rotate the belt 90° anti clock-

wise.

Then slip it over the gear.

Pull the boom back through and into place.

This should result in optimum belt tension.

To test the tension apply pressure onto one

side of the belt. It should not be so tight

as to not move and should not be so loose

as to touch itself. If adjustment is required

move the boom forward or back appropri-

ately. Tighten the boom holder screws once

the boom is correctly positioned.

Boom supports & taIl FIns

Insert rear aluminium rear spacer. Assemble

the boom supports and screw into place on

the spacer - on both sides. Use thread lock.

Screw the other end of the boom supports

into place on the horizontal tail n bracket.

Cut out horizontal n decal and stick to n.

Afx horizontal tail n to the bracket - use

a drop of thin CA to secure the ends of the

boom supports.

8

Cut out vertical tail n decal and stick

into place. Screw vertical tail n onto tail

mount.

Slide tail push rod through the holders on

the boom.

Screw on ball link and clip into place on tail.

InstallInG tHE motor

Attach a suitable pinion to motor shaft, use

a drop of thread lock on the grub screw.

Screw the motor into place on the helicop-

ters frame - use a drop of thread lock on the

mounting screws.

One mounting hole is elongated so as to

allow adjustment. The mesh of the gears

should crimp but not tear a piece of paper

when the gears are turned.

9

InstallInG Gyro, Esc and rX

We recommend installing your gyro and re-

ceiver inside the frame to ensure adequate

protection. Make sure they are easily ac-

cessible for adjustment and conguration.

Once your receiver is securely placed you

can route your wires carefully across the

frame of the INTERCEPTOR 400 ensur-

ing that they clear of all moving parts and

secured rmly with cable ties. The placing

and wiring is dependent on the components

you choose to use on your helicopter.

The ESC can be placed on the bottom or

side of the frame. Whichever is accessible

and within reach of the battery bay. Do not

cable tie into place - use adhesive foam.

InstallInG sErVos

Screw servos into place - don’t attach the

servo arms. Install the aileron servo rst.

Next install the pitch servo using the plastic

servo nuts to secure it into place. Bent nose

pliers can be useful at this point.

Install the elevator servo next.

The tail servo can be tricky so we recom-

mend placing the plastic servo nut onto the

servo prior to mounting as it can make it a

little easier.

10

Attach the servo arms to the elevator and

aileron servos at 90° once their neutral

points have been set. Then connect the

push rods. At this point the swashplate

should be completely at. Consult the dia-

gram on page 22.

The aileron servo should pull the swash-

plate to the left when the cyclic stick on

your radio is moved left. The elevator

servo should pull the swashplate to the

right when the cyclic stick is moved to the

right. If the direction is incorrect rectify us-

ing servo reverser settings/switches.

Set your transmitters throttle to 50% then

attach the pitch servo arm and connect

the push rod. When you now increase the

throttle on your radio the pitch servo should

pull down and the swashplate should rise.

conFIGurInG sErVos

Check that push rod lengths match the dia-

gram on page 21. Connect all the arms to

the relevant ball links (see page 22 for com-

plete diagrams). The links can be easily

pushed into place if you use a small socket

driver.

We recommend disconnecting the motor

from the ESC when conguring the servos.

Congure your radio swash settings to ‘1

SERVO’ or ‘90°’ depending on your radio in-

terface. Connect the battery to your ESC in

order to check servo operation and congu-

ration. Ensure all your trims and sub trims

are initially set to default.

11

Conguring the tail servo requires installing

the servo arm with its neutral point set at an

approximately 90° angle to ensure that the

correct pitch is set for the tail blades.

canopy

It is crucial that you install the window of

the canopy - without it the mechanism will

be restricted.

First cut the window out of the canopy and

trim the ashing from the edges. Trim the

shield around the moulding so that it ts the

window.

Fit the shield to the window with the screws

supplied. Ensure the trim on the upper

edge is trimmed down so as to allow a suit-

able t for the swashplate mechanism.

Apply the decals as desired. Fit to the heli-

copter. If you nd the canopies t is too tight

use a hair dryer to warm the plastic before

gently moulding back to suitable shape.

BladEs

Balance your blades using a blade bal-

ancer. Attach them - they should be tight

enough in the grips to hold their position

when moved, but can still be moved easily

by hand.

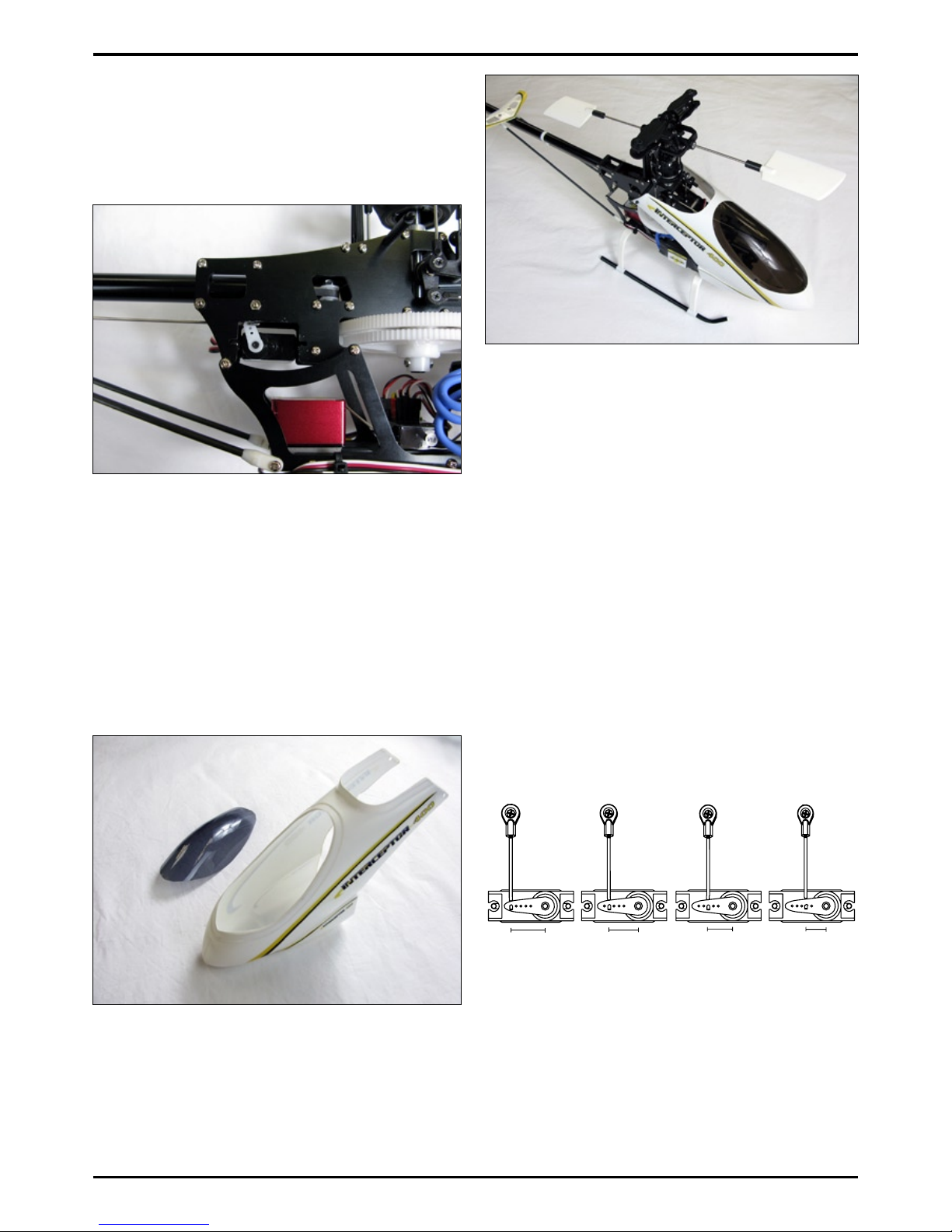

To set the pitch of the blades adjust the po-

sitioning of the push rod on the pitch servo

arm. The distance dictates the level of pitch

the blades have set. Use this rough guide

to set the pitch correctly in conjunction with

a pitch gauge.

That completes the conguration and as-

sembly of the INTERCEPTOR 400. Please

follow guidelines for the individual compo-

nents regarding installation and setup. You

can nd lots more advice, guides and tips

on our website:

12

13mm = ± 13° Pitch 10mm = ± 10° Pitch 8mm = ± 8° Pitch 7mm = ± 7° Pitch

www.helivol.com

13

BEForE startInG a FlIGHt:

1. Pay attention to your surroundings:

Do not y the helicopter in strong winds, •

rain or at night.

Do not y the helicopter near roads, rail-•

ways or electrical lines.

2. Pre-ight checks:

Before starting always check to ensure•

that there is no damage to any part and

that model responds and operates cor-

rectly.

Always be sure to check that all the mov-•

ing parts are correctly positioned and

that all nuts bolts are suitably tightened.

Please ensure that the batteries for your•

transmitter as well as your helicopter are

fully charged and operational.

wHIlst In opEratIon:

1. Always disconnect the battery when:

adjusting parts on the helicopter or trans-•

mitter.

attaching or replacing parts.•

any unusual noises or vibrations occur.•

if any other potentially dangerous situa-•

tions could occur.

2. When connecting the battery please ob-

serve the following procedures:

Be sure that the transmitters throttle is in•

its lowest position.

Ensure the idle up function is disen-•

gaged.

aFtEr a FlIGHt:

1. Inspect parts immediately. If any screws

seem loose or are missing be sure to re-

place or ret. If cracks or damage are

apparent please replace the components.

parts lIst:

modEls:

INT-400 INTERCEPTOR 400 KIT

INT-401 INTERCEPTOR 400 ARF

sparEs:

INT-001 Flush head screw M2x7

INT-002 φ5 Ball with stand

INT-003 Blade holder

INT-004 Center hub CNC

INT-005 Brg φ3xφ8x4 ZZ

INT-006 Bearing collarφ3xφ5x4

INT-007 M3 nylon nut

INT-008 O-ring P3

INT-009 Spindle bush

INT-010 Feathering spindleφ3

INT-011 φ2 Collar with stand

INT-012 Pan head screw M2x4

INT-013 Bearing spacer 2x3x1.5

INT-014 Brg φ2xφ5x2.5 ZZ

INT-015 Pan head screw M2X10mm

INT-016 Seesaw (L)

INT-017 Mixing Arm (L)

INT-018 Stabilizer control set

INT-019 Stabilizer bar

INT-020 Stabilizer blade

INT-021 Set screw M3x3

INT-022 φ2.6 Bail radius pin

INT-023 Swash plate set

INT-024 M2 nylon nut

INT-025 Pan head screw M2x12

INT-026 φ5 Main mast

INT-027 φ5 Mast lock

INT-028 Needle pin 1.5x7

INT-029 Wash-out control arm

INT-030 Radius arm

INT-031 Slide block

INT-032 FW φ2xφ4x0.3T

INT-033 Drive pulley 11T

INT-034 Brg φ3xφ8x3 ZZ

INT-035 Counter gear case

INT-036 Counter gear 21T

INT-037 E-ring E-2.5

INT-038 Bearing block

INT-039 Brg φ5x11x5 ZZ

INT-040 Main gear 138T (w/one way bearing)

INT-041 Auto-ratation gear set

INT-042 Auto-rotation drive shaft

INT-043 Auto-rotation gear 105T

INT-044 M2 nut

INT-045 Radius arm stay set

INT-046 Cabin cross member

INT-047 Tapping screw M2x6

INT-048 Elevator lever

INT-049 Upper frame set (w/bearing)

INT-050 Tail boom holder

INT-051 Elevator shaft

INT-052 Cross member M2x16

14

INT-053 Pan Head Screw 2x21mm

INT-054 Elevator torque lever

INT-055 Elevator mount

INT-056 Flush head screw M2x15

INT-057 Collective pitch lever set (w/bearing)

INT-058 Servo mount

INT-059 Aileron lever

INT-060 Gyro mount

INT-061 Motor mount set

INT-062 Battery mount

INT-063 Cross member M2x34

INT-064 Cross member M2x8

INT-065 Lower frame set

INT-066 Pan head screw M2x14

INT-067 Pan head screw M2x5

INT-068 Skid set

INT-069 servo nut plastic (10pcs)

INT-070 Main rotor blade

INT-071 Tail rotor blade

INT-072 Cap screw M2x6

INT-073 Tail blade holder

INT-074 Tail housing

INT-075 Tail pitch plate set (w/bearing)

INT-076 Tail pitch set (w/bearing)

INT-077 Tail pitch lever set

INT-078 Tail unit case set

INT-079 Tail shaft (w/pulley 11T)

INT-080 Guide pulley (w/bearing)

INT-081 Timing belt

INT-082 Tail stabilizer set

INT-083 Tail boom

INT-084 Tail boom brace set

INT-085 Rudder control rod

INT-086 Pitch rod

INT-087 Mixing arm rod

INT-088 Stabilizer control rod

INT-089 Pitch rod=L29

INT-090 Elevator lever swash rod

INT-091 Aileron rod

INT-092 Elevator rod

INT-093 M1.2 Rod end

INT-094 Canopy

INT-095 Windshield

INT-096 Motor main gear 15T (3.17 mm)

INT-097 Motor main gear 14T (3.17 mm)

INT-098 Motor main gear 13T (3.17 mm)

INT-099 Motor main gear 12T (3.17 mm)

INT-100 Motor main gear 11T (3.17 mm)

INT-101 Motor main gear 10T (3.17 mm)

INT-102 Motor main gear 9T (3.17 mm)

INT-103 Motor main gear 8T (3.17 mm)

upGradEs:

For an up to date and complete list of all of the upgrades

please visit:

powEr EquIpmEnt:

AL-A8SG ACER-LAB A8SG Servo

AL-D12MG ACER-LAB D12MG Servo

AL-3000KV ACER-LAB Brushless Motor 3000 KV

AL-40A ESC ACER-LAB 40A ESC

www.helivol.com

15

Stabilizer blade and stabilizer control arm must

be assembled so that they are parallel to one anotherr.

o

X

INT-001

INT-002

INT-003

INT-004

INT-005

INT-006

INT-007

INT-010

INT-009

INT-008

INT-011

INT-012

INT-016 INT-013

INT-014

INT-015

INT-017

INT-018

INT-002

INT-001

INT-019

INT-020

INT-021

16

INT-002

(Int-023)

INT-022

INT-001

INT-023

INT-024

INT-025

INT-026

INT-021

INT-027

INT-031

INT-011

INT-029

INT-028

INT-014

INT-001

INT-002

INT-015 INT-030

INT-024

INT-032

INT-033

INT-034

INT-036

INT-037

INT-035

INT-038

INT-026

INT-027

INT-039

INT-040

INT-041

INT-042

INT-043

INT-044

INT-025

17

INT-045

INT-044

INT-046

INT-047

INT-048

INT-002

INT-001

INT-049

INT-050

INT-038

INT-039

INT-052

INT-051

INT-053

INT-012

INT-012

INT-054

INT-055

INT-056

INT-012

INT-047

INT-057

INT-058

INT-032

INT-012

INT-002

INT-001

INT-047 INT-012

INT-059 INT-024

INT-066

INT-061

INT-067

INT-066

INT-064

INT-044

INT-012

INT-062

INT

INT-021

INT-060

INT-063

INT-064

INT-065

INT-012

-097

18

Stick tracking tape onto the lighter of the two blades to

compensate the weight difference.

Balance the main rotor blade.

INT-052

INT-066

INT-052

INT-047 INT-047

INT-068

INT-069

INT-069

INT-070

19

INT-

INT-014

INT-072

INT-071

INT-074

INT-075

INT-076

INT-078

INT-034

INT-079

INT-080

INT-077

INT-081

INT-083

INT-082

INT-084

INT-085

073

20

INT-086

INT-088

INT-087

INT-089

INT-090 INT-091

INT-092

INT-085

INT-086

INT-087

INT-088

INT-093

Other manuals for Interceptor 400

1

Table of contents

Other helivol Toy manuals

Popular Toy manuals by other brands

Eduard

Eduard 32 321 quick start guide

Flex innovations

Flex innovations FlexJet Pro 90 mm instruction manual

Kyosho

Kyosho MONSTER TRACKER readyset instruction manual

VTech Baby

VTech Baby Squishy Spikes Alligator instruction manual

Mega Bloks

Mega Bloks World of Waarcraft Rojo 91050 quick start guide

Eduard

Eduard 36 267 manual