Helmer UltraCW User manual

360113-1/A

UltraCW™ Version B

Model UltraCW™

S/N

HELMER, INC. 15425 HERRIMAN BLVD., NOBLESVILLE, IN 46060 USA

PHONE (317) 773-9073 FAX (317) 773-9082

USA and CANADA (800) 743-5637

www.helmerinc.com

Automatic Cell Washing System

Service Manual

TM

i

360113-1

Aboutthismanual...........................................................ii

1 Workingsafely...........................................................1

1.1 Generalsafety....................................................................1

1.2 Electricalsafety...................................................................1

1.3 Chemicalandbiologicalsafety .......................................................1

2 Reviewing information about your cell washer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 Findingmodelandinputpowerinformation..............................................2

2.2 Finding software and part version information ............................................2

3 Troubleshooting..........................................................3

3.1 Troubleshootinggeneraloperationproblems.............................................3

3.2 Addressingerrormessages..........................................................4

4 Servicingthecellwasher .................................................15

4.1 Testing whether the rotor speed is within the design tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Testing whether the imbalance value is in the permissible range . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Adjusting the imbalance microswitch ..................................................17

4.4 Removing and installing the front panel................................................18

4.5 Adjustingthedisplaycontrast .......................................................19

4.6 Viewingandchangingthellspeed...................................................20

4.7 Replacingthefrequencyconverter ...................................................21

4.7.1 Settingjumpers.........................................................22

4.7.2 Initializing the cell washer.................................................22

4.8 Removing and installing the bowl assembly ............................................23

4.9 Performingpost-repairchecks.......................................................25

5 Parts ..................................................................26

5.1 Partsonthefrontandlid ...........................................................26

5.2 Partsontherearandbottom........................................................27

5.3 Partsontheside .................................................................27

5.4 Partsonthebowlandrotor.........................................................28

5.5 Partsbehindthefrontpanel.........................................................29

5.6 Partsbehindtherearpanel.........................................................30

5.7 Partsunderthebowl ..............................................................31

5.8 Accessories.....................................................................33

6 Schematic..............................................................34

Contents

Contents

ii

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

About this manual

Welcome to the UltraCW™ Automatic Cell Washing System Service Manual. This section explains the symbols and

conventions used in this manual, copyright information about this document, and trademark information for products

supplied by Helmer.

Intended audience

This manual is intended for use by qualied service technicians. This manual is to be used in conjunction with the

UltraCW™ Automatic Cell Washing System Operation Manual.

Symbols and conventions

Several symbols and conventions are used in this manual.

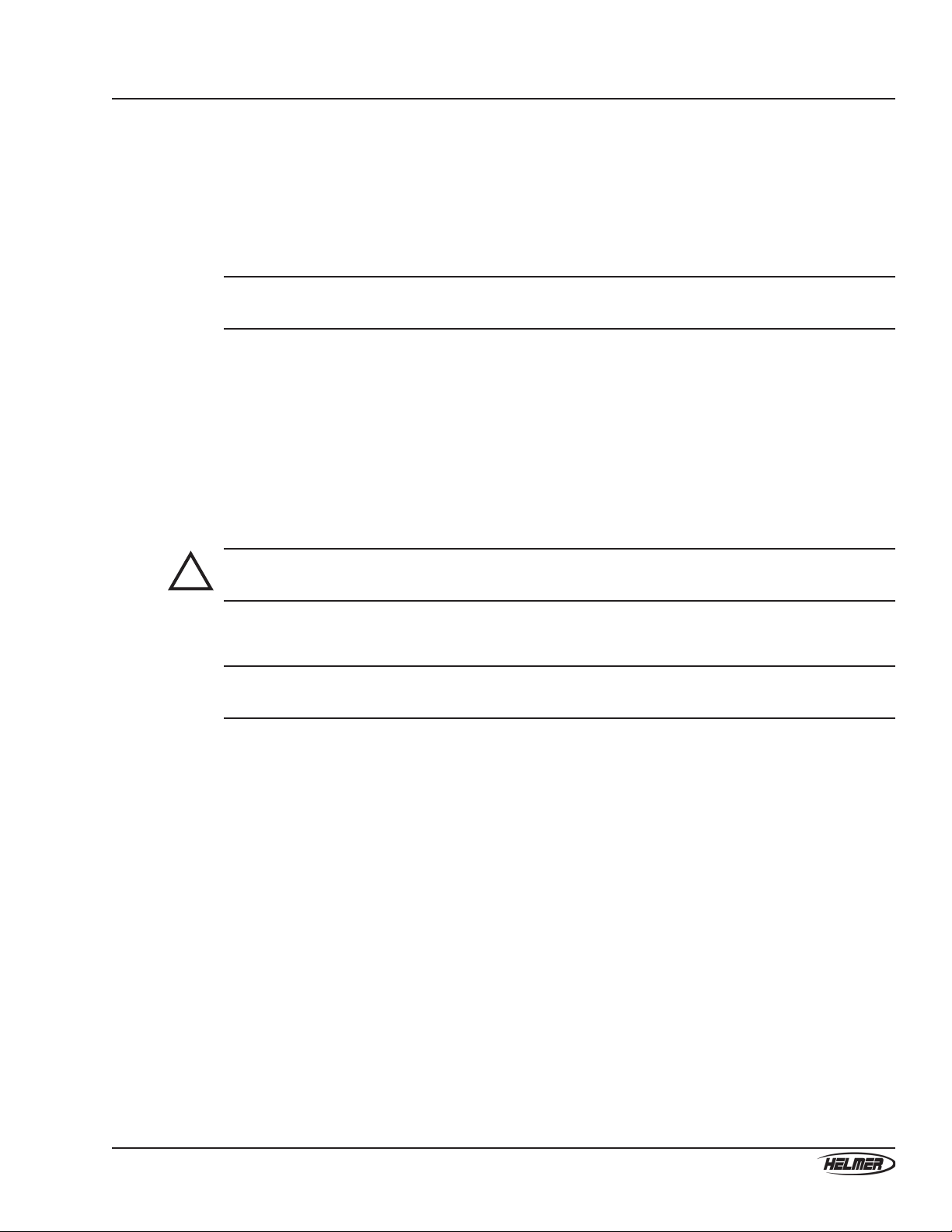

Warnings

A Warning is used to call attention to a condition or possible situation that could cause injury to the operator.

Warnings are identied as follows:

!

WARNING: This is a sample of a warning: Follow all chemical handling and disposal

requirements and procedures that are specied by your organization.

Cautions

A Caution is used to call attention to a condition or possible situation that could damage or destroy the equipment or the

operator’s work.

Cautions are identied as follows:

!

CAUTION: This is a sample of a caution: Be sure that the tubing is free of obstructions.

Blocked tubing can cause uid to back up and cause motor failure.

Notes

Notes contain additional information about a topic. Notes are used to provide information about how a topic relates to another

topic, or background information about a design characteristic.

Notes are identied as follows:

NOTE: This is a sample of a note: Tubing kits are available for purchase through

Helmer.

Copyright and trademark information

Copyright © 2006 Helmer, Inc.

UltraCW™ is a registered trademark of Helmer, Inc. in the United States of America.

All other trademarks and registered trademarks are the property of their respective owners.

1

360113-1

Working safely

1 Working safely

This section describes general safety information for servicing the UltraCW Automatic Cell Washing

System (“cell washer”). The Operation Manual includes additional safety information for operating and

cleaning the cell washer. Your organization may provide additional safety information.

1.1 General safety

To avoid injury to yourself and the cell washer, follow these safety instructions:

► Do not use the cell washer if its components are damaged.

► Never attempt to physically restrict any of the moving components.

► Do not move or bump the cell washer during operation.

► Before performing the procedures in this manual, review the specic safety instructions for them.

► Before using tools, materials, and equipment to perform procedures in this manual, review the

manufacturer’s safety instructions for them.

► Perform only the maintenance described in this manual. Maintenance other than that specied in this

manual should only be performed by technical service representatives authorized by Helmer.

1.2 Electrical safety

!

WARNING: The cell washer has the potential of being a shock hazard. Review all safety

instructions.

Review the following safety instructions before troubleshooting, repairing, or replacing parts in the cell

washer:

► Before removing covers from the cell washer, disconnect the power to the cell washer.

► Use appropriate grounding precautions when replacing circuit boards and other electrical parts.

► Use power cords and other electrical parts that are designed for use with the cell washer.

1.3 Chemical and biological safety

Review the safety instructions in the Operation Manual before using, cleaning, or servicing the cell washer.

!

WARNING: In addition to the instructions included in this manual and the Operation Manual,

follow all chemical handling and disposal requirements and procedures specied

by your organization.

Before sending parts to Helmer or your distributor for service or repair,

decontaminate them as appropriate. Any items that have not been

decontaminated appropriately will not be accepted. Documentation stating

that the contents are not contaminated and are safe to handle must accompany

all returns. Contact Helmer for decontamination instructions and a return

authorization number.

2

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

2 Reviewing information about

your cell washer

This section explains how to nd identication information about your cell washer.

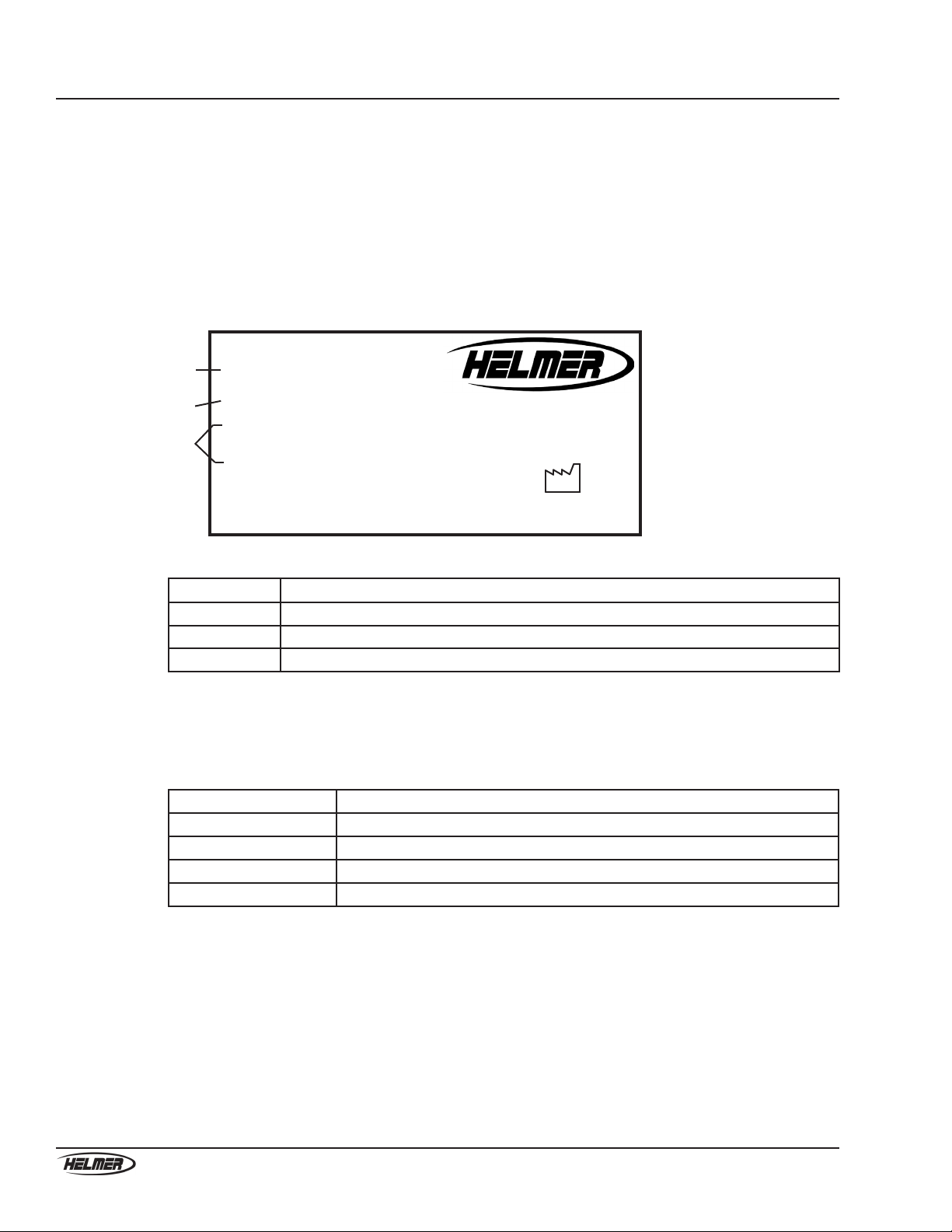

2.1 Finding model and input power information

The Product Specication label is located on the right side of the cell washer next to the power connector.

A

B

C

Type: UltraCW

Serial Number 0000000

Volts Freq Amps Power

110-127Vac 60 Hz 2.5 200 Watts

Kinetic Energy Max. Density RPM

250Nm 1.2Kg/dm 3500R/min

3Made in Switzerland

2005

www.helmerinc.com

Noblesville, IN USA

ProductSpecicationlabel(sample)

Label Description

AType (Model)

B Serial number (S/N)

CPower requirements

2.2 Finding software and part version information

The software version appears on the control panel when you turn on the power.

Additional information is available through the Global menu, as follows:

Parameter Meaning

CONTROL: XXX h Number of operating hours

VERS XX °C/* 00 XX is the software version

FU/CCI - 1001 Frequency converter type

FU/CCI - S. XX.XX Frequency converter software version

To view version information in the Global menu

1 On the control panel, press and hold the parameter selection button () for about eight seconds until

VOLUME ADJUST XX appears on the message screen.

2 Press and release the parameter selection button () to cycle through the global parameters.

3 Exit the Global menu by pressing the STOP button or by not pressing any of the buttons for

approximately 16 seconds. The message screen returns to display mode for the selected program.

3

360113-1

Troubleshooting

3 Troubleshooting

Before taking actions as described in this section, make sure that operational issues have been addressed as

described in the Operation Manual. Also, be sure that the cell washer operator has followed the appropriate

laboratory procedures and used the appropriate materials for the task.

This section describes some problems you may experience, explains possible causes, and provides actions

you can take to correct them.

!

WARNING: Review all safety instructions prior to completing troubleshooting

recommendations. For more information, see Section 1, “Working safely.”

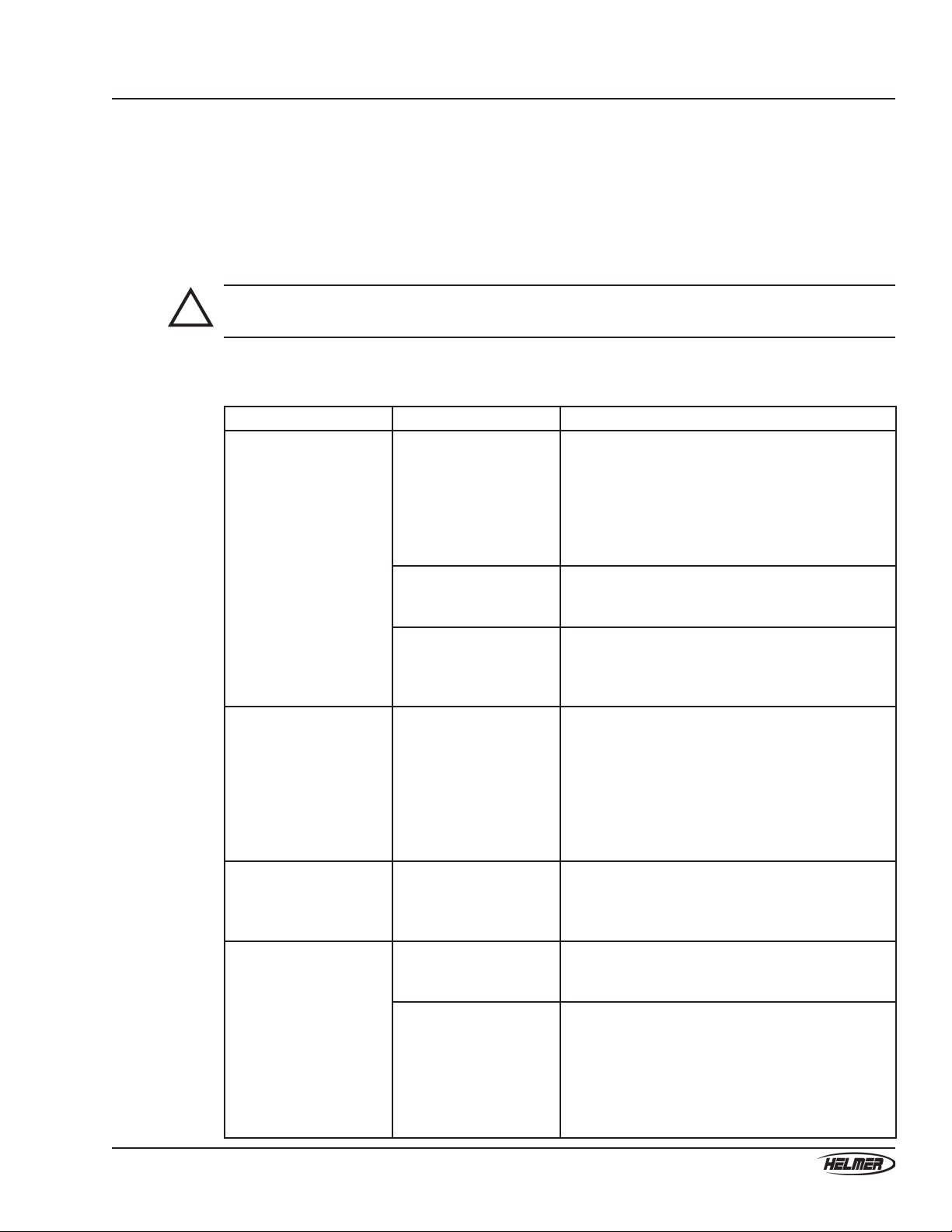

3.1 Troubleshooting general operation problems

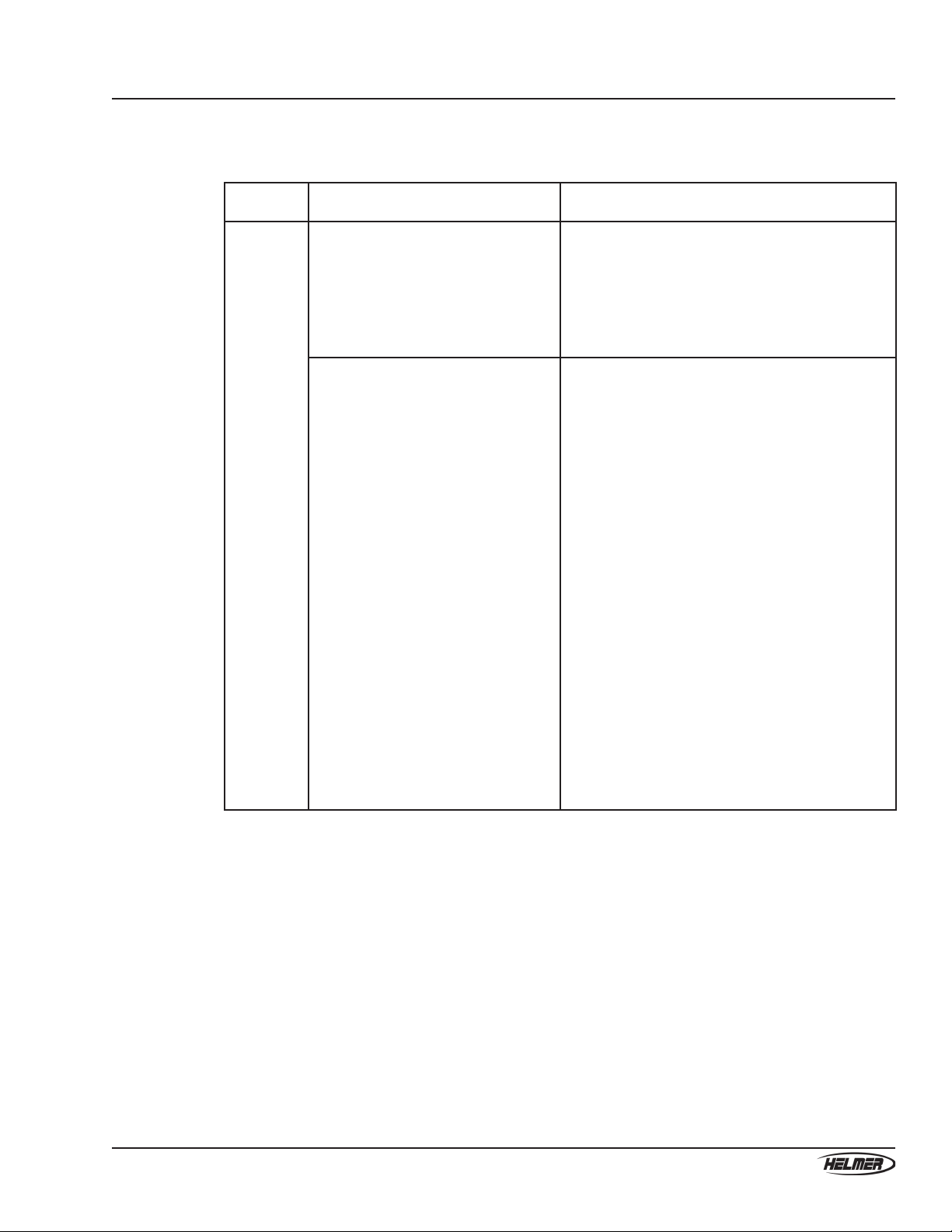

Problem Possible Cause Action

The cell washer is

turned on, but nothing

is displayed on the

message screen.

There is no power to the

cell washer.

1 Verify that the outlet is operational.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the fuse.

b Replace the main power switch.

c Replace the transformer.

d Replace the RFI lter.

The display contrast is

set too low.

► Adjust the display contrast. For instructions,

see Section 4.5, “Adjusting the display

contrast.”

A part in the LCD circuit

is faulty.

► Try the following tasks in order, testing after

each to determine if it solved the problem:

1 Replace the control panel.

2 Replace the power supply board.

During a saline check,

the pump is not making

any sound and saline is

not being dispensed.

A part in the pump

system is faulty.

► Remove the pump tubing from the pump. With

the pump tubing removed, perform a saline

check.

► If the pump does not operate, replace the

pump.

► If the pump does operate, replace the

pump tubing, which may have hardened

over time.

During a saline check,

the pump is operating,

but saline is not being

dispensed correctly.

A part in the liquid

handling system circuit

is faulty.

► Try the following tasks in order, testing after

each to determine if it solved the problem:

1 Replace the ow meter.

2 Replace the liquid handling board.

The tubes were not

decanted when they

were programmed to

do so.

The rotor is faulty. ► Verify that all the rotor locks (decant hooks)

are intact. If any are broken off or damaged,

replace the rotor.

A part in the motor

circuit is faulty.

► Try the following tasks in order, testing after

each to determine if it solved the problem:

1 Replace the motor.

2 Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

3 Replace the power supply board.

4

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

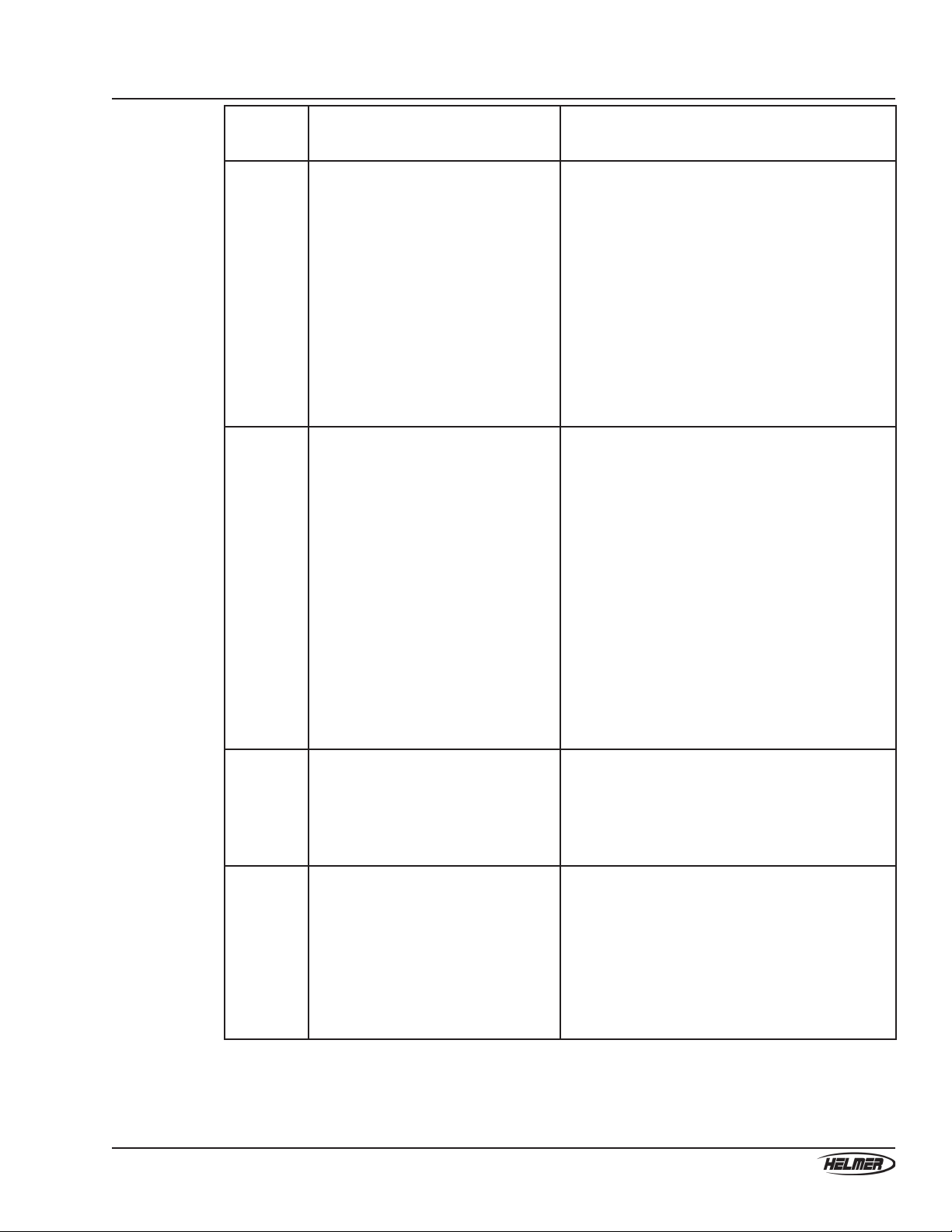

Problem Possible Cause Action

The rotor speed seems to

be too high or too low.

A part in the speed

sensor circuit is faulty.

1 Measure the rotor speed. For instructions, see

Section 4.1, “Testing whether the rotor speed is

within the design tolerance.”

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the speed sensor.

b Replace the motor.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

Tubes are breaking

during processes with a

Decant step.

Tube holder inserts were

not installed correctly

before processing

10 mm x 75 mm tubes.

► Install the tube holder inserts, and repeat

the process to determine if the problem was

solved.

The top of the tube does

not move freely around

the ll port.

► Ensure that the height of the tubes is within the

acceptable tolerance of 75 mm ± 1.5 mm.

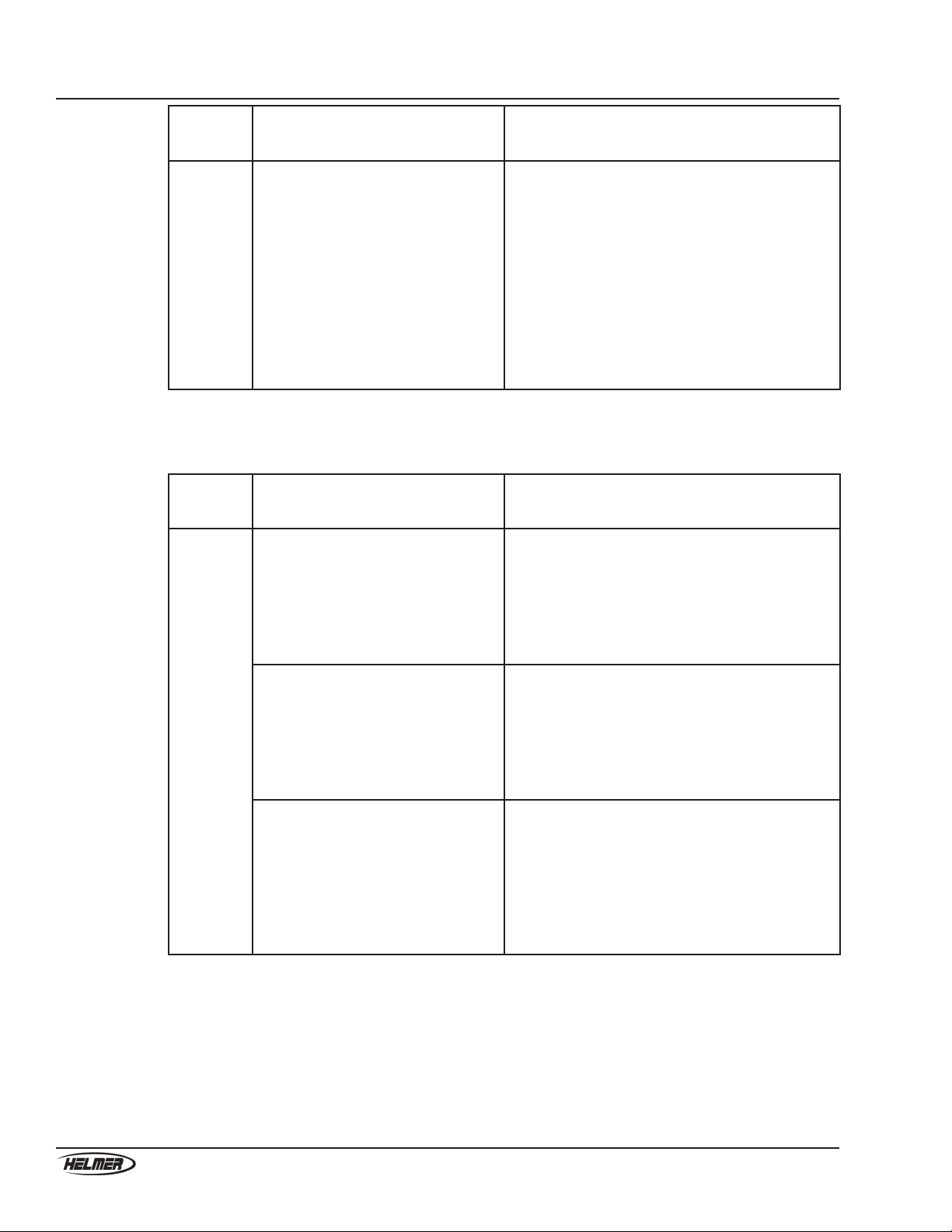

3.2 Addressing error messages

In the event of an error condition, the cell washer displays an error message to assist in troubleshooting.

This section provides possible causes associated with each error message and actions that should be taken.

XX represents the error message number.

CONTROL - ERROR XX

When a message of this type appears, there is a problem with the lid closing or locking, or a problem with

the control panel.

Error

message

number

Possible cause Action

04,

06 to 09

Continued

The lid lock is faulty. 1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check if the lid can be opened while the cell

washer is turned off. If it can, replace the lid

lock.

A connection in the lid lock circuit is

loose.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check the contact connection between the lid

lock and the control/display board.

3 Check that the ribbon cable between the

control/display board and the power supply

board is securely connected.

5

360113-1

Troubleshooting

Error

message

number

Possible cause Action

Continued

04,

06 to 09

A part in the lid lock circuit is faulty. 1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the ribbon cable between the

control/display board and the power

supply board.

b Replace the power supply board.

c Replace the control panel.

21 to 26 The control panel is faulty. 1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Replace the control panel.

FU/CCI - ERROR XX

When a message of this type appears, there is a problem related to the frequency converter.

Error

message

number

Possible cause Action

60 A part in the frequency converter

circuit is faulty, resulting in a false lid

lock release signal.

► Try the following tasks in order, testing after

each to determine if it solved the problem:

1 Replace the ribbon cable between the

control/display board and the power

supply board.

2 Replace the ribbon cable between the

frequency converter and the power supply

board.

3 Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

4 Replace the power supply board.

5 Replace the control panel.

61 A part in the frequency converter

circuit is faulty, resulting in a

processing error.

1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the ribbon cable between the

control/display board and the power

supply board.

b Replace the ribbon cable between the

frequency converter and the power supply

board.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

d Replace the power supply board.

e Replace the control panel.

6

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

Error

message

number

Possible cause Action

62 The main supply voltage is too low,

resulting in an undervoltage condition

to the frequency converter.

1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Verify that the outlet in the facility is

operational and supplying adequate voltage to

the cell washer.

3 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the ribbon cable between the

control/display board and the power

supply board.

b Replace the ribbon cable between the

frequency converter and the power supply

board.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

d Replace the power supply board.

e Replace the control panel.

63 A part in the frequency converter

circuit is faulty, resulting in an

overcurrent condition in the motor.

1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the motor.

b Replace the ribbon cable between the

frequency converter and the power supply

board.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

d Replace the power supply board.

64 A part in the frequency converter

circuit is faulty, resulting in an

overvoltage condition in the braking

resistor.

1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the braking resistor.

b Replace the ribbon cable between the

frequency converter and the power supply

board.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

d Replace the power supply board.

7

360113-1

Troubleshooting

Error

message

number

Possible cause Action

67 A part in the frequency converter

circuit is faulty, resulting in an

overtemperature condition in the

motor.

1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Test the motor windings. If they are faulty,

replace the motor.

b Replace the ribbon cable between the

frequency converter and the power supply

board.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

d Replace the power supply board.

68 A part in the frequency converter

circuit is faulty, resulting in an

overvoltage condition in the

frequency converter.

1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Conrm that the ambient temperature during

operation does not exceed 45 °C.

3 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the ribbon cable between the

control/display board and the power

supply board.

b Replace the ribbon cable between the

frequency converter and the power supply

board.

c Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

d Replace the power supply board.

69 The frequency converter is faulty. 1 Clear the error message: Open the lid, then

turn off the power. After about 1 minute, turn

the power back on.

2 Replace the frequency converter. For

instructions, see Section 4.7, “Replacing the

frequency converter.”

84 A part in the frequency converter

circuit is faulty, resulting the

frequency converter detecting excess

rotor speed.

► Try the following tasks in order, testing after

each to determine if it solved the problem:

1 Replace the ribbon cable between the

frequency converter and the power supply

board.

2 Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

3 Replace the power supply board.

8

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

Error

message

number

Possible cause Action

85 A part in the frequency converter

circuit is faulty, resulting in a

processing error.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the ribbon cable between the

frequency converter and the power supply

board.

b Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

c Replace the power supply board.

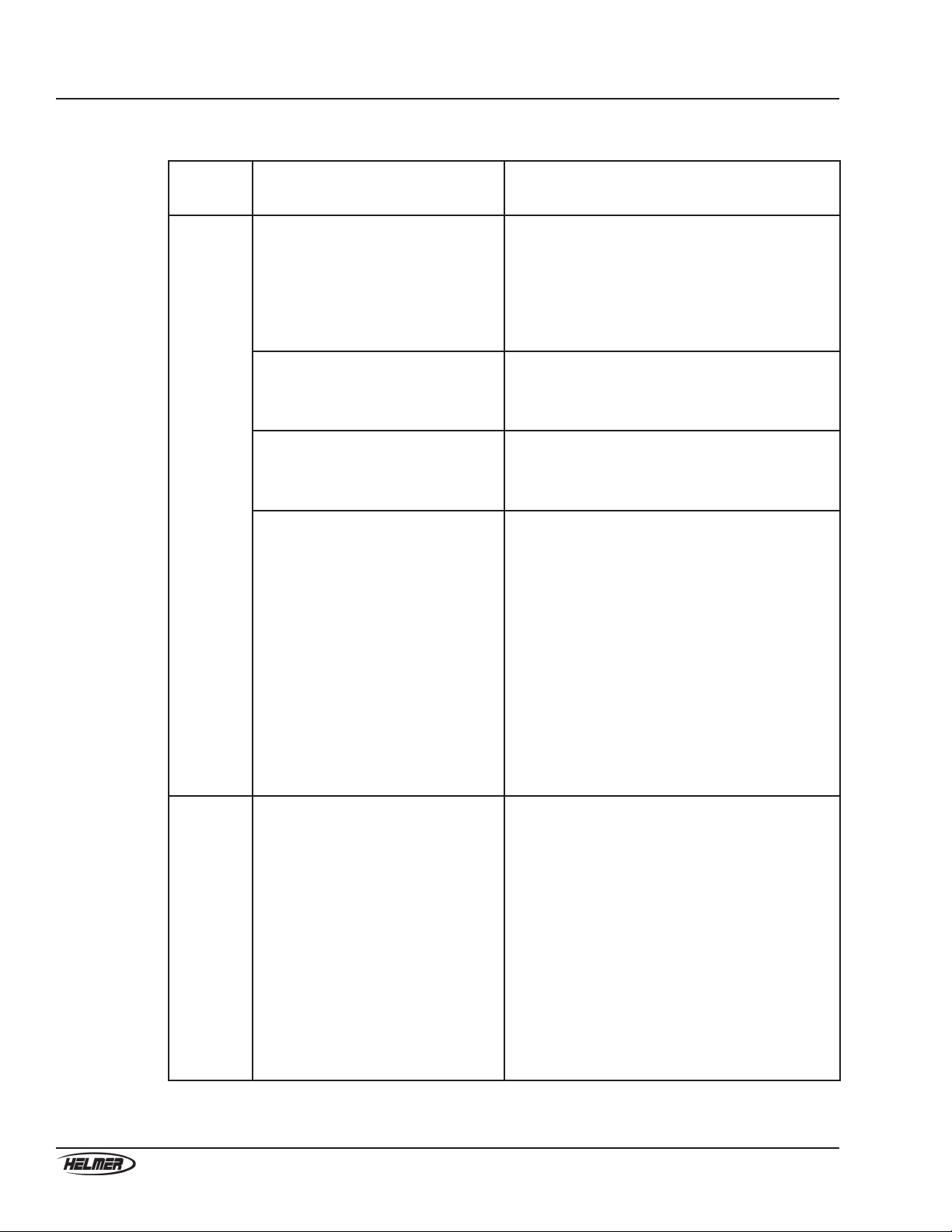

IMBALANCE

When this message appears, there is a problem with the balance of the rotor.

Error

message

number

Possible cause Action

None

Continued

The Imbalance initialization

parameter was set to the wrong value

after the frequency converter was

replaced.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check that the Imbalance parameter is set

to 2. For more information and instructions,

see Section 4.7 “Replacing the frequency

converter.”

The imbalance tolerance is set too

low.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check the imbalance tolerance and adjust it

if necessary. For instructions, see Section 4.2,

“Testing whether the imbalance value is in the

permissible range.”

A connection in the imbalance

microswitch circuit is loose.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check the connection between the imbalance

microswitch and the power supply board.

3 Check that the ribbon cable between the

control/display board and the power supply

board is securely connected.

9

360113-1

Troubleshooting

Error

message

number

Possible cause Action

Continued

None

A part in the imbalance microswitch

circuit is faulty

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Check the continuity of the imbalance

microswitch, which is normally closed.

The resistance should be 0 Ω when the

switch is closed (not activated). If there

is resistance, replace the imbalance

microswitch, then set the imbalance

tolerance. For instructions, see Section 4.3,

“Adjusting the imbalance microswitch.”

b Replace the ribbon cable between the

control/display board and the power

supply board.

c Replace the power supply board.

d Replace the control panel.

LOW SALINE

When this message appears, there is a problem with the ow of saline into the cell washer.

Error

message

number

Possible cause Action

None A connection in the liquid handling

system circuit is loose.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check the connection between the liquid

handling board and the power supply board.

A part in the pump system is faulty. 1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Remove the pump tubing from the pump. With

the pump tubing removed, perform a saline

check.

► If the pump does not operate, replace the

pump.

► If the pump does operate, replace the

pump tubing, which may have hardened

over time.

A part in the liquid handling system

circuit is faulty.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the ow meter.

b Replace the liquid handling board.

10

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

N > MAX XX

When this message appears, the rotor speed being detected exceeds the maximum allowable speed.

Error

message

number

Possible cause Action

05 The insulation on the speed sensor

cable is faulty.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Check the speed sensor cable for wear. If worn,

replace the speed sensor.

A connection in the speed sensor

circuit is loose.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Check the connection between the speed

sensor and the power supply board.

3 Check that the ribbon cable between the

control/display board and the power supply

board is securely connected.

A part in the speed sensor circuit is

faulty.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Test the speed sensor by measuring the

rotor speed. For instructions, see Section

4.1, “Testing whether the rotor speed is

within the design tolerance.” If the speed

is not within the tolerance, replace the

speed sensor.

b Replace the ribbon cable between the

control/display board and the power

supply board.

c Replace the ribbon cable between the

frequency converter and the power supply

board.

d Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

e Replace the power supply board.

f Replace the control panel.

11

360113-1

Troubleshooting

N < MIN XX

When this message appears, the rotor is rotating too slowly.

Error

message

number

Possible cause Action

13 A connection in the motor circuit is

loose.

1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Check the connection between the motor and

the frequency converter.

A part in the motor circuit is faulty. 1 Clear the error message: Open the lid, then

turn off the power. After about 10 seconds, turn

the power back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Test the motor windings. If they are faulty,

replace the motor.

b Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

POWER INTERRUPT

When this message appears, the AC power was interrupted during operation, or was sensed as being

interrupted.

Error

message

number

Possible cause Action

None A connection between the control/

display board and the power supply

board is loose.

1 Clear the error message: Open the lid then

press the START WASH button.

2 Check the connection between the control/

display board and the power supply board.

A part in the control panel and power

supply circuit is faulty.

1 Clear the error message: Open the lid then

press the START WASH button.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the power supply board.

b Replace the ribbon cable between the

control/display board and the power

supply board.

c Replace the control panel.

12

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

SER I/O - ERROR XX

When a message of this type appears, there is a problem with communication between components.

Error

message

number

Possible cause Action

30 and 31 A connection in the frequency

converter circuit is loose.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Check the connection between the frequency

converter and the power supply board.

3 Check the connections between the frequency

converter and the RFI lter and braking

resistor overtemperature switch.

The connections between the

frequency converter and the RFI lter

and braking resistor overtemperature

switch are wrong.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Check that the connections on the frequency

converter at connector S102 are correct.

The braking resistor overtemperature

switch has opened.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Replace the braking resistor overtemperature

switch.

A part in the frequency converter

circuit is faulty.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

b Replace the ribbon cable between the

control/display board and the power

supply board.

c Replace the ribbon cable between the

frequency converter and the power supply

board.

d Replace the control panel.

e Replace the power supply board.

33, 34, and

36

A part in the frequency converter and

control panel circuit is faulty.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

b Replace the ribbon cable between the

control/display board and the power

supply board.

c Replace the ribbon cable between the

frequency converter and the power supply

board.

d Replace the control panel.

e Replace the power supply board.

13

360113-1

Troubleshooting

TACHO - ERROR XX

When a message of this type appears, the rotor is not installed, or the speed is being controlled or sensed

incorrectly.

Message

number

Possible cause Action

01 A connection in the speed sensor

circuit is loose, resulting in the

interruption of speed sensor pulses.

1 Clear the error message by doing the

following:

a Open the lid, then turn off the power.

b While spinning the rotor clockwise by

hand, turn on the power.

2 Check the connection between the speed

sensor and the power supply board.

A part in the speed sensor circuit is

faulty.

1 Clear the error message by doing the

following:

a Open the lid, then turn off the power.

b While spinning the rotor clockwise by

hand, turn on the power.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Test the speed sensor by measuring the

rotor speed. For instructions, see Section

4.1, “Testing whether the rotor speed is

within the design tolerance.” If the speed

is not within the tolerance, replace the

speed sensor.

b Replace the ribbon cable between the

control/display board and the power

supply board.

c Replace the ribbon cable between the

frequency converter and the power supply

board.

d Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

e Replace the control panel.

f Replace the power supply board.

14

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

Message

number

Possible cause Action

02 A connection in the speed sensor and

motor circuit is loose, resulting in no

speed sensor pulses after start-up.

1 Clear the error message by doing the

following:

a Open the lid, then turn off the power.

b While spinning the rotor clockwise by

hand, turn on the power.

2 Check the connection between the speed

sensor and the power supply board.

3 Check the motor connections.

A part in the speed sensor and motor

circuit is faulty.

1 Clear the error message by doing the

following:

a Open the lid, then turn off the power.

b While spinning the rotor clockwise by

hand, turn on the power.

2 Try the following tasks in order, testing after

each to determine if it solved the problem:

a Test the motor windings. If they are faulty,

replace the motor.

b Test the speed sensor by measuring the

rotor speed. For instructions, see Section

4.1, “Testing whether the rotor speed is

within the design tolerance.” If the speed

is not within the tolerance, replace the

speed sensor.

c Replace the ribbon cable between the

control/display board and the power

supply board.

d Replace the ribbon cable between the

frequency converter and the power supply

board.

e Replace the frequency converter. For

instructions, see Section 4.7, “Replacing

the frequency converter.”

f Replace the control panel.

g Replace the power supply board.

VERSION - ERROR XX

When a message of this type appears, there is a problem with the control panel.

Message

number

Possible cause Action

12 The cell washer was not initialized

after replacing the frequency

converter.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Initialize the cell washer. For instructions, see

Section 4.7.2, “Initializing the cell washer.”

Reset the power to clear the error message.

A component on the control panel is

not compatible with the frequency

converter.

1 Clear the error message: Turn off the power.

After about 10 seconds, turn it back on.

2 Replace the control panel.

15

360113-1

Servicing the cell washer

4 Servicing the cell washer

This section explains how to access serviceable parts, as well as how to perform some service procedures.

4.1 Testing whether the rotor speed is within the

design tolerance

NOTE: You cannot test the decant speed, but you can change it by changing a global

parameter value. For instructions, refer to the Operation Manual.

You can measure the rotor speed to determine whether it is within the design tolerance.

The cell washer has a sight window in the lid and an optical reference on the rotor so that you can easily

measure the speed of the rotor during operation.

When the rotor is programmed to spin at 3500 r/min (RPM), the measured speed should be

3500 r/min ± 20 r/min.

For more information and instructions to program and use the cell washer, refer to the Operation Manual.

You will need the following to test the rotor speed:

► Laser tachometer (calibrated and capable of measuring r/min)

!

WARNING: Prior to using the laser tachometer, review all safety and usage instructions

provided by the manufacturer.

To test whether the rotor speed is within the design tolerance

NOTE: Regulations for your organization may recommend test methods different from

what appear here. Use the appropriate methods for your organization.

1 Install the rotor.

2 Program the Spin (S) program with a spin speed of 3500 r/min and a spin time that is long enough for

you to measure the speed.

3 Start the Spin (S) program by pressing the SPIN button.

4 While the rotor is spinning and 3500 is displayed on the message screen, point the tachometer’s laser

beam through the sight window on the lid. As the rotor spins, the laser momentarily reects off the

optical reference on the rotor.

5 Obtain the reading from the tachometer. If the speed is not within the tolerance of 3500 r/min ± 20

r/min, follow the appropriate troubleshooting steps to determine how to proceed.

16

360113-1

UltraCW™ Automatic Cell Washing System Service Manual

4.2 Testing whether the imbalance value is in the

permissible range

The imbalance microswitch senses whether the rotor is balanced during operation. If the rotor is not

balanced, an imbalance error results. The weight at which the imbalance error occurs is the imbalance

value.

At the factory, the microswitch is positioned to allow an imbalance value that lies between 5 g and 10 g

when the rotor is spinning at 1500 r/min. For example, if the imbalance value were 7 g (the middle of the

range), an imbalance error would result only if one side of the rotor were more than 7 g heavier than the

other. One gram is approximately equal to 1 ml of saline solution.

Continual operation of the cell washer when the imbalance value of greater than or equal to 10 g may

damage the cell washer. An imbalance value of less than or equal to 5 g is overly sensitive to the normal

variations in weight that occur during operation.

For more information and instructions to program and use the cell washer, refer to the Operation Manual.

You will need the following to test whether the imbalance value is in the permissible range:

► Tubes (enough to ll all available positions on the rotor)

► Saline solution. One test run requires 15 g (approximately 15 ml)

► Scale (calibrated and capable of measuring 10 g)

To test whether the imbalance value is in the permissible range

NOTE: Regulations for your organization may recommend test methods different from

what appear here. Use the appropriate methods for your organization.

1 Add tubes to all the available positions in the rotor. If you are using 10 mm x 75 mm tubes, conrm

that the tube inserts are installed correctly in all the tube holders.

2 Program the Spin (S) program with a spin speed of 1500 r/min and a spin time of 20 seconds.

3 Test whether the imbalance value is below the upper limit of the permissible range.

a Starting with empty tubes, add a total of 10 g of saline solution to one or more tubes on one side of

the rotor.

b Install the rotor.

c Start the Spin program. If the program completes without an imbalance error, then the imbalance

value is too high and must be decreased. For instructions, see Section 4.3, “Adjusting the

imbalance microswitch.”

4 Test whether the imbalance value is above the lower limit of the permissible range.

a Add a total of 5 g of saline solution to one or more tubes on one side of the rotor.

b Install the rotor.

c Start the Spin program. If an imbalance error occurs, then the imbalance value is too low and must

be increased. For instructions, see Section 4.3, “Adjusting the imbalance microswitch.”

17

360113-1

Servicing the cell washer

4.3 Adjusting the imbalance microswitch

NOTE: For more information about locating and identifying parts, see Section 5, “Parts”

and Section 6, “Schematic.”

The imbalance microswitch senses whether the rotor is balanced during operation. If the rotor is not

balanced, an imbalance error results.

The proximity of the microswitch to the motor shaft determines the value at which the rotor is considered

to be imbalanced. The higher the imbalance of the rotor, the closer the motor shaft moves toward the

microswitch during operation.

You may need to adjust the imbalance microswitch in the following circumstances:

► The imbalance value is outside of the permissible range.

► Imbalance errors continue to appear, even after you have addressed other possible causes.

► You replaced the imbalance microswitch.

You will need the following to adjust the position of the imbalance microswitch:

► #15 TORX® screwdriver

To adjust the imbalance microswitch

1 Remove the rotor from the cell washer, and close the lid.

2 Turn off the cell washer and disconnect it from power.

3 Turn the cell washer so that it rests on the left side.

4 On the bottom of the cell washer, use the screwdriver to loosen the screw in the slot. This screw

secures the imbalance microswitch bracket to the base.

Bottom of cell washer with imbalance adjustment screw circled

5 Do one of the following:

► To decrease the imbalance value, slide the screw toward the center of the cell washer. The switch

moves closer to the motor shaft.

► To increase the imbalance value, slide the screw away from the center of the cell washer. The

switch moves farther away from the motor shaft.

6 Tighten the screw to secure the imbalance bracket to the base.

7 Test the imbalance value to ensure that it in the permissible range. For instructions, see Section 4.2,

“Testing whether the imbalance value is in the permissible range.”

Other manuals for UltraCW

1

Table of contents

Other Helmer Washer manuals