Henderson Prometheus User manual

INSTRUCTIONMANUAL

XS-2/230V Motor Prometheus

Product group: Sliding shutters, -windows, -doors,

Version: 1.4

Language: english

Orig. Language: german

Document: ------

1

About this document

www.baier- g mbh.de

1.4 Used Symbols

Hint

A hint gives important and additional information.

N O T I C E

Description of type and source of hazards

Warnings, marked with this symbol, are related to safety.

Disregard may result in property damage.

Steps to avoid hazards.

C A U T I O N

Description of type and source of hazards

This symbol indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury and/or

property damage.

The following levels of warning show the severity and

probability of possible hazards, in ascending order.

CAUTION, coloured yellow

WARNING, coloured orange

DANGER, coloured red

Steps to avoid hazards.

symbolizes a list with no specific order

1. symbolizes a list or instruction in specific order

symbolizes an action

symbolizes a reference

symbolizes the result of the action

List

Instruction

www.b aier- g mbh.de

2

Safety

2Safety

D A N G E R

Electric Shock

Danger to life and health due to electrical shock.

Electrical connections have to be installed by approved

personnel only

Switch off power before carrying out work and secure

power against being switched on.

Observe relevant safety instructions.

2.1 Requirements for operation

Hint

Read the instruction manual before performing the initial operation.

2.1.1 Environmental conditions

The Prometheus XS-2/230 motor is designed for use in protected outdoor areas. It must

not be exposed to direct moisture, such as rain. More information can be found in the

datasheet.

2.2 Intended Use

This product serves as a drive for sliding shutters, sliding doors and sliding windows. It is

connected directly to the 230V, 50Hz AC mains supply. Various connection options are

available.

The manufacturer’s instructions for dimensioning, i.e. maximum and minimum

dimensions, maximum weights and similar details must be observed.

Any other use of this product shall be considered as improper use.

We cannot guarantee that the product will work with fittings, controls or other electronics

from other manufacturers.

2.3 Behavior in case of an error

In case of an error, the device must be shut down and the manufacturer must be

informed.

Do not operate device

Disconnect device from power supply

Inform the manufacturer

Shut down

3

Functional Description

www.b aier- g mbh.de

3Functional Description

Construction and Function of the Motor

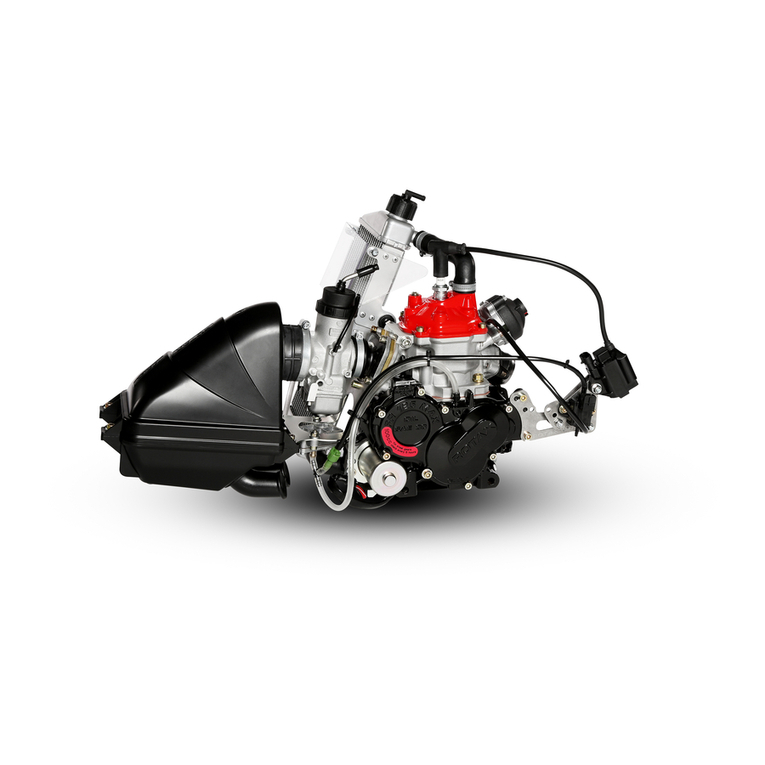

The motor’s internal construction consists of a 24V DC motor, the electronics and a mains

adapter. The motor usually drives a sliding shutter or a sliding door via a toothed belt.

The motor always has 4 wires in the connection cable. The connection of these cables

determines the type of operation:

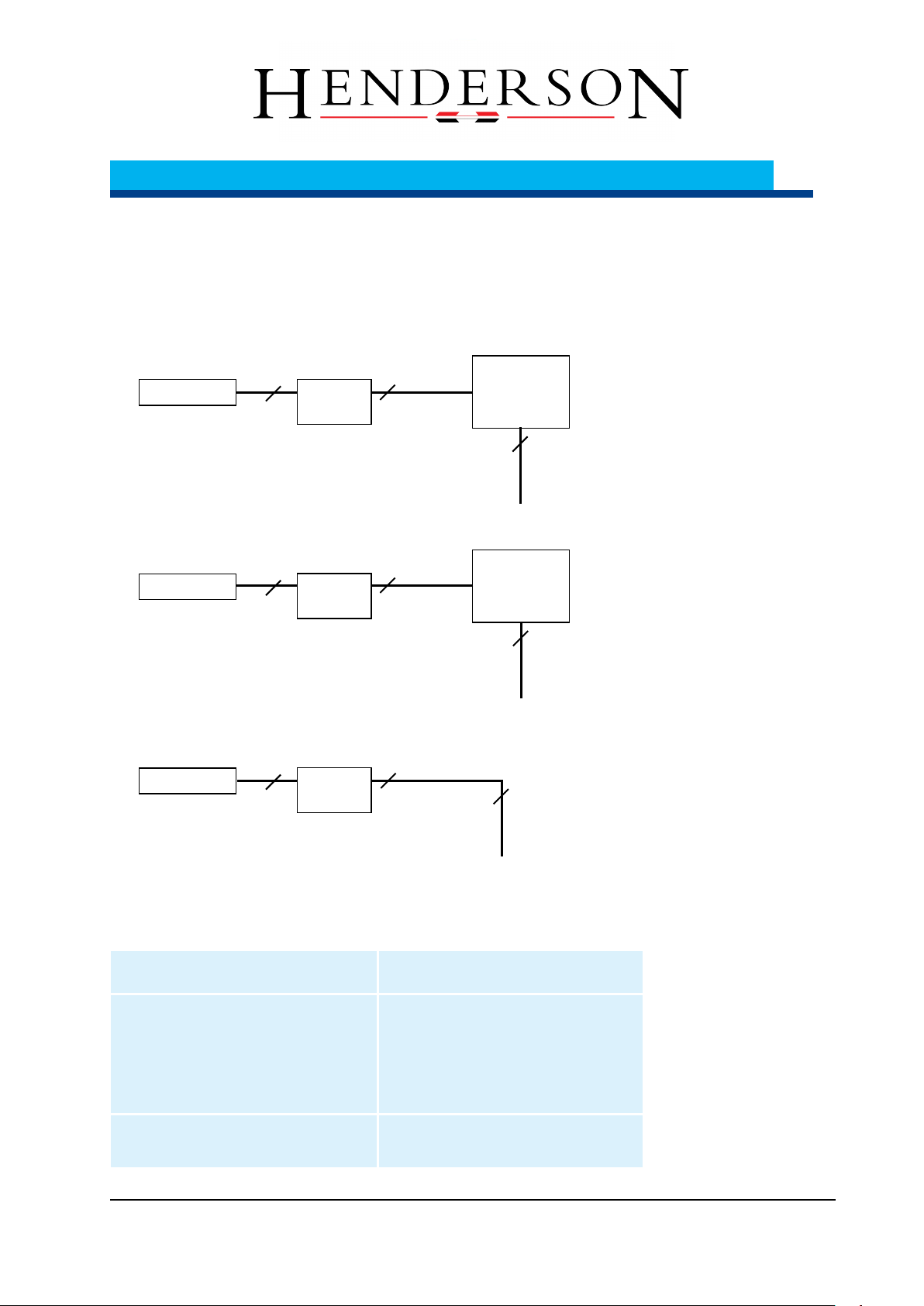

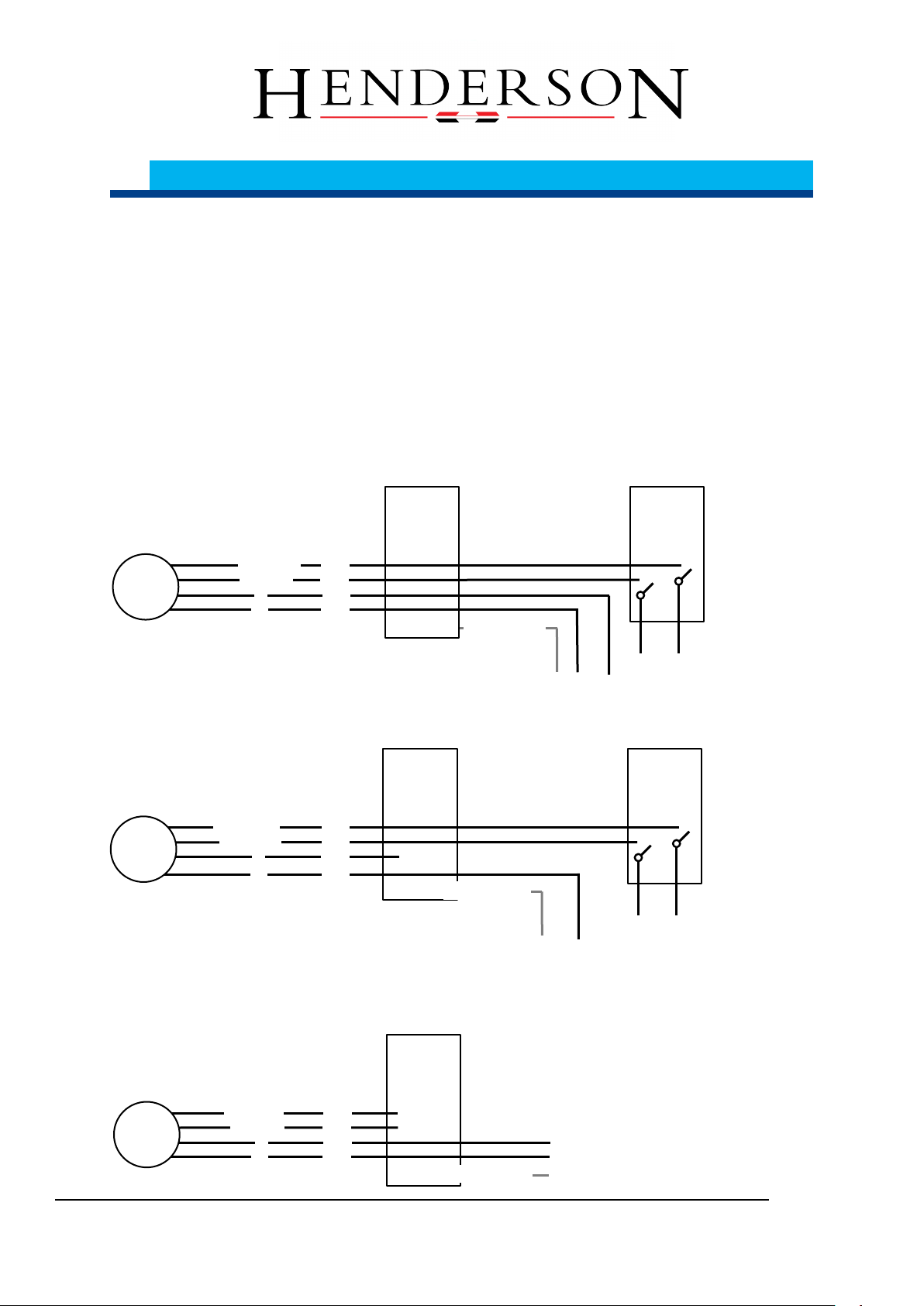

4-Wire Connection, Automatic optional with wireless control

The following connections are made for the 4-wire connection: L (phase, permanent), N

(neutral wire), Open (L phase) and Closed (L phase).

The motor is normally permanently supplied with voltage. If one of the two control inputs is

connected with voltage, the motor starts to run in the desired direction. The control signal

need not be on continuously during the run; a short pulse is sufficient.

The motor stops when an obstacle is detected, if a pulse is given off in the opposite

direction or the end of the track is reached.

3-Wire Connection, Deadman no wireless control possible

The following connections are made for the 3-wire connection:

N (neutral wire), Open (L phase) and Closed (L phase).

L (phase, permanent) is not connected.

The motor is only supplied with voltage via the control inputs. If one of the two control

inputs is connected with voltage, the motor starts to run in the desired direction. The

control signal must stay on continuously during the run.

The motor stops when an obstacle is detected or the end of the track is reached. The

motor also stops when the control signal goes off.

2-Wire Connection, with mandatory wireless control

The following connections are made with the 2-wire connection:

L (phase, permanent) and N (neutral wire).

Open (L phase) and Closed (L phase) are not connected.

The motor is normally permanently supplied with voltage. It is actuated via an integrated

wireless receiver. Once it is activated, the motor starts to run in the desired direction. The

wireless signal need not be on continuously during the run; a short pulse is sufficient.

The motor stops when an obstacle is detected, if a wireless pulse is given off in the

opposite direction or the end of the track is reached.

Wireless Transmitter and Receiver

Optionally, the motor has an integrated wireless receiver for actuation.

With the 4-wire connection, the wireless control can be used optionally for actuation in addition to

on-site button.

With the 3-wire connection, the wireless control cannot be used effectively, due to the non-

permanent voltage supply.

With the 2-wire connection, the wireless control must be used for actuation

www.b aier- g mbh.de

3

Functional Description

Configuration and Commissioning

The motor has no other setting or configuration options. It is ready for operation after

installation. No additional steps are required for commissioning.

Power Shutdown

The integrated motor control unit serves to operate the motor until such time as it

exceeds the permissible torque. This function is called a power shutdown. This allows

the drive to detect obstacles and shut down.

The power shutdown is also used to detect the end positions. Since the motor’s

power consumption increases at the end positions, the drive shuts off.

Low Speed Operation

During the first run, the integrated motor control unit determines the duration of a

normal run. Shortly before the end of this period, the motor runs at reduced speed to

save the mechanics and increase safety.

Likewise, the motor also runs at reduced speed if it shuts off before the end, due to

the power shutdown.

Connecting in Parallel

Several motors can be connected in parallel to one control switch. One motor can be

connected in parallel to multiple control switches. The maximum switching capacity of

the installation should be observed in doing so.

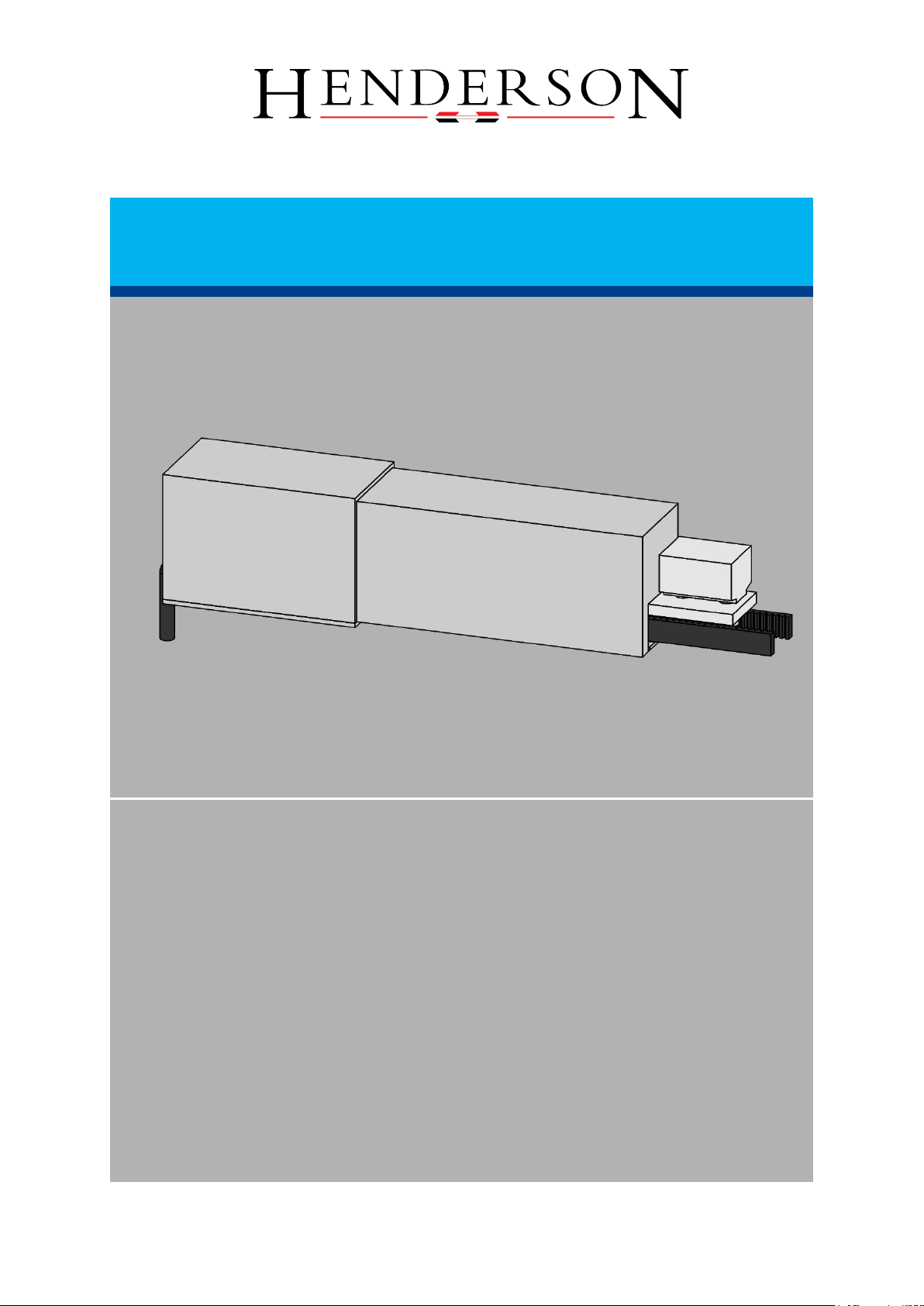

3.1 Dimensions

The control unit is generally located in the motor extension and is firmly connected to

it. The dimensions are approximately 52 x 60 x 225 mm (WxHxL), excluding mounting

block and cable.

.

4

Cable installation

www.b aier- g mbh.de

4Cable installation

4.1 Cable diagrams

4.1.1 4-wire connection

4.1.2 3- wire connection

4.1.3 2- wire connection

4.2 Wiring requirements

The following specifications are minimum requirements.

Wire

Type of wire

between elec. connection and motor

Preassembled cables to the motor

1. H05RN-F (o. glw.)

4 x 0,75 mm², length. 0,5m

without special wire

Optional other type of wire,

Other lengths and connections

available..

between elec. connection and button

and between button and power line

site depending on requirements

Table 1 –Type of wire

power line

230V~ 50 Hz

2 (3)

2

(3)

N

L

(PE)

power line

230V~ 50 Hz

power line

230V~ 50 Hz

2 (3)

Motor

button

On site

/

4

(5)

N

L

open

close

(PE)

connection

(on site)

4

Motor

connection

(on site)

2 (3)

4

Motor

button

On site

/

3

(4)

N

open

close

(PE)

connection

(on site)

4

www.b aier- g mbh.de

5

Connection

5 Connection

5.1 Completing the electrical connections

Disconnect power supply

secure shutdown

safety instructions, see chapter 2

do connections as indicated

The motor is connected

5.2 4-wire-connection

5.3 3-wire-connection

5.4 2-wire-connection

N

PE

yellow/green

N

N

4

Button

(on site)

L

open

(L)

close

(L)

Connection

(on site)

Motor

close (L)

(L)

open (L)

L

3

2

1

Button

(on site)

N

open

(L)

close

(L)

Connection

(on site)

Motor

close (L)

L

3

N

4

PE

yellow/green

2

1

open (L)

L

connection

(on site)

Motor

L

PE

yellow/green

N

4

2

1

3

open (L)

close (L)

6

Wireless Receiver

www.b aier- g mbh.de

6Wireless Receiver

An integrated wireless receiver in the engine is available for operation using one or

more wireless transmitters. The wireless receiver is already installed at the factory and

is ready for use without any further connections.

6.1 Programming Wireless Transmitters

The wireless receiver can be switched to the learning mode for teaching-in and

clearing wireless transmitters. For a unit with wireless transmitters that have not yet

been taught-in, this can be done for about 30 seconds after it has been switched on

or can be accomplished via an already taught-in wireless transmitter using the

learning button.

Note

A maximum of 32 wireless transmitters can be taught-in on one

wireless receiver.

6.1.1 Teaching-in the First Wireless Transmitter

If no wireless transmitter has been taught-in on the wireless receiver yet, the wireless

receiver will be in learning mode for about 30 seconds after being switched on.

Supply motor and thus wireless receiver with voltage

The wireless receiver will be in learning mode for about 30 seconds

Briefly press the learning button on the desired wireless transmitter (<1.6 seconds)

The wireless transmitter’s LED flashes at 1-second intervals

Briefly press one of the function buttons (Open, Closed or the like) on the desired

wireless transmitter (<1.6 seconds)

The wireless transmitter has been taught-in

Learning mode is automatically exited

6.1.2 Teaching-in Additional Wireless Transmitters

If one or more wireless transmitters have already been taught-in, for example using

the above-described procedure or in the factory, the wireless receiver is switched to

learning mode using one of the wireless transmitters that has already been taught-in.

Supply motor and thus wireless receiver with voltage

Briefly press the learning button on the already taught-in wireless transmitter (<1.6

seconds)

The already taught-in wireless transmitter’s LED flashes at 1-second intervals

Briefly press one of the function buttons (Open, Closed or the like) on the already

taught-in wireless transmitter (<1.6 seconds)

Learning mode is activated for about 10 seconds

Briefly press the learning button on the desired wireless transmitter (<1.6 seconds)

The already desired wireless transmitter’s LED flashes at 1-second intervals

www.b aier- g mbh.de

6

Wireless Receiver

Briefly press one of the function buttons (Open, Closed or the like) on the desired

wireless transmitter (<1.6 seconds)

The wireless transmitter has been taught-in

Learning mode is automatically exited

Der Lernmodus wird automatisch verlassen

Clearing Wireless Transmitters with Taught-in Wireless Transmitter

All wireless receivers can be cleared in order to reset the wireless receiver to factory

settings and teach-in the desired wireless transmitter again. An already taught-in

wireless transmitter is required for this purpose.

Supply motor and thus wireless receiver with voltage

Press and hold down the learning button on the already taught-in wireless transmitter

for a longer time (<5 seconds)

The already taught-in wireless transmitter’s LED flashes rapidly

Press and hold down one of the function buttons (Open, Closed or the like) on the

already taught-in wireless transmitter for a longer time (<5 seconds)

All wireless transmitters have been cleared

Disconnect motor and thus wireless receiver from voltage source

The wireless transmitter comes with factory settings installed, without any taught-in

wireless transmitters

6.1.3 Emergency Teach for lost remote controls

If none of the learned transmitters be available, must be taught new, to the so-called

emergency learning needs to be performed.

Note

Run this emergency learning only if the already memorized radio

transmitters are not available. For all other cases, the procedures

described in advance are more comfortable.

supply power to the motor, and also to the wireless receiver,

do as described in the followed: 4 times the motor and thus the radio receiver

must be switched on and off, with the fifth turning on the wireless receiver it is

back in the learning mode for 30 seconds.

Supply motor and thus wireless receiver away from voltage

Supply motor with voltage (<0,5 seconds)

and disconnect immediately.

Stop of the first turn on process

Supply motor and thus wireless receiver away from voltage for min. 10 seconds

Supply motor with voltage (<0,5 Sekunden)

and disconnect again immediately.

Stop of the second turn on process

Supply motor and thus wireless receiver away from voltage for min. 10 seconds

6

Wireless Receiver

www.b aier- g mbh.de

Supply motor with voltage (<0,5 seconds)

and disconnect again immediately.

Stop of the third turn on process

Supply motor and thus wireless receiver away from voltage for min. 10 seconds

Supply motor with voltage (<0,5 seconds)

and disconnect again immediately.

Stop of the forth turn on process

Keep the motor away from voltage

the wireless receiver it is back in the learning mode for 30 seconds

The teaching in of the wireless receiver can be done like described in chapter 6.

This is now an additional wireless receiver all in former times teaches receivers

are still in function.

If the learning mode is not used, i.e. it can be taught no new wireless receiver or

the motor disconnected again from the power, so the already memorized

wireless receiver remains programmed.

The complete procedure must be repeated again if necessary.

Part Number: 100131

Level: 01

This manual suits for next models

1

Table of contents