DE08TS Diesel Engines Index

Index

General Information

General Repair Instructions......................................5

Engine Specific Character........................................5

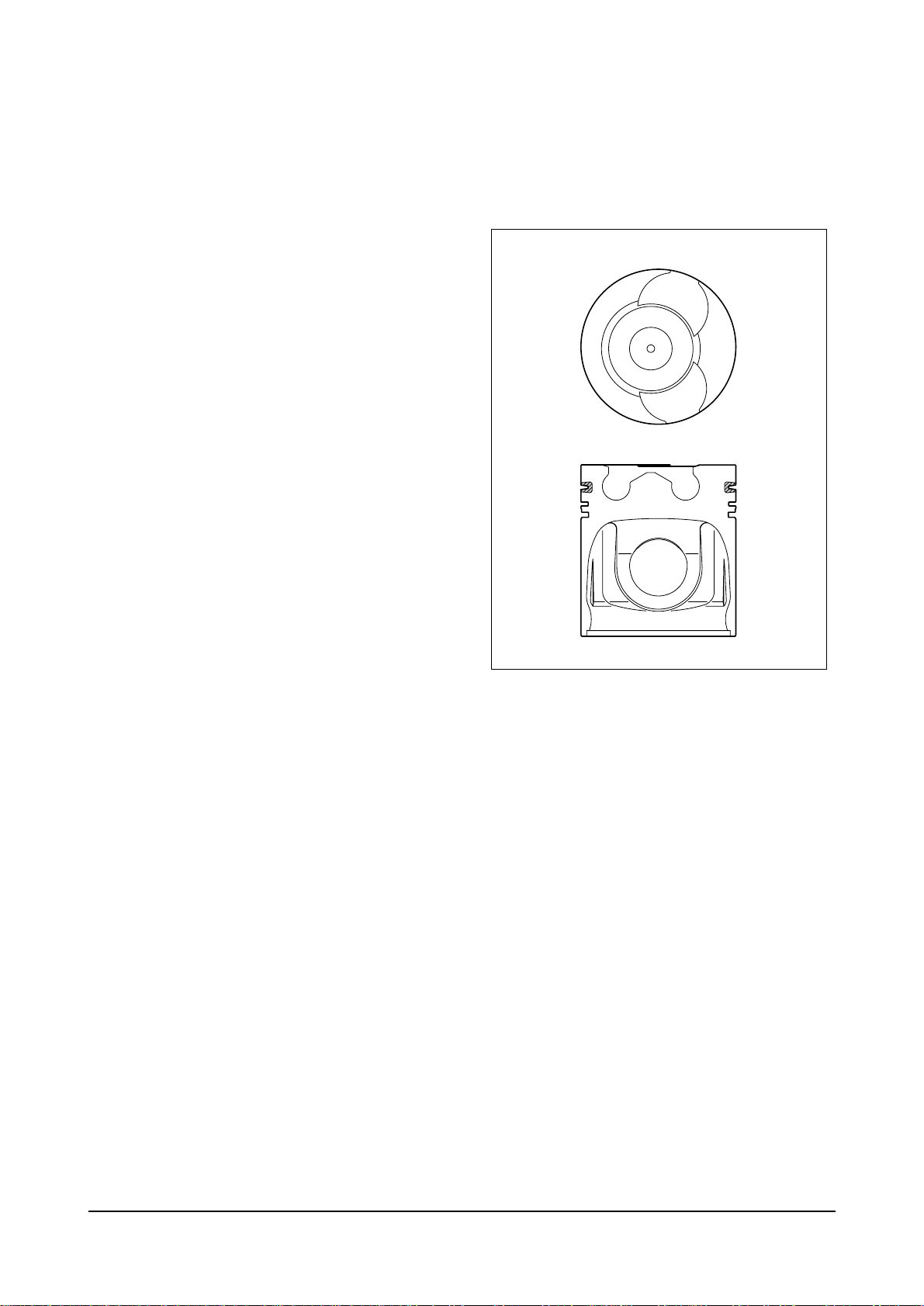

OMEGA Combustion bowl................................5

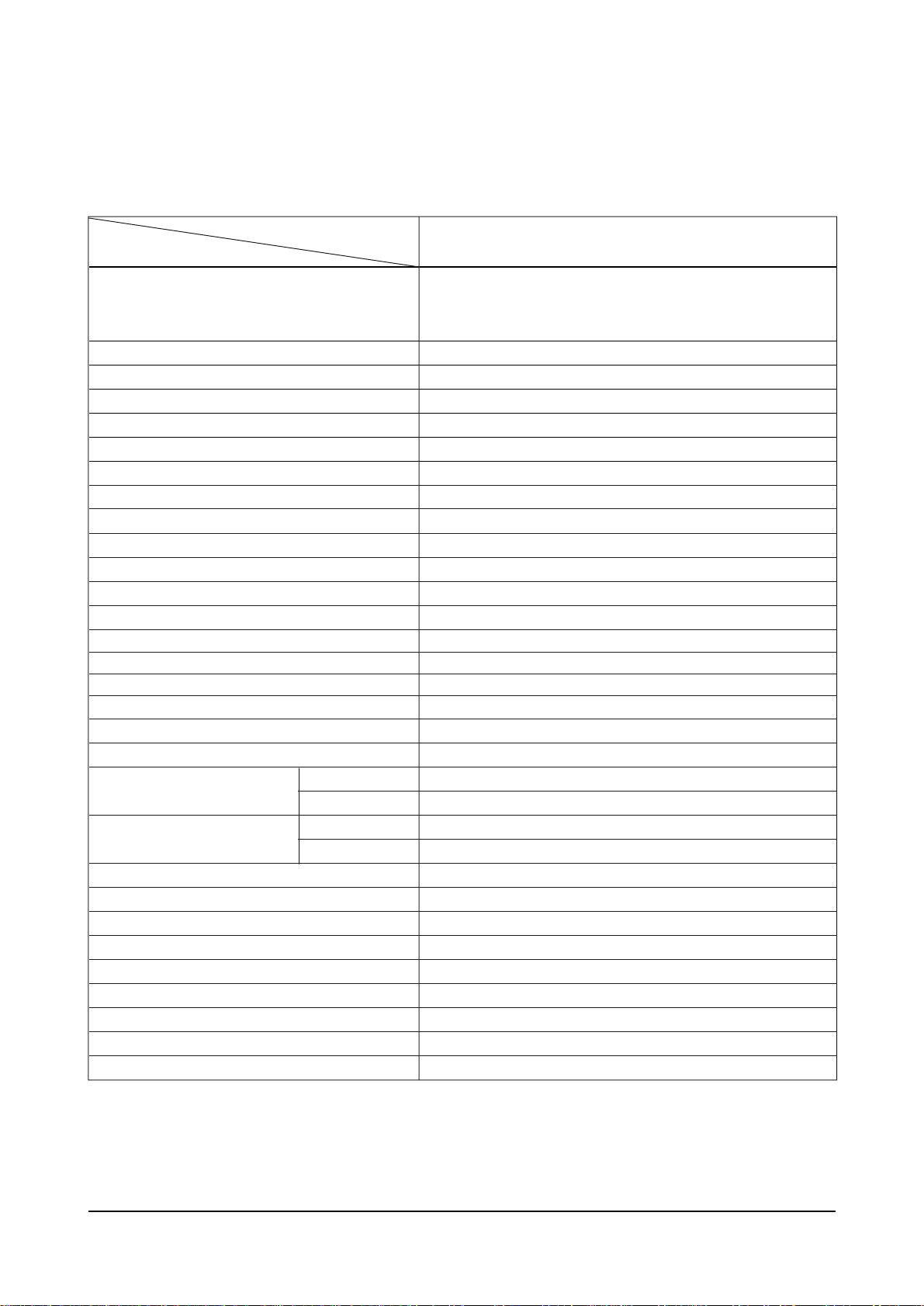

Engine Specifications...............................................6

Specifications....................................................6

Remove & Install Forks ....................................7

Performance curve(DE08TS-140PS) ...............8

Performance curve(DE08TS-160PS) ...............9

Engine Assembly....................................................10

Engine sectionnal view(longitudinal)...............10

Engine sectionnal view(cross) ........................11

Engine assembly view....................................12

Major Maintenance

Preventive Maintenance.........................................13

Cooling Water.................................................13

Fan belt...........................................................14

Engine Oil.......................................................14

OIl filter ...........................................................15

Fuel filter.........................................................15

Valve clearance adjust procedure ..................15

Cylinder compression pressure......................16

Injection nozzle...............................................17

Fuel injection pump.........................................17

Air removal of fuel system..............................17

Fuel supply pump ...........................................17

Turbocharger ..................................................17

Starting motor.................................................17

Diagnosis and Remedy..........................................18

Maintenance

Engine Disassembly...............................................27

Heed at disassembly ......................................27

Oil level gauge................................................27

Engine oil........................................................27

cooling fan ......................................................27

Belt..................................................................27

Thermostat......................................................27

Starter.............................................................28

Fuel filter.........................................................28

Breather..........................................................28

Alternator ........................................................28

Oil cooler.........................................................28

Oil filter............................................................29

Air compressor (if equipped) ..........................29

Idle pulley........................................................29

Water pump ....................................................29

Cylinder head cover........................................30

Fuel injection nozzle.......................................30

Turbo charger .................................................30

Exhaust manifold............................................30

Intake manifold ...............................................31

Cooling water pipe..........................................31

Rocker arm.....................................................31

Cylinder head..................................................32

Oil pan ............................................................32

Vibration damper.............................................33

Timing gear case cover ..................................33

Oil pump .........................................................33

Piston and connecting rod..............................33

Cylinder liner...................................................34

Camshaft gear and idle gear..........................34

Fuel injection pump.........................................35

Water chamber cover .....................................35

Fly wheel.........................................................35

Fly wheel housing...........................................35

Injection pump drive gear...............................35

Timing gear case............................................36

Bearing cap.....................................................36

Crankshaft.......................................................36

Camshaft and tappet ......................................36

Oil spray nozzle..............................................36

Inspection and Measurement on Major Parts........37

Cylinder block.................................................37

Cylinder head..................................................37

Rocker arm assembly.....................................41

Camshaft.........................................................42

Crankshaft.......................................................43

Fuel injection nozzle projection ......................49

Engine Reassembly ...............................................49

General precautions .......................................49

Cylinder block.................................................49

Oil spray nozzle..............................................49

Tappet and cam shaft .....................................50

Crankshaft.......................................................50

Flywheel housing............................................52

Oil seal............................................................52

Flywheel..........................................................52

Magnetic pick-up sensor.................................53

Water chamber cover .....................................53

Cylinder liner...................................................53

Piston and connecting rod..............................54

Timing gear case............................................55

Timing gear and idle gear pin.........................56

Injection pump flange......................................56

Fuel injection pump.........................................57

Oil pump and oil pipe......................................58

Timing gear case cover ..................................58

Front oil seal...................................................58

Water pump ....................................................58

Vibration damper.............................................59

Oil pan ............................................................59

3