Hengst WGM-B User manual

Operating instructions

RE51550-B/04.2021

English

Oil humidity sensor WGM

The data specified serves to describe the

product. If information on the use of the

product is given, it is only to be regarded

as application examples and recommendations.

Catalog information does not constitute

warranted properties. The information given

does not release the user from the obligation

of own judgment and verification. Our products

are subject to a natural process of wear and

aging.

© All rights with Hengst Filtration GmbH,

alsoin case of applications for industrial

property protection. It may not be reproduced

or given to third parties without consent

ofHengst Filtration GmbH.

The cover shows an example configuration.

The product supplied may therefore differ from

the figure shown.

The original operating instructions were

prepared in German.

RE51550-B/04.2021, Hengst Filtration GmbH

3/46Contents

Contents

1 Introduction 5

1.1 Intended use 5

1.2 Functionality 5

1.2.1 Humidity monitoring 5

1.2.2 Temperature monitoring 6

1.2.3 IO-Link 6

1.3 Construction types 6

1.4 Typekey 7

1.5 Scope of delivery 8

1.6 Representation of information 8

1.6.1 Safety instructions 8

1.6.2 Warning signs and symbols 9

2 Safety instructions 10

2.1 Important notes 10

2.2 General hazard notes 10

3 Transport and storage 11

4 Set-up and connection 12

4.1 Assembly 12

4.1.1 Installation recommendations 13

4.2 Electrical connections 13

5 Operation 14

5.1 WGM-D/WGM-R 14

5.1.1 Switch-on procedure 14

5.1.2 LED status displays 14

5.1.3 General key functions 15

5.1.4 Active key lock 16

5.1.5 Menu overview 16

5.1.6 Changing the basic settings 18

5.1.6.1 Restore factory settings (reset) 18

5.1.6.2 Switching off the normal troubleshooting 20

5.1.6.3 Defining the unit for humidity 20

5.1.6.4 Defining the unit for temperature 20

5.1.6.5 Defining the switching outputs 21

5.1.6.6 Setting the update rate of the display 21

5.1.6.7 Activate / deactivate key lock 22

5.1.7 Switching outputs 22

5.1.7.1 Switching output x: Definition of the switching characteristic 23

5.1.7.2 Switching output x: Upper switching limit (switching point) 24

5.1.7.3 Switching output x: Lower switching limit (switch-back point) 24

5.1.7.4 Switching output x: Switch-on delay 25

5.1.7.5 Switching output x: Switch-back delay 25

5.1.7.6 Switching output x: Testing the switching output 26

5.1.7.7 Change display function of the status LED 26

4/46

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

5.1.8 Analog outputs 27

5.1.8.1 Models with analog output 27

5.1.8.2 Analog output x: Assignment of the upper limit 27

5.1.8.3 Analog output x: Assignment of the lower limit 28

5.1.8.4 Analog output x: Determining the signal type 29

5.1.8.5 Analog output x: Testing the analog output 29

5.1.9 Diagnosis options 29

5.1.9.1 Calling the log book 30

5.1.9.2 Calling the error log book 30

5.1.9.3 Maximum and minimum humidity 31

5.1.9.4 Maximum and minimum temperature 31

5.1.9.5 Defining the switching output to be logged 32

5.1.9.6 Delay to min / max storage of humidity 32

5.1.9.7 Delay to min / max storage of the temperature 32

5.2 WGM-B 33

5.2.1 Switch-on procedure 33

5.2.2 Parameter settings 33

5.2.3 Factory setting 33

5.2.4 Switching outputs 33

5.2.5 Analog outputs 33

6 Maintenance and cleaning 34

7 Service and repair 34

7.1 Information on disassembly 34

7.2 Troubleshooting and remedy 35

8 Disposal 36

9 Appendix 36

9.1 General technical data 36

9.2 Technical data WGM-B 37

9.3 Technical data WGM-R / WGM-D 38

9.4 Outputs WGM-B 39

9.5 Outputs WGM-R / WGM-D 39

9.6 Pin assignment WGM-B 40

9.7 Pin assignment WGM-R / WGM-D 40

9.8 Indication ranges 41

9.9 Current settings 41

9.10 Overview menu sequence 42

Appendix: EU Declaration of Conformity

Introduction 5/46

RE51550-B/04.2021, Hengst Filtration GmbH

1 Introduction

1.1 Intended use

Oil humidity sensors are used for monitoring the water content in oil and for

temperature measurement. Oil humidity sensors must not be used in highly

inflammable or corrosive liquids.

Observe the technical data in the appendix with regard to the specific intended

use, available material combinations and temperature limits.

WARNING

All device types are intended exclusively for industrial applications. They

are not safety components. The devices must not be used if the safety and

health of persons is impaired in the event of failure or malfunction.

Any use in potentially explosive areas is inadmissible.

1.2 Functionality

The sensor determines the relative humidity of the oil via the water activity (aW).

The relative humidity is comparable to the water activity.

This can also be called the degree of oil saturation. The sensor is equipped with a

measuring chamber in which the humid air inside and the humidity in the medium

are in balance. The sensor sets these values in relation to the maximum saturation.

We thus obtain a measure of the oil saturation. Furthermore, the temperature is

recorded to be able to correct the values. Water activity is given as a factor between

0 and 1. Multiplied by 100%, we get the relative humidity or the saturation in

percent.

The critical limit of saturation depends on several plant-specific parameters.

The main advantage, however, is the permanent monitoring of humidity and

temperature. This enables the machine end-user to make own statements about

changes in the plant and to adjust the plant parameters, if required.

1.2.1 Humidity monitoring

The sensor element for determining the humidity is located in the medium and

protected by a protective pipe. The relative humidity can be output permanently

as an analog or digital signal (IO-Link) or executed as a switching signal.

The threshold value is pre-set and can be freely configured depending on the type.

Depending on the version, switching outputs combined with an analog output

(4 - 20mA) are available. The display options can show the relative humidity on the

display and output it on the analog output. The threshold values of the switching

outputs can be freely configured. The sensor options offer the possibility of an

analog output of the relative humidity. The threshold value of the switching point

is pre-set and can only be configured ex works or via the digital interface.

6/46 Introduction

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

1.2.2 Temperature monitoring

The temperature is monitored by a temperature sensor (Pt100) located in the

medium and protected by a protective pipe. Depending on the version, switching

outputs combined with an analog output (4 - 20mA) or digital output (IO-Link) are

available. The display options can show the temperature on the display and output it

on the analog output. The sensor options offer the possibility of an analog output of

the temperature.

Please observe the technical data in the appendix.

1.2.3 IO-Link

If an IO-Link interface is available at the sensor, it is possible

to access identification, process and diagnosis data. Sensor parameters such as

switching points or switch-back points can be set during operation. Prerequisite for

this is an IO-Link master with the corresponding configuration tools.

When replacing the sensor, all parameters already set can be transferred to the new

sensor.

The sensor includes an electronic device description, the so-called IODD file. The

IODD file contains all the information required for system integration. The file can

be downloaded from the download area at https://ioddnder.io-link.com.

Further information can be found at www.io-link.com

1.3 Construction types

The WGM is available in three basic types:

Type Description

WGM-B Basic option- Sensor only

WGM-D Display option- Sensor with display

WGM-R Remote display for basic option

(connection only possible to basic optionWGM-B-1X/2A1S-G34-V)

Depending on the configuration, the WGM is equipped with different switching and

analog outputs. The outputs are freely programmable.

The sensor options are available with a digital interface. Here, the sensor uses the

standardized technology IO-Link, a powerful point-to-point communication. It is

based on the previous and proven connection technology. Compatibility with the

previous technology is guaranteed.

Introduction 7/46

RE51550-B/04.2021, Hengst Filtration GmbH

1.4 Typekey

Oil humidity sensor type WGM

01 02 03 04 05 06

WGM – – 1X / – –

Type

01 Humidity sensor WGM

Option

02 Basic option- Sensor only

Display option- Sensor with display

Remote display for basic option

(connection only possible to basic optionWGM-B-1X/2A1S-G34-V)

B

D

R

03 Component series 1X

Data transmission

04

Option B - sensor 4...20mA; 2x analog output / 1x switching output

Option B - digital sensor; IO-Link

Option D - sensor with display 4...20mA; 2x analog output/2x switching

output

Option D - sensor with digital display; IO-Link / 1x switching output

2A1S

1D0S

2A2S

1D1S

Remote display (optionR) can only be combined with basic sensor

WGM-B-1X/2A1S-G34-V:

Option R - remote display 4...20mA; 2x analog output/2x switching output

Option R - digital remote display; IO-Link / 1x switching output

2A2S

1D1S

Connection

05 Thread G 3/4" G34

Option R - Remote display without connection 0

Seal

06 FKM V

Option R - Remote display without seal 0

Accessories Designation

Connecting cable for remote display M12x1, 8-pin,

length 3.0m, angle coupling and straight connector

ZWGM connecting cable for remote

R928058029

Connecting cable IO-Link M12x1, 4-pin,

Length 5.0m angled coupling and braided wires

ZWGM connecting cable for IO-Link,

4-pin R928058030

Connecting cable 4...20mA M12x1, 8-pin,

Length 5.0m angled coupling and braided wires

ZWGM connecting cable 4...20mA, 8-pin

R928058031

Order example Sensor Connecting cable Connecting cable

for remote

Sensor without display

WGM-B-1X/2A1S-G34-V R928057041 R928058031 –

WGM-B-1X/1D0S-G34-V R928057042 R928058030 –

Sensor with display

WGM-D-1X/2A2S-G34-V R928057045 R928058031 –

WGM-D-1X/1D1S-G34-V R928057046 R928058030 –

Remote display

WGM-R-1X/2A2S-0-0 R928057043 R928058031 R928058029

WGM-R-1X/1D1S-0-0 R928057044 R928058030 R928058029

8/46 Introduction

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

1.5 Scope of delivery

▶ Oil humidity sensor WGM

▶ Product documentation

1.6 Representation of information

Consistent safety instructions, symbols, terms and abbreviations are used in this

documentation so that you can quickly and safely work with your product. For

a better understanding, they are explained in the following sections.

1.6.1 Safety instructions

In this documentation, safety instructions are contained in chapter 2

"Safety instructions" and wherever a sequence of actions or instructions are

explained which bear the danger of personal injury or damage to property.

The measures described for hazard avoidance must be observed.

Safety instructions are set out as follows:

SIGNAL WORD

Typeand source of danger!

Consequences in case of non-compliance

▶ Hazard avoidance measures

▶ <Enumeration>

•Warning sign: draws attention to the danger

•Signal word: identifies the degree of danger

•Typeand source of danger!: specifies the type and source of danger

•Consequences: describes the consequences in case of non-compliance

•Avoidance: specifies how the danger can be prevented

Table 1: Risk classes according to ANSI Z535.6-2006

Warning sign, signal word Meaning

DANGER Indicates a dangerous situation which will cause death or

severe injury if not avoided.

WARNING Indicates a dangerous situation which may cause death or

severe injury if not avoided.

CAUTION Indicates a dangerous situation which may cause minor or

medium personal injury if not avoided.

NOTICE Damage to property: The product or the environment could

be damaged.

Introduction 9/46

RE51550-B/04.2021, Hengst Filtration GmbH

1.6.2 Warning signs and symbols

In these instructions, the following warning signs and symbols are used:

Symbol Meaning

Warning – General danger

Warning – High voltage

Warning – Inhalation hazard: toxic gas

Warning – Corrosive liquids

General information

Disconnect mains plug

Wear respiratory protection

Wear face shield

Wear gloves

If this information is not observed, the product cannot be used and/or

operated optimally.

▶ Individual, independent action

10/46 Safety instructions

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

2 Safety instructions

2.1 Important notes

The use of the device shall only be admissible if:

▶ the product is used under the conditions described in the operating and

installation instructions, in accordance with the name plate and for the

applications for which it is intended. Hengst Filtration GmbH accepts no liability

for unauthorized modifications to the device,

▶ the information and markings on the name plates are observed,

▶ the limit values specified in the data sheet and the instructions are observed,

▶ monitoring equipment/protective devices are correctly connected,

▶ the device is protected against mechanical damage and vibrations,

▶ the service and repair work not described in these instructions is carried out

by Hengst Filtration GmbH,

▶ original spare parts are used.

These operating instructions are part of the operating equipment. The manufacturer

reserves the right to change the performance, specification or design data without

prior notice. Keep the instructions for future use.

2.2 General hazard notes

The device may only be installed by specialists who are familiar with the safety

requirements and the risks. It is imperative that you observe the safety regulations

relevant to the place of installation and the generally applicable rules of technology.

Prevent faults and thereby avoid personal injury and damage to property.

The machine end-user must ensure that:

▶ safety instructions and operating instructions are available and observed,

▶ applicable national accident prevention regulations are observed,

▶ admissible data and application conditions are complied with,

▶ safeguards are used and prescribed maintenance work is carried out,

▶ legal regulations are observed during disposal.

Maintenance, repair

During maintenance and repair work, the following must be observed:

▶ Repair works on the operating equipment may only be carried out by personnel

authorized by Hengst Filtration GmbH.

▶ Only carry out modification, maintenance or assembly works described in these

operating and installation instructions.

▶ Only use original spare parts.

Transport and storage 11/46

RE51550-B/04.2021, Hengst Filtration GmbH

When carrying out maintenance work of any kind, applicable safety and operating

regulations of the country of use must be observed.

The cleaning method for the devices must be adapted to the IP protection class of

the devices. Do not use cleaning agents that can damage the materials used.

DANGER

Toxic, corrosive gases / liquids!

Protect yourself from toxic, corrosive gases/liquids during all work. Wear

appropriate protective equipment.

3 Transport and storage

The products should only be transported in their original packaging or a suitable

replacement.

When not in use, the operating equipment must be protected against humidity and

heat. They must be kept in a covered, dry and dust-free room

at room temperature.

12/46 Set-up and connection

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

4 Set-up and connection

DANGER

Electrical voltage!

Danger of electric shock

▶ De-energize the plant.

▶ The device may only be installed, maintained and commissioned by

instructed, expert personnel.

▶ The applicable safety regulations of the place of use must be observed.

DANGER

Toxic, corrosive gases / liquids!

Protect yourself from toxic, corrosive gases/liquids during all work. Wear

appropriate protective equipment.

CAUTION

Overpressure!

Protect the device from static and dynamic overpressures.

Provide suitable measures for prevention!

4.1 Assembly

Before installing the device, make sure that the plant is depressurized, otherwise

liquid may escape. If necessary, use a collecting container. The WGM is delivered

completely assembled and can be screwed into the pipeline with the thread. Make

sure that the sensor part is always completely surrounded

by the medium in order to display correct measured values.

DANGER

Electrical voltage!

Danger of electric shock

When connecting the devices, the maximum admissible voltages and

currents (see technical data) must be observed and the required wire

cross-sections and circuit breakers must be dimensioned accordingly.

When selecting the connecting cables, the maximum admissible operating

temperatures of the devices must also be observed.

Set-up and connection 13/46

RE51550-B/04.2021, Hengst Filtration GmbH

The display units mounted on a flange can be rotated about 270° around the vertical

axis for better readability of the display.

Please observe the integrated twisting stop. When the stop is reached, you will feel

an increased resistance. Turning beyond this stop can damage the display unit.

4.1.1 Installation recommendations

For the humidity sensor to function properly, ensure that the sensor element is fully

and permanently immersed in the medium.

The sensor is suitable for lateral tank installation if installed below the minimum

filling level. In the event of return line installation ensure that the maximum flow

velocity is not exceeded.

With the WGM-R option, the remote display is mounted onto a profile rail.

4.2 Electrical connections

Voltage supply is provided via plug-in connectors. For installation dimensions,

nominal voltage and pin assignment, please refer to the attachment.

The switching outputs are designed as PNP transistors (see figure):

Fig. 1: Circuitry of switching outputs

Notice: When measuring the switching output with high-impedance measuring

device inputs or using it as a frequency output, a 10kΩ resistor must be connected

between the output and the ground (GND) to prevent incorrect measurements.

Supply voltage

14/46 Operation

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

5 Operation

NOTICE

The device may not be operated outside its specifications!

5.1 WGM-D/WGM-R

This explanation of operation refers to options equipped with a display unit.

5.1.1 Switch-on procedure

When the device is connected to the supply voltage, it switches on immediately.

At the beginning, the software version appears briefly and the device checks the

installed components simultaneously. The display then changes to the measured

value display.

The function of the display and control unit is described below:

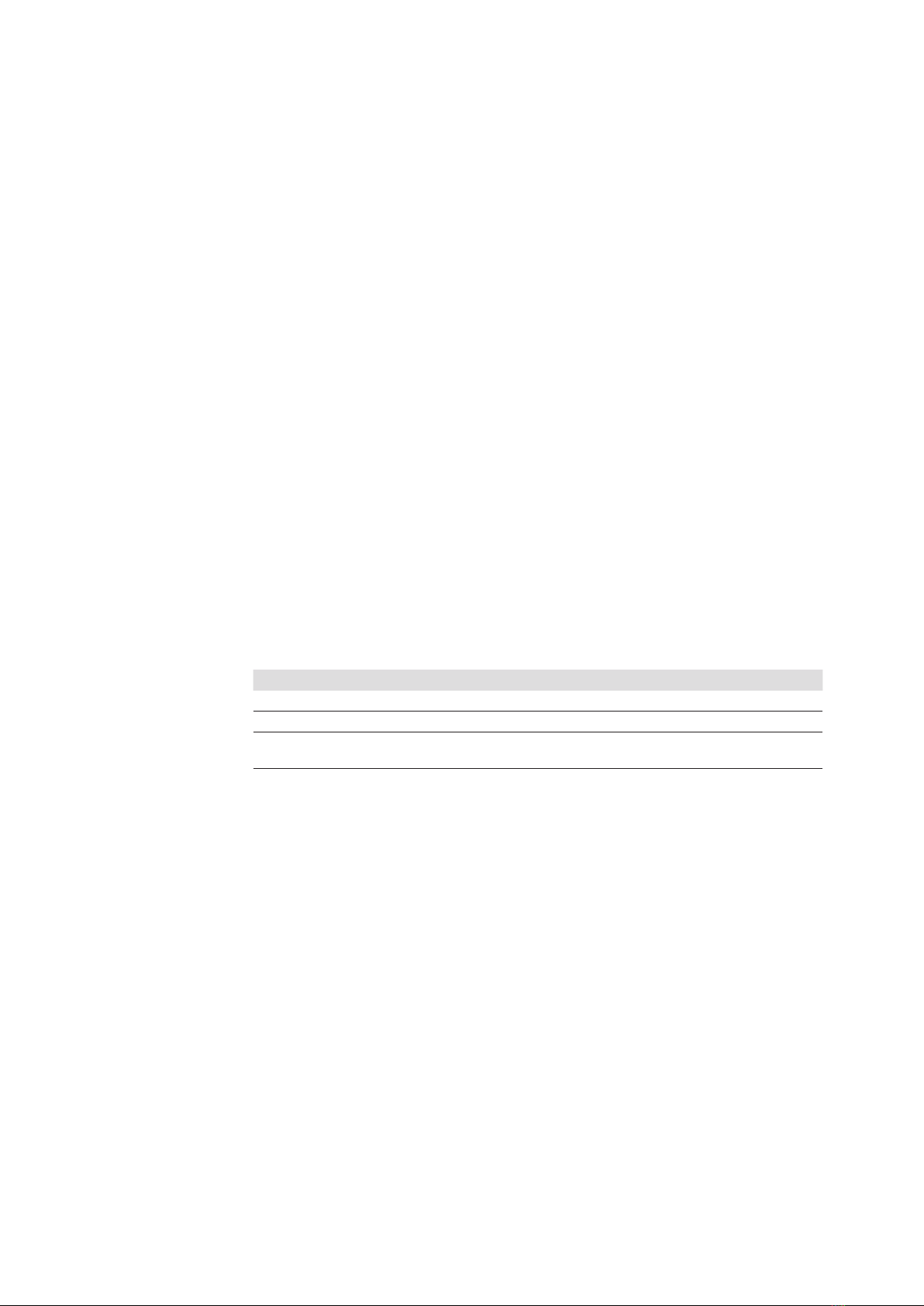

Fig. 2: Switch-on procedure

If an error message appears in the display during operation, please refer to the table

Troubleshooting in chapter "Service and Repair".

5.1.2 LED status displays

LEDs above the measured value display indicate the status of the switching outputs.

The LEDs are permanently assigned to the switching outputs.

The following table shows the factory settings for the assignment of the switching

outputs to filling level and temperature:

Table 2: Description of LED status displays

Figure Description 2 switching outputs

LED 1 - yellow

Status switching output 1

Humidity

LED 2 - red

Status switching output 2

Temperature

The switching behavior of the LEDs (illuminated with closed or open switching

contact) can be changed.

dtet

dt

e

e

e

e

t

t

t

Operating

buttons

Operation 15/46

RE51550-B/04.2021, Hengst Filtration GmbH

5.1.3 General key functions

Operation is carried out via the keys below the display.

A detailed explanation of the menu control can be found in the following chapters.

Key Mode Function

uMeasured value display: Change of the displayed measurement.

In the menu: Change to a subordinate menu.

Change to the superior menu.

At the end of the menu:

The display indicates the end of the menu.

After input/selection: Confirm and save an entered numerical value or

a function selection.

If the parameter is changed, the display flashes.

pMeasured value display: Display of the configuration.

In the menu: Scroll menu item, numerical value or function

selection upwards. When holding down the key,

this is done continuously.

qMeasured value display: Change to the main menu.

In the menu: Scroll menu item, numerical value or function

selection downwards. When holding down the key,

this is done continuously.

q+ uIn the menu: Exit the main menu/submenu/optional menu and

return to the measured value display without

saving the changed parameters.

p+ uIn the menu: Change to the next higher menu level.

60s

no action

In the menu: Exit the main menu/submenu/optional menu.

Proceed as follows to select a menu item and set the values:

▶ Open the main menu with the qkey.

▶ Select the submenu with the qand pkeys and open the submenu with the ukey.

▶ If necessary, select the next submenu with the qand pkeys and open it with the

ukey.

▶ Select the desired menu item with the qand pkeys and open the value list with

the ukey.

▶ Use theqandpkeys to set the value and confirm with theukey. The changed

settings are saved and the device returns to the submenu.

▶ Exit the submenu by selecting the EXIT menu item and confirming with the ukey.

The device returns to the superior menu or to the measured value display.

16/46 Operation

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

5.1.4 Active key lock

If the key lock is activated, the display appears instead of the main menu

when the menu is called up with the qkey. The active digit is identified by a point.

▶ Enter the code with the pand qkeys and confirm with the ukey. The active digit

moves one position to the right. After entry of the third digit, the main menu is

opened.

If the numerical code is entered incorrectly, the device returns to the measured value

display. If you have forgotten your password, you can access the menu at any time

with master code 287.

You can cancel the key lock by resetting the code in the menu item lOC in the

submenu Basic settings Advanced functions B.ef by entering 000.

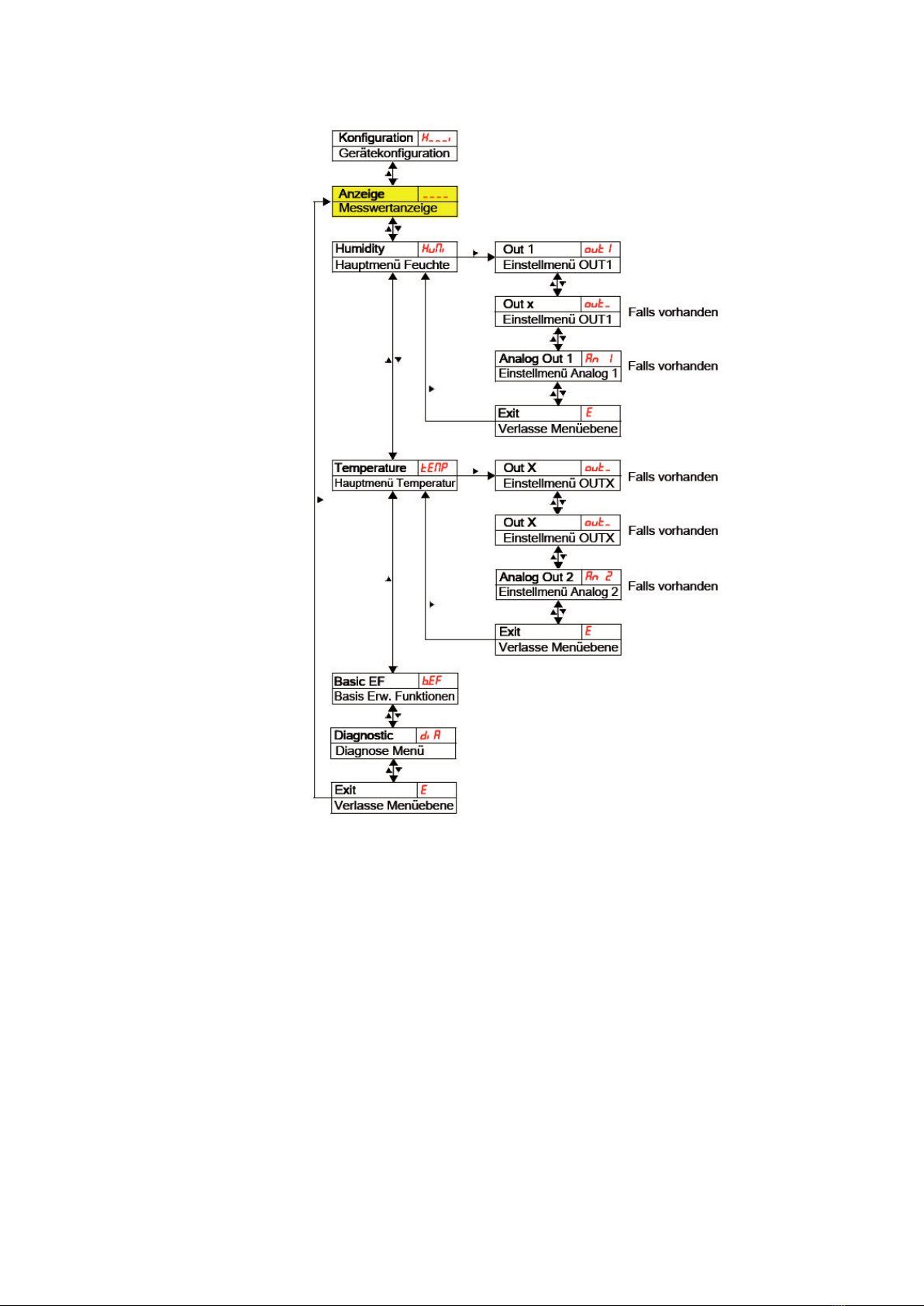

5.1.5 Menu overview

The structure of the menu is based on the VDMA standard sheet 24574-1.

The menu has a hierarchical structure. The top menu level contains the main menu

items, e.g. hUMi, TeMp, B.ef, DIa, e. Each main menu contains further submenu

items.

The menu items can vary depending on the configuration of the device. Not all menu

items described in the following may apply to your device.

You can call up the configuration by pressing the pkey in the display mode. A 4-digit

code is displayed, e.g.

Here the 4 digits mean tsav:

t: Type h= humidity and temperature

measurement

2 or 4

s: Number of switching outputs 0 or 2

a: Number of analog outputs i=standard assembly

(tank installation)

v: Assembly type of the device r=remote installation

Operation 17/46

RE51550-B/04.2021, Hengst Filtration GmbH

The individual menu items do not appear if the optionis not available. Example:

If a=0, the menu items for setting the analog output are not available. You can then

skip the description of these items.

The structure of the main menus Humidity (hUMi) and Temperature (TeMp) is

identical. The settings for the switching outputs or the analog outputs (if available)

are made here.

18/46 Operation

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

The basic settings of the device can be changed. General settings are made in the

menu Basic settings Advanced functions (B.ef).

These settings should be made first, as they affect the displays and adjustment

options in the individual menus. Such settings are e.g. the units used and the

assignment of the switching outputs to filling level and temperature measurement.

The assignment of the analog outputs cannot be changed.

In addition, the menu Diagnostic (DIa) contains options for diagnosis.

A detailed representation of the entire menu structure can be found in the

original operating instructions at the end of this chapter.

5.1.6 Changing the basic settings

The generally valid basic settings are made in the menu Basic settings advanced

functions (B.ef). These settings affect the representation in the measured value

display as well as the adjustment options in the various main menus. The assignment

of the switching outputs can also be changed here.

▶ Press the qkey to enter the main menu.

▶ Select the menu item (B.ef) with the qand pkeys and open the menu with the

ukey.

NOTICE

Switching off the normal troubleshooting!

Switching off the normal troubleshooting and error assessment is the factory

setting and, under certain circumstances, it can lead to dangerous operating

states, hazards for operators or machines. Before using this option, check the

hazard potential within your process. Hengst Filtration GmbH is not liable for any

health or material damage that may occur as a result of this setting.

5.1.6.1 Restore factory settings (reset)

The Reset (Res) function can be used to restore the factory settings. All changes will

be lost. Since the limit values are also reset, it is essential to check the settings for

filling level and temperature.

The following options are available:

Condition as supplied:

No, the current settings

are retained

Condition as supplied:

Yes, the settings are reset

to the default settings made

at the factory.

Operation 19/46

RE51550-B/04.2021, Hengst Filtration GmbH

The factory settings are as follows:

Definitions:

spx / Rpx Switching point / switch-back point x

Dsx / DRxSwitch-on delay / switch-back delay for switching output x

axhI / axlO maximum and minimum measured value for the output

a.OUx Signal form of the analog output

OUx Switching characteristic of the switching output x

h.UNI / T.UNI Unit for humidity / temperature

R.OUx Assignment of the switching outputxto filling level or temperature monitoring

DIs Update rate of the display

lOC Key lock

sj.OU logged switching output

Dh.MM Delay for recording the minimum / maximum humidity

DT.MM Delay for recording the minimum / maximum temperature

Notice: In the case of customer-specific requirements, the default settings made

at the factory may deviate from the values listed here.

Version with 2 switching outputs:

Switching outputs Basic settings

spi / Rpi 80 % / 75 %eRR.

£

NO

Dsi / DRi / OUi 0 / 0 / hNO h.UNI -i- (%)

sp2 / Rp2 60 / 55 c T.UNI c

Ds2 / DR2 / OU2 0 / 0 / hNO R.OUi hUMi

R.OU2 TeMp

DIs fasT

lOC 000

Version with analog outputs:

Analog outputs

ai.hI / ai.lO / a.OUi 0 / 100 / Ii

a2.hI / a2.lO / a.OU2 0 / 100 / Ii

Diagnostic settings:

Diagnosis

sj.OU OUTi

Dh.MM 0.0

DT.MM 0.0

20/46 Operation

Hengst Filtration GmbHHengst Filtration GmbH, RE51550-B/04.2021, RE51550-B/04.2021

5.1.6.2 Switching off the normal troubleshooting

Here you can activate/deactivate the normal troubleshooting and error assessment.

The function Switching off troubleshooting (eRR.

£

) deactivates normal

troubleshooting and error assessment. Under certain circumstances this can lead to

dangers for operators and machines.

Normal troubleshooting is deactivated in the factory setting of the WGM.

The following options are available:

Deactivates the normal

troubleshooting.

(standard setting)

Activates the normal

troubleshooting

Important notice: If the measuring range is exceeded or sensor errors

occur, the measured value is frozen and all six LEDs in the status bar

flash. When the measured value is within the valid range again, the LEDs

stop flashing and the display is updated normally.

5.1.6.3 Defining the unit for humidity

Here the displayed unit symbol for the humidity is defined:

The following options are available:

Percent

5.1.6.4 Defining the unit for temperature

Here the displayed unit symbol for the temperature is defined:

The following options are available:

Degrees

Celsius

Degrees

Fahrenheit

Notice: The measured value conversion and the adjustment of the

measurement range take place automatically. Nevertheless, the

corresponding switching and switch-back points must be checked.

This manual suits for next models

2

Table of contents

Popular Accessories manuals by other brands

Lord MicroStrain

Lord MicroStrain 3DM-GX5-10 user manual

Pepperl+Fuchs

Pepperl+Fuchs U-P R4 Series manual

Joolz

Joolz Geo lower raincover instruction manual

Carefree of Colorado

Carefree of Colorado Eclipse Service manual

Makita

Makita DFJ210 instruction manual

Siemens

Siemens Wireless Room Sensor Solution user guide