HERKULES HCR1 User manual

Page 1 of 8

Part# 1002439-05

6/4/12

Model: HCR1

This manual contains important information concerning the

installation and operation of the crusher listed above.

Read manual thoroughly and keep for future reference

INSTRUCTIONS

Herkules Equipment Corporation

2760 Ridgeway Court

Walled Lake, MI 48390-1662 USA

248-960-7100

800-444-4351

Fax 248 960-7109

Patents USA 7070167 4793369, 4960142, 5174317, 5193561, 5485860 Canada 1299468 & Patents Pending

website: www.herkules.us

Made in the USA

e-mail: info@herkules.us

Page 2 of 8

Table of Contents

Warnings …………………………………………………………………………………………………………………. 3

Model Information (List of models with descriptions and data) ……………………………………………… 4

Installation ……………………………………………………………………………………………………………….. 5

Inspection ………………………………………………………………………………………………………………… 6

Operation ………………………………………………………………………………………………………………… 6

Maintenance …………………………………………………………………………………………………………. 7

Repair …………………………………………………………………………………………………………………….. 7

Drawings with part lists: ……………………………………………………………………………………………. 7-8

Warning Symbol Caution Symbol

Serial Number

Model Number

Purchase Date

Distributor

CAUTION

WARNING

This symbol alerts you to the possibility of

serious injury or death if you do not follow the

instructions.

This symbol alerts you to the possibility of

damage to or destruction of equipment if you

do not follow the instructions.

This product has patent protection under

one or more of the following patent numbers:

7070167, 5485860, 5193561, 5174317

4960142, 4793369, 1299468

and Patents Pending

website: www.herkules.us

1002742

PATENT NUMBERS

Page 3 of 8

FAILURE TO HEED THE FOLLOWING WARNINGS MAY RESULT

IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

1Herkules will not be held responsible for any personal injury and/or property damaged caused

due to owner/operator failure to follow the warnings and cautions listed in this manual.

2Read and understand all warnings, cautions and instructions before operating this equipment.

3It is the owner/operators responsibility to maintain the legibility of all warning and instruction labels.

4Do not alter or modify any part of this equipment.

5Do not attempt to bypass the door/latch interlock system. The door interlock is provided for operator safety.

6DO NOT open the door while the unit is operating. Always wait for the crusher to cycle completely.

7Crush only intended matter for the crusher.

8Always wear safety glasses when operating the crusher.

9Always wear suitable industrial gloves when handling crushed objects to prevent injury.

10 Check equipment regularly for proper operation and repair or replace worn or damaged parts immediately.

11 Any crusher that appears to be damaged in any way, is badly worn or operates abnormally shall be removed

from use until repairs are made. Use only manufacture's approved accessories and service parts.

Contact a factory authorized service center for repairs.

12 DO NOT REMOVE THIS LABEL. REPLACE IF DAMAGED.

WARNING

Page 4 of 8

Model Information

SPECIFICATIONS

Maximum crushing pressure 3.75 tons

Can capacity Four 1-gallon cans

Seven 1-quart cans

One 5-gallon can

Time to crush can 20 seconds

Overall width 33"

Overall height 91"

Overall depth 29"

Chamber width 14"

Chamber height 17.5"

Chamber depth 14"

Required air pressure 90-120 p.s.i.

Total weight 350 Ibs.

DESCRIPTION

Model HCR1 is a production crusher capable of crushing four 1-gallon cans or seven 1-quart cans or one 5-gallon can.

The stand accommodates a 55-gallon drum to collect crushed and ejected cans

The crusher provides the following features:

•Powerful 3.75 ton cylinder crushing plate assures the force necessary to do the job when crushing up to

7 quart cans.

•Operates with external air. No electric power is required.

•Safe double lock door protects operator.

•Lower slider plate automatically slides open at the end of the crushing cycle to eject cans into a disposal

drum located under the stand.

Page 5 of 8

OWNER/OPERATOR RESPONSIBILITY

It is the owner/operator responsibility to properly use and maintain this equipment.

The instructions and warnings contained in this manual shall be read and understood by the owner/operator prior

to operating this equipment.

If an owner/operator does not understand English, the contents of this manual shall be explained in the owner/

operator native language to assure the owner/operator comprehends.

It is the owner/operator responsibility to maintain the legibility of all warning and Instruction labels.

The owner/operator shall retain this manual for future reference to important warnings, operating and maintenance

instructions.

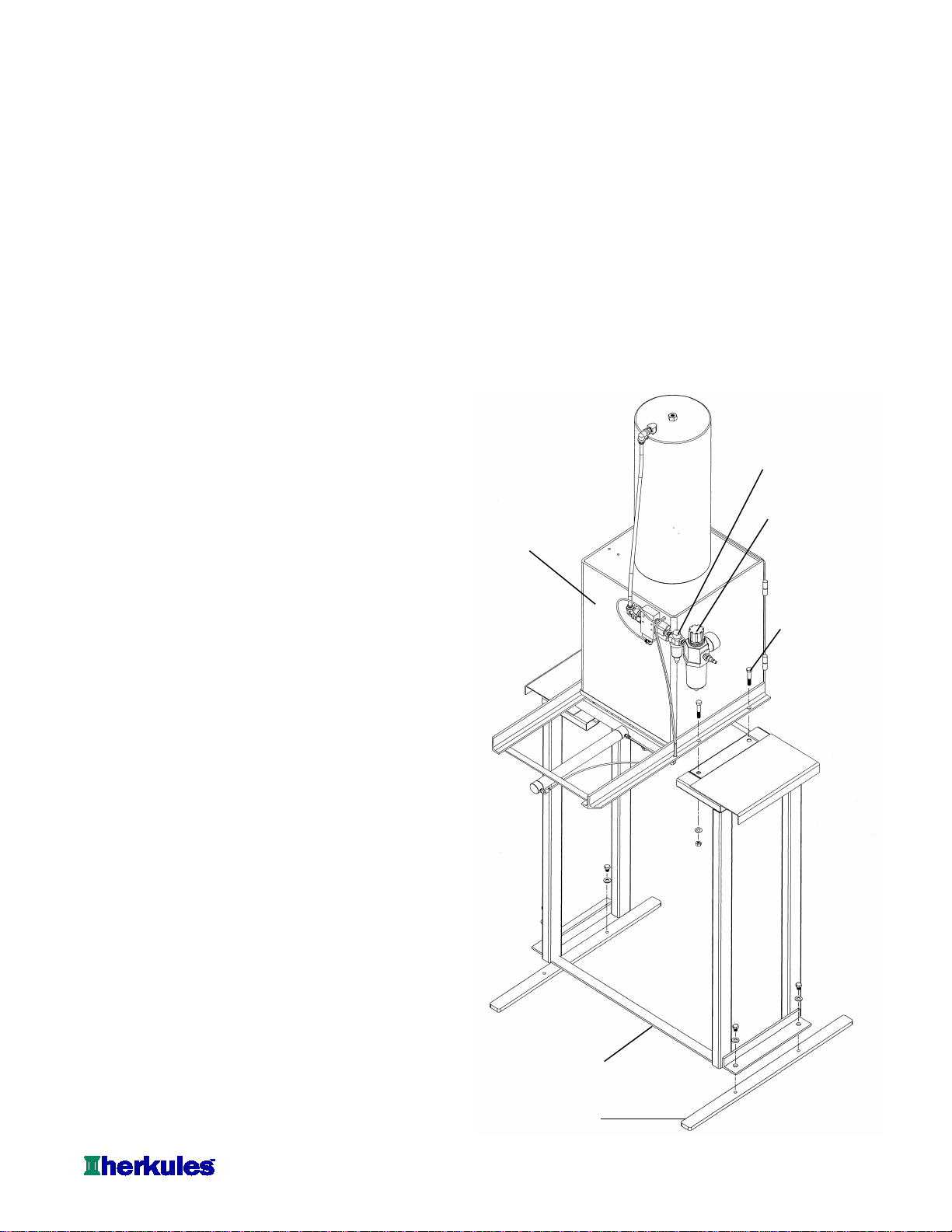

INSTALLATION

Installation consists of attaching the stabilizer

feet to the stand, the stand to the crushing

chamber, and connecting an external air

supply with 90 to 120 p.s.i.

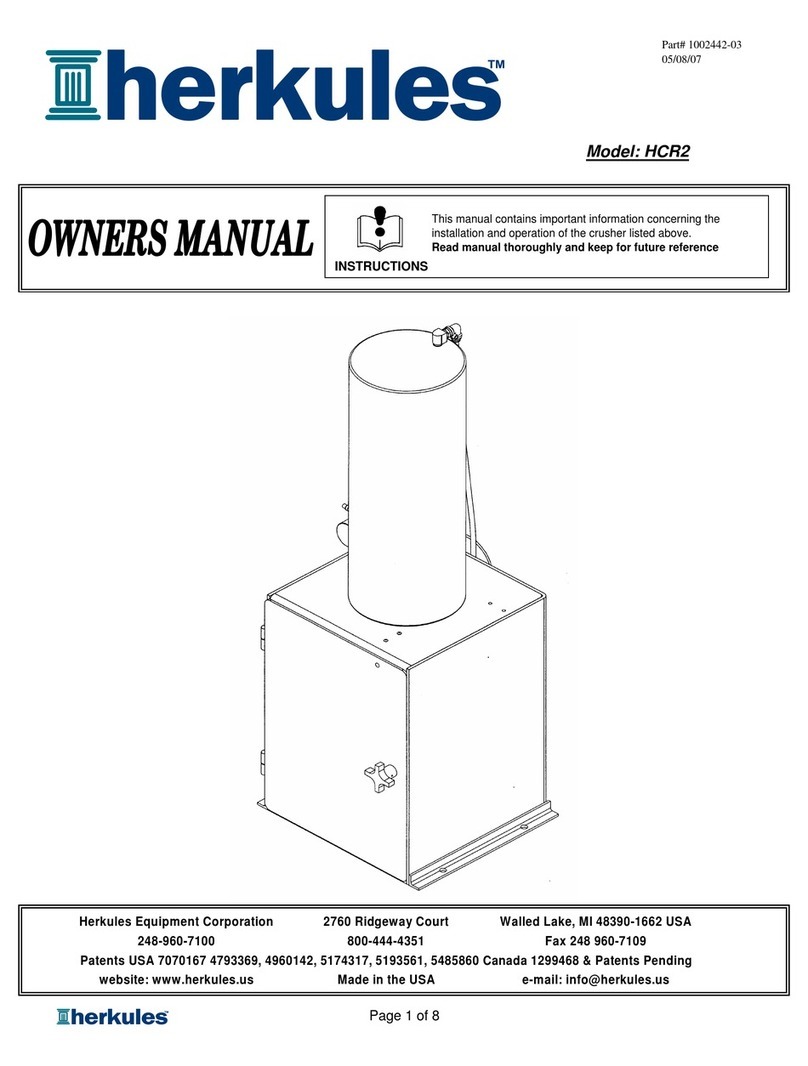

See Figure (1). Install the crusher as follows.

A. Bolt stabilizer feet to the crusher stand

using the four 3/8-16 x 3/4 bolts & washers.

B. Using a hoist or Hi-Lo, set the crusher chamber

on the stand with the upper crossbar facing

the front of the unit.

C. Bolt crusher chamber to stand using the remaining

3/8" hardware supplied.

D. Connect the supplied pressure

regulator/filter and oiler assembly to the 3/8"

valve located on the back of the crushing chamber.

E. Remove the bowl of the oiler and fill to 3/4 full with

30W non-detergent oil, replace bowl.

F. Set the oiler at about 1/3 of it's maximum drip rate.

Drip rate should be lowered if oil is noticed leaking

from the cylinder.

G. Connect the external air supply to

the pressure regulator/filter.

Figure 1

Stabilizer foot

Filter/Regulator

Crusher stand

3/8" Hex bolt

Crusher chamber

Oiler

Page 6 of 8

INSPECTION

Prior to operation a visual Inspection shall be made. Check crusher for leaks, worn or missing parts.

Periodically check oil level of oiler. DO NOT RUN WITHOUT OIL.

Any crusher that appears to be damaged in any way, is badly worn or operates abnormally shall be removed

from use until repairs are made. Contact a factory authorized service center for repairs.

If over pressurizing of the equipment is believed to have occurred, contact a factory authorized service center for

inspection of the crusher.

An annual inspection by a factory authorized service center is recommended.

OPERATION

Turn the external air supply on.

Verify the pressure gauge on the pressure regulator/filter reads between 100 and 120 p.s.i. Adjust the regulator

as required.

NOTE:

If the external air supply is less than 100 p.s.i., the crusher will operate but the crushing performance is reduced.

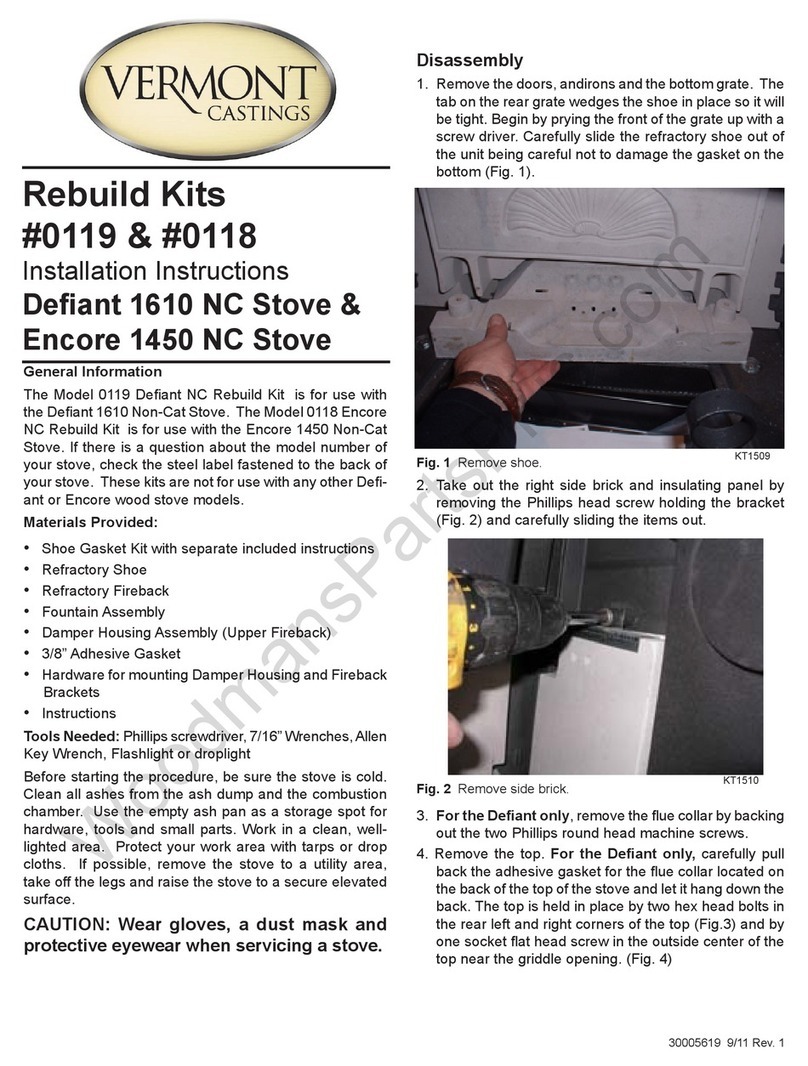

Open door and place empty can(s) in center of chamber. See fig.2 for proper placement of cans in crusher.

Close the door and latch it firmly.

The pneumatic piston will descend to crush the can(s). At the end of the crushing cycle (approx. 20 seconds) open the

door to end the crushing cycle. This will trigger the automatic ejection plate. The crushed can(s) will fall from the

chamber. Make sure and have a container underneath the crusher to catch the crushed can(s).

WARNING DISCLAIMER

The crushing mandrel may be still moving when the Remove all solvents from cans

door is opened. Wait until the mandrel stops before prior to crushing.

placing hand in chamber.

IMPORTANT!! LEAVE THE DOOR AJAR WHEN NOT IN USE.

WARNING

A crushed can may have jagged metal edges. Use

good industrial work gloves to protect the hands

when handling a crushed can.

Figure 2

CORRECT

INCORRECT

Page 7 of 8

SAFETY INFORMATION

Read and understand all warnings, cautions and instructions before operating this equipment. Caution should be used

when operating this equipment as personal injury and/or property damage can result from equipment misuse. Adequate

personal protection is recommended to prevent splashing of fluids on the skin or in the eyes.

MAINTENANCE

Regularly check the pressure filter/regulator moisture trap for water. Drain as required.

Periodically check oil level in oiler bowl. Fill with 30W non detergent oil to 3/4 full when necessary.

DO NOT RUN WITHOUT OIL.

Regularly clean the crusher chamber to remove any accumulated sludge, metal particles or any other debris that

could affect the crusher operation.

Apply grease to door hinges on a regular basis to prevent the door from binding.

Apply motor oil to door latch pivot points on a regular basis to prevent latch from binding.

REPAIR

No service parts are available for this can crusher. Special tools and procedures are required for repair. If

repair is required, contact Herkules Equipment Corporation Customer Service, (800-444-4351) for your nearest authorized

service center.

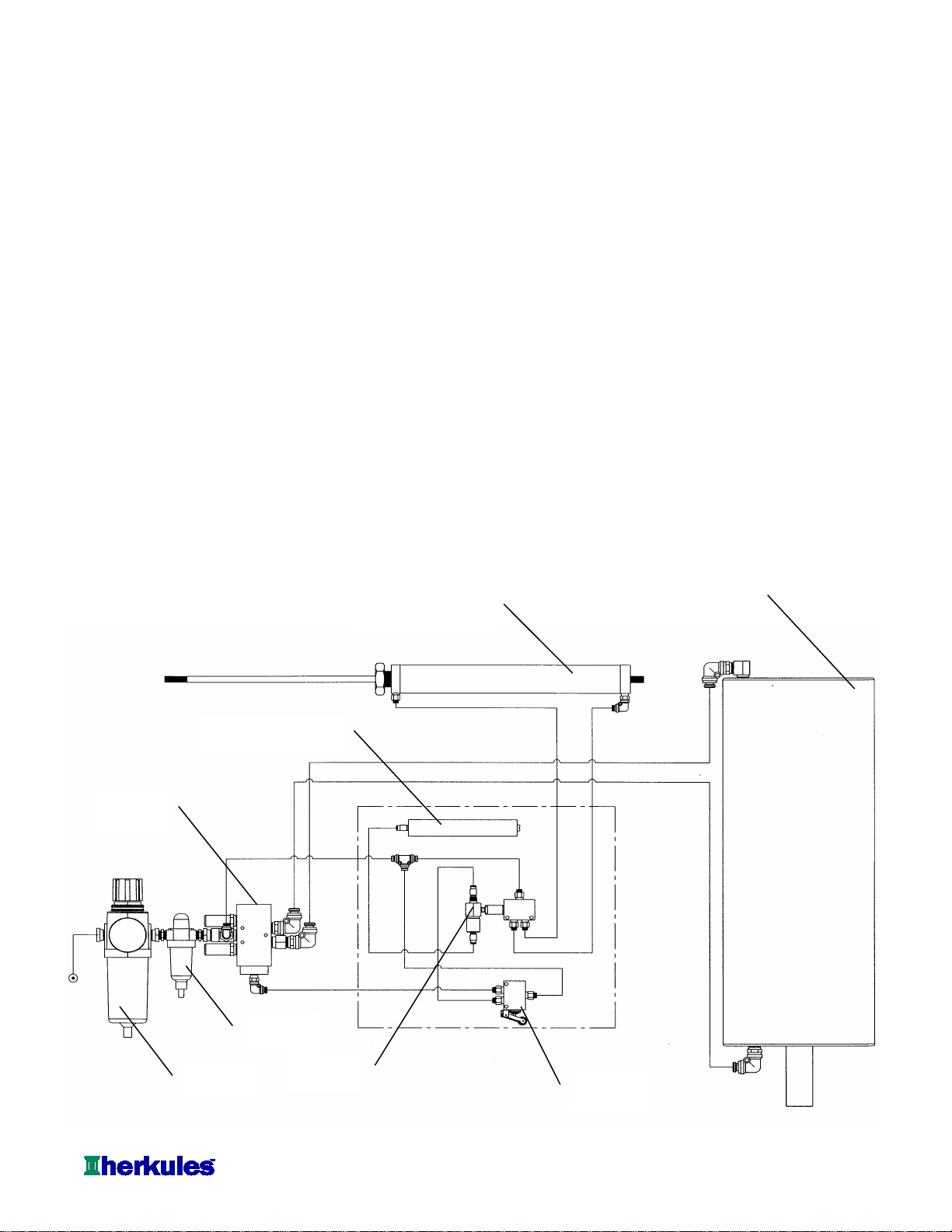

AIR SCHEMATIC/SERVICE PARTS

Valve

#10060

Valve

#10278 Valve

#10172

Volume Chamber

#008-642

Regulator

#008-236

Oiler

#T18

Cylinder

#1003499

Cylinder

#008-604

Page 8 of 8

SERVICE PARTS

Crusher Chamber

#12032

Cylinder

#008-604

Ram Plate

#10055

Stand

#12031

Cylinder

#1003499

Pilot Valve

#10060

Stabilizer Foot

#10244

Ejection Plate

#10067

Table of contents

Other HERKULES Stove manuals

Popular Stove manuals by other brands

Comfort Glow

Comfort Glow SL30PT Series OWNER'S OPERATION AND INSTALLATION MANUAL

Woodfire

Woodfire Passiv Operation and installation manual

WANDERS

WANDERS Larix User guide and installation manual

Ecowood

Ecowood TROLLEY Installation, User’s and Maintenance Handbook

IKOS

IKOS ECOpellets 8 user manual

Intertek

Intertek 25-CAB80 manual