Hetronic Locomotive Nova XL User manual

OOPMN_LNO__009

April 2015

LOCOMOTIVE

OPERATING INSTRUCTIONS

LOCOMOTIVE SYSTEM

www.hetronic.com

LOCAL BUT GLOBAL

1

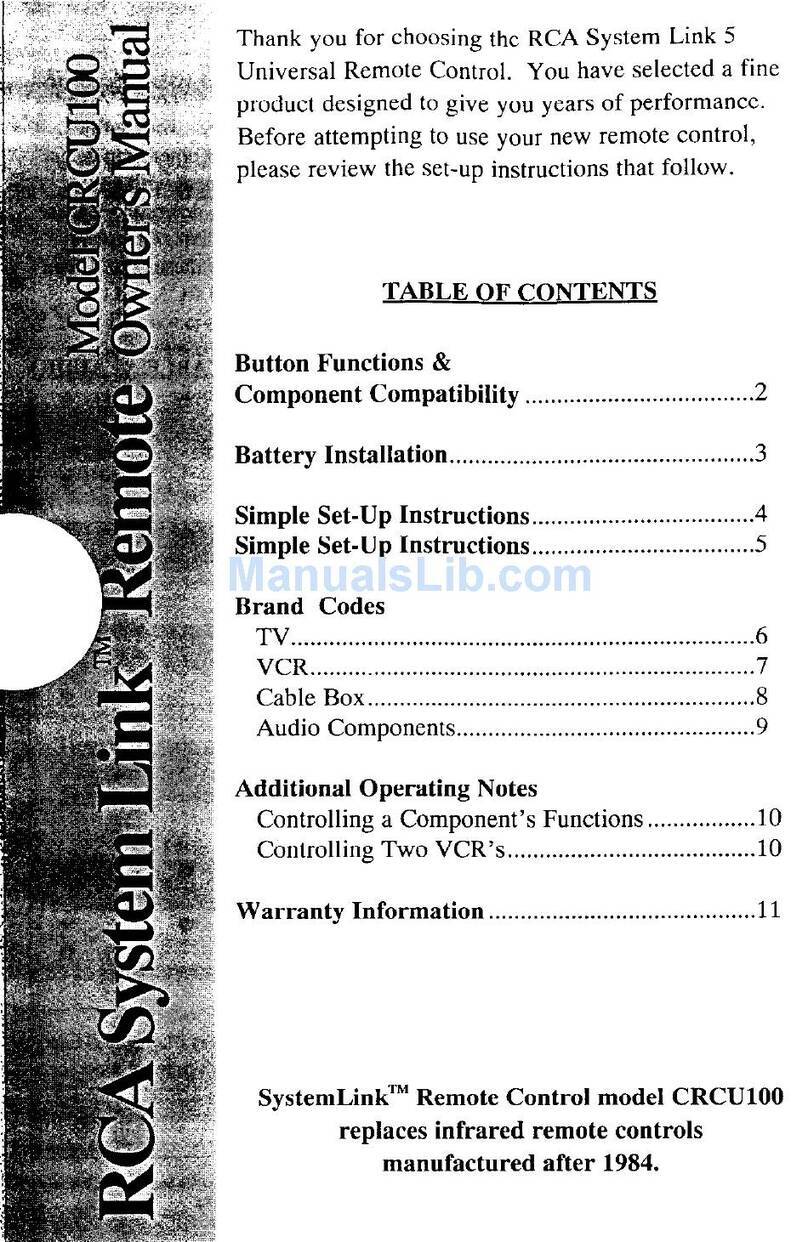

TABLE OF CONTENTS

SAFETY................................................................................................................................................................ 4

SAFETY ALERTS ............................................................................................................................................ 4

NOTATIONS .................................................................................................................................................... 4

PRACTICES AND LAWS................................................................................................................................. 4

REQUIRED OPERATOR TRAINING............................................................................................................... 4

POSSIBLE SOURCES OF DANGER..............................................................................................................4

PROTECTIVE FEATURES..............................................................................................................................4

TO STOP IN AN EMERGENCY ...................................................................................................................... 4

MAINTENANCE...............................................................................................................................................4

DRAWINGS AND OPERATION GUIDE..........................................................................................................4

INTRODUCTION.................................................................................................................................................. 5

YOUR MANUALS ............................................................................................................................................ 5

PRODUCTION AND SYSTEM NUMBERS .....................................................................................................5

BEFORE OPERATING YOUR SYSTEM......................................................................................................... 5

INSTALLATION CONSIDERATIONS .................................................................................................................. 6

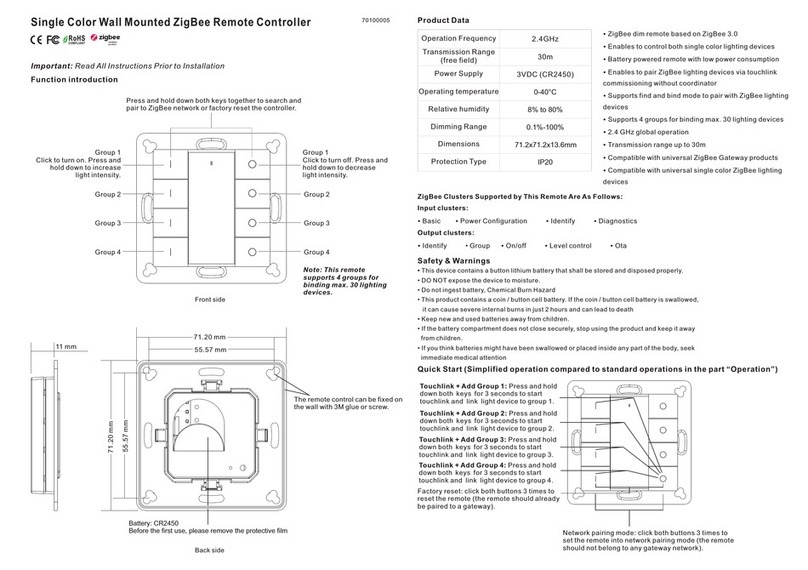

COMPONENTS.................................................................................................................................................... 7

LOCOMOTIVE PNEUMATIC PANEL (H0-00133)........................................................................................... 7

LOCOMOTIVE LCD PANEL (H0-00133).........................................................................................................7

LOCOMOTIVE ISOLATION PANEL (H0-00132).............................................................................................8

ISOLATION CONNECTION............................................................................................................................. 8

JUMPER CABLE (H9-00769) ..........................................................................................................................8

ESTOP JUMPER (H9-00644)..........................................................................................................................8

MU MOUNTING EQUIPMENT.........................................................................................................................8

MU Cable (H9-00734).................................................................................................................................. 8

Main Reservoir (K18009) –L Gladhand...................................................................................................... 8

Train Brake (K18019) –F Gladhand............................................................................................................ 8

Independent & AP Brake (K18008) –H Gladhand......................................................................................9

Pneumatic Horn (K18010)................................................................................................................................9

Electric Bell (K18138)....................................................................................................................................... 9

REMOTE ESTOPS (HL0001).......................................................................................................................... 9

REMOTE SPEED SENSOR (HL0004) ............................................................................................................ 9

MAST (HL0002) ............................................................................................................................................... 9

UPRIGHT ANTENNAS (K18064)...................................................................................................................... 9

OPTIONAL EXTERNAL ANTENNAS (K18125) .............................................................................................. 9

2

CHANGING YOUR BATTERY...........................................................................................................................11

DISPOSABLE BATTERIES:...................................................................................................................... 11

RECHARGEABLE BATTERIES (68108580.A):........................................................................................11

RECHARGING YOUR BATTERIES (OPTIONAL).........................................................................................11

FAST CHARGE .........................................................................................................................................11

BATTERY DISPOSAL....................................................................................................................................12

OPERATING YOUR TRANSMITTER ................................................................................................................ 13

TRANSMITTER..............................................................................................................................................13

READ THIS FIRST.........................................................................................................................................13

YOUR OPERATING RANGE......................................................................................................................... 13

HOLDING YOUR TRANSMITTER.................................................................................................................13

VISUALLY CHECKING YOUR TRANSMITTER............................................................................................13

CHECKING HOSES AND THE CONNECTION ............................................................................................13

STARTING YOUR TRANSMITTER...............................................................................................................14

STOPPING YOUR TRANSMITTER .............................................................................................................. 14

SAFETY FEATURES.....................................................................................................................................14

LOW BATTERY INDICATOR....................................................................................................................14

VIGILANCE (RADIO CONTROL SYSTEM or RCS) S2 and S3 ...............................................................14

TILT ALARM..............................................................................................................................................15

PUSH TO OPERATE THROTTLE (PTO) - Optional.................................................................................15

OPERATING THE TRAIN.............................................................................................................................. 15

RELEASING THE BRAKES ...................................................................................................................... 15

SELECTING DIRECTION..........................................................................................................................15

SAFE MODE CONSIDERATIONS ................................................................................................................15

AUTOMATIC SAFE MODE ACTIONS ......................................................................................................15

EXITING SAFE MODE ..............................................................................................................................15

ENGAGING THE THROTTLE (S12) .........................................................................................................15

OPERATING THE TRAIN BRAKES..........................................................................................................16

OPERATING THE INDEPENDENT BRAKES (LOCOMOTIVE) ............................................................... 16

CHANGING DIRECTION...........................................................................................................................16

ADDITIONAL FUNCTIONS (OPTIONAL)......................................................................................................16

SAND FUNCTION (S4) .............................................................................................................................16

BELL FUNCTION (S7)............................................................................................................................... 16

HORN FUNCTION (S5).............................................................................................................................16

PITCH and CATCH....................................................................................................................................16

SPEED CONTROL....................................................................................................................................16

INCREASE SPEED ...................................................................................................................................16

3

INCREASE SPEED AGAIN.......................................................................................................................16

REDUCE SPEED ......................................................................................................................................16

COAST.......................................................................................................................................................17

ROLL BACK PROTECTION ..........................................................................................................................18

DATA LOGGING (option)............................................................................................................................... 18

GPS and/or GSM (option)..............................................................................................................................18

VIDEO (option)...............................................................................................................................................18

LCD, LED AND OPTIONAL RECEIVER DISPLAY INDICATOR MEANINGS..............................................19

Table 1: LCD Indicators and Meanings .....................................................................................................19

Table 2: Typical LED Indicator Meanings..................................................................................................19

Table 3: Receiver Graphic Display ............................................................................................................20

TROUBLESHOOTING ....................................................................................................................................... 22

MAINTENANCE .................................................................................................................................................23

PNEUMATIC FILTERS..............................................................................................................................23

MAIN RESERVOIR FILTER (AFF-EL11B)................................................................................................23

MIST REMOVER FILTER (AF30P-060S) ................................................................................................23

PILOT FILTER (AFM30P-060AS)..............................................................................................................23

Changing Filters.............................................................................................................................................23

SPECIFICATIONS..............................................................................................................................................23

SPECIFICATIONS FOR ALL MODELS.........................................................................................................23

WEIGHT, DIMENSIONS AND TRANSMITTER OPTIONS PER MODEL.....................................................24

4

SAFETY

SAFETY ALERTS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

Understand the safety message. It contains

important information about personal safety on or

near the unit.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT

in death or serious injury.

DANGER: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD

RESULT in death or serious injury.

DANGER: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT

in minor or moderate injury. It may also be

used to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for proper

operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions for the benefit of yourself and others.

Be alert to unsafe conditions and the possibility of

minor, moderate, or serious injury or death. Learn

applicable rules and laws in your area.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be

used by someone other than original purchaser;

loaned, rented or sold, ALWAYS provide this manual

and any needed safety training before operation.

ALWAYS read and understand the documentation

for any machine to be controlled by radio remote

control.

POSSIBLE SOURCES OF DANGER

This device is part of a system that makes remote

control via radio signals possible. However, the

transmission of control commands can take place

around obstacles and out of the operator’s direct

sight. Take the following precautions to prevent

accidental start-up and possible injury or damage:

1. Switch “OFF” the transmitter when it is not in

use. If equipped, remove the key if the unit is

placed any distance away from the operator.

2. Disconnect the power supply from the

receiver before any assembly, maintenance

or repair work is done.

IMPORTANT: AVOID SYSTEM DAMAGE -

ALWAYS disconnect receiver power

supply and control wiring before

welding on any part of the machine.

3. NEVER remove or alter any of the safety

features.

4. ALWAYS confirm that the machine and

radio remote control Stop functions work

properly BEFORE beginning any machine

operation.

PROTECTIVE FEATURES

This system is equipped with electronic and

mechanical safety features. Control signals from

other transmitters cannot be processed because

transmission coding is unique to each system

TO STOP IN AN EMERGENCY

Push the emergency stop on the machine.

MAINTENANCE

ALWAYS shut off power to the machine, transmitter

and receiver before any assembly, maintenance or

repair.

DRAWINGS AND OPERATION GUIDE

ALWAYS refer to your system drawing and

Operational Guide if you have specific questions on

how your system should operate. This manual is

intended only as a supplement to your system

drawings for reference. Your system may be

customized for your specific application.

5

INTRODUCTION

Thank you for purchasing the Hetronic radio remote

control system. Hetronic radio remote controls

provide outstanding remote control value, quality,

performance, and safety.

YOUR MANUALS

Before operating your machine and radio remote

control system, review your drawings and read and

understand the manuals for all of your system

components.

PRODUCTION AND SYSTEM NUMBERS

Before contacting your dealer or Hetronic about

service, repair or replacement parts, note the

equipment Production and System numbers. These

numbers are located on the label affixed to the unit.

BEFORE OPERATING YOUR SYSTEM

Confirm that installation of all your system

components has been properly completed.

Before start up, ALWAYS confirm that the machine

and radio remote control Stop functions work

properly.

Understand all Safety Precautions provided in the

manuals and review control functions and operation

of the machine and this radio remote control system.

When not in use, turn the transmitter off and store in

a safe place to prevent unauthorized use.

If the machine does not respond properly,

immediately stop operation, turn off the transmitter

and report the condition to your supervisor.

Turn off the transmitter and remove the key (if so

equipped) before any maintenance work is done.

Always have fresh batteries on hand or an optional

rechargeable battery pack in the battery charger to

ensure the availability of a fully charged battery.

Installation, setup and service must be performed by

authorized and qualified personnel only.

6

INSTALLATION CONSIDERATIONS

Read and understand the following considerations

to ensure the proper installation of your system:

•Isolate the radio control system from the

locomotive when operating in manual

mode.

•The relays in the radio control system are

rated for up to 5 amps unless otherwise

specified. We have an optional relay

intended to operate (turn on) the lights.

Please check your drawings to ensure this

was included on your order.

•When installing the antennas always touch

the ends of the antenna and connector at

the same time with your fingers to remove

any static charge.

•The system must have the antennas

installed on the receiver and transmitter

prior to turning the system on. Operating

the system without antennas will damage

the system over time.

•Depending on the locomotive condition,

please determine the need for isolation

(surge suppression) to protect our radio

control system. If necessary, please

contact the factory for parts.

7

COMPONENTS

Use the following as guidelines; always refer to your drawings for your specific system. The components

described in this section pertain to an MU installation system with isolation and a mast antenna. We are using

this system as a reference. Other systems may have different components and/or configurations. Again,

please refer to your drawings for your specific system as it may be different.

LOCOMOTIVE PNEUMATIC PANEL (H0-00133)

This is not applicable for all other versions of locomotive panels. This panel provides all pneumatic control for

the locomotive. There is a program (diagnostic) port (X3) for remote connection, programming updates and

troubleshooting.

LOCOMOTIVE LCD PANEL (H0-00133)

This is not applicable for all other versions of locomotive panels. This panel provides the electrical connection

to the locomotive.

8

LOCOMOTIVE ISOLATION PANEL (H0-00132)

This is not applicable for all other versions of locomotive panels. The isolation panel provides fusing for all

external voltages from the locomotive. If a fuse or breaker has been overloaded, the locomotive LCD panel will

display the error “FUSE”.

ISOLATION CONNECTION

This connects X12 to the locomotive LCD panel X5.

It also connects X11 to the locomotive pneumatic

panel’s X2. The ESTOP jumper (H9-00644) is

connected to X1. The MU cable (H9-00734) is

connected to X6.

JUMPER CABLE (H9-00769)

This connects the locomotive pneumatic panel X1

with the locomotive LCD panel X4.

ESTOP JUMPER (H9-00644)

This is connected to the Isolation panel’s X1.

MU MOUNTING EQUIPMENT

The Hetronic mounting equipment described is for

H12-00344 only. Locomotives vary widely and

Hetronic cannot guaranty the locomotive’s

configuration. All locomotive documentation and

procedures supersede information in this document.

MU CABLE (H9-00734)

This cable connects to the isolation panel’s X6

connector and the locomotive’s MU plug.

MAIN RESERVOIR (K18009) –LGLADHAND

Connects to locomotive pneumatic panel’s “MAIN”

and the locomotive main reservoir.

TRAIN BRAKE (K18019) –FGLADHAND

Connects to locomotive pneumatic panel’s “TRAIN

BK”and the locomotive train brake

9

INDEPENDENT &AP BRAKE (K18008) –HGLADHAND

This Connects to locomotive pneumatic panel

connection “IND BK” & “ACTUATING PIPE” and the

corresponding independent brake and actuating

pipe.

PNEUMATIC HORN (K18010)

The horn is utilized when a man-down is present or

when it is manually activated by the operator. It

connects to the locomotive pneumatic panel’s

pneumatic connection “HORN”.

ELECTRIC BELL (K18138)

The bell is activated when locomotive motion is

commanded or when it is manually activated by the

operator. It connects to the locomotive pneumatic

panel electrical connection X4.

REMOTE ESTOPS (HL0001)

The remote estops provide a junction for the remote

speed sensor, Estop and direction selection. The

estops connect to the locomotive LCD panel at X1 &

X2. The direction switch should always be switched

to the direction of the locomotive pneumatic panel.

REMOTE SPEED SENSOR (HL0004)

The remote speed sensor provides closed loop

feedback to the locomotive LCD panel. X2. The

direction switch should always be switched to the

direction of the locomotive pneumatic panel.

MAST (HL0002)

This is not applicable for all other versions. The

mast provides additional range and clearance of

antenna cables on the locomotive. The system

requires external antennas for operation. Please

refer to your drawing for assembly.

UPRIGHT ANTENNAS (K18064)

These are upright antennas that mount on the mast.

They connect to the locomotive pneumatic panel at

W1 and W2. The antennas are interchangeable. For

a picture, see mast (HL0002).

OPTIONAL EXTERNAL ANTENNAS

(K18125)

These are magnetic mount antennas that should be

placed a minimum of five feet apart and as high as

possible. The two antennas connect to the

locomotive pneumatic panel at W1 and W2. The

antennas are interchangeable.

10

11

CHANGING YOUR BATTERY

You may power your transmitter with disposable or

rechargeable batteries. Both types use adapter

cases that are inserted into the back of the

transmitter.

Follow the instructions below for your battery type.

DISPOSABLE BATTERIES:

1. Insert 3 AA batteries into the back of the

Standard Battery Adapter Case

(11243600).

NOTE: Battery positions are shown in the battery

slots on the back of the Standard Battery

Adapter Case housing.

2. Slide the loaded Standard Battery Adapter

Case into the battery compartment on the back

of the transmitter housing and snap into place.

RECHARGEABLE BATTERIES (68108580.A):

1. Confirm that your batteries are fully-charged.

See “Recharging Your Batteries (Optional)” on

page 11.

2. Slide a fully-charged battery into the battery

compartment on the back of the transmitter as

shown, and snap it into place.

RECHARGING YOUR BATTERIES

(OPTIONAL)

DANGER:EXPLOSIVE GASES AND FLYING

DEBRIS can cause death or serious injury.

Use only Hetronic replacement rechargeable

batteries. Use of unauthorized replacement

batteries can cause a battery explosion,

resulting in injury or death of the operator or

other people in the work area.

1. Insert the spent optional rechargeable battery

adapter case into the battery charger and snap

into place as shown.

The LED labeled “CHARGE” flashes for two

seconds, then stays lit during the charging process.

When the battery is fully charged, the “READY”

LED lights up and the “CHARGE” LED goes off.

NOTE: Charging time could take up to 5 hours,

depending on the condition of the battery.

Leave the battery in the charger until it is needed.

The charger supplies a “trickle” charge but will not

over-charge the battery.

FAST CHARGE

Insert the battery into the charger as described

above. The LED labeled “CHARGE” flashes for two

seconds, then stays lit.

Press the “FAST CHARGE” button. The FAST

CHARGE LED lights also and stays lit during the

charge process.

When the battery is fully charged, the “READY” LED

lights up and the “CHARGE” and “FAST CHARGE”

LEDs turn off.

12

BATTERY DISPOSAL

AVOID ENVIRONMENTAL POLLUTION.

Recycle your rechargeable batteries according to

local recycling rules and regulations.

If you have questions or problems operating your

battery charger, please contact your dealer or

Hetronic.

Standard Hetronic rechargeable batteries are the

nickel metal hydride type. These batteries have no

“memory effect” when charging a battery that is not

fully discharged.

13

OPERATING YOUR TRANSMITTER

TRANSMITTER

Use the following as guidelines; always refer to your drawings for your specific system.

READ THIS FIRST

Understand the following safety considerations and

take the appropriate actions:

•Always store your transmitter key in a safe

location to avoid unauthorized use

•Do not allow your transmitter batteries to

completely run down. Your transmitter is

programmed to notify you when there are 10

minutes of remaining battery life.

•The transmitter sends STOP messages

when battery power has 30 seconds or less

battery life.

•When the battery is removed, the transmitter

enters STOP mode, brakes are applied and

all functions are disabled.

YOUR OPERATING RANGE

The standard system range is 3,000 feet (line of

sight) in an interference free environment. More

range is available upon request.

HOLDING YOUR TRANSMITTER

Hold your transmitter upright with the front facing

you. Confirm that you are able to easily read and

understand any operation text or symbols.

Complete the following procedures once a day,

before the start of an operation and at shift changes.

WARNING: Test the stop function as

described in the locomotive manufacturer’s

documentation prior to operation.

VISUALLY CHECKING YOUR

TRANSMITTER

Always check the transmitter for any physical

damage before any operation.

Check equipment for wear or damage and confirm

that you can read and understand all of the safety

labels.

Never operate with worn or damaged parts.

CHECKING HOSES AND THE

CONNECTION

Before starting the transmitter, ensure that all hoses

and the MU connection is properly seated.

14

STARTING YOUR TRANSMITTER

WARNING: To avoid accidental start-up,

always press STOP when not in use.

NEVER operate the locomotive if the stop

function does not work properly.

NOTE: When the transmitter is not in use, store the

transmitter in a secure place.

WARNING: Improper operation,

maintenance or adjustment may cause

serious injury or equipment damage, and

may void the warranty.

1. Confirm that all safety measures required by

the equipment manufacturer were followed.

2. Insert a battery adapter with fresh ‘AA’

batteries into the battery compartment.

NOTE: If using rechargeable batteries, confirm

that they are fully charged.

3. Verify that all switches, levers and joysticks

are turned OFF or neutral position.

4. Follow the equipment manufacture

guidelines and testing for switching the

locomotive from manual mode to trail mode.

The receiver powers ON and Isolation is set

to RUN, engages STOP, sets any applicable

brakes and disengages any set functions.

5. Rotate the KEY SWITCH (Q1) to the ON

position.

A buzzer sounds, the transmitter LEDs flash

and the antenna icon appears on the LCD

display.

On the receiver, a radio link and safe mode

message appears.

6. Press the green START button (S1).

Main reservoir and preset brake pressures

are verified. See the LEDs light green.

7. Wait for the system to complete the following

checks:

NOTE: If pressures are out of range, the STOP

command will be transmitted.

•Main reservoir pressure check—if the

pressure is in range (default 90 psi), the Main

Reservoir LED lights green.

•Locomotive independent brake fully applied

check—if the pressure is in range (default 45

psi), the Loco Brake Fully Applied LED lights

green.

•Train brake fully applied check—if the

pressure is in range (55 psi is the default,

your application may vary from 0 to 70psi),

the Train Brake Fully Applied LED lights

green.

8. Press the START button (S1) again if

needed.

9. The safe mode indicator disappears and

brake pressure readings appear on the

transmitter display.

10. The word ACTIVE appears on the

receiver display and the safe mode

message disappears. You are now in

radio remote control of the locomotive.

NOTE: The independent brake must be fully applied

(S9) before activating the reverser switch

(S10) or the system will enter safe mode.

NOTE: See “Safety Features” on page 15 to

understand the safety features designed to

shut down the system if it is not activated in a

specified amount of time.

DANGER: If the locomotive does not operate

as expected. Shut down the system and

contact your supervisor for next steps.

STOPPING YOUR TRANSMITTER

Press STOP (S0).

The following actions automatically occur:

•Locomotive throttle is set to idle.

•Locomotive brake pressure is adjusted to

the preset level (typically above 45 psi).

•Train brake pressure is adjusted to preset

level (typically 55 psi or below).

SAFETY FEATURES

LOW BATTERY INDICATOR

When the low battery indicator LED lights red, insert

fresh batteries. The battery compartment is located

on the back of the transmitter.

NOTE: The low battery indicator LED lights red when

there is about 10 minutes of remaining

battery life.

VIGILANCE (RADIO CONTROL SYSTEM OR RCS)

S2 AND S3

For safety reasons, if the throttle, brakes, horn, sand

or bell functions are not used within a specified

amount of time (default-50 seconds, some

applications require a longer time), a warning buzzer

will sound for up to a specified amount of time

(default-10 seconds) before system shutdown.

To avoid system shutdown, touch handle S2 or S3

(optional RCS buttons are available). The touch

sensors are looking for a change in state. So you

may have to let go of the handles. Please see your

system drawings if you have any questions.

15

TILT ALARM

For safety reasons, if the transmitter is tilted at an

angle of 45 degrees or more for a specified amount

of time (default -2 seconds), the tilt alarm will sound

for a specified amount of time (default- 10 seconds).

If the transmitter is not tilted back to an acceptable

angle within a specified amount of time, the system

will shutdown (some models may have the optional

audio out to the walky-talky system).

** Cellular Man Down Feature

1) This should not be considered as a

PRIMARY SAFETY feature.

2) SUPPLIER DOES NOT GUARANTEE YOU

UNINTERRUPTED SERVICE OR COVERAGE.

3) SUPPLIER MAKES NO WARRANTY,

EXPRESS OR IMPLIED, FOR THE SUITABILITY,

ACCURACY, SECURITY, TIMING, OR

PERFORMANCE REGARDING THE “MAN DOWN”

ALERT, AND IN NO EVENT SHALL SUPPLIER BE

LIABLE, WHETHER OR NOT DUE TO THEIR OWN

NEGLIGENCE, FOR DAMAGE OR INJURY

CAUSED BY FAILURE OR DELAY IN

TRANSMITTING THE “MAN DOWN” ALERT.

PUSH TO OPERATE THROTTLE (PTO) -OPTIONAL

The touch sensor (S2 and S3) in the handle may

also be used as a type of PTO. Please refer to

your drawings if you have any questions on

operating your specific system.

OPERATING THE TRAIN

RELEASING THE BRAKES

Always follow the manufacture

recommendation for testing brakes.

1. Hold the Independent (Locomotive) Brake lever

or joystick (S9) in the release position until the

brakes are fully released (pressures vary per

application).

2. Any time the Independent brake is released,

you systems will automatically put 90 psi to the

actuating pipe. If this is not necessary, please

plug this port.

3. Hold the Train Brake lever or joystick (S8) in

the full release position. As a standard, the

system puts 90 psi to the train brake line

(pressures may vary per application).

SELECTING DIRECTION

With the independent brakes applied, place the

Reverser switch (S10) in the desired position. As a

standard, the independent brakes are automatically

applied if the operator fails to set the brake prior to a

direction change. Refer to you drawings for more

details.

SAFE MODE CONSIDERATIONS

If a fault is detected, the system will automatically

enter safe mode. Faults include, but may not be

limited to, the following conditions:

•Main reservoir below preset level;

•Communication has not taken place in the

preset amount of time (transmitter is turned

off, battery is removed from the transmitter,

and the transmitter goes out of range);

•Train brake pressure below preset level

•Change of direction without the independent

brake set.

AUTOMATIC SAFE MODE ACTIONS

The following actions automatically occur in safe

mode:

•The preset brakes are applied (typically the

independent brake);

•Directional outputs are disabled;

•The transmitter LCD will alternately display

the “!!” symbol and brake pressure numbers.

EXITING SAFE MODE

To exit safe mode, confirm that the following

conditions have been met:

•Main reservoir LED is ON;

•The train brake BELOW 45 PSI LED is OFF

(if applicable);

•The INDEPENDENT BRAKE LED is ON;

•The TRAIN BRAKE LED is ON;

•The throttle (S12) is set to the IDLE position;

•The FORWARD/REVERSE (S10) toggle

switch is in the CENTER or NEUTRAL

position.

ENGAGING THE THROTTLE (S12)

Refer to your drawing to determine the type of

throttle used with your application and take

the appropriate steps to engage the throttle:

•Non-push to Operate—press the joystick or

lever in the desired direction.

•Push to Operate—Touch handle S2 or S3

and then press the joystick or lever in the

desired direction. (S12).

16

OPERATING THE TRAIN BRAKES

Use the following as guidelines; always refer to

your drawing for your specific system.

•Releasing the Train Brakes: Hold the Train

Brake lever (S8) in the full release position.

As a standard 90 psi will be put into the train

brake line.

•Applying the Train Brakes: Move the Train

Brake lever (S8) to the desired train brake

position and release it when the desired

pressure is reached.

NOTE: Refer to your locomotive manufacture

recommendations for applying and

releasing train brakes.

OPERATING THE INDEPENDENT BRAKES

(LOCOMOTIVE)

Use the following as guidelines; always refer to

your drawings for your specific system.

NOTE: Independent brake pressures increase and

decrease as the locomotive brake lever (S9)

is held in the desired position.

•Applying the Independent Brakes: Hold the

Independent Brake lever (S9) toward

Independent Brake, and release it when the

desired pressure is reached.

•Releasing the Independent Brakes: Hold the

Locomotive Brake lever (S9) in the Release

position, and release it when the desired

pressure is reached.

CHANGING DIRECTION

WARNING: Failure to bring the locomotive to a

complete stop before changing direction may

result in damage to the locomotive.

Take the following steps to change direction:

1. Bring the locomotive to a complete stop.

2. Fully apply the independent brake (S9) if this

was not already completed

3. Place the Reverser switch (S10) in the

desired position.

4. Release the independent brake (S9) as

needed

ADDITIONAL FUNCTIONS (OPTIONAL)

SAND FUNCTION (S4)

Press the Sand button to release sand onto the

track.

BELL FUNCTION (S7)

Press the Bell button or toggle to sound the bell.

HORN FUNCTION (S5)

Press the Horn button or toggle to sound the horn.

PITCH AND CATCH

Note: Both Transmitters must be in the same state.

The locomotive must be stopped and the reverse

switch (S10) be in the neutral position

1. Operator 2 requests control of the locomotive

by pressing S1 for five seconds. Both

transmitters will flash 1/2 to indicate P&C

mode.

2. Operator 1 (identified as transmitter 1 on the

transmitter) releases control of the

locomotive (S1 for five seconds).

3. Operator 2 now has control of the

locomotive. Operators 2’s transmitter will

now be identified as transmitter 1.

SPEED CONTROL

Use the following as guidelines; always refer to your

drawings for your specific system. Also, not all

locomotive MU plugs are equipped for excitation. Please

refer to your locomotive’s manual.

INCREASE SPEED

1. Move S6 to the desired position for your

application

a. Yard (left) –Speed Control using

notch for flat grade

b. Manual (center) - Manual control like

the cab

c. Hump (right) –Speed Control using

excitation for a track with a grade

2. Follow you locomotive manufacture

recommendation for releasing the train

brakes and independent brake (see

Operating the Train Brake and Operating the

Independent Brake sections in this manual)

3. Touch the transmitter handles (S2/3) see the

blue vigilance LED turn on

4. Move the throttle joystick (S12) into the

desired speed position

INCREASE SPEED AGAIN

1. Touch the transmitter handles (S2/3) see the

blue vigilance LED turn on

2. Move the throttle joystick S12) into the new

speed position.

REDUCE SPEED

Use the following as guidelines; always refer to your

drawings for your specific system.

1. Move the throttle (S12) back to the new

desired speed position.

2. As a standard, it is not necessary to touch

the RCS (if applicable) or the transmitter

17

handles (S2/3) to reduce speed.

COAST

Use the following as guidelines; always refer to your

drawings for your specific system.

1. Move the throttle (S12) back to the coast

position.

2. As long as the locomotive is not exceeding 5

mph, the locomotive will coast to a stop and

the brakes will apply after 20 seconds of no

movement.

3. If the locomotive is exceeding 5 mph, the

brakes will apply in a set amount of time at a

set rate until the locomotive goes below

5mph, at which time the brakes will release

and coasting can proceed.

18

ROLL BACK PROTECTION

Use the following as guidelines; always refer to

your drawings for your specific system.

1. If applicable, please confirm that the

direction switches on the remote Estop

(HL0001) point toward the locomotive

system.

2. If the wheel sensors detect the locomotive

rolling the opposite direction than what is

selected, the independent brakes will be

applied to stop the roll back.

DATALOGGING (OPTION)

Check your drawings to confirm you system

includes this option.

Your locomotive system has the capability of

working with a data logger. The data logger

captures all the inputs and outputs of the system.

It also captures any status information.

The information is stored on a removable card.

The information can also be remotely accessed.

Please see your drawings for more information.

GPS AND/OR GSM (OPTION)

Check your drawings to confirm you system

includes this option.

Your locomotive system has the capability of

working with a GPS/GSM for speed control,

tracking, fencing, area restriction (3 set points),

and communication. Please check your drawings

for more information.

VIDEO(OPTION)

Check your drawings to confirm you system

includes this option.

Your locomotive system has the capability of

working with up to four video cameras. These

cameras are able to send a signal back to some of

our displays. Please check your drawings for more

information.

19

LCD, LED AND OPTIONAL RECEIVER DISPLAY INDICATOR MEANINGS

The following icons appear on your transmitter LCD.

See the meanings listed below:

TABLE 1: LCD INDICATORS AND MEANINGS

!!

Safe Mode

**

Return the throttle to NEUTRAL

Antenna icon

Transmitter is not receiving

with a line

feedback and is in control of the

through it

locomotive.

NOTE: Unless specified by the customer, LCD

screens are not backlit. Optional

backlighting features are available.

TABLE 2: TYPICAL LED INDICATOR MEANINGS

LED

Color

State

Meaning

Main Reservoir

Green

ON

Pressure above 90 psi

OFF

Pressure below 90 psi

Independent Brake

Red

ON

Actuating pipe pressure above 30 psi, Ind. brake applied

OFF

Independent brake pressure below 30 psi

Train Brake

Green

ON

Train brake pressure below 55 psi (may vary per your specs)

Fully Applied

OFF

Train brake pressure above 55 psi

Independent Brake

Green

ON

Independent (locomotive) brake pressure above 45 psi

Fully Applied

OFF

Independent (locomotive) brake pressure below 45 psi

Low Oil Pressure

Red

ON

Receiving low oil pressure signal from locomotive (72 VDC)

OFF

Not Receiving low oil pressure signal from loco. (72 VDC)

Hot Engine

Red

ON

Receiving Hot Engine signal from locomotive (72 VDC)

OFF

Not Receiving Hot Engine signal from locomotive (72 VDC)

Wheel Slip

Red

ON

Receiving Wheel Slip signal from locomotive (72 VDC)

OFF

Not Receiving Wheel Slip signal from locomotive (72 VDC)

Table of contents