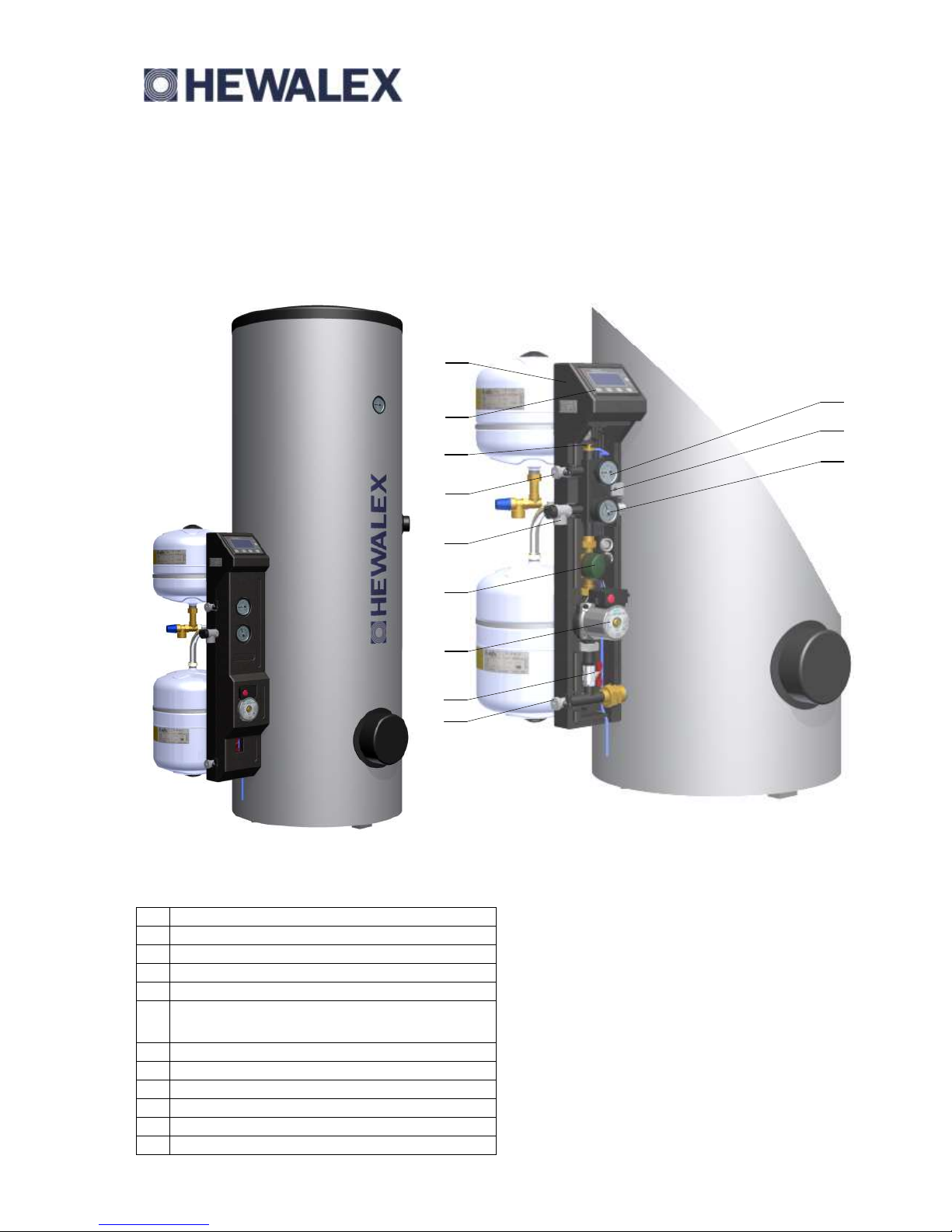

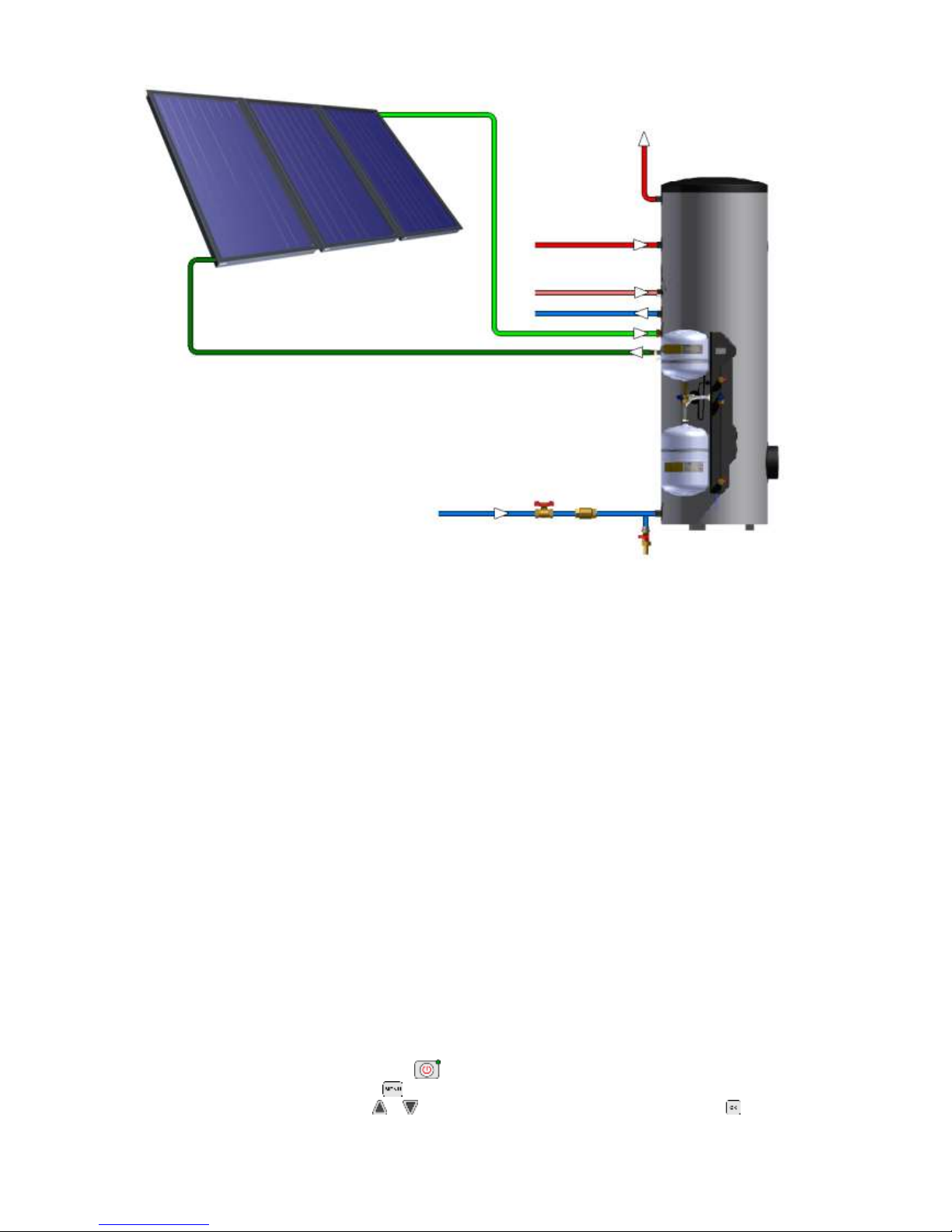

Hewalex KOMPAKT 300HB User manual

Popular Boiler manuals by other brands

SAS

SAS BIO SOLID 19 Operation and maintenance manual

Nibe

Nibe VEDEX 1000 Installation and maintenance instructions

ECR

ECR DUNKIRK ESC3100 Installation, operation & maintenance manual

LAMBORGHINI

LAMBORGHINI MEGA 92 Operating, installation and maintenance instructions

Ravenheat

Ravenheat HE 25 C COMPACT Instructions for use installation and servicing

Fröling

Fröling Lambdatronic SP 3200 Service manual

Flavel

Flavel RENAISSANCE RETRO FRRRF0MN Installation and maintenance instructions

Drazice

Drazice OKC 200 NTRR/SOL OPERATING AND INSTALLATION Manual

Devex

Devex X Boiler BD Series instruction manual

Saunier Duval

Saunier Duval Themaclassic F30E SB Instructions for use installation and servicing

Instanta

Instanta SureFlow Touch WMS6PB Installation and user instructions

Worcester

Worcester Greenstar 8000 Style GR8700iW 35 C Installation and maintenance instructions

thermital

thermital THC V E OIL BLU Series manual

Potterton

Potterton Cold HE A user guide

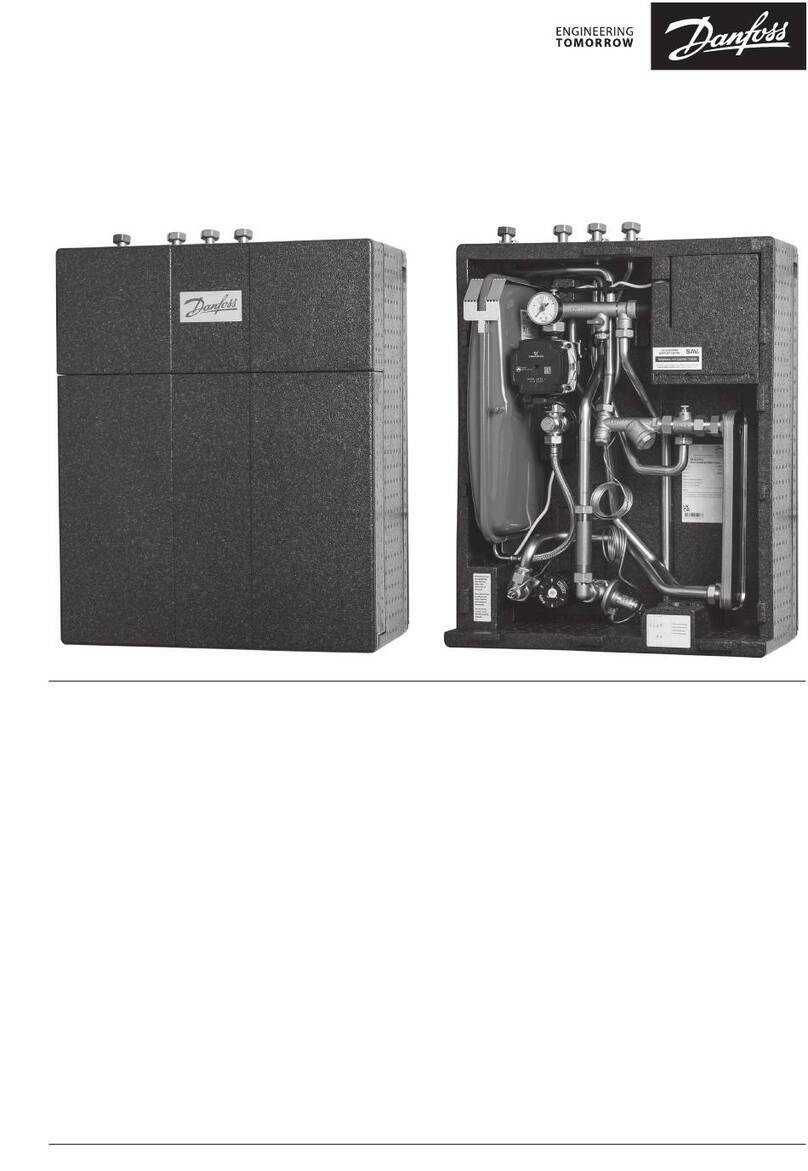

Danfoss

Danfoss 3 Series operating guide

Joannes

Joannes EPOCA 25-29 NS Installation and maintenance manual

Ariston

Ariston CLAS 28 FF Installation and servicing instructions

Viessmann

Viessmann Vitocrossal 300 CU3A Application guide