Hexagon JOGBOX User manual

H00017135 Rev01

CMM ACCESSORIES

JOGBOX – CORDLESS AND TETHERED VERSIONS

ii

•

dCC Jogbox –User Manual

© Copyright April 2020 Hexagon Manufacturing Intelligence

All rights reserved. Hexagon Manufacturing Intelligence is part of Hexagon.

Other brands and product names are trademarks of their respective owners.

Hexagon Manufacturing Intelligence believes the information in this publication is accurate as of its

publication date. Such information is subject to change without notice

What is documented in this manual is a product of Hexagon Metrology, Inc.

Hexagon Manufacturing Intelligence

Strada del Portone, 113

10095 Grugliasco (TO), Italy

Tel.: (+39) 011 4025 111

Internet: http://www.HexagonMI.com

Hexagon Manufacturing Intelligence

250 Circuit Drive

North Kingstown, RI 02852, U.S.A.

Tel.: +1 (800) 766-4673

Internet: http://www.HexagonMI.com

Hexagon Manufacturing Intelligence

Siegmund-Hiepe- Strasse 2-12,

35578 Wetzlar, Germany

Tel.: +49 (0) 6441 207 0

Internet: http://www.HexagonMI.com

Hexagon Manufacturing Intelligence

188 Zhuzhou Road

Qingdao, 266101,

P.R. China

Tel.: +86 (532) 870-2188

Internet: http://www.HexagonMI.com.cn

Hexagon Manufacturing Intelligence helps industrial manufacturers develop the disruptive technologies of

today and the life-changing products of tomorrow. As a leading metrology and manufacturing solution

specialist, our expertise in sensing, thinking and acting the collection, analysis and active use of

measurement data gives our customers the confidence to increase production speed and accelerate

productivity while enhancing product quality.

Through a network of local service centers, production facilities and commercial operations across five

continents, we are shaping smart change in manufacturing to build a world where quality drives productivity.

For more information, visit hexagonMI.com.

Hexagon Manufacturing Intelligence is part of Hexagon (Nasdaq Stockholm: HEXA B; hexagon.com), a

leading global provider of information technologies that drive quality and productivity improvements across

geospatial and industrial enterprise applications.

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

iii

Contents.............................................................................................................................iii

Preface ................................................................................................................................5

Documentation Provided with the Jogbox........................................................................................6

User Manual.................................................................................................................6

Conventions .....................................................................................................................................6

Safety Information..............................................................................................................7

EMERGENCY STOP...................................................................................................7

2.5. Warnings ...................................................................................................................................8

2.6. Safety Devices ..........................................................................................................................9

Overview............................................................................................................................10

Dimensions.....................................................................................................................................12

Operation........................................................................................................................................14

EMERGENCY STOP.................................................................................................14

SPEED CONTROL....................................................................................................14

ENABLE.....................................................................................................................14

JOYSTICK .................................................................................................................14

MACHINE START .....................................................................................................14

Keypad ...........................................................................................................................................15

TOUCHSCREEN DISPLAY ...........................................................................................................18

Appendix A –Battery Replacement ................................................................................27

Appendix B - Glossary .....................................................................................................28

Declaration of Conformity................................................................................................29

Declaration of Conformity Applies to European Union................................................................29

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

5

dCC is an operator control pendant often referred to as a jogbox for a Coordinate Measuring Machine

(CMM). The pendant allows the operator to move the sensor portion of the CMM to a desired location in

the work volume. In addition to driving the machine, dCC allows the operator to pull up part programs on

the embedded tablet in the pendant. dCC is available either as a tethered wired version or a wireless

version.

This manual was written for Customers who own or intend to purchase the Hexagon Manufacturing

Intelligence (hereafter referred to simply as Hexagon) dCC Jogbox (hereafter referred to simply as Jogbox).

This document is a supplement to the operating manual of the CMM. Only after you have read and

understood both will you be able to operate the CMM safely with the Jogbox. Which functions you can run

from the Jogbox depends on which CMM is connected to it. Therefore, you will find the machine-specific

functions in the operating manual of the CMM that is connected to the Jogbox.

Keep the user manual in such a way that it is accessible when required. Ensure that the user manual is

always complete and in a readable state. The information it contains is essential to ensure the safety of the

equipment and personnel operating it. We therefore recommend you read it carefully before proceeding to

use the Jogbox or carrying out maintenance activities.

This documentation is only valid for the versions of the Jogbox described here. The figures and drawings

shown are not to scale. All dimensions are in millimeters. This user manual does not claim to be a

comprehensive technical description. All the information on the functionalities and specifications hold good

only in conjunction with the original accessories of the manufacturer.

This Jogbox is intended for use for operating CMMs that are equipped with a DC and B3C controller.

i

Note. You may print as many copies of this copyrighted manual as desired for personal

use.

i

Note. Due to continuous product development, the images included in this manual

may not resemble the customer’s configuration.

6

•

dCC Jogbox –User Manual

The information provided with the Jogbox offers a wide range of solutions for getting to know and using its

functions.

The Jogbox comes with a USB key containing the following documentation.

User Manual

Contains essential information on how to use the Jogbox safely and efficiently. The manual includes a

detailed description of the Jogbox, the instructions for use, and the routine maintenance procedures

recommended by Hexagon. This document is provided in the form of a PDF file.

In this documentation, the safety references according to DIN ISO 3864-2 are marked as follows:

Danger

Indicates a hazardous situation that, if not avoided, will result in death or serious

injury.

Warning

Indicates a hazardous situation that, if not avoided, could result in death or serious

injury.

Caution

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury or damage to equipment.

Notice

Is used to address practices not related to physical injury.

i

Note. Tip to make your work easier or reference to further information.

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

7

All the operations described in this document for which you are responsible must be performed in respect

of the national, local and company safety regulations.

In case of conflict with said directives, please contact Hexagon.

Purpose-conformant use

The jogbox is available as a tethered or wireless version. In any event, the wireless version shall be able

to be operated in a tethered configuration (Cable will supply power only). The wireless communications

between the jogbox and the PC as well as the wireless communications between the jogbox and the

controller shall be encrypted to avoid hacking or monitoring of signals. The Jogbox is used for operating

CMMs that are equipped with a DC and B3C controller. With the Jogbox you can move the axes manually

using the joysticks. In addition, you can input and transmit editing commands and commands to the

application software of the CMM.

Impermissible use

错误!未找到引用源。 identifies the location of the cell components.

EMERGENCY STOP

To initiate an emergency stop:

1. Press the emergency stop button till it clicks into the lower locked position.

The drives of the CMM are immediately stopped. A corresponding message regarding the fault is

shown in the display and notification area.

Recovering From an E-Stop:

Switch to the operating mode Switched on.

1. Rectify the cause of the emergency stop.

2.

The current coordinates of the axes are shown in the display and notification area. The Jogbox

mode.

8

•

dCC Jogbox –User Manual

Danger

When removing covers or parts (except parts removable by hand), live parts can be

uncovered and touched. Pay attention to all contacts.

Danger

In case specific maintenance or repair works must be carried out on the open machine

with power switched on, this work should be undertaken by authorized personnel

only.

Danger

Make sure to use exclusively fuses of the specified type and nominal current.

Danger

Basically, all international and national safety standards have to be observed.

Repair operations are to be carried out by authorized personnel of Hexagon

Metrology GmbH only. The warranty expires in the event of unauthorized tampering

with the System.

Danger

If the safety operation of the system cannot be ensured, the machine must be put to

a standstill and to be secured against unintended use.

In this case, please contact Hexagon

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

9

Danger

The system is equipped with specific safety devices for operator protection. These

devices should never be put out of use, not even partially.

Any infraction can lead to physical injuries!

All safety devices have to be checked regularly for correct operation. Possible malfunctions have to be

reported immediately to our local subsidiary.

Refer to the corresponding operating instructions for further information on our safety devices.

Notice

Please observe the safety guidelines of the operating instructions of the machine.

10

•

dCC Jogbox –User Manual

JogBox tethered and JogBox wireless with Base station

The JogBox

advanced functionality and allows for future enhancement, customization, and integration with the HMI

Ecosystem.

The jogbox features a Windows 10 Tablet with virtual buttons in addition to physical buttons similar

to standard Jogboxs.

Capability to run wireless or tethered.

Wireless version will have tethered back up capability.

Capable of Supporting DC and B3C Controllers

Asymmetrical Thumb Stick Design

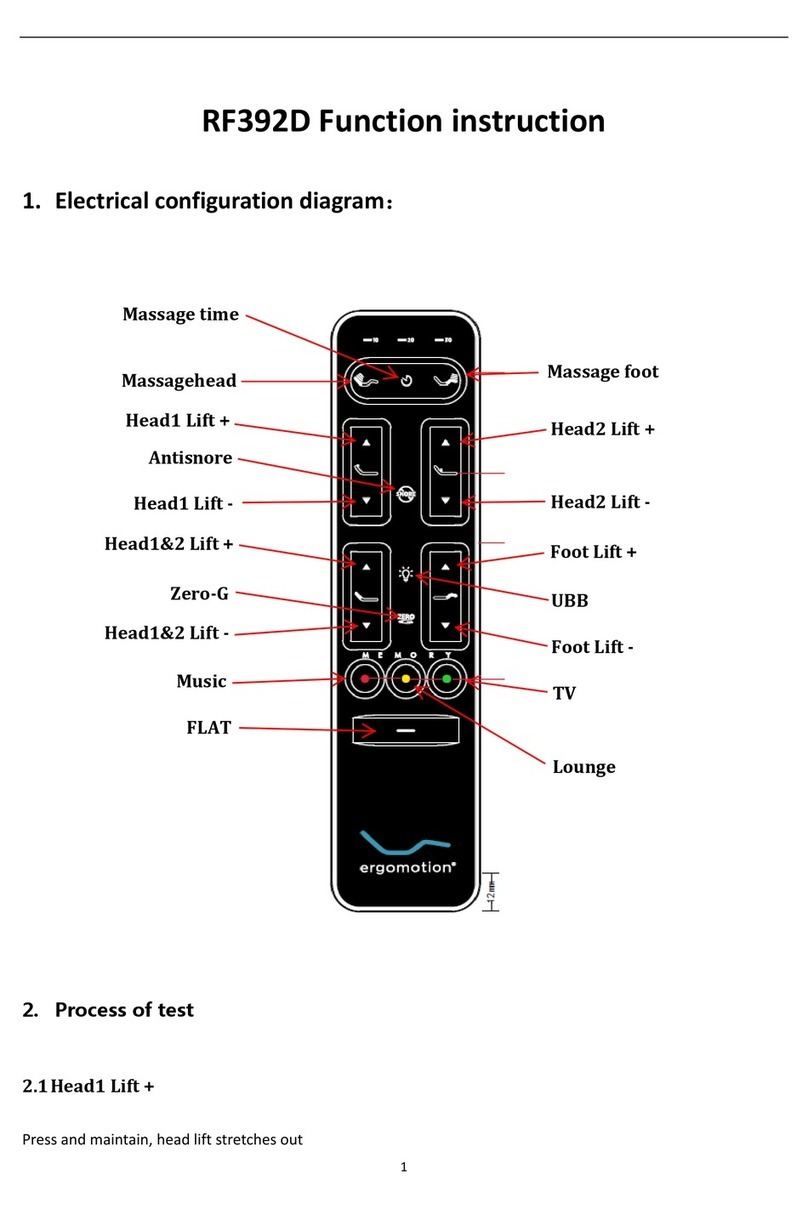

Figure 1 - The Jogbox - Front

EMERGENCY

STOP

KEYPAD

ENABLE

MACHINE START

JOYSTICK

JOYSTICK

TOUCHSCREEN

DISPLAY

SPEED CONTROL

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

11

Figure 2 - The Jogbox - Rear

Radio Base Station :

Connects to the controller and allows the jogbox to communicate with the controller.

Status pad

ENABLE

ENABLE

Status pad

Optional: Magnetic

attachment pads

12

•

dCC Jogbox –User Manual

Compact

Jogbox

Weight:

Wireless

1.55 kg (3.42 lb)

Tethered

1.40 kg (3.09 lb)

Power Requirements

24V

Software requirements

Windows 10

BATTERY

Lithium rechargeable

BATTERY LIFE

8 HOUR

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

13

BB 8 Software Architecture

14

•

dCC Jogbox –User Manual

EMERGENCY STOP

This latching pushbutton causes an ESTOP condition when depressed. The Emergency Stop button is

connected so that it interrupts the supply to the motor drive circuits by de-energizing a control relay. Joystick

control is unavailable in this condition. To re-enable system, the ESTOP pushbutton must be unlatched; to

do this rotate it clockwise 1/4 turn. Program may need to be reloaded and the MACH START pushbutton

depressed (for about 2 seconds) after the cause of the emergency stop is rectified.

SPEED CONTROL

This knob allows for a variable increase or decrease of machine movement.

ENABLE

Must be pressed and held while deflecting the joystick to allow the machine to move. This prevents

unwanted movement. This button has no function in jogbox mode as the CMM has control of this button.

JOYSTICK

Provides operator with an independent means of moving the machine's axes at variable speeds. A

connection to the three DC servo motors within the controller allows independent axis selection and

indicated on the portable station. The machine is moved axially by depressing the appropriate axis button

and deflecting the joystick in the desired direction.

MACHINE START

Depress and hold for about 1 second to enable power to the servo drive system. This must be pressed to

start homing procedure.

EMERGENCY

STOP

ENABLE

MACHINE START

JOYSTICK

JOYSTICK

SPEED CONTROL

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

15

The JOGBOX keypad contains controls for operating the machine. The symbols in the following list of

functions refer to the symbols on the Keypad diagram. The functions of these buttons are:

PROBE ENABLE: This informs the operator of one of the following three conditions:

•NOT ILLUMINATED - The probe is enabled, but the controller

will not report hits. Note: Since all probe signals are ignored by

the controller, the machine will not stop moving after the probe

has registered a hit.

Attempting to take points while this condition exists may

result in damage to probe.

•ILLUMINATED - The probe is enabled and the host computer is

ready to accept a point location.

•FLASHING - This temporarily disables probe. This feature is

useful when manually aligning a part to a machine axis or when

cleaning a probe tip. Hits taken will not be recorded. Re-enabling

the probe changes the indicator light from flashing to illuminated.

16

•

dCC Jogbox –User Manual

SHIFT: This is used to access the lower registers of buttons

with two fields. (X/A, Y/B, Z/W, LOCK/UNLOCK,

RUN/HOLD). When active, the lower registers can be

accessed. W is for other machines with optional rotary tables.

Power On/Off:

AXES BUTTONS

This constrains movement of the machine to the selected axes when the joystick is deflected. Axes with

-, Y- and Z-axis cannot be activated

but the lower register A- and B- axis can be, if available. X-, Y- and Z-axis represent the axes of the machine.

A- and B- refer to the axes of the motorized wrist.

Z AXIS: Must be pressed to unlock

Z joystick enable. This prevents unwanted movement.

X AXIS: Must be pressed to unlock X joystick enable. This

prevents unwanted movement.

Y AXIS: Must be pressed to unlock Y

joystick enable. This prevents unwanted movement.

DEL PNT: This will delete last point manually taken.

MOVE POINT: This button is used to learn positional moves,

enter points or to continue program execution when prompted.

When learning positional moves or entering points, the coordinate

pressed. The function of this button is software dependent.

RUN/HOLD: This is a two function button: the HOLD button

stops program execution, accessed by pressing this button with

SHIFT inactive. RUN resumes execution of a program placed

in HOLD state, activated by SHIFT (lighting SHIFT LED) then

pressing RUN; RUN LED lights.

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

17

JOG MODE: PROBE/PART/MACH LEDs light to identify

each motion mode that machine is in. These settings can be

toggled to vary the way probe is manually steered. This

promotes probe contact at right angles to part, which improves

measuring accuracy and repeatability.

•MACH: WHEN THIS LED IS LIT, PROBE MOVES IN THE

OMACHINE’S COORDINATE SYSTEM. THIS IS THE DEFAULT POSITION.

•PART: WHEN THIS LED IS LIT, PROBE MOVES ACCORDING

OTO THE PART COORDINATE SYSTEM.

•PROBE: WHEN SUPPORTED THIS LED IS LIT, THE PROBE

OMOVES IN LINE WITH ITS OWN CENTER AXIS.

SLOW: This button enables either slow machine

movement (LED illuminated) or fast machine

movement (LED extinguished).

DONE: This is used to accept and register software

commands. The function of this button is software

dependent.

18

•

dCC Jogbox –User Manual

Log In

Enter Passcode

•Operator

•Programmer

TOUCHSCREEN

DISPLAY

错误!使用“开始”选项卡将 Heading 1 应用于要在此处显示的文字。

•

19

Change Passkey

Setting Customize

•Change Machine Picture

•Language

•Zero Joysticks

•Set Logout time

20

•

dCC Jogbox –User Manual

Audio - Notification sounds

oVolume

oMute

Power Management

- Change Backlight Brightness

- Set Auto Backlight Timeout

Table of contents

Popular Remote Control manuals by other brands

Flying Industry Development

Flying Industry Development S1PF-DC12 quick guide

VDO

VDO AcquaLink Installation instruction

Panasonic

Panasonic PVCC50 - COLOR CORRECTOR operating instructions

Motorola

Motorola MXv3 operating instructions

Universal Electronics

Universal Electronics CERVINO user manual

Sony

Sony RM-V201 instruction manual