Heyco 764 User manual

Dear User,

Thank you for choosing this Digital

Torque Wrench. This manual will help

you to use the many features of your new

Digital Torque Wrench. Before

operating the torque wrench, please

read this manual completely, and keep it

nearby for future reference.

HEYCO-WERK

HEYNEN GMBH & CO. KG

BIRGDEN III/1

D-42855 REMSCHEID

TEL. +49 (0)2191/205-0

FAX +49 (0)2191/205-203

www.heyco.de

Service Manual

Digital Torque Wrench

with digital angle applicator

764 - 765 - 766

08956001200

2 3

Table of contents

• Digitaltorquevaluereadout

• highmeasurementaccuracy

• Interchangeablehead

• ergonomic2-K-handle

• reversible

• BuzzerandmulticoloredLEDIndicator

• 9pre-settabletargetvalues(Torque)

• 5variousUnits(Nm,ft-lb,in-lb,kg-cm,Angle°)

• 50or250datastoragelocationsforretrievinganda

combinedtorquemonitoring

• Communicationfunctions

• Autosleepafterabout2minutesidle

• compatiblewithAAandalsorechargeablebatteries

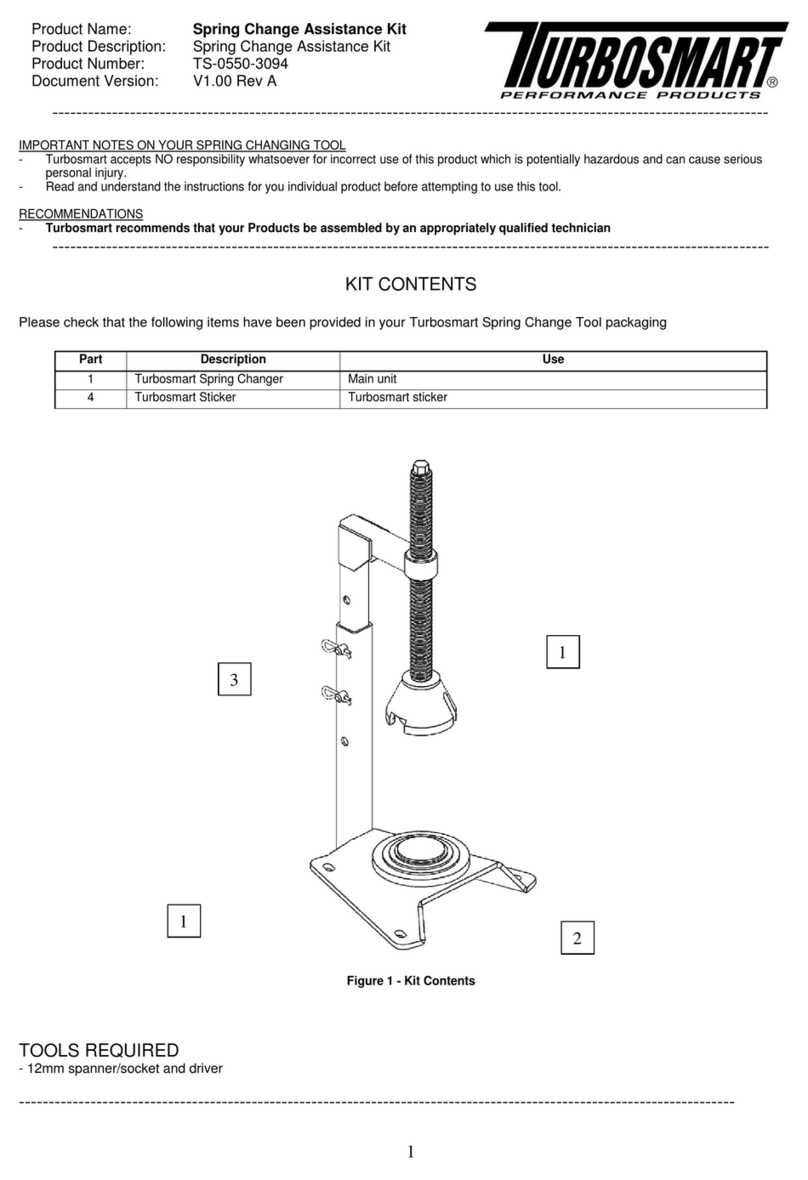

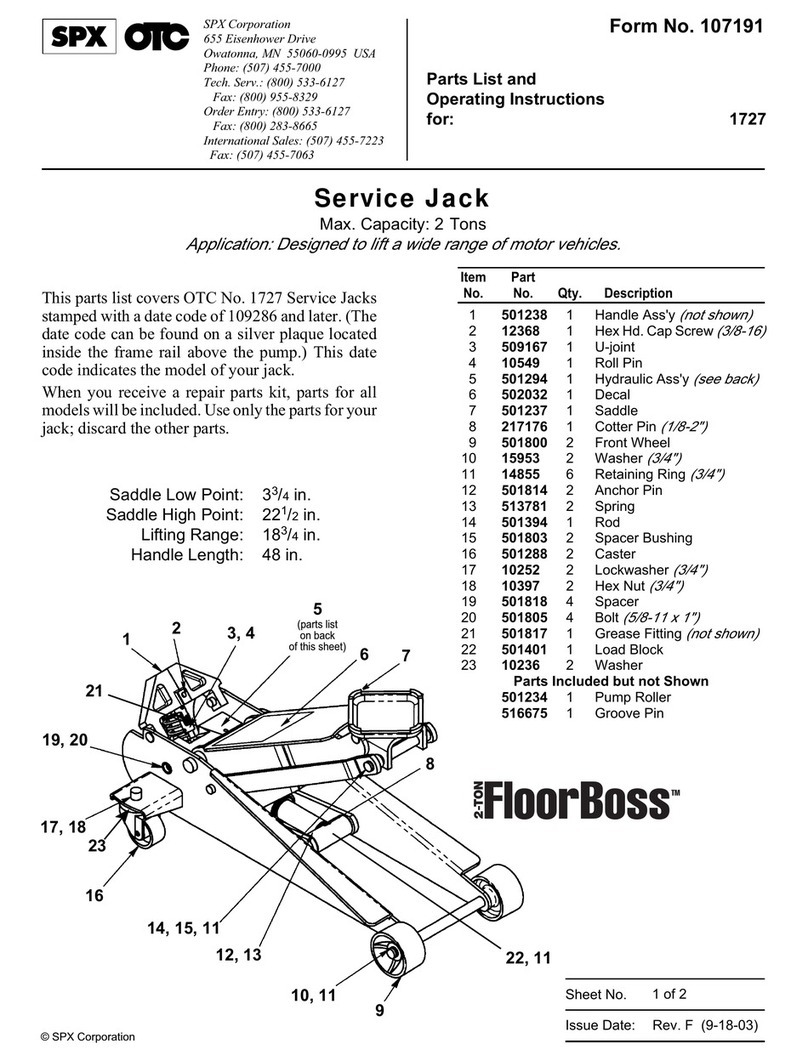

1. InterchangeableHead

2. SensorYoke

3. LCDDisplay

4. Buzzer

5. CommunicationPort

6. Buttons

7. BatteryCap

8. SquareDrive

9. Ergonomic2-Khandle

10. LEDIndicator

11. Torque/AngleValue

12. Pre-settingnumber

13. Unit

14. P(PeakHold)/T(TrackMode)

15. PowerOn/Delete

16. M-Memory

17. Unit/SettingButton

18. Up/DownButton

Names and functions of the parts

N·m

MP

1

Features ....................................3

•Namesandfunctionsoftheparts...............3

•ModelOverview ..........................4

•Specications ............................4

•Note...................................4

Before using the Digital torque wrench........5

•BatteryInstallation .........................5

•Poweronandzeroreset .....................6

•ActivationandStand-by .....................6

•Zeroreset ...............................6

•LowVoltageIndicator .......................7

•Changingthetypeofhead ...................7

Setting, Presets and Operation ................8

•Presettings...............................8

•Unitselection............................10

•SelectTorqueUnit ........................11

•PeakHold/TrackModeSelection.............12

•TrackMode.............................13

•PeakHold .............................14

•PeakHoldModerecordedValueReview ........15

•Anglefunction ...........................16

Communication............................ 16

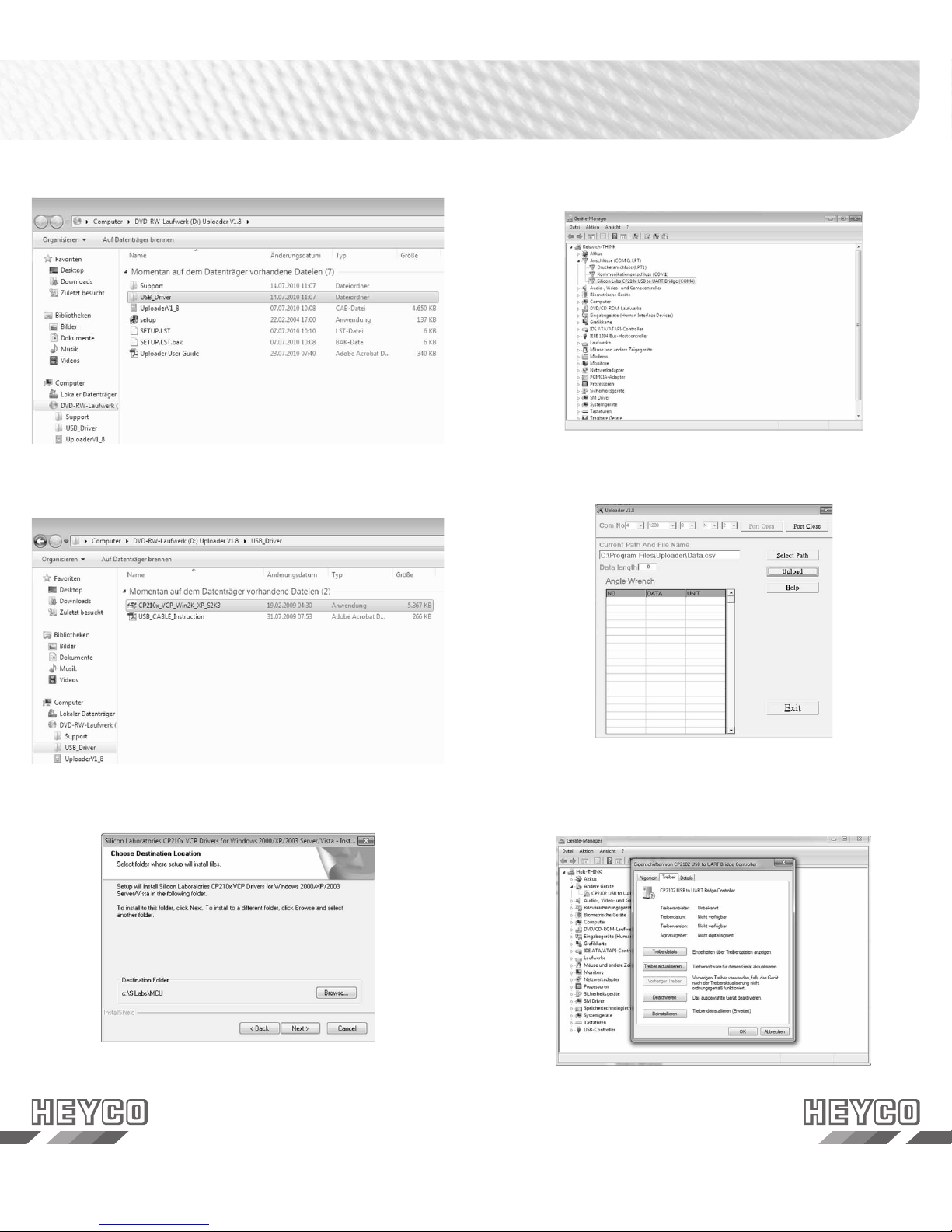

•Installationofthedriversoftware ..............16

•Transmissionofrecordeddata ................18

Maintenance and Storage .................. 22

•batterymaintenance .......................22

Calibration................................ 23

4 5

Note:

Theaccuracyofreadoutisguaranteedfrom20%to100%of

maximumrange+/-1increment.Theaccuracyoftheindicated

torquevalueisatype-boundsize.Formaintainingaccuracy,

calibratethewrenchinregularintervals.Theintervalsdepend

onthefrequencyofapplications.Generallywerecommendto

calibratethetorquewrenchonceayear.

Model Overview / Specifications

Before using the

Digital torque wrench

Model Art. No. Drive Max. Reach Accuracy

00764000080 764 1/2“ 135 Nm 1 % CW / 2 % CCW

00765000080 765 1/2“ 200 Nm 1 % CW / 2 % CCW

00766000080 766 1/2“ 340 Nm 1 % CW / 2 % CCW

Model Overview

Model Art.No. Drive Max. Reach alarm setting range

(Nm)

Length

(mm)

00764000080 764 1/2“ 135 Nm 6,8 - 135 410

00765000080 765 1/2“ 200 Nm 10 - 200 545

00766000080 766 1/2“ 340 Nm 17 - 340 640

Specifications

All models

measurement accuracy CW +/- 1 % CCW +/- 2 %

data storage locations 50 - 250

communication Yes

pre-settings 9 settings

Operation mode Peak Hold / Track Mode Selection

Units Nm, ft-Ib, in-Ib, kg-cm, Angel°

Head Interchangeable

Bit size 12 (B) x 9 (H)

Axial distance 17,5

teeth 52

Buttons 5

Battery 2 x AA

operating temperature -10°C - 60°C

Storage temperatur - 20°C - 70°C

humidity Up to 90% without condensation

Drop test 1 m

Inserting the batteries

Removethebatterycapwitharotationcounterclockwise.

Insert2AAbatteriesmatchingthe+/-polaritiesofthe

batterytothebatterycompartment.

Replacethebatterycapwithaclockwiserotation.

Battery and cap

+

-

6 7

Power On and Zero reset

of the Torque Wrench

Pressbutton CtoturnontheTorqueWrench.

BeforeusingtheTorquewrench,normallyanauto-reset

willbeprocessedautomatically.

ATTENTION!

MakesurethatnoforcesactingontheTorquewrench

duringthepoweron/resetoperation.Ifyoudidnot

followtheabovementionedpoints,thedisplaywill

showsthefollowingsymbol

Pleaseproceedasdescribedabove.Ifthedisplayshows

ErOafterswitchingon,themaxtorquehasbeen

exceededabout10%Inthiscaseanewcalibrationis

absolutelynecessary.

Activation and Stand-by

TheTorquewrenchwillautomaticallyturnoffafter2min

forpowersaving.Pleasepress CtoturnontheTorque

wrench.

ATTENTION!

Duringthecommunicationperiod,theautopower-off

functionisdisabled.

Reset the Torque wrench

To reset the Torque wrench please press button C.

Should a fault occurs, you could reset the Wrench by

loosen the battery cap, then tight it to re-start. After reset

remember to press C

Activation

Low Voltage Indicator

Ifthebatteryserialvoltageisinlowvoltagestatus,the

DisplaywillshowabatterysymbolandthentheWrench

willturnoff.Pleasereplacebatteries.

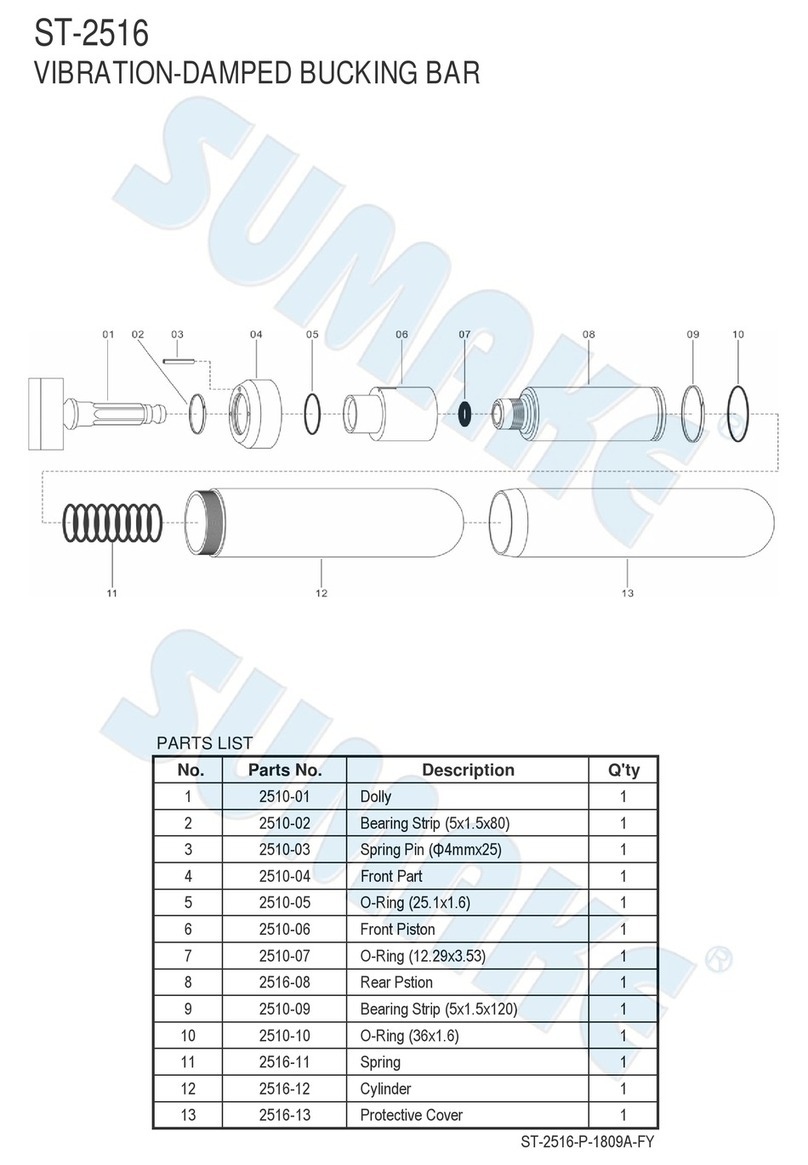

Changing the type of the head

Whenusingdifferentinserttoolsthetorquevaluetobeset

duetodifferentdimensions(L1)mustbecalculatedusingthe

followingformula:

D: Thesettorque

D1:Theactualtorqueappliedtothenut.

L1:Thechangedlength

L2:Thestandardlength

L3:Thelengthfromthettingpintothecalibrationpoint

Reference dimensions for all models:

Model Art. No. Drive L2(mm) L3(mm)

00764000080 764 1/2“ 39,5 287,7

00765000080 765 1/2“ 49 381,2

00766000080 766 1/2“ 49 501,2

D=D1* (L3+ L1) / (L3+ L2)

calibrationpoint

L2

L3

x

L1

8 9

Setting, Presets and Operations

Pre-settings

1M-Memory

2Up/DownButton

3Unit/Settings

4Poweron/Delete

TheTorquewrenchcanpreset9targettorquesorangles.

Topresetthevalues,pleasedothefollowingsteps.

1.Throughpressingthebutton Mseveraltimesyouwill

reachtherequestedmemorylocations.

2.Inthememorylocationyoucanselectthepreferedunit

bypressingthebutton

2.Inthememorylocationyoucanselectthepreferedunit

2.Inthememorylocationyoucanselectthepreferedunit

U/S

3.Withtheselectionkeys

>

>

youcanenterthetarget

value

4.Bypressingthebutton Magainyousavethepre-setted

valueandskiptothenextmemorypoint.

Pre- settings

Pre-setting: M2

Pre-setting: M1

25.00

N·m

M

1

T

25.00

N·m

M

2

T

25.00

N·m

M

9

T

Pre-setting: M3

Pre-setting: M9

Press M

Press M

10 11

Setting, Presets and Operations

Unit Selection Set torque

Pre-setting: N·m

25.00

N·m

MT

Press U/S

22 1.2

in·lb

MT

U/S

Unit Selection: in·lb

Unit Selection: ft·lb

18.43

ft·lb

MT

U/S

Unit Selection: kg·cm

255.1

kg·cm

M

1

T

U/S

360°

M

Unit Selection: °(Deg.)

Pre-setting Value

25.00

N·m

>

Press

Increace target Value

30.00

N·m

>

Decrease Target Value

28.00

N·m

1

1

1

1

MT

1

MT

1

MT

1

Press

Press

Press

Press

12 13

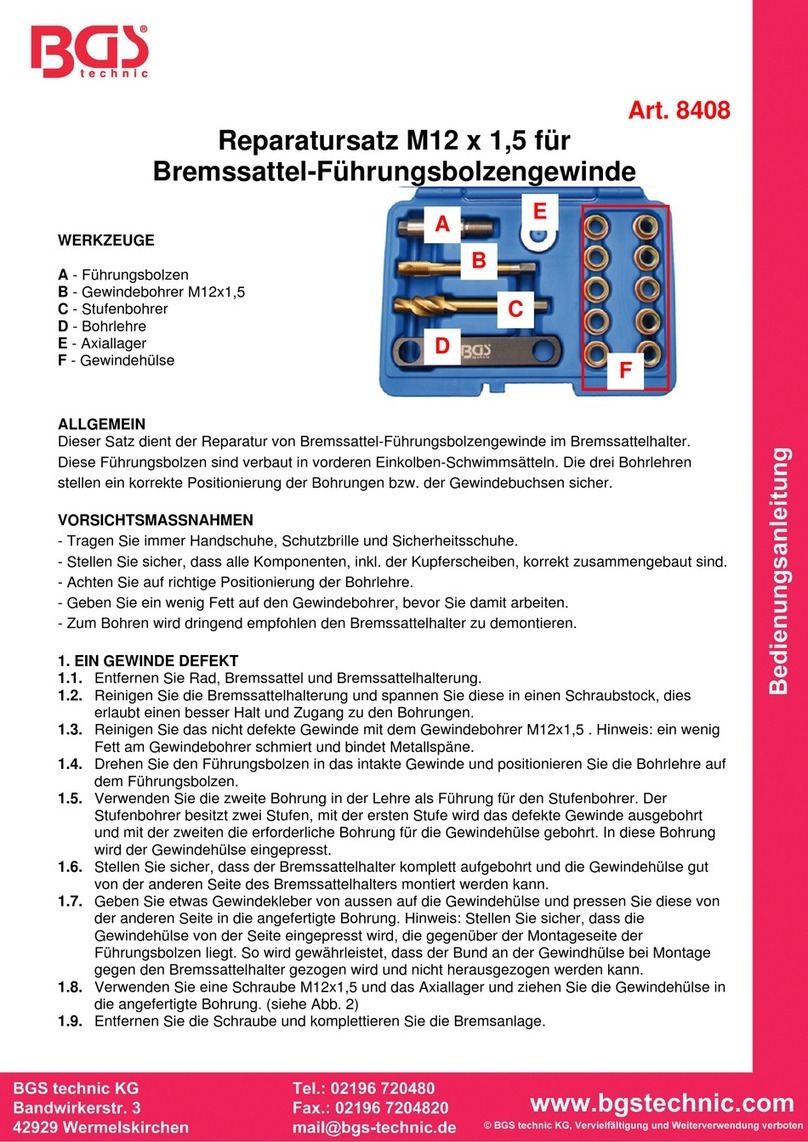

Selection of Peak Hold or Track Mode

TheTorquewrenchofferstwodifferenttorquefunctions.

InTrackModeitispossibletotriggerapresettargetvalue.

InthePeakHoldModeyoucanholdorsavetheactually

reachedmeasuredvalue.

Thebothdifferentmodescanbeviewedasfollows:

Note:

1.IfErOappears,itmeansthewrenchhasbeentorquedto

morethan110%ofmaximumtorque.

2. IfyoucreateaTorquevalueof5NmintheTrackModethe

displaywillshowanstartwith5Nm,sowhenyoucreate

lessthan5NmtheDisplaywillshownovaluechanges.The

minimumTorquevalueforthe1/4“+3/8“seriesis3Nm.

3.Whenyoureachthemaximumsettingrangethegreenandred

LEDwillflashtogether.

Track Mode

25.00

N·m

long pressing

Peak Hold-/ Track Mode

e

T

For selection

press

Setting the Peak Hold-/ Track Mode

e

P

Press

Record number

*Note 1

Press

Delete recording

*Note 1

Press

Peak Hold or Track Mode

25.00

N·m

Max. Torque value

*Note 1

START

C

(System initial)

25.00

N·m

*Note 2

Create a torque above 5 Nm

Current torque value

18.00

N·m

Reached 90% of Target Torque

Current torque value

22.50

N·m

Buzzer Green LED

Reached above 90% of setted Torque

((...((... ...))...)) ((...((... ...))...))

Reached the max. target torque

Track Mode

25.00

N·m

*Note 3

Buzzer Red LED

Target Torqe is exceeded

((...((... ...))...)) ((...((... ...))...))

MT

1

MP

1

MT

1

MT

1

MPT

1

MT

1

>

>

U/S

U/S

U/S

U/S

14 15

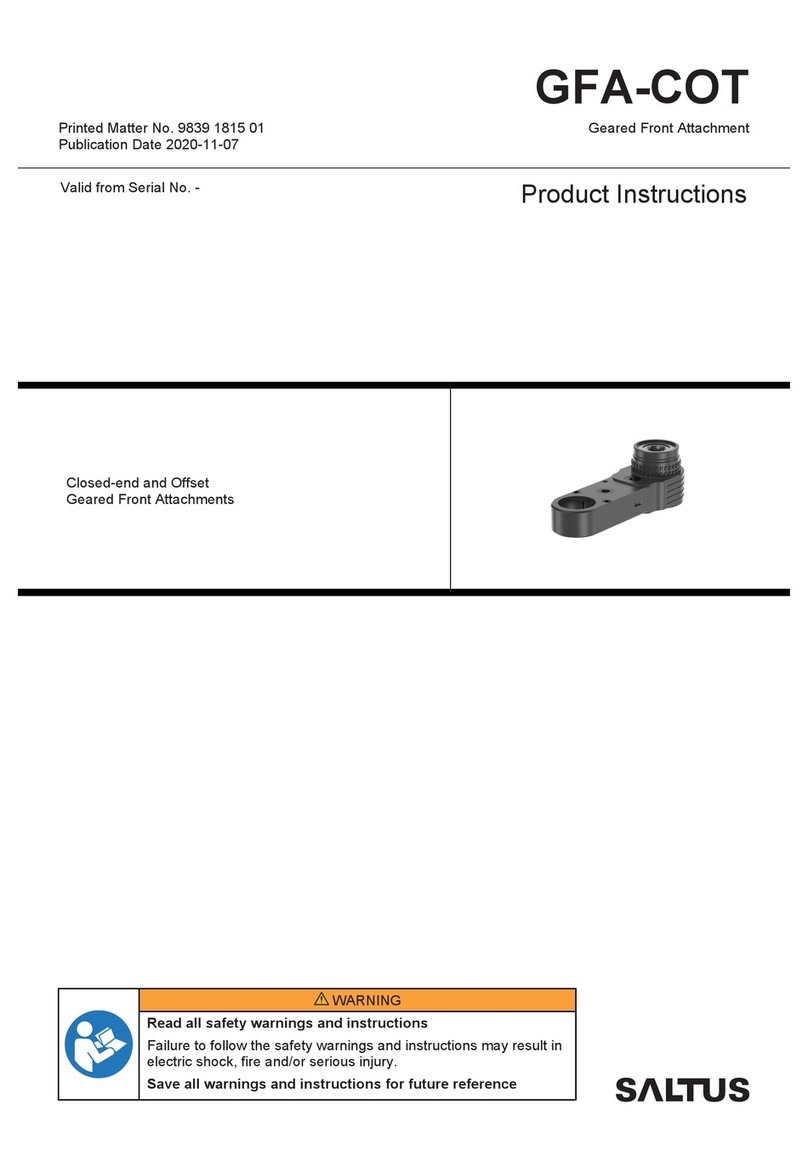

Peak Hold

Note:

1.IfappearsErO,itmeansthattheWrenchhasbeentorqued

tomorethan110%ofthemaximumtorque.

2.IfappearsFULL,itmeansthewrench‘smemoryisfullandno

morevaluescanberecorded.Pleaserefertothe„PeakHold

ModerecordedValueReview“toclearthememoryrecords.

3.Whenyoureachthemaximumsettingrangethegreenandred

LEDwillflashtogether.

Peak Hold Mode

recorded Value Review

Note:

1.ThePeakHoldrecordedvaluereviewcanalsobeperformedin

themode„monitoring“.

2.Ifyouoperateinthe„PeakHold“mode,thedisplaywillshow

MODE.Pleasegoovertothenextstep.

3.Iftherearenorecords,thedisplaywillshowNONE

4.Thisfunctionisnotsupportedonalltypesofmodels.

5.TheCommunicationmodeisforuploadingrecordeddatatoa

PC.

6.TheCommunicationmodeisalsoforcalibratethetorque

wrench.Pleasecontactyourlocaldealerformoreinformation.

Max. Torque value

*Note 1

START

C

(System initial)

22.50

N·m

Create Torque value

Current Torque

value

18.00

N·m

P

Reached 90% of Target Torque

22.50

N·m

Buzzer Green LED

Reached above 90% of setted Torque

((...((... ...))...)) ((...((... ...))...))

Reached the max. target torque

25.00

N·m

*Note 3

Buzzer Red LED

Target Torqe is exceeded

((((((((( ))))))))) ((((((((( )))))))))

18.00

N·m

P

Released

Create Torque

value flashes

M

*Note 2

ec

Recording

MP

1

MP

1

MP

1

Peak Hold / Track Mode

*Note 1

25.00

N·m

Delete

22.50

N·m

*Note 2

MP

1

MP

1

Setting Peak Hold / Track Mode

long pressing U/S

Press U/S

Record No.

005

Auto

change

*Note 3

18.00

N·m

>

>

Recorded value

Press U/S

Peak Hold /

Track Mode

Delete Record

CL

>

Press

U/S

*Note 4, 5, 6

Communication

Yes

C

C

(Exit)

U/S

No

(Task)

U/S

EL

Deleted

5E

16 17

Angle function

Iftheanglefunctionisnotalreadyselected,youreachthe

anglemodebypressingthebutton

Iftheanglefunctionisnotalreadyselected,youreachthe

Iftheanglefunctionisnotalreadyselected,youreachthe

U/S severaltimes.Inthe

anglefunctionyouhavethepossibilitytosetatargetvalue

asdesired.

Communication

Attention:

BeforetheTorquewrenchwillbeconnectedwiththePC

pleasemakesurethatthesoftwarefromtheenclosedCD

isalreadyinstalledonthePC.

Pleaseusetheprovidedaccessoriestotransmitthedatas

only.

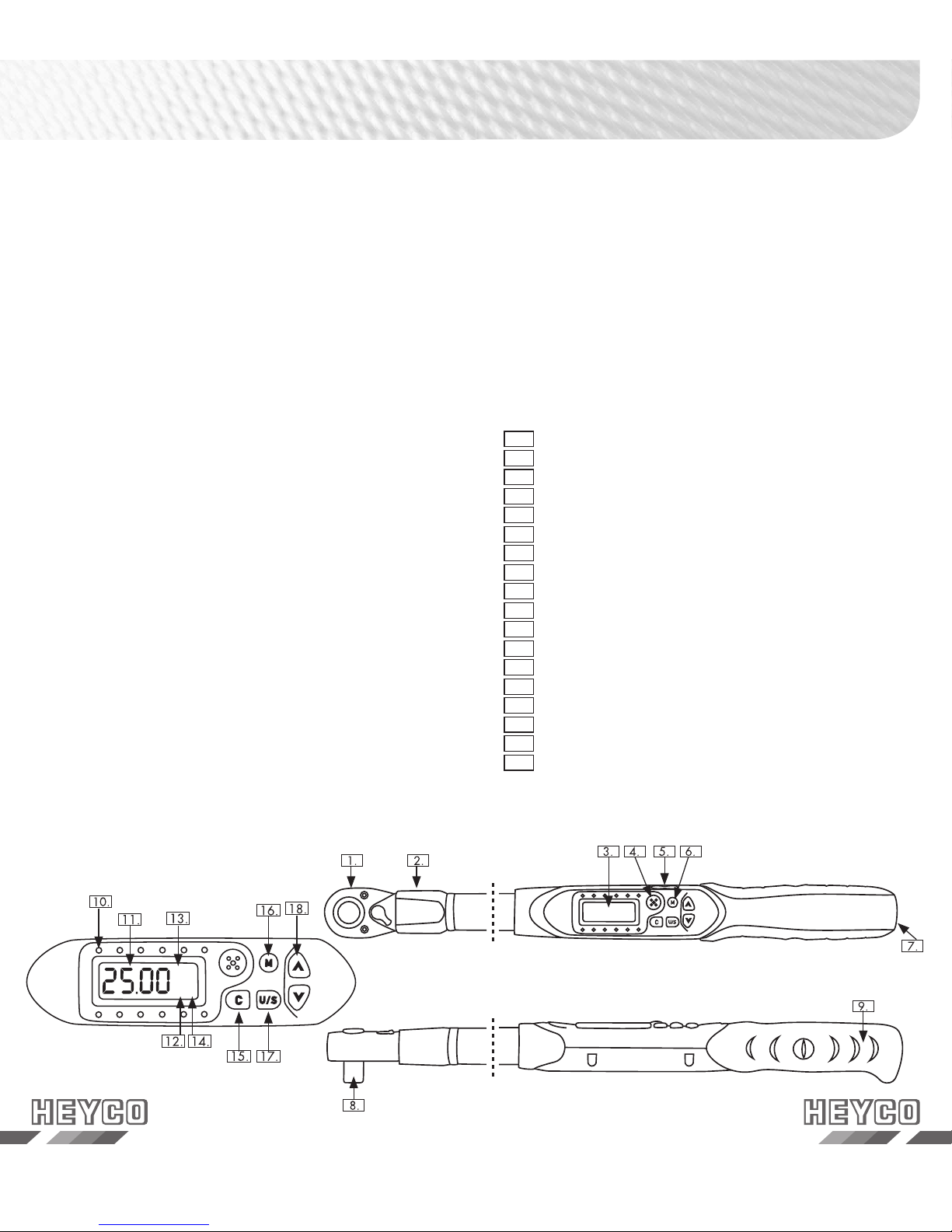

Installation of the driver software

PleaseinserttheinstallationCDintoyourCD-ROMdrive.

Pleaserunthesetup.exe intherootdirectoryoftheCDto

installtheuploader.

Pleasefollowtheinstructionsduringtheinstallation.

Communication

Selctthefollowingle:

Start/Programm/UploaderV1.x/UploaderV1.x

Thenthefollowingwindowsareshown.

ConnectthecommunicationcablebetweenthePCandthe

Torquewrench.ThenpleasechoosethemodeSENDor

COMU.(Pleasereadthesection„Transmissionofrecorded

data“toreachthemodeSENDorCOMU)

18 19

Pleaseopenthele„USB-Driver“

Pleaseexecutethe.exe-le

Pleasefollowtheinstallationinstructions

PleaseselecttherespectiveComPortinthe„Uploader“and

click„Portopen“

PleasecheckthedevicemanagerwhichCOMPortwas

assigned

IftheComPortshouldnotberecognizedautomatically

pleaseclicktwiceontheassigneddevice.

Then,pleasechangeintotheregister„driver“

20 21

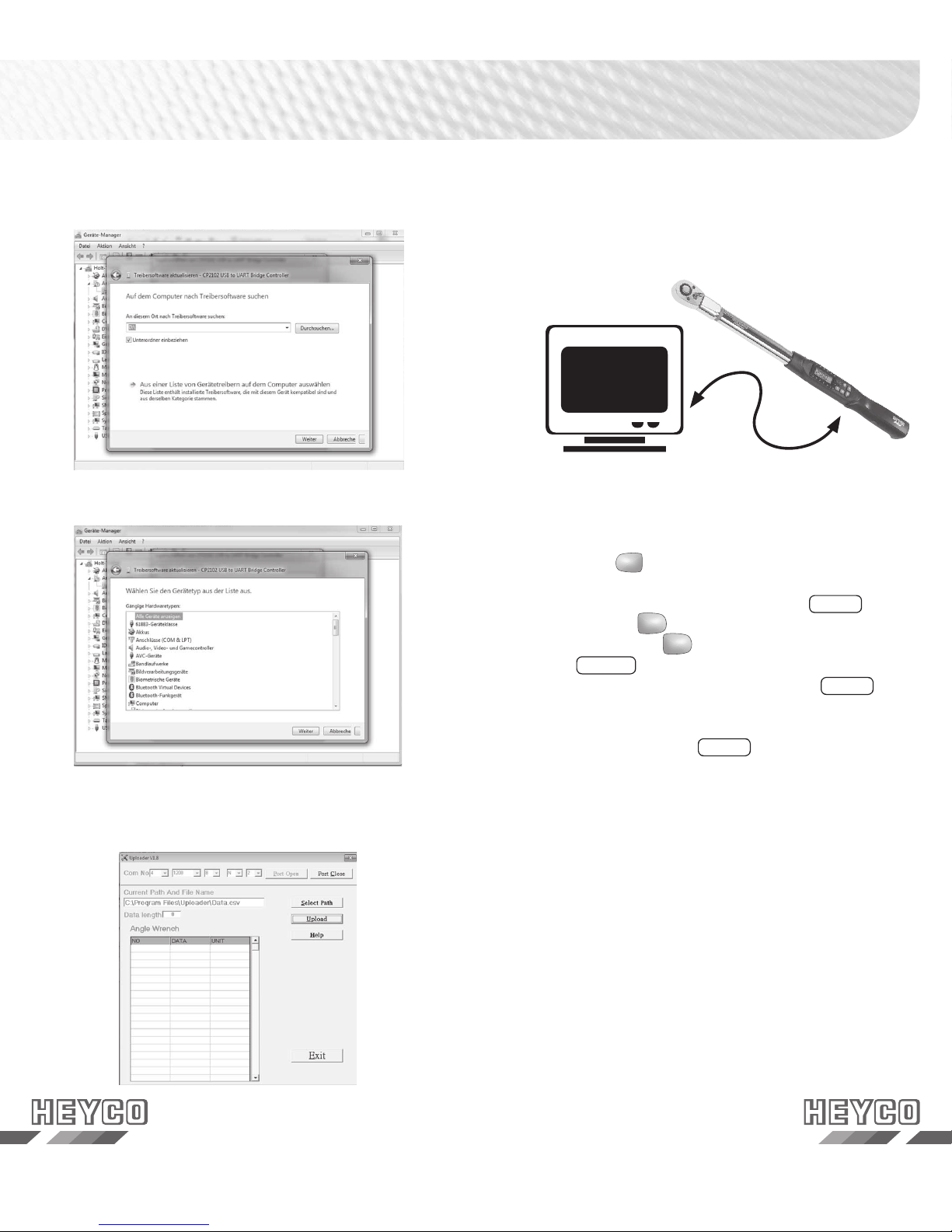

Pleaseclick„driverstobeselectedfromlist“

PleaseselecttherespectiveComPortinthe

„Uploader“andklick„Portopen“

Pleaseclick„Next“

Connection of the communication cable

TurnofftheTorquewrenchandconnecttheaccessorycable

betweentheCOMPortofthePCandthetorquewrench.

Transmission of recorded data

1.Pleasepress Caftersuccessfullconnectiontoturnon

theTorqueWrench.

2.PleasechangeintotheoperationmodeSENDby

pressingbutton

2.PleasechangeintotheoperationmodeSENDby

2.PleasechangeintotheoperationmodeSENDby

U/S untilyoureachthemenue.By

pressingthebutton

untilyoureachthemenue.By

untilyoureachthemenue.By

U/S severaltimesyoureachthe

modeCOMU.

BypressingthearrowkeysyoureachtheSEND

mode.

3.PleasestarttheuploaderprogramonyourPC.

4.PleaseselectthecorrectCOMportintheuploader

program.

5.Thenpleaseselectthelepathtosavetheuploaded

data.

6.Finally,pressUploadtotransmitthetorquerecordstothe

PC.

7.Theuploadeddatasareshowninacolumnandsavedin

a*.csvle.PleaseuseMicrosoftExceltoview*.csvle.

22 23

Attention!

1. An excessive torque ( 110% of the max.

torque range) can cause damage or loosing

of accuracy.

2. DonotshakeviolentlyordroptheTorquewrench.

3. DonotusethisWrenchasahammer.

4. DonotleavethisWrenchexcessiveheat,humidityor

directsunlight.

5. DonotusethisWrenchinthewater.(notwaterproof)

6. IftheWrenchgetswet,wipeitwithadrytowelas

soonaspossible.Thesaltoftheseawatercandamage

theWrench.

7. Donotuseorganicsolvents,suchasalcoholorpaint

thinnertocleantheWrench.

8. KeeptheWrenchawayfrommagnets.

9. DonotexposethisWrenchtodustorsand.

10.DonotapplyexcessiveforcetotheLCDpanel.

11.Createthetorqueslowlyandcomprisethemiddleof

thehandle.

Battery maintenance

1. Pleaseremovethebatterieswhenyoudidnotusethe

Wrenchoveralongerperiod.

2. Donotmixthebatterytypesorcombineusedbatteries

withnewones.

3. Pleasedisposethebatteriesatanofcialwaste

disposallocation.

CalibrationMaintenance and Storage

Calibration

PleasecalibratetheTorquewrenchinregularintervalsto

savetheaccuracy.Theintervalsdependonthefrequency

ofapplications.Generallywerecommendtocalibratethe

torquewrenchonceayear.

This manual suits for next models

5

Table of contents