Heyl Testomat Modul TH User manual

1

Testomat®Modul TH

Measuring converter

for residual total hardness

(water hardness)

Operating Instructions

Content

2

Content

Content.................................................................................................2

Important safety information.............................................................4

Intended use .........................................................................................4

Qualification of personnel .....................................................................4

Warnings in this manual........................................................................5

Additional documentation......................................................................5

Special attention is required at this point..............................................5

General Information ..............................................................................5

Requirements for the installation site....................................................5

Requirements of cable for operating voltage and system components

and installed lines .................................................................................6

Requirements for cable ducts...............................................................6

During assembly ...................................................................................7

During operation ...................................................................................7

During cleaning.....................................................................................8

Repairing a defective device.................................................................8

During disposal .....................................................................................8

Operating requirements........................................................................9

Scope of delivery ..............................................................................10

Performance specifications.............................................................10

Interaction with the controller..............................................................10

Available indicators.............................................................................11

Assembly...........................................................................................12

Assembling the Testomat®Modul TH.................................................12

Use of the Testomat®Modul TH within a pressure range of 0.3 to 1

bar.......................................................................................................12

Connecting the water intake and discharge........................................13

Water intake........................................................................................13

Water drain..........................................................................................13

Connect mains and devices................................................................14

Block diagram of Testomat®Modul TH...............................................15

Connecting inputs and outputs ...........................................................16

Internal design Testomat®Modul TH..................................................17

Commissioning.................................................................................18

Inserting the indicator bottle................................................................18

Opening the water inlet.......................................................................18

Venting indicator line...........................................................................19

Functions of the operating and display elements.........................20

Function keys......................................................................................20

Additional control elements on the circuit board.................................20

Display elements of the function keys ................................................21

Adjusting parameters in the device................................................22

Calling up selection mode on the device ............................................22

Starting USB communication..............................................................22

Entering parameters via the Service Monitor program.......................22

Exiting selection mode........................................................................22

Start of measurements........................................................................23

Other functions in selection mode ......................................................23

Functions of the SD card ....................................................................24

Storage of measured values and alarms............................................24

Content

3

Functions of the USB connection........................................................25

The Service Monitor program..........................................................27

Installing the Service Monitor..............................................................27

Selecting language .............................................................................28

Adjusting parameters..........................................................................28

Example: Changing the interval pause in the Service Monitor for

Testomat®Modul TH...........................................................................31

Description of the signal inputs and outputs ................................32

Control input STOP/START................................................................32

Fault signal output “Alarm”..................................................................33

Current output 4-20 mA ......................................................................33

Calculation of output currents.............................................................33

Serial interface....................................................................................34

Notification format...............................................................................34

Error messages and troubleshooting....................................................35

Temporary faults.................................................................................35

Error messages...................................................................................35

Indicator shortage ...............................................................................37

Correct water level in the measuring chamber ...................................38

Maintenance message........................................................................38

Maintenance ......................................................................................39

Cleaning intervals ...............................................................................39

Service instructions.............................................................................39

Cleaning of the measuring chamber and the sight-glass windows.....40

Cleaning the filter housing ..................................................................40

Changing an empty indicator bottle ....................................................41

Replacing an indicator bottle without a shortage notification..............41

Firmware update ...............................................................................42

Firmware update error list...................................................................42

Testomat®Modul TH spare parts and accessories .......................44

Indicators.............................................................................................45

Additional accessories........................................................................45

Optional display for measured value display ......................................45

Technical data...................................................................................46

Conformity Declaration .......................................................................47

Important safety information

4

Important safety information

Read the operating instructions carefully and in full before working

with the device.

Ensure that the operating instructions are accessible at any time for

all users. When an SD card is used in the device, it can also be

stored on the same as a PDF file.

If transferring the Testomat®Modul TH device to third parties, ensure

these operating instructions are always included.

Observe the safety precautions and safety recommendations when

using reagents, chemicals and cleaning agents. Observe the relevant

safety data sheet! For reagents we supply, the relevant safety data

sheets are available online at www.heylanalysis.de.

Intended use

The scope of use of the Testomat®Modul TH is the automatic deter-

mination and monitoring of the residual total hardness (water hard-

ness) in water. In the process, the required measurement scope is

determined based on the selected indicator and corresponding user

programming.

Comply with the output limits specified in the Technical data section

on page 46.

Observe the areas and limits of application of the indicators and the

requirements imposed by the medium to be measured.

The scope of intended use presumes that you have read and under-

stood the instructions and particularly the section Important safety

information.

Improper use is deemed to occur if you use the device

•outside the applicable scope, as specified in these instructions,

•under operating conditions that deviate from the scope specified in

these instructions.

Qualification of personnel

The assembly and commissioning require basic electrical and pro-

cess engineering expertise as well as knowledge of the applicable

specialist terms. The assembly and commissioning must therefore be

performed only by a specialist or a properly trained person instructed

and supervised by a specialist.

A specialist is a person who can draw on professional training,

knowledge and experience as well as knowledge of applicable provi-

sions to assess work assigned to him/her, detect potential hazards

and implement suitable safety measures. A specialist must comply

with the applicable professional rules.

Important safety information

5

Warnings in this manual

These instructions include warnings against specified actions that

involve the risk of injury or property damage. Warnings are structured

as follows:

Description of the type or source of danger

Description of the consequences of non-compliance

Hazard prevention indications. Compliance with these hazard pre-

vention measures is imperative.

The signal word "RISK" refers to a significant danger that represents

a direct threat and will definitely result in severe injuries or even be

fatal if not avoided.

The signal word “WARNING" refers to a possible danger that may

result in severe injuries or even be fatal if not avoided.

The signal word "CAUTION" refers to a potentially dangerous situa-

tion that could result in minor to moderate injuries or property dam-

age if not avoided.

The signal word "NOTE" refers to important pieces of information. If

this information is not heeded, it may adversely affect operational

procedures.

Additional documentation

The Testomat®Modul TH is a system component. Accordingly, you

should also observe the system documentation of the system manu-

facturer.

Special attention is required at this point

General Information

•During assembly and commissioning, observe the specific national

and local requirements.

•Observe the accident prevention and conservation requirements in

the country of use and at the installation site.

•Make no changes or modifications to the device that go beyond the

scope of use specified in these instructions. Doing so will void the

warranty.

Requirements for the installation site

Ensure that the following conditions are met at the installation site:

•Use the device in indoor locations only.

•The ambient temperature is between 10 and 40 °C.

•The installation site is at altitudes under 2000 m.

•The maximum relative humidity is 80 % at temperatures of up to

31 °C (linear declining up to 50 % relative humidity at 40 °C).

SIGNAL WORD!

WARNING

!

CAUTION

!

DANGER

!

NOTE

WARNING

!

Important safety information

6

•The device must always be protected against wetness and mois-

ture. Under no circumstances may it be exposed to splashed water

or condensate.

•Surge category II

•Soiling degree II

Requirements of cable for operating voltage and

system components and installed lines

Use only cables and installed lines which meet the following require-

ments:

•The terminal strips on the circuit board require core cross-sections

of between 0.08 and 2.5 mm2. This applies to single-wire and fine-

wire cores with wire end ferrules without plastic collar.

For fine-wire cores with wire end ferrules and plastic collar, the

cross-section may be up to 1.5 mm2.

For single-wire cores, AWG28 –AWG12 can also be used.

•The cable ducts installed by the manufacturer in the device have a

clamping range of 4.5 to 10 mm. This means that the external di-

ameter of the laid cable must remain within the range of 4.5 to 10

mm. If you use other ducts, the cable diameters must correspond

to the ducts.

Optimum cross-section of the cores

If the core cross-section is less than 0.5 mm2, jamming may occur

when the cores are loosened from the terminal strip. We therefore

recommend using wires with cross-sections greater than 0.5 mm2.

Requirements for cable ducts

•The recesses in the housing are intended for M16 ducts.

•The ducts should have a smooth and rounded opening (to protect

against bending and abrasion).

•The duct should include a strain relief that prevents slippage of the

cable and that cannot be disengaged without a tool.

•You can order cable ducts from us as spare parts (see Testomat®

Modul TH spare parts and accessories on page 44).

NOTE

Important safety information

7

During assembly

•Always disconnect the relevant system component from the power

source before assembling the device or connecting it to the power

supply or disconnecting it from the same. Prevent any inadvertent

reactivation of the device.

•Only connect the device to the operating voltage as specified on

the type plate.

•Observe the technical data and the environmental parameters.

•The connections for operating voltage and relay outputs must be

laid separately from each other, to guarantee corresponding insu-

lation between the cables.

Avoiding interference voltages

The Testomat®Modul TH device requires stable and uninterrupted

supply voltage. Where applicable, use a mains filter to shield the

Testomat®Modul TH device from interference voltages, which may

be generated for example within the network by magnetic valves or

large-scale engines. Never lay the connecting cables in parallel to

mains cables.

Handling may cause damage or destruction of electrical compo-

nents!

If you need to open the upper door, you should take the necessary

safety measures to avoid electrostatic discharge onto the compo-

nents (ESD safety).

Make sure you are earthed before opening the casing.

During operation

•The device has no On/Off switch.

Use an external switch to turn the unit on and off. The switch must

be installed next to the device and must be marked as power

switch for the device - for example with a label.

•Ensure that the maximum electrical load capacity of the switching

outputs is not exceeded, particularly for inductive loads. The power

supply for the user inclusive device is secured with a 1 A fuse,

which means the total of all loads must not reach 1 A.

•In the event of any malfunctions, immediately switch off the Tes-

tomat®Modul TH device and inform the service personnel. Never

attempt to repair the Testomat®Modul TH device yourself. Doing

so will invalidate the guarantee. Repairs must be performed by au-

thorized service personnel only.

WARNING

!

NOTE

ATTENTION

!

Important safety information

8

During cleaning

•Only use a dry and lint-free cloth to clean the device.

•Maintenance and care instructions are included in the section

Maintenance on page 39.

Repairing a defective device

•A defective device, regardless of the guarantee period, can be

serviced only when the device is dismantled and the error is de-

scribed. Also inform us of the indicator type currently in use and

the measured medium. Make no changes or modifications to the

device that go beyond the scope of use specified in these instruc-

tions. Doing so will void the warranty. This applies particularly to

the measuring chamber, the seal of which must remain undam-

aged. If you send the device in for repair, completely empty the

measuring chamber and remove the indicator bottle and the drain

funnel.

Before dismantling, the type of error must be noted (error number,

error effect, log file of the SD card).

•Once a protective device has been triggered (safety fuse), initially

try resolving the cause of error (e.g. by replacing a defective

valve), before reactivating the protective device. Frequent trigger-

ing always signifies an error, which under certain circumstances

may also damage the device.

During disposal

•Dispose of the device in accordance with the regulations of your

country.

Batteries:

The device is built with a removable lithium battery (CR2032 / 3V)

made by VARTA or similar.

Batteries and devices must be disposed of separately! Dispose

of batteries in accordance with the guidelines in your country.

Important safety information

9

Operating requirements

•Wait at least 5 seconds before switching the instrument on and

then off again at the main switch.

•Problem-free operation of the Testomat®device is only possible

when using Heyl Testomat 2000®indicators and only within the pH

range of 4 –10.5! Using external indicators may invalidate the

guarantee.

•Only operate the device within the scope of parameters specified

under section Technical data on page 46.

•For Testomat®devices used to monitor water hardness, large

quantities of heavy metal ions in the hardened water may disturb

the color reaction, particularly

oIron over 0.5 mg/I

oCopper over 0.1 mg/I

oAluminum over 0.1 mg/l (brown-red color indication).

•If the test water contains more than 20 mg/I CO2 (carbonic acid),

erroneous evaluations cannot be ruled out. In this case, use an ir-

rigator (e.g. optional accessory from Gebr. Heyl.).

•The water to be measured must be clean and free of bubbles!

•The concentrations of disruptive ingredients can be determined

with colorimetric TESTOVAL® test comparators from Gebr. Heyl.

•Erroneous evaluations can occur in the event of

oexcessive carbonate hardness

othe presence of disinfecting agents

othe presence of silicate (used to protect pipes). The measur-

ing chamber may become soiled.

•Careful handling of the device enhances the operational safety and

the service life! With this in mind, perform a visual inspection of the

device at regular intervals as follows:

oHas the expiry date of the indicator elapsed?

oAre the hose connections of the dosing pump leakproof?

oIs there any air in the dosing hoses?

oAre all water connections leakproof?

oIs the device excessively soiled?

oAre the measuring chamber and drain channel/drain hose

clean?

•Problem-free operation is contingent on regular maintenance!

Maintenance and care instructions can be found in the Mainte-

nance section on page 39.

•Indications of problems can be found in the Error messages and

troubleshooting section on page 35.

CAUTION

!

NOTE

Scope of delivery

10

Scope of delivery

1x Testomat®Modul TH

1x plastic bag including a screw cap with hole and an insert for the

indicator bottle

1 package with 1 plastic bag with drain funnel

1 User manual

Performance specifications

•The scope of use of the Testomat®Modul TH is the automatic de-

termination of the residual total hardness (water hardness) in wa-

ter. In the process, the required measurement scope is determined

based on the selected indicator and corresponding user program-

ming.

•The device is connected to an overriding control system.

•The output of the measurement values occurs via a 4-20 mA inter-

face and via RS232 interface.

•Analysis trigger:

- Interval mode (the interval pause can be adjusted

from 0-99 minutes)

- External analysis input (start/stop)

- Manual starting

•Shared output for the alarm

Connect to the max. 35 VAC / 60 VDC relay.

•Parameterisation with the Service Monitor program, logging of

error and maintenance messages and a firmware update with the

SD card

•USB connection for service purposes and for parameterisation

with the Service Monitor program

•History for error and maintenance messages

•Free selection of hardness units in °dH, °f, ppm CaCO3, or mmol/l

•Highly accurate measurement thanks to the use of precise pis-

ton-dosing pump

•Built-in self-test with ongoing monitoring

•Extended operating periods due to a 500 ml reagent stock

Interaction with the controller

When using the 4-20 mA interface, the Testomat®Modul TH sends its

determined measurement result as a current value to the controller,

which determines the measurement value from the current, e.g. in

°dH.

CAUTION

!

11

The reagents used determine the device’s measurement range.

To calculate the measurement value, the controller requires the

measurement range final value for the indicator model used. This is

assigned to the 20.0 mA current.

When using the RS232 interface, the Testomat®Modul TH transfers

its determined measurement result to the control system. All meas-

urement data and error messages are always transferred to the

RS232 interface, even if they are not used.

Available indicators

Parameter/indicator type

Water hardness

TH 2005

TH 2025

TH 2100

TH 2250

Unit

°dH

(resolution)

0.05 - 0.50

(0.01)

0.25 - 2.50

(0.05)

1.0 - 10.0

(0.2)

2.5 - 25.0

(0.5)

°f

(resolution)

0.09 - 0.89

(0.02)

0.45 - 4.48

(0.1)

1.8 - 17.9

(0.4)

4.5 - 44.8

(1.0)

[ppm]

CaCO3

(resolution)

0.89 - 8.93

(0.2)

4.5 - 44.8

(0.9)

18 - 179

(3.8)

45 - 448

(10)

mmol/l

(resolution)

0.01 - 0.09

(0.01)

0.04 - 0.45

(0.01)

0.18 - 1.79

(0.04)

0.45 - 4.48

(0.1)

Be careful to ensure that Heyl indicators are used!

Using external indicators may result in considerable measurement

deviations or measurement errors. Damage caused by foreign parti-

cles in the area of the dosing pump, measuring chamber or valves is

also possible. This may invalidate the guarantee!

At Heyl, we always strive to ensure the consistently high quality of

our indicators. They are specially tailored to the requirements of our

measuring devices and guarantee flawless measurement results.

NOTE

Assembly

12

Assembly

Hazard due to defective assembly!

Assemble the Testomat®Modul TH device in a location shielded

from drips and splashes of water, dust and aggressive substances

–e.g. in a switching cabinet or on a suitable wall.

Notes for problem-free operating procedures

Assemble the Testomat®Modul TH device vertically and without

mechanical stresses.

Assemble the Testomat®Modul TH device in a location free of

vibration.

Assembling the Testomat®Modul TH

Requirements for the installation site

We recommend short intake lines (under 3 m) to the Testomat®Mod-

ul TH. For intake lines longer than 3 m, purge periods of longer than

60 s must be configured (see section Internal “Flush time” on page

29).

Drill the mounting holes as specified in the accompanying sketch-

es.

Secure the device with three screws in a suitable place in the

switching cabinet or on the wall.

Use of the Testomat®Modul TH within a pres-

sure range of 0.3 to 1 bar

Before assembling please check whether adaptation to a lower work-

ing pressure is required. When delivered, the device is equipped for a

pressure range of 1 to 8 bar. To operate the device within a pressure

range of 0.3 to 1 bar, the flow controller valve body should be re-

moved (e.g. when using a type R mini irrigator, see section Additional

accessories on page 45). For this purpose, take the locking pin

from the controller/filter housing . Then pull the controller plug

on the metal brackets out of the drill hole. Then remove the flow con-

troller valve body and re-insert the controller plug and locking pin.

At pressures under 0.3 bar or when sucking out of a tank, our Me-

puClip booster pump can be used (see section Additional accesso-

ries on page 45).

NOTE

NOTE

Remove the

flow controller

valve body for a

pressure range

of 0.3 to 1 bar

CAUTION

!

Assembly

13

Connecting the water intake and discharge

When using a cooler

Water exceeding 40 °C may lead to burns and may damage the

parts of the Testomat®Modul TH exposed to the water.

Notes for problem-free operating procedures

The water pressure must be within the range 0.3 to 8 bar.

To operate within a pressure range of 0.3 to 1 bar or when supply-

ing via a booster pump, please remove the controller valve body

from the controller and filter housing. The pump should have a ca-

pacity of 25 to 35 liters/hour and be correspondingly resistant to

the medium being measured (e.g. our booster pump MepuClip Art.

No. 270410).

For operation exceeding 8 bar, a pressure reducer must be used.

Significant pressure fluctuations should be avoided.

The measurement water temperature must be between 10 and

40 °C.

For water temperatures exceeding 40 °C, a cooler must be in-

stalled in the intake of the Testomat®Modul TH.

Water intake

The test water is extracted from the sampling pipe and channelled to

the supply nozzles of the Testomat®Modul TH. The device comes

with a plug connection for plastic hoses 6/4 x 1 as standard (external

diameter 6 mm / internal diameter 4 mm, wall thickness 1 mm).

Connect the linking piece for the water intake of the Testomat®

Modul TH directly to the sampling pipe directly behind the water

treatment plant.

Always establish the connection vertically upwards, to prevent dirt

particles from being conveyed from the sampling pipe to the de-

vice.

Assemble a manual stop valve in the water intake to the

Testomat®Modul TH.

For the water intake use opaque plastic pressure hose 6/4 x 1

(max. length 5 m).

Purge the water intake to remove dirt particles.

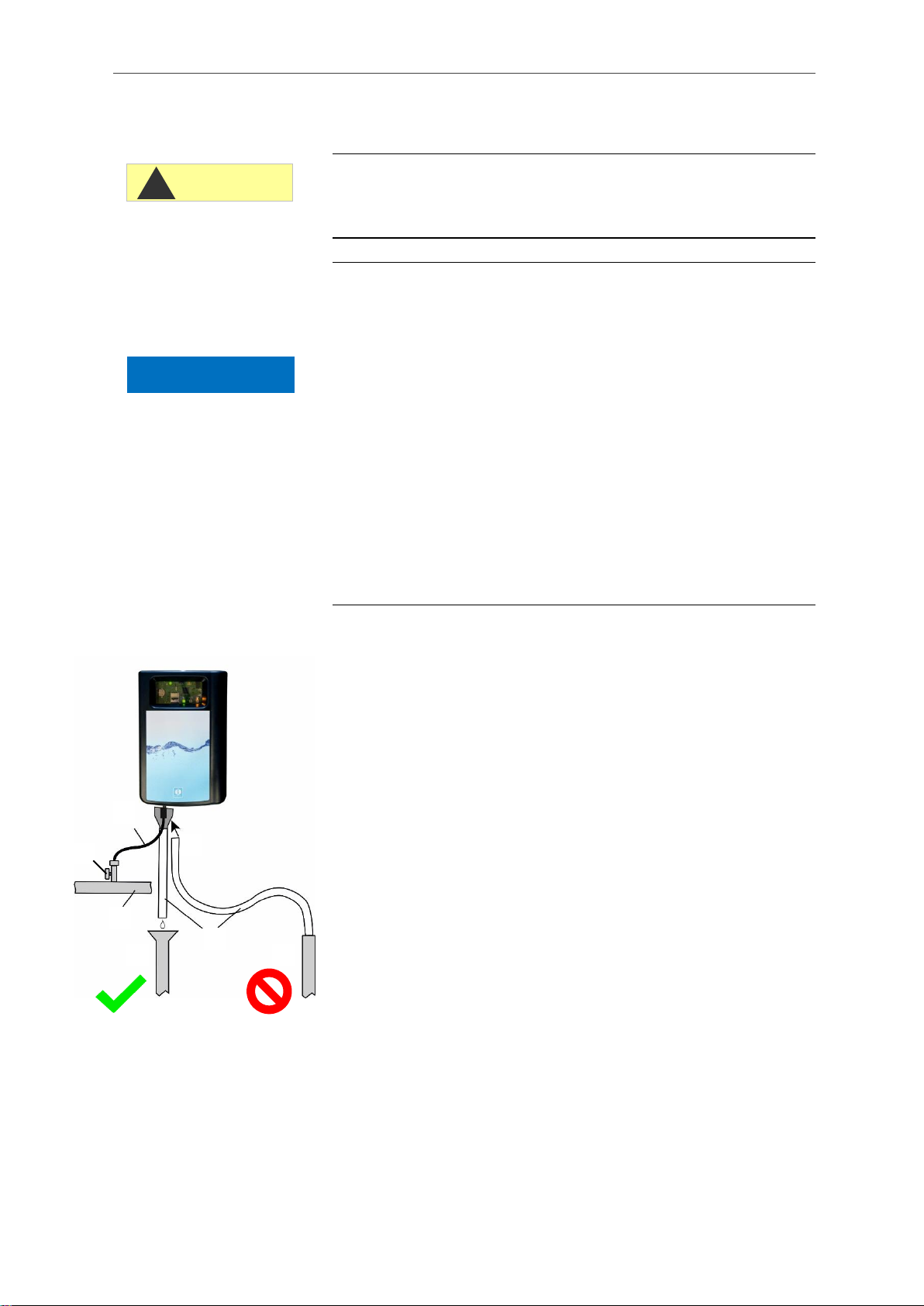

Water drain

The water is conveyed through the measuring chamber via an open

funnel and the drain hose installed on the same and into the

duct.

Remove the supplied funnel.

NOTE

CAUTION

!

Assembly

14

Accommodate the funnel underneath, in the recess of the hous-

ing designated for that purpose.

Connect the funnel of the Testomat®Modul TH with a drain hose

(internal diameter 12 mm).

Lay this hose free of back pressure and without the siphon

effect to the drain .

Connect mains and devices

Connect the device only to a 24 VDC power supply.

Risk of injury from assembly when voltage is present!

Unless you disconnect the power supply before commencing assem-

bly, you risk injury, destruction of the product or damage to system

components.

Disconnect all power to the relevant system component before

assembling the Testomat®Modul TH device.

When connecting, use only verified cables with sufficient line

cross-section (see Requirements of cable for operating voltage

and system components and installed lines on page 6).

Danger of damage due to electromagnetic fields!

If you assemble the Testomat®Modul TH device or connecting cables

parallel to mains cables or in the vicinity of strong electromagnetic

fields, the device may be damaged or the measurement disrupted.

Keep the connecting cables as short as possible.

Lay the connecting cables and mains cables separately.

Shield the device from strong electromagnetic fields.

WARNING

!

CAUTION

!

Assembly

15

Block diagram of Testomat®Modul TH

Illustrated position of relays: Device without current

Assembly

16

RS232

Connecting inputs and outputs

Correct connection of the inputs and outputs

Incorrect connections will damage the device!

Do not expose the connections to any external voltage!

Ensure that the cores in the terminals are securely in place.

A detailed description is included in section Description of the signal

inputs and outputs on page 32.

Terminal

designation

Type

Function

Note

OUT +

OUT -

OUT

Current loop 4 - 20 mA

Galvanically isolated

START

GND

IN

External start/stop of analysis

Ground

Only connect isolated

break contacts/closing

contacts!

GND

IN

Ground

RxD

TxD

IN

OUT

RS232 interface

Not galvanically isolat-

ed (RxD currently not in

use)

Terminal

designation

Type

Function

+ / -

Operating voltage

24 VDC

NO

Alarm output –NO contact

floating relay output/

max. 35 VAC/60 VDC

C

Alarm output –Root

floating relay output/

max. 35 VAC/60 VDC

NC

Alarm output –NC contact

floating relay output/

max. 35 VAC/60 VDC

CAUTION

!

Assembly

17

Internal design Testomat®Modul TH

Control circuit board,

Base circuit board with terminal strips for inputs and outputs is behind

it

Cable gland on both sides

Dosing pump

Optical unit (transmitter right/receiver left)

Solenoid valve

Water connections, inlet and outlet

Controller / Filter receiver

Measuring chamber

Commissioning

18

Commissioning

Flawless operation of the Testomat®Modul TH device is only

guaranteed when Heyl indicators are used! The use of external

indicators may invalidate the guarantee.

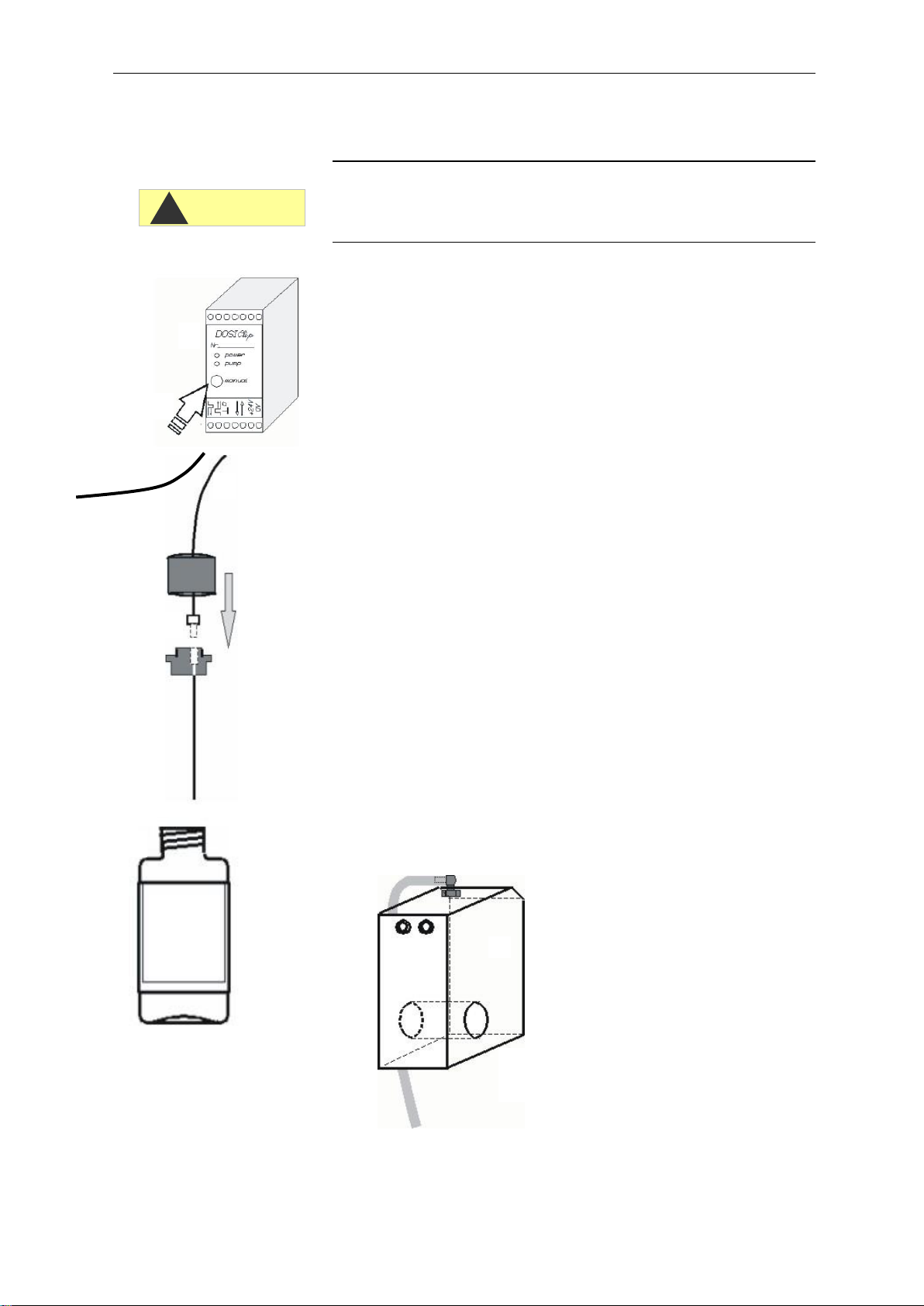

Inserting the indicator bottle

Remove the cover of the Testomat®Modul TH. To do this, raise

the cover slightly and push it forward to remove it.

Remove the cap from the indicator bottle.

Remove the plastic bag from inside the lower housing door. The

plastic bag contains the screw cap with hole and the insert

for the screw cap.

Connect the parts as shown on the left:

Screw the hose connector of the intake hose hand-tight into

the insert .

Place the insert with the screwed-in intake hose into the indicator

bottle .

Now screw the screw cap with hole hand-tight onto the indicator

bottle.

Opening the water inlet

Slowly open the manually operated shut-off valve to prevent the

measuring chamber from overflowing. The flow controller re-

quires a few seconds to function correctly.

Make sure that the water conducting parts are not leaky.

If water sprays from the tube of the measuring chamber ,

reduce the amount of inlet water via manually operated shut-off

valve. It should take 2 to 6 seconds to fill the measuring chamber!

CAUTION

!

Indicator

Measuring chamber

with tube

19

Venting indicator line

The pump (DOSIClip) automatically primes the indicator in opera-

tion.

The pump’s suction hose and transport hose must be filled with

the indicator up to the measuring chamber so indicator is present for

initial analyses.

To do this, press the “Manual” button on the DOSIClip pump sev-

eral times until the suction and transport hose are filled with indica-

tor up to the measuring chamber.

In the event of a build up of bubbles, turn the suction and transport

hose’s hose connector a bit tighter by hand if required.

Press the Manual function key on the control circuit board to quit

standby mode.

The device starts the analysis.

Functions of the operating and display elements

20

Mini

USB

Internal

interface

BOOT

Slot

optional display

Functions of the operating and dis-

play elements

Function keys

The Manual function key is used to start the standby mode which

prevents the intermittent start of an analysis. The yellow LED flashes

above the key in the process. After pressing the key again, the

standby mode is cancelled again, and an analysis starts. During an

analysis, the key flashes.

Acknowledge error and maintenance messages with the Alarm func-

tion key. An alarm message (key lights up red) is acknowledged

when the error has been corrected. The key’s light goes out. A

maintenance message (the LED above the key lights up yellow) is

acknowledged when the maintenance work has been performed.

You can set the indicator stock to 100% with the 100% function key

(see section Changing an empty indicator bottle on page 41).

Additional control elements on the circuit board

•RESET key: To reset the controller, proceed as for switching on

and off.

•BOOT key: Used for firmware update and selection mode.

•Plug-in slot for SD card: For parameterisation, errors and

maintenance messages and firmware updates

•USB socket: For connecting a computer to the Service Monitor for

parameterisation.

•Battery holder: The battery holder houses a CR2032 lithium bat-

tery to retain the time setting even if the device is switched off.

Manual

100%

Alarm

RESET

Battery holder

Mini

USB

Slot for

SD card

Other manuals for Testomat Modul TH

1

Table of contents