HF PackerAmp V4 Instructions for use

HFPA V4 R6 CONSTRUCTION MANUA

L

HF PACKER –AMP VERSION 4 REV 6

www.hfprojects.com vstamps@comcast.net 281-467-9424 Revised 10/10/15

Rev 6 of the HF PackerAmp V4 includes LED indication for

the band of operation plus all the features of Rev 5. The

amp circuit board (R5) remains unchanged but there are

significant additions warranting the Rev 6 designation for

the project. Changes are:

1. The Low Pass Filter Module (LPF) is revised to

include an interface cable for the LED module (HFPA-

FILTER-12 R1).

2. A new LED Module (LEDM-100 R0) including an

interconnecting cable between the LED and the LPF.

3. The chassis revised to include the holes for the

LED module.

4. The front panel silk screen was revised for better

clarity.

HF Packer-Amp V4 R6

Revised 10/10/2015

Contents

Circuit Details......................................................................5

Performance........................................................................6

Terms used in the descriptions............................................6

Preparation..........................................................................7

Construction Techniques.....................................................7

Good Soldering Technique..................................................7

Suggested Tools .................................................................8

Included Speciality Tools.....................................................8

Component Installation........................................................8

Care of the IRF-510 MOSFET's...........................................9

Other Construction Notes....................................................9

Section Two – Amplifier Module Construction.......................10

Assembly Steps.................................................................10

Spacer Assembly ..............................................................12

Fabrication and Assembly of T2 ........................................13

Fabrication and Assembly of T3 ........................................14

Fabrication and Assembly of L1 and L3.............................14

Fabrication and Assembly of L2.........................................15

Assembly of RFM2............................................................15

Clean and Inspect the Board.............................................16

Section 3 -Low Pass Filter Module Assembly......................17

Organize for Assembly ......................................................17

Install Relays and Diodes .................................................17

Capacitor Assembly..........................................................17

Core Winding Table..........................................................18

Core Winding Technique ..................................................18

Core Installation................................................................19

Switch Assembly...............................................................19

Connector Assembly.........................................................19

In-Circuit Tuning Adjustments...........................................20

.........................................................................................20

Selector Switch Stop Pins Installation...............................20

.........................................................................................20

Amplifier Cable Connections Error! Bookmark not defined.

Section 4 – Case and Chassis Assemblies...........................23

Case Preparation..............................................................23

Heat Sink Assembly..........................................................23

RF Input Cable..................................................................23

RF Output Cable...............................................................24

Low Pass Filter Input Cable Fabrication............................25

Low Pass Filter Output Cable Fabrication.........................26

On/Bypass Switch and LED Wiring...................................27

Power Pole Physical Installation .......................................28

Power Wiring Connections................................................29

Install Rear Panel Power Switch.......................................29

Install Wiring for Power.....................................................29

TO-220 THERMASIL III with adhesive back......................30

IRF510 MOSFET Lead Bend.............................................30

MOSFET Attachment to the Circuit Board.........................31

Circuit Board and Case Assembly Procedure....................31

MOSFET Alignment over Heat Sink Holes ........................31

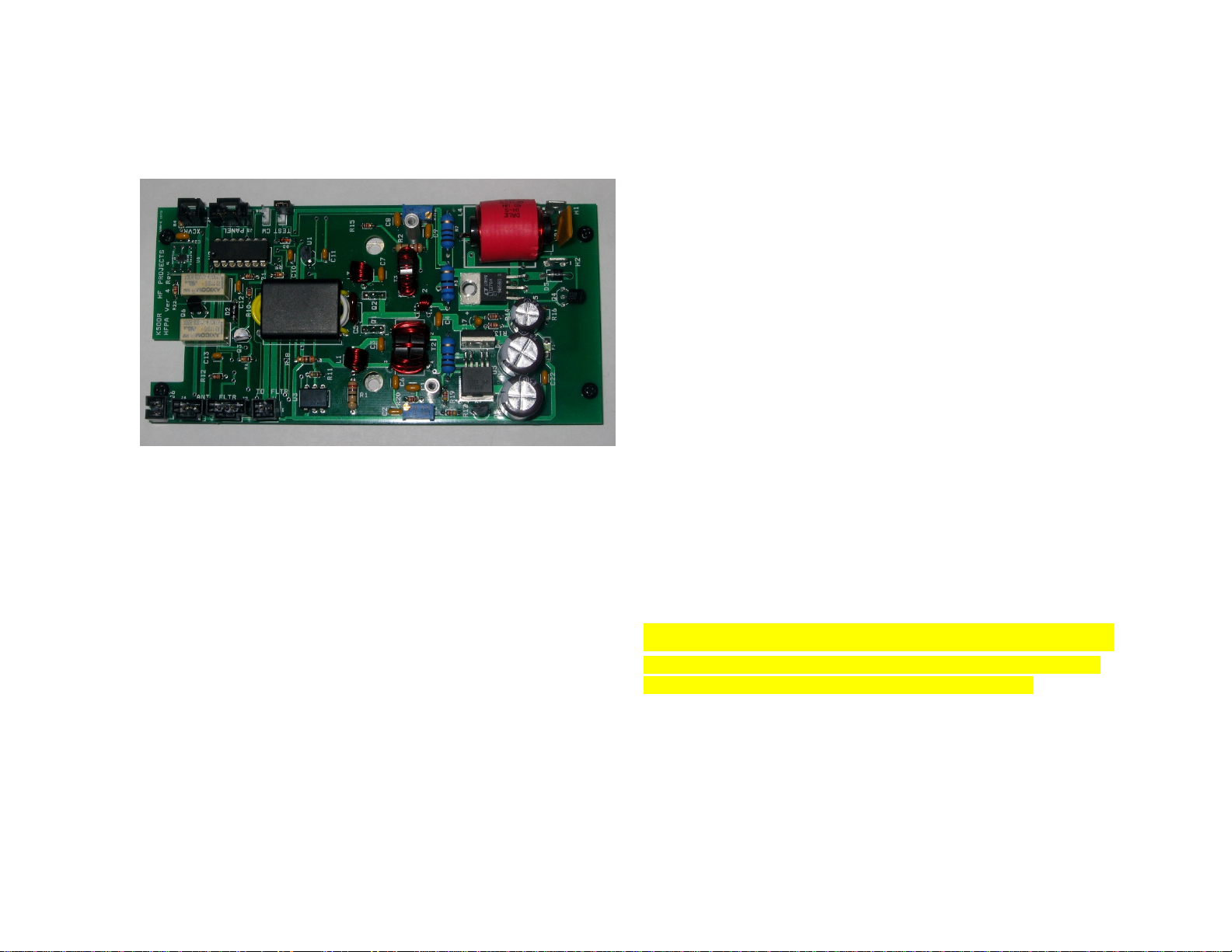

LT1270A, U4 Attachment to the heat sink .........................32

PINET 100-PI Option Module................................................33

100-PI Assembly...............................................................33

100-PI Cable Fabrication...................................................33

Attach the Model PI-100 Module........................................35

Cable Connections on the Model PI-100 Module...............35

Set the Jumper at the 3-pin header J3 on the PI-100 Module

..........................................................................................35

100-PI Theory of Operation...............................................36

Section Five – Adjustment and Testing.................................37

Ohmmeter Test .................................................................37

Basic Current Test.............................................................37

RF Signal Testing..............................................................38

DC Current Test and Bias Adjustment...............................38

Voltage Test......................................................................38

LPF RF Testing.................................................................39

LT1270ACT Alert Notice....................................................39

RF Power Testing..............................................................40

PTT Connections FLEX 1500 and FT817..........................41

Section SIX – Specifications and Operation .........................42

Specifications....................................................................42

Operation..........................................................................42

Do’s and Don’ts for Successful Operation.........................43

Maintenance Issues..........................................................43

CW/SSB Auto Selection....................................................43

Section 7 Theory of Operation and Troubleshooting.............44

Power Supply Unit ............................................................44

Power Input...................................................................44

Reverse Voltage Protection...........................................44

DC-DC Converter, U4....................................................45

Timing Sequence of Control Signals..............................45

U4 Control.....................................................................46

Fully Protected High Side Power MOSFET Switch, U5..46

CONTROL HFPA 10.....................................................46

Big Picture.....................................................................46

U6 .................................................................................46

K2, K3 and J4................................................................46

TX Signal Generation....................................................47

PTT Control...................................................................47

CW or SSB option.........................................................47

TEST Jumper, H3..........................................................47

FAN Option J6...............................................................48

5V Regulator.................................................................48

Panel LED......................................................................48

MOSFET AMP HFPA 10 Schematic ..............................48

Pi-resistive Network.......................................................48

L2 and T3.......................................................................48

T2..................................................................................49

T1..................................................................................49

BIAS ..............................................................................49

BIAS Adjustment............................................................49

Heat Sinking the MOSFETs...........................................49

HFPA FILTER MODULE 12 ..............................................50

J1, Filter Input................................................................50

J2, Filter Output .............................................................50

MANUAL CHANGES.........................................................50

Section One - Introduction

Welcome all builders to the homebrew Hfpacker-Amp

V4 R6 Project. This project parts and your efforts will

eventually provide you with a compact 5 watt input to 30-35

watt output linear amplifier for use with QRP SSB/CW

transmitters on the amateur bands 160 through 10 meters and

which can be powered from a 12 volt DC supply. In this

section, you are introduced to the building of the HF Packer

Amp. The design is a good balance between output power,

physical size and battery power consumption. The completed

amplifier will reward the builder with a clean, more powerful

output signal for a QRP rig when radio conditions become

marginal.

This project is not a beginner's project and requires a

medium skill level to complete it successfully. You can take

advantage of some fabricated options available to you.

•Fabricated Coil Set

•Fabricated Cable Set

•Fabricate and install Amp circuit board

Inductors

Builders require soldering, hand tool, basic electronics

and component identification skills. This project manual is not

included with the kit in order to keep kit costs to a minimum. All

builders will receive the construction manual in a pdf format.

You can also download from the hfprojects site:

http://groups.yahoo.com/group/hfprojects/ Membership is free.

The manual is produced in landscape format to allow more

readable text per screen. This manual provides all you will

need to successfully complete the amplifier project, however,

some additional PDF files are provided at the above website

for those interested in seeing more pictures of the project at

various stages of construction.

The genesis of the basic amp circuit is fully described

in the 2001 ARRL Handbook and in reprint articles from the

ARRL. If you are an ARRL member, you can view the amplifier

articles on-line. Full amplifier circuit design credit is given to

Mike Kossor, WA2EBY. The amplifier module is mounted to

the inside bottom of the chassis box and its MOSFETs are

attached to a heat sink. The power supply unit is an integral

part of the amplifier module while the filter board is mounted

above the amplifier module.

Circuit Details

The amplifier module is a push-pull design, biased for

Class AB linear operation and uses low-cost power MOSFETs

in its output stage. Maximum efficiency is at 10 MHz and

develops over 50 watts output. QRP transmitter RF input is

first sensed, which trips a relay, feeding RF through an RF

attenuator pad. The signal is then applied to the primary of T3

via an input impedance-matching network consisting of L2. T3

is a 1:1 balun that splits the RF signal into two outputs 180

degrees out of phase. One of these signals is applied by C3 to

Q1's gate. The other signal is routed via C7 to Q2's gate. The

drains of Q1 and Q2 are connected to the primary of output

transformer T1, where the two signals are recombined in

phase to produce a single output. T1 also provides impedance

transformation from the low output impedance of the

MOSFETs to the 50Ω antenna port. DC power is provided to

the drains of Q1 and Q2 by phase-reversal choke, T2. This is

a very effective method to provide power to Q1 and Q2 while

presenting a high impedance to the RF signal over a broad

range of frequencies. The drain chokes for Q1 and Q2 are

wound on the same core, and the phase of one of the chokes

is reversed. C5 increases the bandwidth of impedance

transformation provided by T1, especially at 21 MHz. The 5 V

bias supply voltage is derived from a 78L05 regulator. Bypass

capacitors C4, C6, C8 and C1 remove RF voltages from the

bias supply voltage. Gate bias for Q1 and Q2 is controlled

independently. VR1 adjusts Q1's gate-bias voltage via R1 and

L1. VR2 works similarly for Q2 via R2 and L3. At low

frequencies, the amplifier's input impedance is essentially

equal to the series value of R1 and R2. L1 and L3 improve the

input-impedance match at higher frequencies. The low value

of series resistance provided by R1 and R2 also reduces the

Q. A Resistive Pi Network comprised of R3, R7 and R8

provide a 50 ohm impedance to the transceiver and to the

AMP. The standard network attenuates the RF Input by 9dB

which is a 8:1 power ratio. The maximum RF input of 5W is

reduced to 0.63W to the gates of the MOSFETs. The

attenuation matches the popular FT817 power setting of 5W.

The maximum of 0.63W is below the distortion level of the

MOSFETs. This is important for distortion free SSB operation.

The bias current is 100mA per MOSFET while transmitting.

The switch-mode power supply circuits boost the

nominal 12 VDC input to 29 VDC at 3-4 amperes during voice

peaks. The power supply is normally off unless commanded to

be on by the Controller IC, U2. During receive or standby

current is very low. There is an approximate 26 mA current

draw when power supply is off, and 95 mA current draw when

power supply is on and 3-10A current draw when the amplifier

is keyed by a transceiver.

Performance

The chart shows the typical gain vs frequency you can

expect from the HF Packer-Amp. The average power out is

approximately 35W. The fall off in performance at 30MHz is

due to the MOSFET characteristics. This chart was made with

a constant RF drive input.

The Controller , U2 is a Microchip PIC16F688 device.

RF input at J3 is tapped by U6, RFM2 Module to provide a

signal to the controller for Carrier Operated Sensing. This

signal causes the controller to sequence the PSU signal, the

IPS signal and TX signal for correct operation. The PTT input

may also be used to activate the amp independent of RF

sensing. The TX signal (Q6) operates the T/R relays K2 and

K3 to switch from the RX state to the TX state. The controller

is asleep during receive mode to inhibit controller noise..

Terms used in the descriptions

•PSU – Power Supply Unit

•IPS – Intelligent Power Switch

•PTT – Push To Talk

•AMP – Amplifier

•TX - Transmit

•On/Standby – TX Enable

•LPF – Low Pass Filter

•XCVR - Transceiver

The IPS signal passes the PSU voltage to the

MOSFETs through the IPS electronic switch U5. The PSU

signal activates the DC-DC converter on from a standby state.

The IPS device acts as a power switch and a over-current

sensor to protect the DC-DC converter IC, U4. The U5 device

purposely heats up rapidly to provide a thermal time constant

circuit breaker if the current exceeds 5A. After the U5 device

cools, the circuit breaker automatically resets.

A TEST jack, H3, provides a means to set the bias

current. A jumper is provided to activate during calibration. CW

and SSB post delay time is an automatic function. If the amp

senses you are operating SSB, the post delay time is

optimized for SSB. Revert to CW mode by cycling power. A

front panel switch through J5 sets the AMP for ON/STANDBY.

In STANDBY, the transceiver signals are routed directly to the

antenna jack via J4.

Preparation

You may have purchased a fabricated cable set or the

fabricated coil set. Skip over the sections that don’t apply. The

most important preparation step before building is to

completely and thoroughly read this section of the manual.

This will familiarize you with the circuitry, building requirements

and components.

After reading this document and prior to assembly you

should do an inventory of parts (Appendix A-C). In the unlikely

event that you appear to have missing parts, duplicates or

wrong parts please first double check for the parts in all bags,

recheck the inventory and if this fails please contact the project

organizers. This might also be the time to re-acquaint yourself

with how to identify resistors and capacitors by the standard

coding (Appendix E), if you have forgotten.

Construction Techniques

It is a fact that 90-95% of problems with completed

electronics/radio kits are due to either component

misplacement or soldering faults. We cannot stress highly

enough the importance of double checking component

installation before soldering and then good soldering technique

in order to have a working amplifier at the end of this project.

Other builder faults are active component damage due to over-

heating and damage to circuit board pads and tracks caused

by poor de-soldering, too high a wattage of soldering iron or

carelessness. It is very rare to have initially faulty components

or printed circuit boards (PCBs).

Good Soldering Technique

use a 12-25 watt soldering iron with a clean, non-

corroded, well-tinned, fine tip

keep the tip clean by frequently rubbing it along a wet

sponge

keep the tip tinned

ensure all circuit board pads and component leads are

clean (not a problem with this project because boards

and components are new)

ensure the soldering iron tip is at its working

temperature and is in contact simultaneously with both

surfaces to be soldered (the pad and the component)

let the contact zones heat before applying only

electronics grade rosin cored solder (usually 3-6

seconds will do)

apply the solder to the two surfaces (not the iron tip)

and only enough solder to coat both surfaces

ensure that the joint does not move after you remove

the soldering iron tip and until the solder has solidified

the resultant good solder joint should be shiny, in perfect

contact with pad and wire and often has a concave upwards

appearance

toroids and inductors you will wind and solder in this project

use enamel coated magnet wire. The enamel wire used is

designed to be stripped by a soldering iron at 750 deg F.

This makes it much easier to tin the wire before insertion

into the circuit board holes. The project provides 2 sizes of

magnetic wire #22 AWG (thickest), 24 AWG (thinnest).

Suggested Tools

12-25 watt electronics soldering iron, electronics grade

solder, iron stand and sponge

De-soldering braid and/or desoldering pump or bulb

fine needle nose pliers, small fine wire cutters, wire stripper

small screwdrivers including jewelers screwdrivers, small

file

multi-meter

LCR meter (used to measure inductance and capacitance)

Crimp tools for Molex pins and Power Pole Terminals

Included Speciality Tools

1/16 and 7/64 Hex Head tool

Component Installation

For each component, our word “Install” always means:

Pick the correct part to start with – in the assembly notes

that follow we often provide a part number only. You must

match this part number with the correct component using

the parts lists (Appendix A).

Insert the component into the correct PCB position. Refer to

the PCB component outline (silkscreen). Orient it correctly,

following the PC board outline. This is vital for active

components, electrolytic and tantalum capacitors and

diodes. Also, it is good practice to mount resistors and

capacitors in identical orientations (for resistors normally

read color code left to right in same direction as the

silkscreen on the PC board). This makes component

checks easier.

Arrange the resistors on the table before you from left to

right with the lowest values on the left progressing to higher

values on the right. Use the multi-meter to confirm the

resistor values.

Install all low profile components first: usually resistors,

capacitors, diodes, then electrolytics and active

components.

Resistors should be mounted flush to the board.

Mount all capacitors, relays and connectors as flush to the

board as possible.

Bend the wires of the components at the bottom side

slightly outwards in order to hold the component in place for

soldering.

Solder as per techniques described above.

Flush cut excess wire leads and reflow the solder

connection for assurance and a better looking solder joint.

Mark off each installation step in sequence as you complete it, in the

box provided (e.g. ).

Warnings and important points are posted with a symbol.

Care of the IRF-510 MOSFET's

MOSFETs are susceptible to electrostatic discharge

damage (ESD). It is important to use proper grounding

techniques while handling the amp circuit board and the

MOSFETs in particular. While working with MOSFETs you

should wear a grounding strap and have an antistatic mat at

your feet. At the very least you should frequently ground your

hands to the nearest ground point. The IRF510 is a good

compromise MOSFET that will work up to 30 MHz but has

poor thermal characteristics of 3.5°C/Watt. When used in

intermittent SSB and CW service forced-air cooling is not

required. Tuning time with full power should be limited to less

than 30 seconds with 1-2 minutes between cycles to prevent

overheating. Operating at 29VDC does not press the MOSFET

to their limits. The Sil-Pad TO220 mounting kit has excellent

thermal performance and provides a greaseless thermal

interface between the MOSFET and the heat sink. Users

report that this amplifier can be safely used for contest CW

operation without further cooling. For PSK/RTTY forced air

cooling is necessary or a reduction of power by reducing the

input drive.

Other Construction Notes

1. Follow the sequence given to locate the next

component in a series to install.

2. The header parts are installed by matching the part to

the outline. Start by soldering one pin and then while

reheating, align the part flush and perpendicular to the

board. Solder the remaining pins.

3. The IPS511S, U5 component is pre-mounted since it is

a surface mount part.

4. The reference numbers used are not in sequence and

some references are skipped.

5. The circuit boards should be cleaned after soldering to

remove solder flux residue. I recommend “TechSpray

BLUE SHOWER” available in a can: 1630-16S. Use in

a ventilated area following instructions on the can.

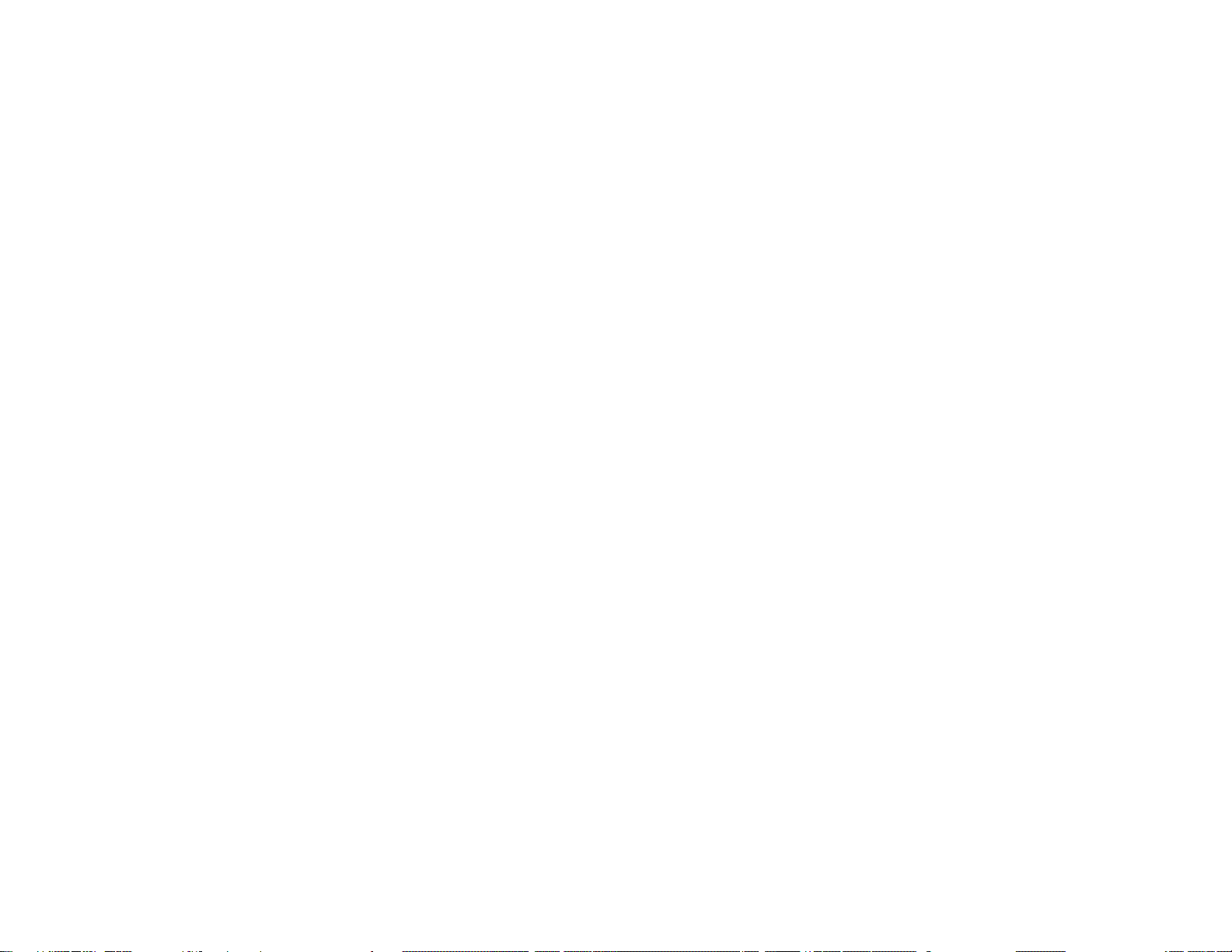

Section Two – Amplifier Module Construction

Circuit Board ID is HFPA-2013 V 4 R5

Circuit Board Assembly, HFPA V5

Assembly Steps

•Install 0.1 uF capacitors (104): C22, C4, C1, C9, C2,

C6, C8, C3, C7, C23 Install

•Install 47 pF (470J): C5

•Install 0.01 uF capacitors (103): C11, C10, C12

•Install 1000 pF capacitor (102): C13 Install

•Install 1 uF capacitor (105): C17. The long lead is (+)

and goes in square pad marked (+)

•Insert 1N4007 diode at D2 (smaller of two axial

components with cathode stripe at one end). Bend

leads very close to the body to match the component

outline on the board. Make sure cathode bar on the

part matches the cathode symbol on the silk screen

outline.Install

•Insert RL251 diode at D5. The leads are bent

approximately 1/8 inch away from the body to fit the

component outline on the board. Make sure cathode

bar on the part matches the cathode symbol on the silk

screen outline. Install

•Install six 1K 1/8W resistors (BRN BLK RED): R14,

R20, R15, R10, R21 and R12. Install

•Insert two 4.7K 1/8W resistors (YEL VIO RED): R17,

R19. Install

•Insert two 27 ohm ½ w resistors (RED VIO BLK):

R1,R2 Install

•Insert three 10K 1/8w resistor (BRN BLK ORN): R5,R6

and R4 Install (R5 partial symbol on board)

•Insert one 27K 1/8w resistor (RED VIO ORN): R13.

Install

•Insert one 3K 1/4W resistor (ORN BLK RED): R18.

Install

•Insert two 1.2K 1/8W resistor (BRN RED RED): R16,

R22. Install

•Insert one 1M 1/8w resistor (BRN BLK GRN): R11

Install

Note: if you did not purchase the PINET 100-PI Option Module,

install R3, R7 and R8 next. Otherwise wait until instructed to install

alternate values for R3, R7 and R8 in the 100-PI section.

•Insert two 100 ohm 2W resistors at R7 and R8. Install

•Insert one 62 ohm 2W resistor at R3. Install

•Insert one 78L05 regulator (3 pin TO92 package) at

U1. Match the outline.

•Insert four 2N5089 transistors (3 pin TO92 package) at

Q3, Q4, Q5, Q6 Match the outline. Install

•Insert two 2-pin headers (no rib back) at H3, H4. Install

•Insert Diode D3, 1N4148 at the D3 location. Install

•Insert three 2-pin headers at J1, J3, J6. Install

•Insert one 3-pin header at J4. Install

•Insert two 4-pin headers at J2 and J5. Install

•Insert two Power Tabs at H1 and H2. Solder one pin,

reheat and align perpendicular. Solder both pins of

each tab Install

•Insert one Circuit breaker, CB1. Leave leads long.

Insert just the tips through the board. Install

•Insert Inductor (Red 50 uh coil) at L4. Note that L4

leads are adjusted to fit the hole pattern. The ends are

not symmetrical. Install the bent lead to the right as

shown. Press the component flat on the circuit board.

Solder the pins, flush cut and re-solder the

connections. Install

•Insert two 10K- potentiometers, VR1 and VR2, on the

board. The lead under the adjustment screw is inserted

in the square pad in the circuit outline. Do not bend the

leads. Solder one pin, reheat and align part

perpendicular and flat on the board. Solder all pins

Install

•Turn the 25-turn potentiometers CCW at least 20 turns.

You will not hear a click and there is no mechanical

stop.

•Install the 14 pin DIP socket for U2. Align the notch on

the socket with the notch shown on the component

outline. Solder one corner pin. Reflow connection while

pressing the socket flat. Solder the other corner pin.

Reflow the pin while pressing the socket flush. Solder

the remaining pins. Install

•Insert U2, PIC16F688 Integrated Circuit in the socket

Install

•Insert two relays at K2, K3. Do not bend or cut the

leads. Solder one corner pin. Reflow while pressing the

relay flat to the board. Solder the other corner pin.

Reheat pin as necessary to make the relay flat to the

board. Solder all pins Install

•Insert two 330 uF Capacitor at C21 and C16. The long

lead (+) goes to the square pad of outline near the (+)

symbol on the board. Solder one pin, reflow and align

part flush. Solder other pin repeating reflow and

alignment. Flush cut leads and reflow. Install

•Insert one 100 uF Capacitor at C15. The long lead (+)

goes to the square pad of outline near the (+) symbol

on the board. Solder one pin, reflow and align part

flush. Solder other pin repeating reflow and alignment.

Flush cut leads and reflow. Install

•Insert a MBR1060G diode (2 pin package) in the

outline for D4. The part is mounted vertically. Press the

part down until the body is resting on the circuit board.

Install

•Insert a LT1270A Switching Regulator U4 is mounted

horizontal into the 5 holes on the circuit board outline

for U4. First bend the legs straight. Bend to match

pattern while keeping the mounting hole centered. You

will later screw this component down to a stud

projecting from the heat sink below.

LT1270ACT Lead Insertion Detail

•Install 4N33, 6-pin IC at U3. Make sure the round

depression dot on the package is closest to the notch

in the component outline. Install

Spacer Assembly

•Locate four 4-40 x ¼ inch threaded hex spacers and

four 4-40 x 3/16 inch length screws.

•Install the spacers on the bottom side of the circuit

board. Tighten the screws extra snug so they will not

come loose when removing the circuit board from the

case in the future.

•Locate two 4-40 x ¾ inch threaded round spacer and

two 4-40 x ¼ inch length screws.

•Install the spacers on the top side of the circuit board

near VR1 and VR2. Tighten the screws extra snug so

they will not come loose when removing the filter

module in the future.

Note: Identify the correct size wire for T2 and T3

Fabrication and Assembly of T2

•Two stacked FT50-43 torroid cores are used for this

transformer. Cut two #22 AWG wire (0.026 inch diameter)

15 inches long. Do not twist the wires. To prevent chaffing

of the wire on the edge of ceramic cores, insert a common

soda straw (same length as the thickness of the two

stacked cores). Through the stacked cores, insert the two

parallel wires. Bend the wires into a U-shape. Holding the

two wires together in one hand with the cores at the bottom

of the U-Shape, grasp the wires in the rear and insert the

wires on front right side through the core four additional

times. Pull each wrap snug keeping the wires parallel

without crossovers. After completion of the loops on the

right side, pass the remaining wires through the cores on

the front left side 5 times. Pull each wrap snug keeping the

wires parallel without crossovers. You will now have 10

turns passing through the core.

•Separate and scrape the ends of the wires so you can

measure continuity and isolation to determine the start and

finish of each wire.

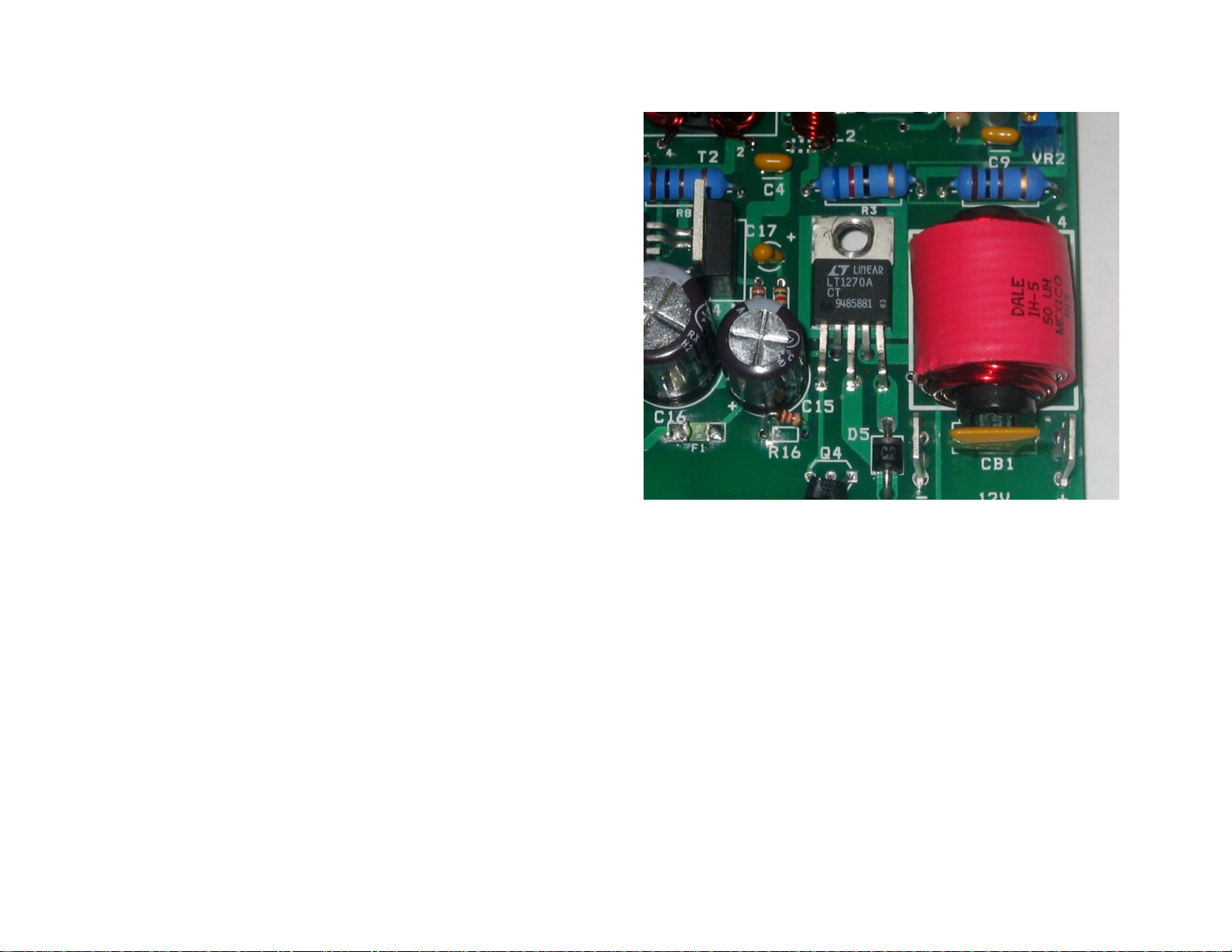

Circuit board showing cores with wire exits for T2 and T3

•Winding # 1 goes to pins 1 and 2. Winding #2 goes to

pins 3 and 4.

•Insert the wires through the appropriate holes and pull

snug to form the leads in the shape required.

•Remove T2 from the mounting holes and use a

soldering iron to heat the insulation at the points where

you will be soldering to the board. You need at least

750 degrees F to remove the insulation. Tin the leads

removing insulation and excess solder.

•Re-insert T2 on the board at the T2 outline. Pull the

leads tight and solder in place. Install

•Trim the excess lead length and reflow connections.

•This is a typical spot where you can have a poor solder

connection. Inspect and re-solder if necessary.

Adjust the wire spacing to match the picture. The top and

bottom of the core should be clear so T2 and T3 will be

minimum height to not create a clearance problem with the

board above.

Fabrication and Assembly of T3

•One FT50-43 torroid core is used for this transformer.

Cut two #24 AWG wire (0.022 inch diameter) 11 inches

long . No twist is required or desired. Insert the two

wires through the core. Bend the wires into a U-shape.

Holding the two wires together in one hand with the

cores at the bottom of the U-Shape, grasp the wire in

the rear and insert the wires on the front right side

through the core four additional times. Pull each wrap

snug. Avoid crossover of the leads.

•After completion of the loops on the right side, pass

the remaining wires through the core on the front left

side 5 times. Pull each wrap snug. You will now have

10 turns passing through the core.

•Separate and scrape the ends of the wires so you can

determine the start and finish of each wire. Use the

multi-meter to measure continuity.

•Winding # 1 goes to pins 1 and 2. Winding #2 goes to

pins 3 and 4.

•Insert the wires through the appropriate holes and pull

snug to form the leads in the shape required.

•Pull T3 from the mounting holes and use a soldering

iron to heat the insulation at the points where you will

be soldering to the board. You need at least 750

degrees F to remove the insulation. Tin the leads

removing excess accumulated Install

•Re-insert T3 on the board at the T3 outline. Pull the

leads tight and solder. Install

•Trim the excess lead length and reflow connections.

Fabrication and Assembly of L1 and L3

•L1 and L3 are identical and require 12 inches each of

the remaining #24AWG wire.

•Use a ¼ inch drill bit as a winding form and wrap 10

complete turns of the wire tightly around the drill bit.

•Trim the excess lead length to ½ inch and tin the leads.

•Insert L1 and L3 into the L1 and L3 positions on the

circuit board. Install

•Use the end of a ball point pen to push into the end of

the air coils slightly to reform the wires should they

become deformed during soldering.

Fabrication and Assembly of L2

Note: If you purchased the PINET 100-PI Module with

your Amp, it is not necessary to install L2. Leave the holes

clear. Instead, refer to the page for the PINET 100-PI Module

option.

•L2 require 4 inches of the #24AWG remaining wire.

•Use a 3/16 inch drill bit as a winding form and wrap 4

complete turns of the wire tightly around the drill bit.

•Trim the excess lead length to ½ inch and tin the leads.

•Insert L2 into the L2 position on the circuit board. Install

•Use the end of a ball point pen to push into the end of

the air coils slightly to reform the wires should they

become deformed during soldering.

Assembly of RFM2

•Insert the RFM-2 Module in the U6 location.

•The square pad (pin 1) on PCB aligns with the square

pad on the RFM-2 Module. (see bottom right in pix

below)

RFM-2 just below U2 above

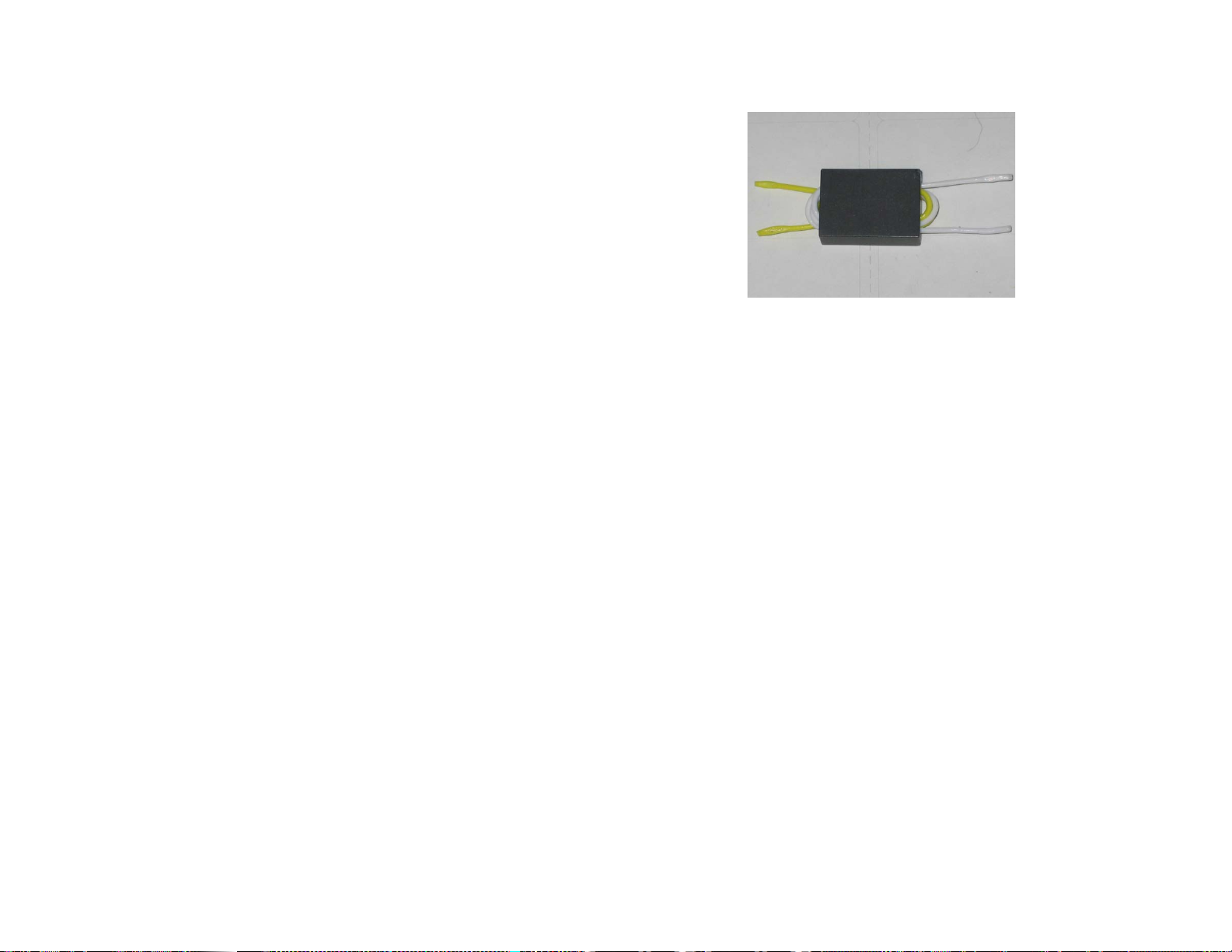

•T1 is fabricated using a Binocular core with a primary

and secondary winding.

•The primary is a 7 inch yellow #20AWG Teflon coated

wire. There will be 2 loops through the cores.

•The secondary is a 10 inch white #20 AWG Teflon

coated wire. There will be 3 loops through the cores.

•Make a U shape of the 7 inch yellow wire and insert

into the two tubes. Equal distance the wires.

•Make a U shape of the 10 inch white wire and insert

into the same end of the two tubes. Equal distance the

wires. At this point, you have 2 yellow and two white

wires coming out the same end.

•Push one of the yellow wire leads through the adjacent

tube. Push the other yellow wire lead through the other

adjacent tube. Pull the leads tight. You are finished

with the yellow wire.

•Push the white wires through in the same manner. Pull

the wires tight. Push the white wires through a final

time through the adjacent tubes. You now have the

yellow wire leads on one end and the white wire leads

on the other.

•You are done winding the core.

•Trim about 3/8 inch length off each lead. Strip each

wire about 3/8 inch and lightly tin the tip. You are now

ready to install the transformer into the board. The

yellow primary (input) and white secondary (output).

•Insert the primary wires at holes 1 and 2. Pin 1 is the

square pad.

•Insert the secondary into holes 3 and 4

•Pull leads snug and solder. Install

T1 with Yellow Primary, White Secondary

Clean and Inspect the Board

•Remove the flux from the circuit board with a flux

removal spray in a ventilated space.

•Inspect the solder joints for the entire board

This completes assembly of this module. The MOSFETs will

be installed in a later assembly.

Section 3 - Low Pass Filter Module Assembly

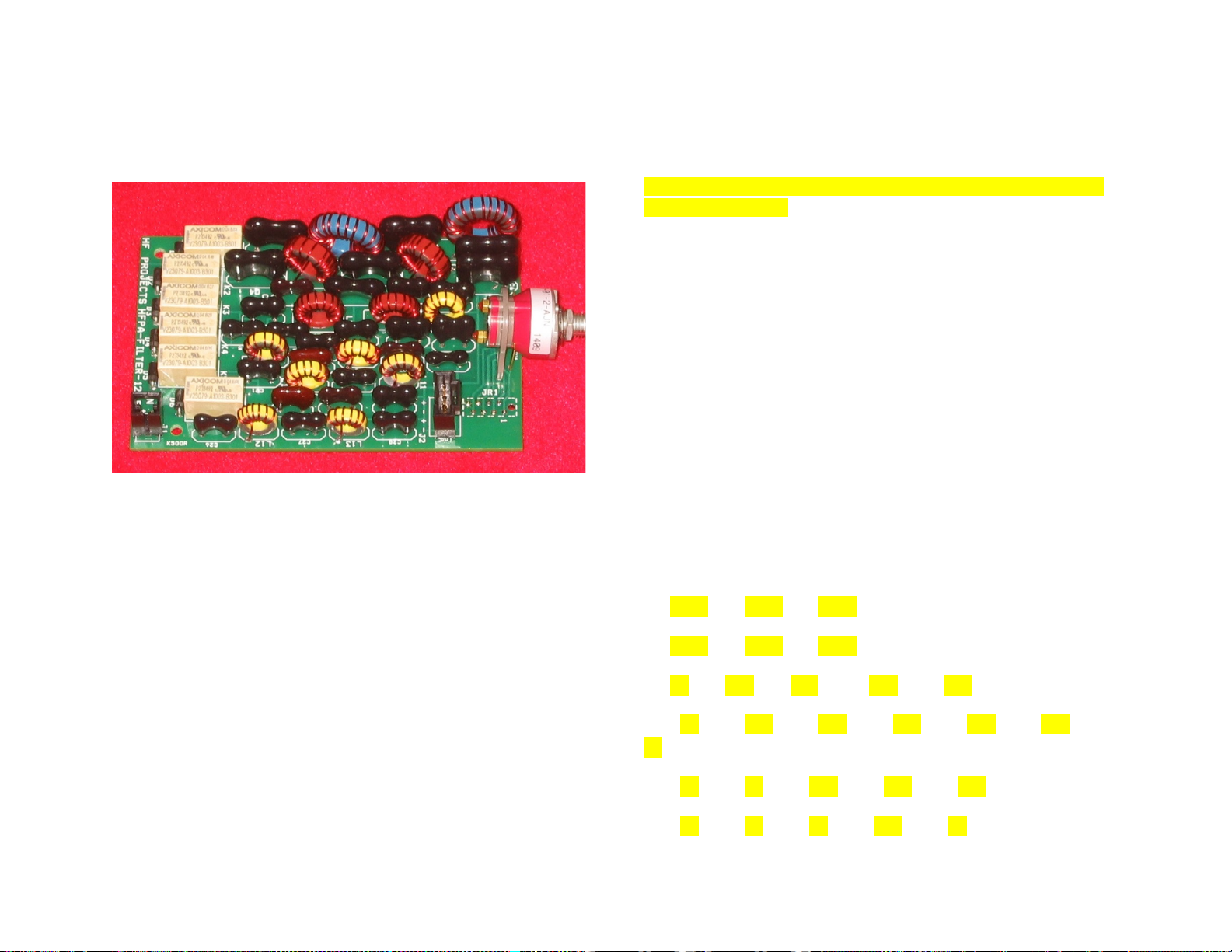

This is the 10‐Band Filter Module HFPA‐FILTER‐12

Size: 3.8 x 2.4 inch; Bands: 160‐10M Power Rating: 50W; Control:

Front panel switch

Design: Four‐Layer Ground Plane with greater than ‐40dB

rejection in the stop band;

Relay Front End controlled by front panel switch, LED display.

Organize for Assembly

Place on the table in front of you all the capacitors ranging

from smallest value to largest value from left to right.

Organize the cores and relays into like groups.

Two Blue Cores – T68-1

Two Larger Red Cores – T50-2

Two Smaller Red Cores – T44-2

Seven Yellow Small Cores – T37-6

Wind the cores referring to the core winding table

"REALLY CHECK THE POLARITY OF THE DIODES FOR THE RELAYS

ON THE LPF BOARD"

Install Relays and Diodes

Install the six diodes on the circuit board observing that the

stripe on the diode matches the board silkscreen for the part.

Be careful that your tools do not damage the circuit board. The

diodes require that the leads are bent very close to the body of

the diode. Before installing, scrape the leads near the body to

remove any oxidation on the leads. Install

Install six relays. Solder one pin, reheat and align flat. Install

Capacitor Assembly

Install the capacitors in the sequence given and soldering

when called for. The part may be oversized for the insertion

holes. Form the leads for a best fit. Double check your work.

C1 1500, C2 2700, C3 1500 Install

C4 1000, C5 1800, C6 1000 Install

C7 39, C8 110, C9 390, C10, 680, C11 330 Install

C12 27, C13 150, C14 100, C15 100, C16 220, C17 220, C18

47 Install

C19 12, C20 39, C21 150, C22 220, C23 100 Install

C24 12, C25 39, C26 82, C27 150, C28 68 Install

Core Winding Table

REF

TYPE

T

IN.

Wire

IND.

Clock

L1, L2

T68-1

(BLU)

20

19

22

5.08 uH

7-5

L3,L4

T50-2

(RED)

22

17

24

2.65 uH

7-5

L5

T44-2

(RED)

15

13

24

1.37 uH

7-5

L6

T44-2

(RED)

13

12

24

1.17 uH

7-5

L7

T37-6

(YEL)

12

9

24

580 nH

7-5

L8

T37-6

(YEL)

11

8

24

470 nH

5-7

L9

T37-6

(YEL)

10

8

24

430 nH

8-3

L10

T37-6

(YEL)

11

8

24

470 nH

7-5

L11

T37-6

(YEL)

10

8

24

430 nH

7-5

L12

T37-6

(YEL)

8

7

24

360 nH

10-2

L13

T37-6

(YEL)

7

7

24

280 nH

11-1

Where: T=turns; IN.=inches; IND= inductance; Wire=AWG

Clock – Clock Face where winding occupy space on the

core between a start time (7pm) and a end time (5pm)

example. Evenly adjust the wire spacing to match the clock

setting.

Core Winding Technique

The starting position: Divide

the wire in half letting the

core hang down. The wire

passing through the core

counts as one turn.

L3 Example:

Wind one side. Start with

the wire in the back and

wrap 10 turns on the right

side.

Use a pair of needle nose

pliers to aid in pulling

the wire tight against the

core as you wrap it around

the core.

Wind the other side. Wrap

10 turns on the other

side.You now have 21 turns

through the core. I

squeeze up the wraps to be

tight. Your inductors must

be wound with the wires on

the sides shown or the

inductor footprint will

not match the circuit board layout.

If the core does not fit the pattern (wound wrong), do not

try to make it work, strip the wire and wind it again correctly.

Spread the windings equally about the core using the clock

code.

Core Installation

Install L1-L2 last because of the size (see picture for detail).

Install L3-L13. Pull the leads tight. Align the core vertical

and solder.

Repeat for each inductor one by one. Solder as you go.

Install

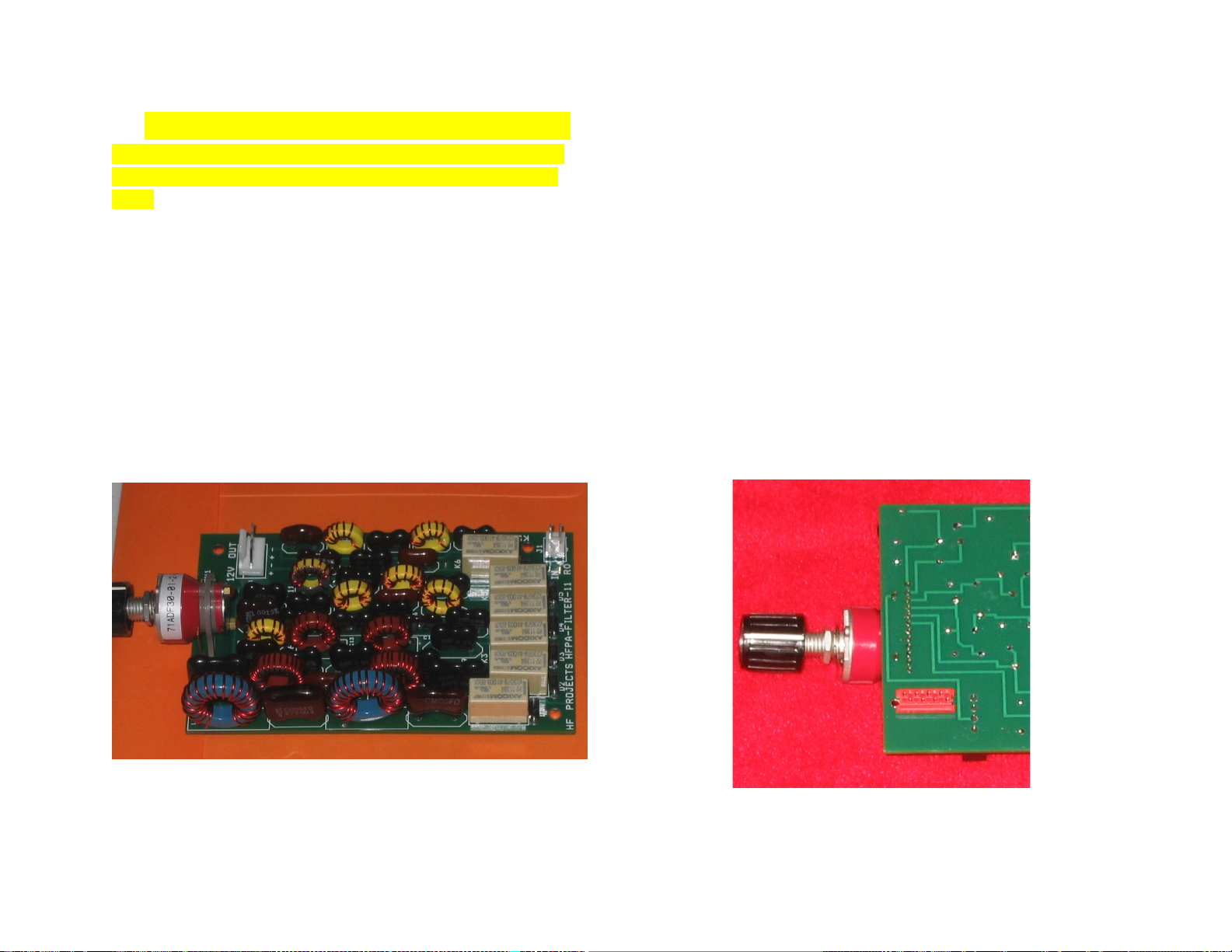

Switch Assembly

Insert the switch on the top side of the assembly. Make sure

the leads are flush with the board. Install

Connector Assembly

Insert J1 and J2. Make sure the parts are flush and vertical.

Solder one pin to start, reheat while making final alignment.

Solder the remaining pins. Make sure the friction tab is in the

position shown below. The J1 tab is to the right and the J2 tab

is down in the drawing below. Install

Insert JR1. This component is installed from the back side of

the circuit board and soldered on the top side. It will only fit the

pattern one way. See picture below. Solder. Install

In-Circuit Tuning Adjustments

If you have a miniVNA device for your PC you can adjust the

filter in real-time for the best response curve. If you do not, you

can use the clock method of lead spacing and you should be

pretty close.

Note: You must attach 12V to J2 in order to use a

miniVNA. Observe polarity, pin 1 is +12V. You need power

because only the energized circuit does not have the input and

outputs grounded.

Consolidated Filter Response Where Y-axis = dB; X-axis = F

MHz

The Plot was acquired using a miniVNA sweeping 1 – 100

MHz. Data was captured to an Excel spread sheet and

graphed.

Selector Switch Stop Pins Installation

•The switch includes a little package that has two stop

pins and a sticker. Your goal is to install the pins in the

correct holes without losing the stop pins.

•Turn the shaft so the flat is on the right. Check ___

•Insert the pins at 12 and 6 o’clock. Cover with sticker.

Install

‐60

‐50

‐40

‐30

‐20

‐10

0

10

050 100 150 F160 dB

F8075 dB

F6040 dB

F3020 dB

F1715 dB

F1210 dB

Table of contents

Popular Amplifier manuals by other brands

AMS

AMS 1073DPA user guide

DX Engineering

DX Engineering RF-KIT Operating and Installing Instructions

Harris

Harris DA-DHR6804+D Installation and operation manual

Dekolink

Dekolink MW-CBDA-SMR-800-900-1W65 Installation and operating instructions

Kistler

Kistler 5074A Series instruction manual

Adcom

Adcom GFA-5800 Service manual

Ashly

Ashly Electronic Amplifier none operating instructions

Cobalt Digital Inc

Cobalt Digital Inc 9910-DA-AV product manual

Crown

Crown PSA-2 Specifications

Origin Effects

Origin Effects Cali76 instructions

Navison audio

Navison audio NVS-003G Setup and operation manual

FiberLabs

FiberLabs EDFA-1550 Series Technical Passport