Hidea EF20 User manual

EF30

EF20

The EF20 EF30 and the standard accessonries

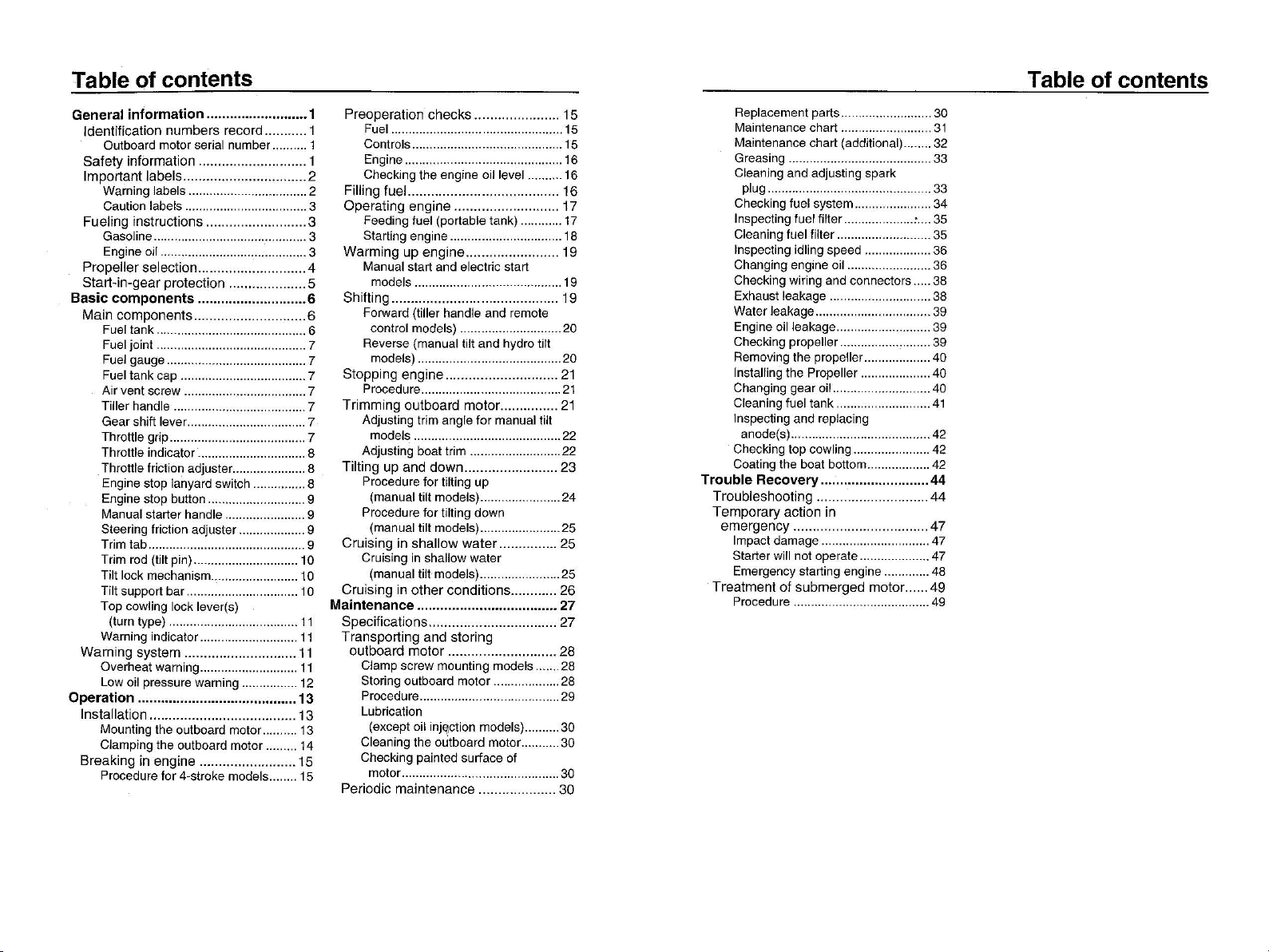

Table

of

contents

General

information

.....

.........…

.........1

Identificatio

门

numbers

record...........1

Outboard motor serial number...

....…

1

Safety

information ............................ 1

Important

labels................................2

Warning labels .............….................2

Caution labels

.....川

........

..

.....

.

............3

Fueling instructions

......…

.........

.......3

Gasoline..

……·………..…

3

Engine oil.

………………

..

.

....3

Propeller

selection......................

......4

Sta

同斗

n-gear

protection ..............

......5

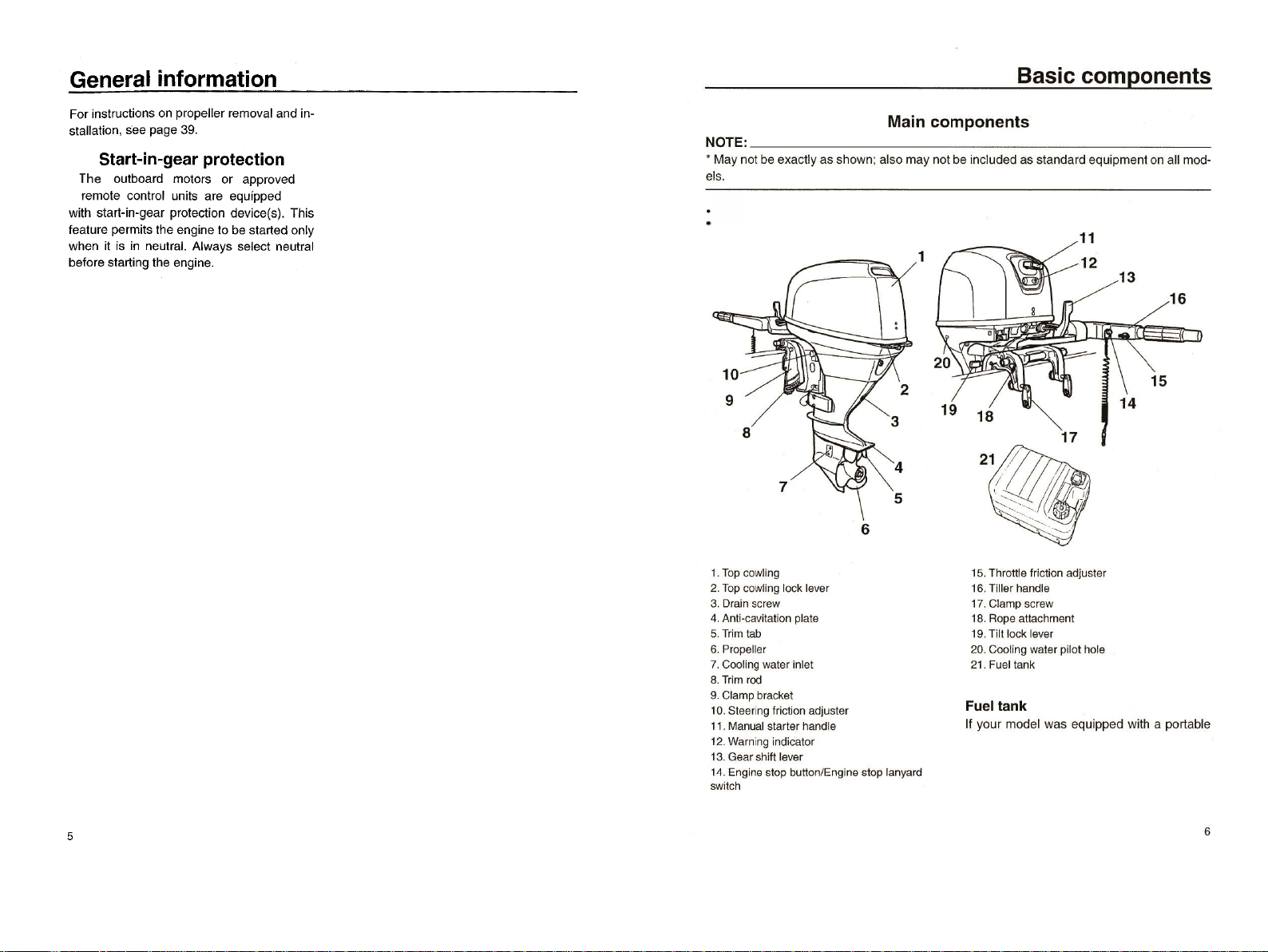

Basic

components

............................6

Main

components

…-………...............6

Fuel tank

.....…

…

……

.

,……

.6

Fuel joint .............

..

.....

..

.........… ........7

Fuel gauge.........

…..............…………

.7

Fuel tankcap

..

....... .......................... 7

Air vent screw

..

......................

....

.......7

Tiller handle .......

..

..

........................... 7

Gear shift lever.........

..

.....

......

............ 7

Throttle grip..……...….........…...........7

Throttle indicator….................…........8

Throttle friction adjuste

r..

...........

.....…

8

Enginestop lanyard switch ...............8

Engine stop button...........

....

............. 9

Manual starter handle ..............

..

....

...

9

Steering Iriction adjuster

..

................. 9

Trim tab....

..

.......................................9

Trim

rod

(tilt pin)..............................10

Tilt lock mechanism......................... 10

Tilt support bar

..

...............

....

........

...

10

Top cowling lock lever(s)

(turn type)

..

..........川…….."..…‘

....

.

.11

Warning indicator.................

....……

.11

Warning

system

.............................11

Overheat warning.....…....…..........

11

Lowoil pressure warning

….........

12

Operation

....

..

.........……

....................13

Installation ......……..…………..........13

Mounting the outboard motor........

..

13

Clamping the outboard motor….....14

Breaking

in

engine

...............口

......15

Procedure for 4-stroke models........15

Preoperation

checks

...........……

..15

Fuel

……·…

..................................15

Controls....................

………

…

………

15

Engine............

……

..................16

Checking the engine oil level

..

........16

Filling

fue

l..............................………

16

Operating

engine

....……....…

.....17

Feeding fuel (portable tank) .

...…

..17

Sta

同

ing

engine.............................

...

18

Warming

up

engine..

…........………

..19

Manual startand electric

sta

内

models .........….......... ................19

Shifting

......................……

...............19

Forward (tiller handle and remote

control models)

...……

............20

Reverse (manual tilt and hydro tilt

models).............

………

...................20

Stopping

e

门

gine.....................

.

.......21

Procedure........................................

21

Trimming

outboard

motor..

…..........

21

Adjusting trim angle

lor

manual tilt

models ..........................................22

Adjusting boat trim ..........................22

Tilting

Up

and

down

…-…-…

..........23

Procedure for tilting up

(manual tilt models)..

……

.............24

Procedure for tilting down

(manual tilt models).......................25

Cruising

in

shallow

water

...............25

Cruising in shallow waler

(manual tiltmodels).........

……

........25

Cruìsing in

other

conditions............

26

Maintenance

.................圃..............…

.27

Specificatiorls..........................

……

.27

Transpo

同

ing

and

storing

outboard

motor

............................

28

Clamp screw mounting models.......28

Storing outboard motor

..

.................28

Procedure........................... ......…..29

Lubrication

(except oil

inj~ction

models)..........30

Cleaning the outboard motor...........30

Checking painted surface

01

motor.........….................................30

Periodic

maintenance

............…

....30

Replacement parts..........................30

Maintenance chart

....…....………

.31

Maintenance chart (addilional)........32

Greasing ..............................… ...33

Cleaning and adjusting spark

plug..............

……...牛

.33

Checking fuel system.........

..

........... 34

Inspecting fuel filter

...............叫

...:....35

Cleaning fuel filter ..............

..

.…

....35

Inspecting idling speed ...................36

Changing engine oil

.….....…

........36

Checking wiring and

connecto

邸

....38

Exhaust leakage ..........

..

.................38

Water leakage.....................

..

..

........39

Engine oilleakage.

…...

….....‘

...39

Checking propeller........….........…… 39

Removing the propeller...................40

Installing the Propeller ........

..

..........40

Changing gear oil............................40

Cleaning fuel tank

..

...........…

..

.........41

Inspecting and replacing

anode(s)........ …

..

.......................42

Checking top cowling

………….4

2

Coating the boat bottom... …...........42

Trouble

Recovery

............................

44

Troubleshooting ........…..................44

Temporary

action

in

emergency

...................................47

Impact damage

.…

........................47

Starter will not operate....... ............ 47

Emergency starting engine .............48

Treatment

of

submerged

motor......

49

Procedure .......................................49

Table

of

contents

General

information

Identification

numbers

record

Outboard

motor

serial

number

The

outboard motor

ser

ial

number

is

stamped

on

the

label attached

to th

e port

side

of

the cl

amp

bracket or

the

upper

part

of

the

sw

i

ve

l bracket

Record

your

outboard motorserial

number

in

the

spaces

provided to assist you in ordering

spare

pa

川

s

from

your

dealer

or

for

reference in case your

outboa

rd

motoris sto-

len.

ZMU02638

1.

Outboard

motor

ser

ial

number

loc

ation

& Safety

information

• Beforemounting or operating the outboard

motor, read this entire manua

l.

Reading it

should give you an understanding of the

motor and its operation.

• Before operating the boat, read any own-

er's or operator's manuals supp

li

ed with it

and all labels. Be sure you understand

each item before operating

•

00

not overpower the boat with this out-

board moto

r.

Overpowering the boatcould

result

in

loss ofcontrol. The rated powerof

the outboard should be equal to or less

than the rated horsepower capacity of the

boa

t.

If the rated horsepower capacity

of

the boat is unknown, consult the dealer

or

boat manufacturer.

•

00

not modify the outboard. Modifications

could make the motor unfit

or

unsafe to

use

• Incorrect propeller selection and incorrect

use may not only cause engine damage,

but al

so

adversely affectfuel consumption.

Consult your dealer for correct use.

• Neveroperate afterdrinking alcohol

or

tak-

ing drugs. About 50% of a

ll

boating fatali-

ties involve intoxication

• Have an approved personal flotation de-

vice (

PF

O)

on board for every occupan

t.

It

is a good idea to wear a

PFO

whenever

boating. At a minimum, childr

en

and non-

sw

immers should always wear PFOs, and

everyone should wear PFOs when there

are potentially hazardous boating condi-

tions

• Gasoline is highly flammable, and its va-

pors are flammable and explosive. Handle

and store gasoline carefull

y.

Make sure

there are no gas fumes

or

leaking fuel be-

fore

s

t

a

同

in

g

the engine

• This product

em

its exhaust gases

wh

i

ch

contain carbon monoxide, a colorless,

。

dorless

gaswhich may cause brain dam-

age

or

death when inhaled. Symptoms in-

clude nausea, dizziness, and drowsiness

Keep cockpit and cabin areas well ventilat-

ed.

Avoid blocking exhaust outlets

• Check throttle, shift, and steering for prop

er operation before starting the engine.

• Atlach the engine stop switch lanyard to a

secure place

on

your clothing, or your arm

or leg while operating. If you accidentally

leave the helm, the lanyard will pull from

Ihe swilch, stopping the engine.

• Know Ihe marine laws and regulations

where you will beboating -and obey them

• Stay informed aboul the wealhe

r.

Check

wealher forecasts before boating. Avoid

boating in hazardous weather.

• Tell someone where you are going: leave

a Float Plan with a responsible person. Be

sure

10

cancellhe Float Plan when you re-

turn

• Use common sense and good judgment

when boating. Know your abililies, and be

sure you understand how your boat han-

dles lindérthe different boating conditions

you may encounte

r.

Operate within your

limits, and the limils

ofyour

boa

t.

Always

operate at safe speeds,and keep a careful

watch for obslacles and olherIraffic.

• Always watch carefuUy for swimmers dur-

ing the engine operation.

• Slay away from swimming areas.

• When a swimmer is in the water near you

shift inlo neulral and shut offIhe engine.

•

00

not iIIegally discard empty containers

used

10

replace or replenish

oi

l.

For the

correct processing

of

empty

containe

邸,

consult the dealer where.you purchased

the oil.

• When replacing oils used to lubricate the

product (engine

or

gear oil), be sure

t

口

wipe away anyspilt

oi

l.

Neverpouroil wilh-

out using a funnel

or

similardevice. If nec-

essary, verify Ihe necessary replacemenl

General information

procedure with the dealer.

• Neverillegallydiscard (dump) the product

re

∞

mmends

∞

nsulting

the dealer

on discarding the produc

t.

Important

labels

Warning

labels

Label

,?‘

'1"!':I~II~[

e'I

•

Be

sure

shift

control

is

in

neutral before

starting

engine. (except 2HP)

• Do

not

touch

or

remove electrical

pa

叫

S

when

starting

or

during

operation.

• Keep hands,

hair

,

and

clothes

away

from

flywheel

and

other

rotating parts

while

engine

is

running_

Label

,【帽

•

This

engine

is

equipped

with

a neutral

starting

device.

• The

engine

will

not

start

unless

the

shift

control

is

in

neutral

position.

2

General

information

Caution

labels

Label

腾腾腾;

Transport

and

store

the

engine

only

as

shown.

Otherwise

,

engine

damage

could

result

from

Leaking oil.

Fueling

instructions

,

1

‘

,

'I'/!':I~

11

H

帽

GASO

Ll

NE

AND ITS VAPORS ARE HIGH-

LY FLAMMABLE AND EXPLOSIVE!

•

Do

not

smoke

when

refueling,and keep

away

from

sparks

,

Ilames

,

or

other

sources

of

ignition.

•

Stop

engine

before

refueling.

• Refuel

in

a well-ventilated area. Refuel

portablefuel

tanks

ofl

the

boat.

• Take care

not

to

spill

gasoline.

If

gaso-

line

spills

,

wipe

it

up

immediately

with

dry

rags.

• Do

not

overfill

the

fuel

tank

,

• Tighten

the

filler

cap

securely

after re-

fueling.

•

If

you

should

swallow

some

gasoline,

inhale a

lot

of

gasoline

vapor

,

or

get

gasoline

in

your

eyes,

get

immediate

3

medical attention,

•

11

any

gasoline

spills

onto

your

skin

,

im-

mediately wash

with

soap

and

water.

Change

clothing

if

gasoline

spills

on

i

t.

•

Touch

the

fuel

nozzle

to

the

filler

open-

i

ng

or

funnel

to

help prevent

electro

圃

static

sparks.

装翩翩

Use

only

new

clean

gasoline

which

has

been

stored

in

clean

conlainers

and

is

not

contaminated

with

water

or

foreign

mat-

ter.

Gasoline

Recommended gasoline

Regular unleaded gasoline

1I

knocking

or

pinging occurs, use a

di

仔

erenl

brand

01

gasoline or premium unleaded fuel

1I

unleaded gasoline is not available, then

premium gasoline can be used, If leaded

gasoline is usually used, engine valves and

related partsshould

be

inspected aflerevery

300 hours

01

operation.

Engine

oil

Recommended engine oil:

4-stroke moloroil wilh a combination

01

lhe

following SAE and API oilclassi-

lications

Engine oil type SAE:

1

OW-30

or

10W-40

Engine oil grade API

SE,SF,

SG

,SH,SJ,SL

Engine oil quantity (excluding oil lilter):

1.7 L (1.80 US qt) (1.50 Imp.qt)

NOTE:

1I

Ihe recommended engine oil grades are

not available, select

an

alternalive Irom

Ihe

lollowing chart according to the average

temperalures in your area,

SAE

API

-4

14

32

50

68

86

104

122'F

-20 -10

D

10

20

30

40

511ß

K

10W-30

卫

SE

SF

:

ISG

仆

<:

10W

-4

0

:::>

:

ISH

: ISJ

k'

50

30

~

: : ISL

I

15W

-

40

二辛:

SH

:匾匣巫二丰

SJ

SL

翩翩

;

AII 4-stroke enginesare

shipped

from

the

factory

without

engine oi

l.

Propeller

selection

The performance

01

youroulboard motor will

be

criticallyaffected by your choice

01

propel-

ler, as

an

incorrect choice could

adversely

affect performance and could also seriously

damage the moto

r.

Engine speed depends

on

the propeUer size and boat load.

1I

engine

General

information

speed is

100

high or

100

low for good engine

perlormance, this

wiU

have

an

adverse effect

on

the engine

These outboard molors are litted with pro-

pellers chosen

10

pe

斤。rm

well over a range

01

applications,butthere may be uses where

a propeller with a different pitch would be

more appropriate. For a greater operating

load, a smaller-pitch propeller is more suit-

able as it enables the correct engine speed

to be maintained. Conversely, a larger-pitch

propeller is more suitable

lor

a smaller oper-

ating load.

The dealers stock a range ofpropellers,

and can advise you and install a propelleron

your outboard that is besl suiled to your ap-

plication.

1.

Propeller

diameter

in

inches

2.

Pr

o

peller

pitch

in

inches

3.

Type

01

p

盯

p

e

ller

(propeller

mark)

NOTE:

Selecta propellerwhich will allow the

e门

glne

to reach the middle

or

upper half

01

the oper-

ating range at lull throttle with the maximum

boat load. If operating conditions such as

lightboat loadsthen allow the engine r/min to

ris

e above the maximum

recommEmded

range, reduce the throttle setting to maintain

the engine

in

the properoperating range.

4

EF20

EF30

Basiccomponents

fuel tank, its funclion

is

as follows.

r

,,,,

"'il~

,,

~[1

幅

The1uel tank supplied

with

th

ls engine Is

its dedicated fuel reservoir and

must

not

be

usedasa fuel storage container. Com-

merclal usersshould

conform

to

relevant

IIcensing

or

approval

authority

reguia-

tions.

1.

Fuel

join

t

2.Fu

el

g

auge

3.

Fue

lla

nk

cap

4.

Air

v

ent

screw

Fuel

joint

了

his

joint

is

used to connecl Ihe

fu

e

llin

e

Fuel

gaug

.e

This gauge islocated on either the fuel tank

cap oron the fuel

jo

intbase. 1I shows the ap-

proximale amount

01

fuel remaining in the

tank

Fueltank

cap

This cap seals the

lu

el tank.When removed,

Ihetankcanbelilledwi

lh

lue

l.

To removethe

cap, turn it

co

unterciockwise

Air

vent

screw

This screw is on the luel tank cap. To loosen

the screw, turn it counterclockwise.

7

Tiller

handle

Tochange direction, mo

ve

the tiller handle to

the left or right as necessary

到

U

Throttle

indicator

The luel consumption curve

on

the throttle

indicator shows the relative amount

01

luel

consumed

lor

each Ihrottle posilion. Choose

the setting that olfers Ihe best performance

and luel economy

lor

the desired operation.

Gear

shift

lever

Pulling the gear shift lev

er

to

wa

rds you puts

the engine in lorward gear so that Ihe boat

mo

ves ahead. Pushing the lever away Irom

you puts the engine in reverse gear so th

al

the boal moves aslern. 1

1.

Thr

o

ttle

indi

ca

tor

1.

Forw

ard

宇

"

2.

Neut

ral"N"

3.R

ev

erse

"R"

Throttle

friction

adjuster

A Iriction device provides adjustable resis-

tance to movement

01

the throttle grip

or

the

remote controllever, and can be set accord-

ing to operatorprelerence.

To increase resistance, turn the adjuster

clockwise. To decrease resistance, turn the

adjuster counlerclockwise

Throtlle

grip

The throlt

le

grip is on the liller handle. Turn

the grip counle

rcl

ockwise

10

increase speed

and clockw

is

e 10 decrease speed

,

1

‘

""!':I~II~r

e'l

Do

not

overtighten

the

friction

adjuster

.

If

Basic

components

there

is

too

much

resistance,

it

could

be

difficult

to

move

throttle

lever

or

grip

,

which

could

result

in

an

acciden

t.

When constant speed is desired, lighten the

adjuster to maintain the desired throttle set-

ting

Engine

stop

lanyard

switch

The lock plate must be attached

10

the en-

gine stop switch

lor

the engine to

run

. The

lanyard should be attached to asecure place

on the operator's clothing, or arm

or

¥

leg

Should the operator lall overboard or leave

the helm, the lanyard will pull out the lock

plate, stopping ignition to the engine. This

will prevent the boat Irom running away un-

derpower

,?‘

.""!':I~II~

【帽

• Attach the

engine

stop

switch

lanyard

to

a secure place

on

your

clothing

,

or

your

arm

or

leg

while

operating.

• Do

not

attach

the lanyard

to

clothing

that

could

tear

loose.

00

not

route

the

lanyard where

it

could

become entan-

gled,

preventing

it

from

functioning.

•

Avoid

accidentally

pulling

the la,nyard

during

normal

operation.

Loss

of

en-

gine

power

means

the

loss

01

most

steering

contro

l.

Also

,

without

engine

power

,

the

boat

could

slow

rapidly.This

8

Basic components

could

cause people and objects

in

the

boat

to

be thrown forward.

NOTE

:

The engine ca

nn

ot be started with t

he

lock

plate

re

moved.

1.

Lanyard

2.L

∞

k

pl

ate

Engine

stop

button

To open the ignition

ci

rcuit a

nd

stop the en-

gine, push this button.

Manual

starter

handle

To

sta

rt

the engine, first gently pull the h

an

-

dle out until resistance is fel

t.

Fromthat posi-

ti

on, then pull

th

e handle straig

ht

out quic

kl

y

tocrank t

he

engine.

9

St

回

ring

friction

adjuster

A friction device provides adjusta

bl

e resis-

tance tothesteering mechanism, and can be

set according to operatorpreference. An ad-

justing screw orbolt is located on the swivel

bracke

t.

,

1

‘

,

'I'I

!

1:mm

帽

00

not

overt

ightenthe

friction

adjuster.

If

ther

e is t

oo

much

resistance,

it

could

be

dif

f

icult

to

steer

,

which

could

result

in

an

accident.

Trim

tab

The trim tab should be

a

啕

us

t

ed

so that t

he

steering control can be

tu

med to either the

right or left by applying the same amount 01

lorce.

,?‘,

'1"

!1:1~

1I~【帽

An

improperly

adj

uste

d

trim

tab could

cause

difficult

st

e

ering

. A

lw

ays

tes

t run

aft

er

the

trim

tab

has

been

ins

talled

or

re-

placed

to

be sure steering

is

correc

t.

Be

sure

yo

u have tightened

the

bolt

a

ft

er

ad-

iusting

the

trim

tab.

1I

th

e boat tends to veer the left

(po

叫

s

i

de

)

,

tum the trim tab rear end to the port side "

A"

in the ligure.

1I the boat tends

to

veer the right (starboard

side), tum the trim tab end to the starboard

side"8" in the figure

1.

T

ri

mt

ab

2. 8olt

Tr

im

r

od

(til

t pi

n)

T

he

posi

ti

on

of the trim rod determines the

minimum trim angle ofthe outboard motor in

re

lat

ion

to the transom.

Basic components

1.

Tilt

lock

l

ever

To lockit,set the tilt lock leverin the lock

po

胃

sition. To

re

lease, push the tilt lock lever in

the

re

lease position

Ti

lt

support

bar

Thetiltsupportbarkeepsthe outboard

mo

to

r

in

the tilted

up

position.

10

Basic

components

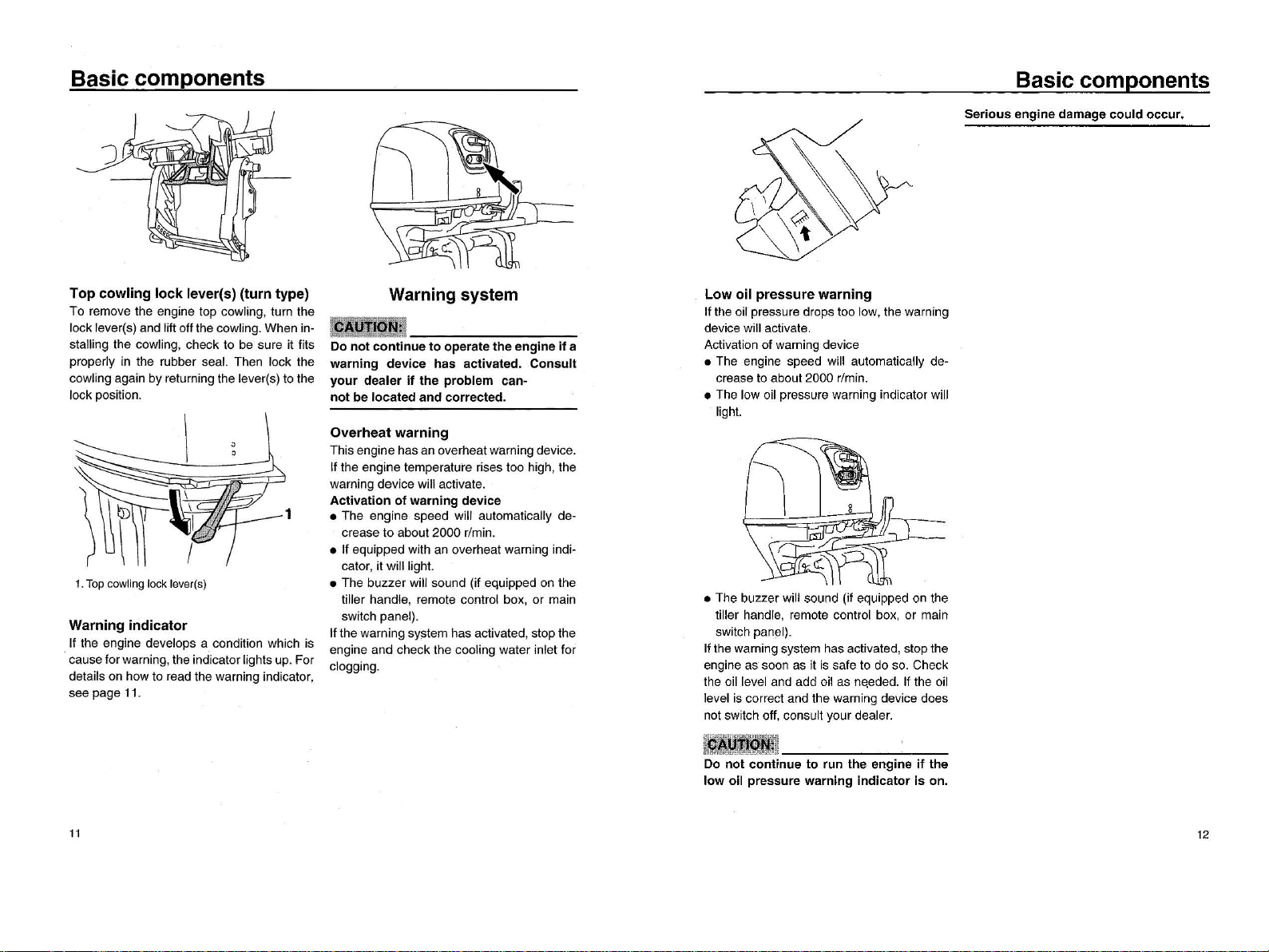

Top

cowling

lock

lever(s)

(turn

type)

To remove the engine top cowling, turn the

locklever(s) and liftoffthe cowling. When in-

st

剖

ling

the cowling, check to be sure it fits

properly in the rubber sea

l.

Then lock the

cowling again

by

returning the lever(s) to the

lockposition.

1.

Top

cowling

lock

l

ever(s)

Warning

indicator

If the engine develops a condition which is

causeforwarning,the indicatorlights up.For

detailson how to read the warning indicator,

see page

11.

11

Warning

system

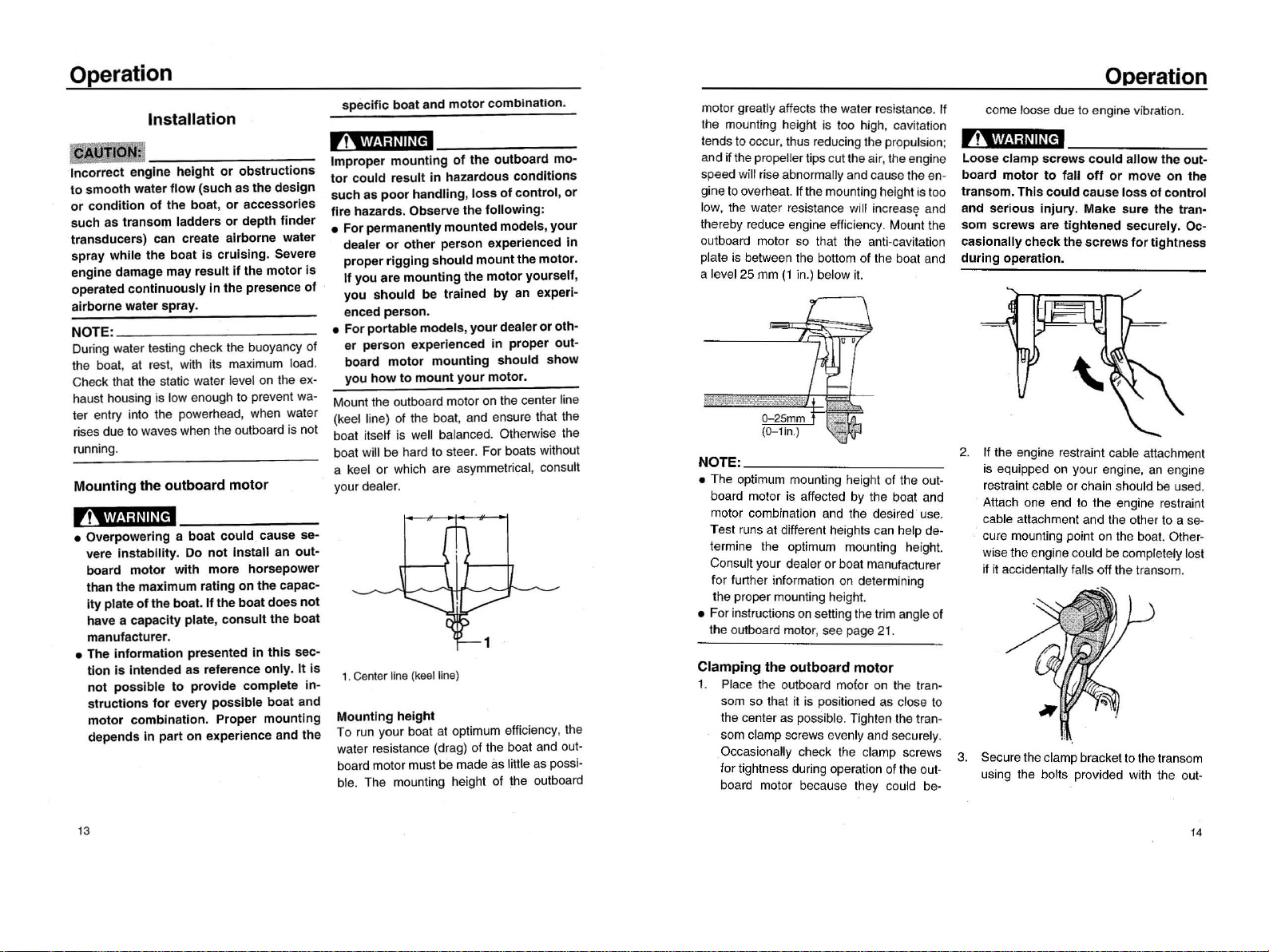

Low

oil

pressure

warning

1I

the oil pressure drops too low, the warning

device will activale.

Activation

01

warning device

• The engine speed will automatically de-

crease to aboul

2000

旷

mm.

• The low oil pressure warning indicalor will

lighl.

嫌腾

腾

接

00

not

continue

to

operate

the

engine

if

a

warning

device

has

activated.

Consult

your

dealer

if

the

problem

can-

not

be

located

and

corrected.

Overheat

warning

Thisengine has an overheatwarning device.

1I

the engine temperalure rises too high, Ihe

warning device will aclivale.

Activation

of

warning

device

1 • The engine speed will automalically de-

crease

10

aboul2000 r/min.

• If equipped wilh an overheal warning indi-

calor, it willligh

l.

• The buzzer will sound (if equipped on the

till

er

hand

怡,

remote control box,

or

main

switch panel).

1I

the warning system has activated, stop the

engine and check the cooling water inlel for

clogging.

• The buzzer will sound (il equipped on the

tiller handle, remote control box, or main

switch panel)

1I

the warning system has activated,stop the

engine as soon as it

is

safe to do so. Check

the oil level and add oil as needed.

1I

the oil

level is correct and Ihe warning device does

nol swilch

011

, consult your deale

r.

e

1n

uO

Hs

a-VE

no

--E&E

‘-

qHa

nc

ed

awnH

hi

---nB

n-m

un

,

-VE

bm

ee

』

r

mu

;15

谧黯叫地

挡回慰。阿

摇撼

cp

it-

;;

倘…附

mo

m

蛐翩翩

DW

淄燃

nub

Basic

components

Serious

engine

damage

could

occur.

12

Operation

Installation

Incorrect

engine

height

or

obstructions

to

smooth

water

flow

(such

as

the

design

or

condition

of

the

boat

,

or

accessories

such

as

transo

l'!l ladders

or

depth

finder

transducers)

can create

airborne

water

spray while the

boat

is

cruising.

Severe

engine damage

may

result

if

the

motor

is

operated

continuously

in

the

presence

of

airborne

water spray.

NOTE

:

During water testing check the buoyancy

01

the boat, at rest, with

it

s ma

xi

mum load.

Check that the static wat

er

level on the ex-

haust housing is low enough to prevent wa-

ter entry into the powerhead, when

wa

ter

rises due to waves when the outboard is not

runnlng.

Mounting

the

outboard

motor

,

1

‘ljlI!,

mll~

【帽

• Overpowering a

boat

could

cause se-

vere Instabliity.

00

not

install an

out-

board

motor

with

more

horsepower

than

the

maximum

rating

on

the

capac-

ity

plate

of

the

boat.

If

the

boat

does

not

have a capacity plate,

consult

the

boat

manufacturer

.

• The

information

presented

in

this

sec-

tion

is

intended

as

reference only.

It

is

not

possible

to

provide

complete

in-

structions

for

every

possible

boat

and

motor

combination. Proper

mounting

depends

in

part

on

experience

and

the

13

specific

boat

and

motor

combination.

,

"5'jjjij~

lI~【帽

Improper

mounting

of

the

outboard

mo-

tor

could

result

ín hazardous

conditions

such

as

poor

handling

,

loss

of

cont

r

ol

,

or

fire

hazards. Observe

the

following

:

• Forpermanently

mounted

models

,

your

dealer

or

other

person

experienced

in

proper

rigging

should

mount

the

motor

.

if

you

are

mounting

the

motor

yourself

,

you

should

be

trained

by

an experi-

enced

person

.

• For

portable

models

,

your

dealer

or

oth-

er

person

experienced

in

pr

oper

out-

board

motor

mounting

should

show

you

how

to

mount

your

motor.

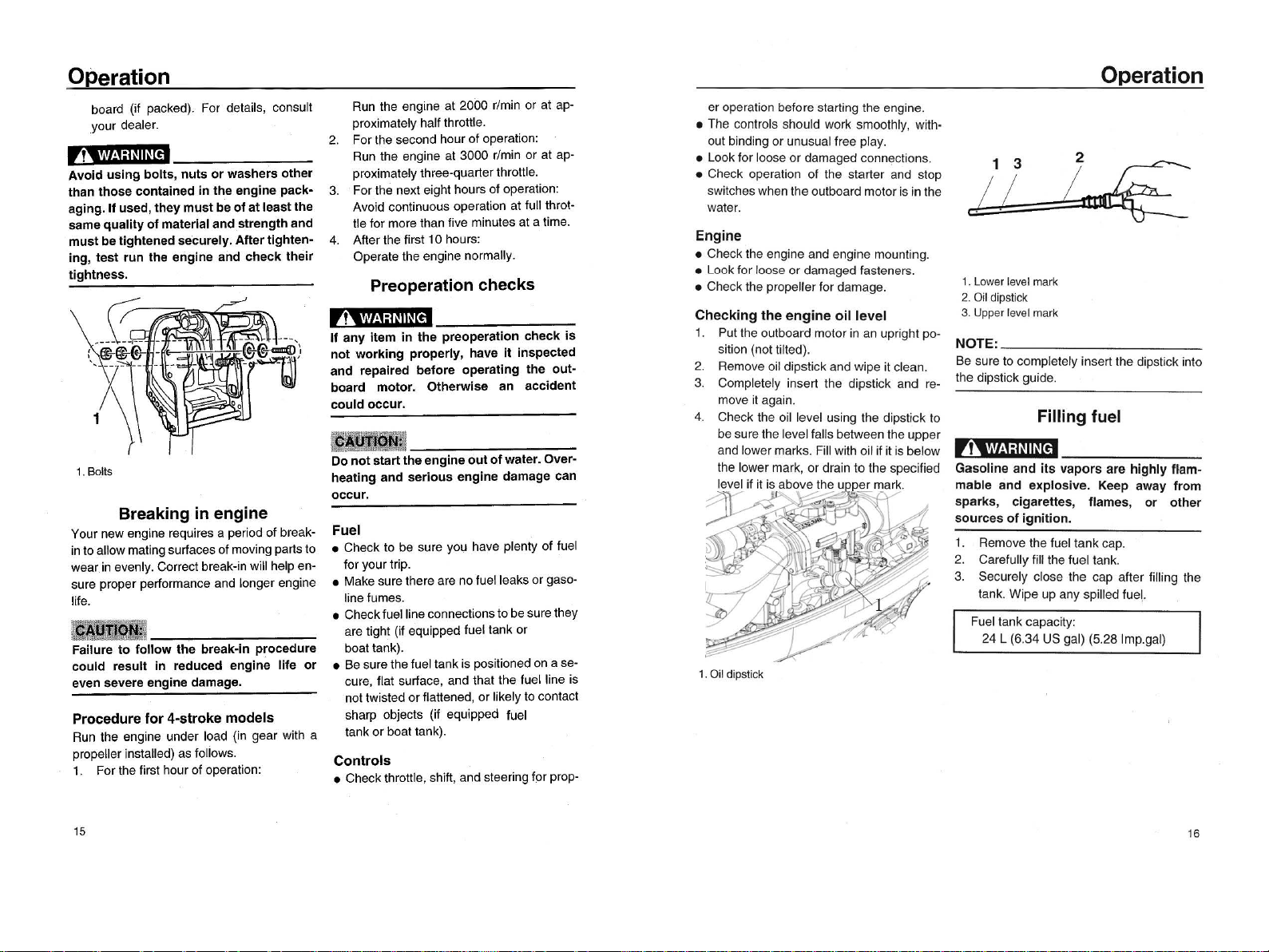

Mounl

lhe

outboard mot

or

on the center line

(keel line)

01

the boat, and

e

n5U

陀

t

ha

t

lhe

boat itself is well balanced. Otherwise the

boal

wi

ll

be

hard to steer. For boats without

a keel

or

which are asymmetrical, con

su

lt

your deal

er

1.

Cen

terl

ine

(keel

Un

e)

Mountlng

height

To run your boat at optimum efficiency, the

water resislance (drag) 01the boat and out-

board motormustbe made às little as

poss卜

bl

e.

The mounting height

01

the outboa

rd

motor

gr

eatly affects the water resistance. If

the mounting height is too high, cavitalion

tends

10

occur, Ihus reducing

lhe

propulsion;

and ifthe propellerlips cutIheair,the engine

speed will rise abnormally and cause the en-

gine to overhea

t.

1I the mounting heightis100

low, the waler resistance will inc

re

as!?

and

Ihereby reduce engine efficien

cy

. Mount the

oulboard motor

50

lha

t lhe anti-cavilalion

plale is belween the

bo

ttom

01

Ihe boat and

a le

ve

l 25 mm (1 in.) below i

t.

NOTE:

• The optimum mounting height 01the oul-

board molor is affected by Ihe boal and

motor combination and the desired'

U5

e

Test runs at different heights can help de-

termine Ihe optimum mounling height

Consult your dealeror boat manulacturer

for lurther inlormation on determining

the p

ro

per mounting height.

• F

or

instructio

ns

on setting IheIrim angle

01

the outboard mot

or

, see page 21.

Clamping

the

outboard

motor

1. Place the outboard molor on the tran-

som so that it is positioned as close to

the center as possible. Tighlen the tran-

som clamp screws evenly and securely.

Occasiona

ll

y check the clamp screws

lo

r tightness

du

ri

ng operation 01the oul-

boa

rd

motor because Ihey could be-

Qperation

come loose dueto engine vibration.

,?‘,

""~':J~lhH

帽

Loose

clamp

screws

could

allow

the

out-

board

motor

to

fall

oft

or

move

on

the

transom.

This

could

cause

loss

01

control

and

serious

injury. Make

sure

the tran-

som

screws

are ti

ghtened

securely. Oc-

caslonally

check

the

screws

for

tightness

during

operation.

2. 1I Ihe engine restra

int

cable attachment

is equipped on your engine, an engine

re5traint cable

or

chain should

be

use

d.

Attach one end

10

the engine restrai

nl

cable attachment and Ihe other

10

a

se-

cure mounting point on lhe boa

t.

Other-

wisethe engine could be complelely lost

il

it

a

∞

i

de

ntally

falls off the transom.

3. Securethe clampbrackeltoIhe

tr

ansom

using the bolts

pr

ov

ided wi

lh

the out-

14

QPeration

board (il packed). For details, consult

your dealer

,?‘

.'1'

1!

1

剖

~lhH

帽

Avoid

using

bolts

,

nuts

or

washers other

than

those

contained

in

the

engine pack-

aging.11 used,

they

must

be

01

at

leastthe

same

quality

01

material and strengthand

must

betightened securely.After tighten-

ing

,

test

run

the engine and

check

their

tightness.

1.

Bolts

Breaking

in

engine

Your 门

ew

engine requires a period

01

break.

in to allowmating surfaces

01

moving

pa

民

sto

wear

in

evenly. Correct break-in will help en-

sure proper

pe

斤。

rmance

and longer engine

lile.

翻腾腾意

Failure

to

follow

the

break-in procedure

could

result

in

reduced engine

lile

or

even severe engine damage.

Procedure

for

4-stroke

models

Run

the engine under load (in gear with a

propeller installed)

as

lollows

1.

For the lirst hour

01

operation:

15

Run

the engine at 2000 r/min or at ap-

proximately hallthrottle.

2.

For the second hour

of

operation:

Run

the engine at 3000 r/min or at ap-

proximately three-quarterthrottle.

3. For the next eight hours of operation:

Avoid continuous operation at luli throt-

tle for more than five minutes at a time.

4.

After the first 10 hours:

Operate the engine normaliy.

Preoperation

checks

,!'-'i!l唱

I~II~[

帽

1I

any

item

in

the

preoperation

check

is

not

working

properly

, have

it

inspected

and repaired

belore

operating

the

out-

board motor. Otherwise an accident

could

occur.

楼翻数通意

00

notsta

民

the

engine

out

01

water. Over-

heating and

serious

engine damage can

occur.

Fuel

• Check to be sure you have plenty

01

luel

lor

your trip.

• Make sure there are noluelleaks or gaso-

linelumes

• Checkluellineconnectionsto be sure they

are tight (il equipped fuel tank or

boat tank).

•

Be

sure the fuel tank is positioned on a se-

cure, Ilat surface, and that the luel line is

not twisted orIlattened, orlikely to contact

sharp objects (if equipped luel

tank orboat tank).

Controls

• Check throttle, shift, andsteering

lor

prop-

er

operation before starting the engine

• The conlrols should work Smoolhly, wilh-

out binding orunusual free play

• Look for loose or damaged connections.

• Check operation

01

the starter and stop

switcheswhen the outboard motoris in the

wa

ter.

Engine

• Check the engine and engine mounting.

• Look for loose

or

damaged fasteners.

• Checkthe propellerfor damage.

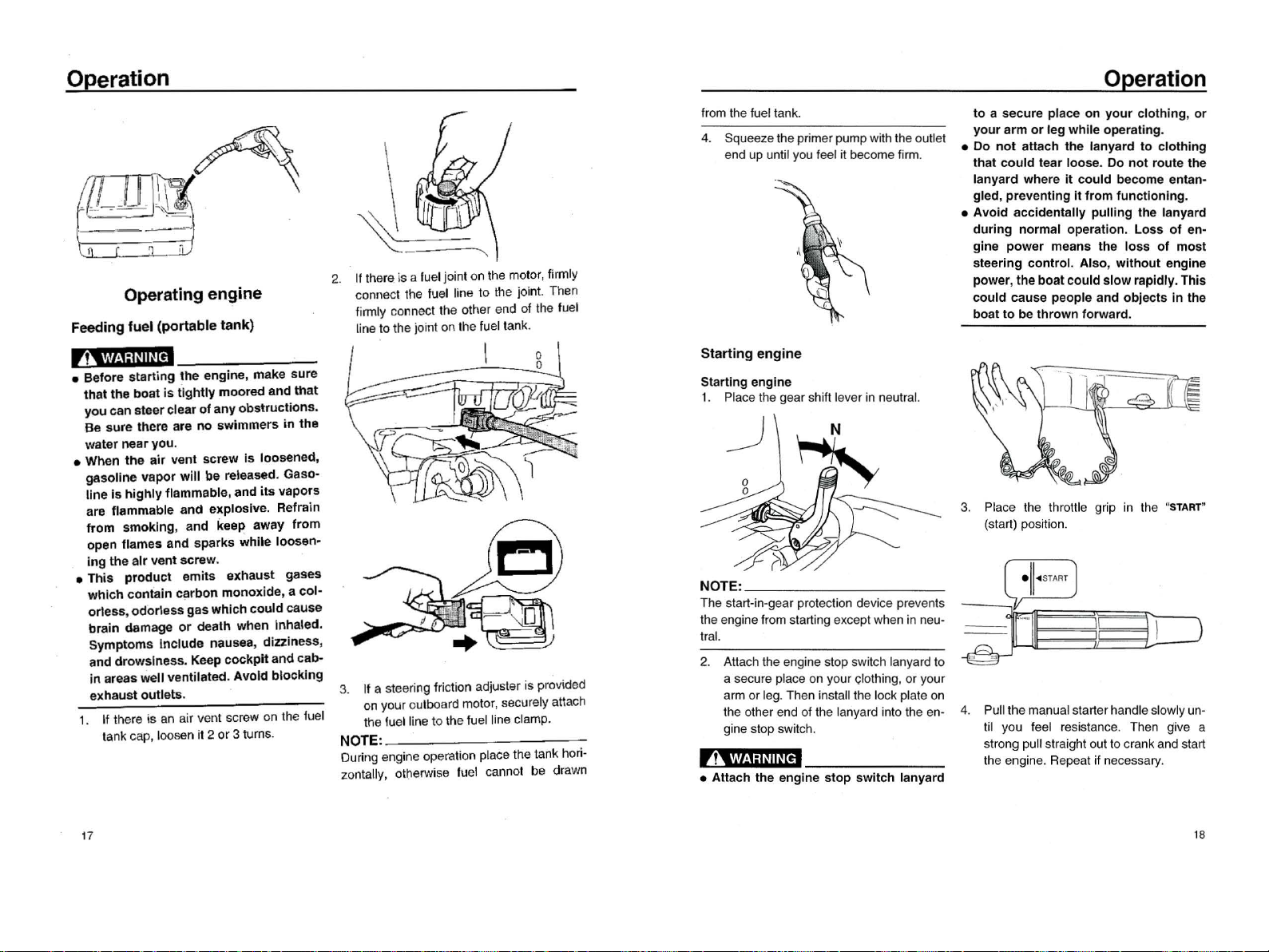

Checking

the

engine

oil

level

1. Put the outboard motor

in

an upright po-

sition (nol tilted).

2.

Remove oil dipstick and wipe it clean.

3. Completely insert the dipstick

and

re-

move

it

again

4. Check the oil level using the dipstick to

besure the level falls between the upper

and

l

ower

marks. Fill with o

il

if it is below

the lower

mark

,

or

drain

10

Ihe specified

level if

it

is

above

the upper mark

y

号

---

II

'

~

‘--

---

~

-.

'

/

1.

Oil

dipstick

Operation

1.

Lower

lev

el

mark

2.

Oil

dipstick

3.

Upper

level

mark

NOTE:

Be

sure to completely insert the dipstick into

the dipstick guide.

Filling

fuel

,帽

Gasoline

and

its

vapors are

highly

flam-

mable and explosive. Keep away

Irom

sparks

, cigarettes, flames,

or

other

sources

01

ignition.

1.

Remove the luel tankcap

2. Carelully lill the

lu

el tank.

3.

Securely close the cap after lilling Ihe

tank. Wipe up any spilied lue!

Fuel tank capacity:

24 L (6.34

US

gal) (5.28 Imp.gal)

16

Operation

Operatingengine

Feeding

fuel

(portable

tank)

,?‘

~"'~1:1"

1I1H帽

•

Before

starting

the

engine

,

make

sure

1hat 1he

boat

is

tightly

moored

and

怡、

at

you

can

steer

clear

of

any

obstruct

i

ons.

Be

sure

there

are no

s

硝

immers

in

the

water

near

you.

• When

the

air

vent

screw

is

loosened,

g8soline

vapor

will

be released. Gaso-

line

is

highly

flamm

自

ble

,

and

its

vapors

are flammable

and

explosive

. Refrain

from

smoking

,

and

keep

away

from

open

flames

and

sparks

while

1005en-

ing

the

alr

vent

screw

.

•

This

product

emits

exhau5t

gases

which

contain

carbon

monoxide

,a

col-

orless

,

odorl

e

ss

gas

which

could

cause

brain

damage

or

death

when inhaled.

Symptoms

include

nausea, dizzi

ness

,

and

dro

峭

Iness.

K

锦

P

cockpit

and

cab-

in

areas well ventilated.

Avold

blocking

exhaust

outlets.

1.

1I

there

恪

an

air vent scr

ew

on the fuel

tank cap, loosen it 2 or 3tu

rn

s.

17

2.

1I

Ihere is a luel joint on Ihe molor,lirmly

connect lhe

lu

el line 10 Ihe join

t.

Then

lirmiy

co

们

necl

the olher end 01Ihe luel

line 10 the joinl on Ihe

fu

eltank.

3.

lf

a steering

Iri

ctio

r、

adjuste

r

is provided

on your o

ulb

oard molor,securely a

ll

ach

the fue

llin

e to

Ih

e fuel iine clamp.

NOTE:

During engine operalion place

th

e tank hori-

zonlally, olherwi

se

fu

el cannol be drawn

from the fuel tank

4. Squeeze the primerpump withthe outlet

end up untii you feel

it

become lirm.

Starting

engine

Starting

engine

1. Place Ihe gear s

hilll

ever

in

neulral.

NOTE:

The

sla

rt-in-gear proleclion device prevenls

Ihe engine from slarting excepl when in neu-

Ira

l.

2. Attach

lhe

engine slop swilch lanyard 10

a secure piace on your çlothing. or your

arm

or

leg. Then inslalllhe lock plale on

Ihe o

lh

er end

01

the lanyard inlo the en-

gine slop sw

il

ch.

,

1

‘币,主,

':I~II~[

帽

• Attach the engine

stop

switch

lanyard

Operation

to

a

secure

place

on

your

clothing

,

or

your

arm

or

leg

while

operating.

•

00

n01 attach

the

lanyard

to

clothing

that

could

tear

loose.

00

not

route the

lanyard

where

it

could

become entan-

gled

,

preventing

it

from

functioning.

•

Avoid

accidentally

puliing

the lanyard

during

normal

operation.

Loss

of

en-

gine

power

means

the

loss

of

most

steering

contro

l.

Also

,

without

engine

power

,the

boat

could

slow

rapidly. This

could

cause

people

and

objects

in

the

boat

to

be

thrown

forward.

3. Place Ihe Ihrottle grip in Ihe "

START

"

(s

t

a叫

)

position.

4. Pull the manualslarter handleslowly un-

lil you leel resislance. Then

ωve

a

slrong pull straight ou

ll

o crank and slart

Ihe eng

in

e. Repeal if necessary

18

Operél

tion

5.

A

ft

er Ihe engine slarts, slowly relu

rn

Ih

e

manual slarler handle 10

il

s

or

iginal po-

silion belore releasing

il

NOTE:

•

Wh

en

Ih

e engine is cold,

il

n

ee

ds 10 be

warmed up. For lurth

er

inlorma

li

on, see

page 1

9.

• If Ihe engine is wa

rm

and lails

10

slart,

open

Ih

eIhrottle slightly andI

ry

10 sla

rt

Ihe

engine again. If Ihe engine slill lails 10

s

l

a

川

,

see

page 44

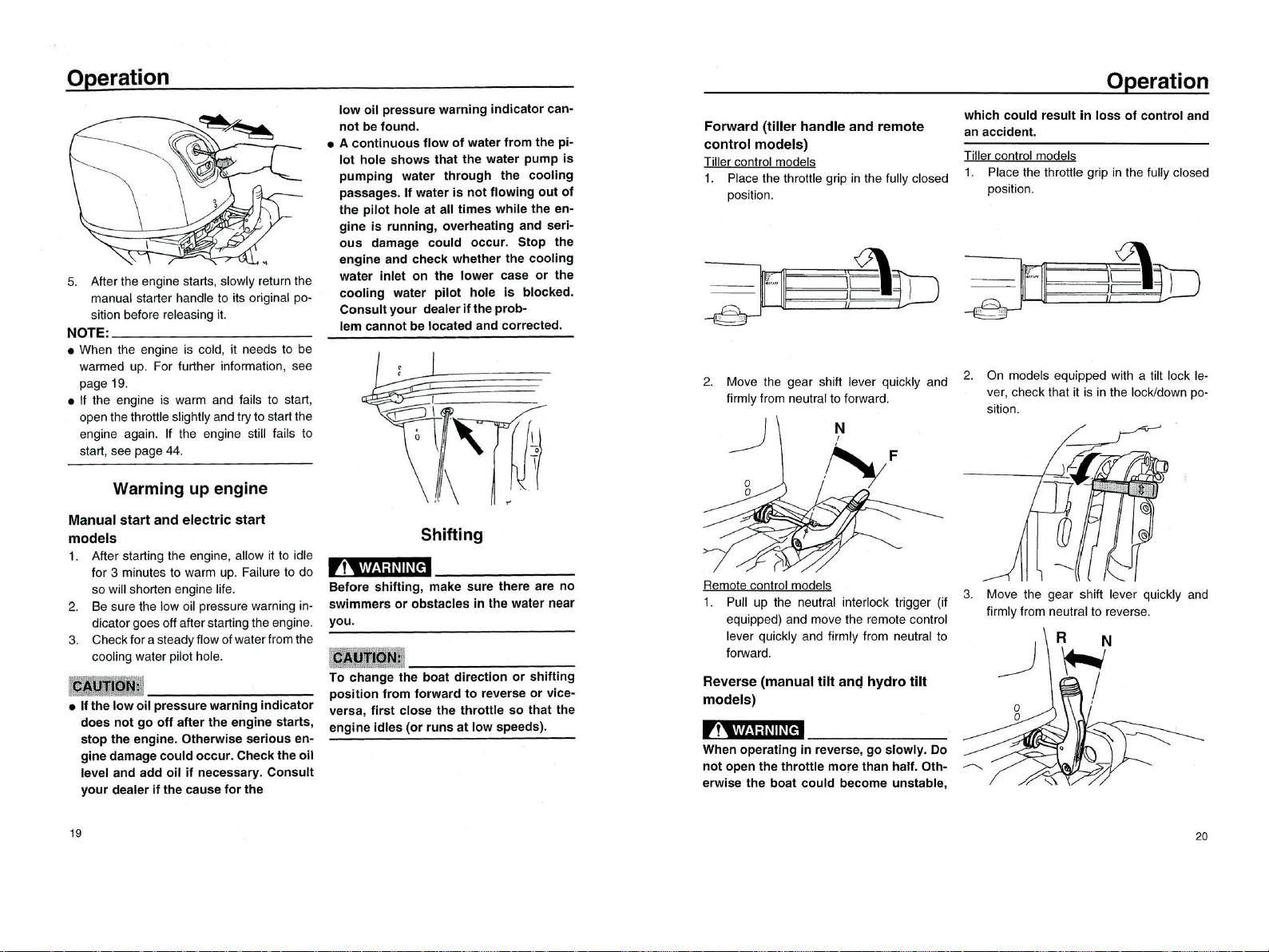

Warming Up engine

Manual

start

and

electric

start

models

1. Aft

er

sla

rti

ng

Ih

e engine, allow il 10 idle

lor 3 minules 10 warm up. Failure 10 do

sowill sho

rt

en engine lil

e.

2. Be sure Ihe low

oi

l pressure

wa

rning in-

dicalor goes 0

11

afterslartingIhe eng

in

e

3. Checkl

or

a

sl

eady

fl

ow 01walerIromIhe

cooling waler pilol hol

e.

激鳞

剿

罢

•

If

the

low

oil

pressure

warning

indicator

does

not

go

off

after

the

engine

starts

,

stop

the

engine

.

Otherwise

serious

en-

gine

damage

could

occur.

Checkthe

oil

level

and

add

oil

if

necessary.

Consult

your

dealer

if

the cause

for

the

19

low

oil

pressure

warning

ind

icator can-

not

be

found.

• A

continuous

flow

of

water

from

the

pi-

lot

hole

shows

that

the

water

pump

is

pumping

water

through

the

cooling

passages.

If

water

is

not

flowing

out

of

the

pilot

hole

at

all

times

while

the

en-

gine

is

running

,

overheating

and

seri-

ous

damage

could

occur

.

Stop

the

engine

and

check

whether

the

cool

i

ng

water

inlet

on

the

lower

case

or

the

cooling

water

pilot

hole

is

blocked

.

Consult

your

dealer

if

the

prob-

lem

cannot

be

located

and

corrected.

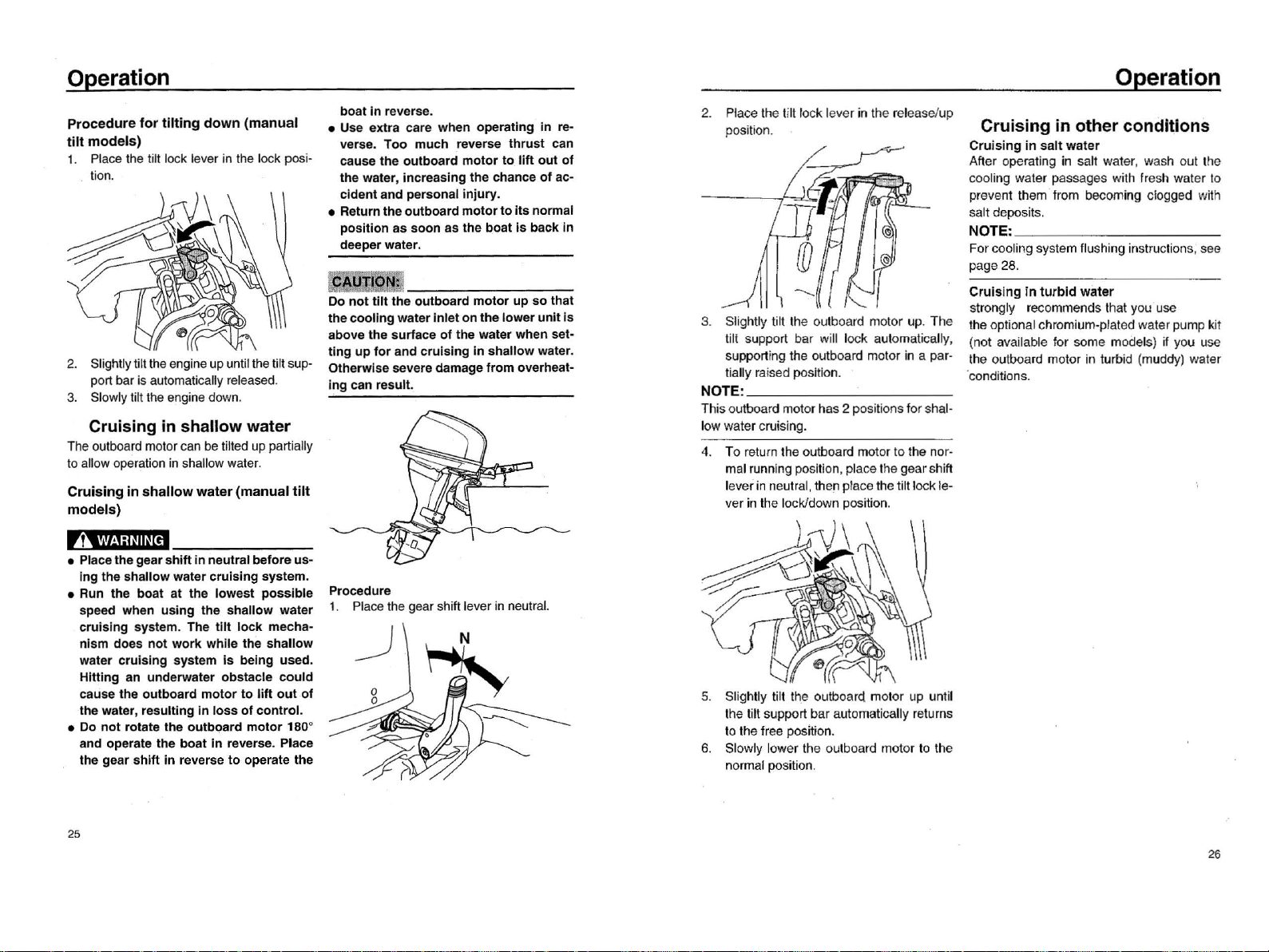

Forward

(tiller

handle

and

remote

control

models)

Tiller conlrol models

1.

Pl

ace Ihe Ihrottle grip in Ihe lully closed

P

臼

Ili

o n

Operation

which

could

result

in

loss

of

control

and

an accident.

Tiller conlrol models

1.

Pl

ace

th

e throttle grip in

Ih

e fully closed

position

2.

Move Ihe gear shill lever quickly and

2.

On

m

od

e.

I

S.

.

e

~ui

pp

e

d

w

it~

a

:i

.

lI.

lock le-

lirmly

Ir

om neutral 10 lorwa

rd.

v

凹,

check Ihat it is in Ihe

10

c

kJ

down po-

sition

Shifting

,,

V/

!1

ilm~

【帽

Remote control models

1. Pull up the ne

ul

r

al

inlerlock Irigger (il

eq

ui

pped) and move Ihe remole control

lev

er

quic

kl

y and lirmly Irom ne

ulr

al 10

lorward

oW

nE

。

5

en

vE

a

创

咀

@ν

刽

创

w

山山川

e

41

』

H

et

W.m

怠-

s

ee

b

民UA

啤卸

mu

·

冒‘

『

S

'

hu

go

n

ι.

,,.

"uo

u

m

宫

S

创

em

创

mL

fiu

ewα

BSY

嫌翻腾

To

change

the

boat

direction

or

shifting

position

from

forward

to

reverse

or

vice-

versa,

first

close

the

throttle

so

that

the

engine

idles

(or

runs

at

low

speeds).

Reverse

(manual

tilt

an~

hydro

tilt

models)

,?‘

'1'1

!

1:1~

1I~[帽

When operating

in

reverse,

go

slowly

.

00

not

open

the

throttle

more

than

half

.

Oth-

erwise

the

boat

could

become

unstable

,

3. Move Ihe gear shift lever quickly and

lirmly Irom neulral

10

reverse.

20

Operation

Remote control models

1. Checkthat the tilt lock leveris in the lock

positíon.

2.

Pull up the neutral inte

rl

ock trigger (if

equipped) and move the remote control

lever quickly and firmly

fr

om neutral to

reverse.

Stopping engine

Before stopping

th

e engine, first let it cool oft

for a few minutes at idle or low speed. Stop-

3.

Disconnect the

fu

el line if you are using

pi

ng the engine immediately after operating an external

fu

el tank.

at high speed is not recommended.

Procedure

1. Push and hold the engine st

op

button

until the engine comes to a complete

stop

2.

After stopping the engine,tighten the aír

vent screw on the fuel tank cap and set

the fuel cock lever or

kn

ob to the closed

position, ife

qu

ipped.

21

NOTE

:

If the outboard motor is equipped with anen-

ginestop switch lanya

rd

, theengine can also

be

stopped bypulling the lanyard and remov-

ing the lock plate from the eng

in

e stop

switch

Trimming

outboard

motor

The trim angle of the outboard motor helps

determine the position of the bowof the boat

in the wate

r.

Correct t

ri

m angle will help im-

prove

pe

斤

。rm

a

n

ce

and fuel economy while

r

ed

ucing strain on the eng

in

e. Correct trim

an

gle depends upon the combina

ti

on of

boat, engine, and propelle

r.

Correct t

rim

is

also affected by variables such asthe load in

the boat, sea conditions, and running speed

,,

..

协

1:1~

1I~【帽

Excessive

trim

for

the

operating

condi-

tions

(either

trim

up

or

trim

down)

can

cause

boat

instability

and

can make

steering the

boat

more

difficul

t.

This

in-

creases

the

possibility

of

an accideh

t.

If

the

boat

begins

to

feel unstable

or

is

hard

to

steer,

slow

down

and/or

readjust

the

trim

angle.

」

γ

二

1.T

ri

m

ope

ra

tin

g

angle

Adjusting

trim

angle

for

manual

tilt

models

There a

re

4 or 5 holes pro

vi

ded

in

the ciamp

bracket to adjust the outboard motortrim an-

gl

e.

1.

Stop

th

e engine.

2.

Remove the trim

rod

from the clamp

Operation

br

acket while slightly tilting the outboa

rd

motor up.

1. Trim

rod

3.

Reposition the rod

in

the desired hol

e.

To ra

is

e

th

e b

ow

("trim-ou

t"

),

move the

ro

d

away from the transom

To lowerthe bow ("trim-in"), move the rodto-

wa

rd the tran

so

m.

Make test

run

s with the trim set to different

angles to find

tn

e p

os

ition that wo

rk

s best for

yo

urboat and operating conditions

,?‘

.'I'H:I~II~

【帽

•

Stop

the

engine

before

adjusting

the

trim

angle.

• Use care

to

avoid

being pinched when

removing

or

installing

the rod.

• Use

caution

when

trying

a

tr

im

position

for

the

first

time. Increasespeed gradu-

ally

and

watch

for

any

signs

of

instabil-

ity

or

control

problems.

Improper

trim

angle can cause

loss

of

cont

rol.

NOTE

:

The outboard motor trim angle can be

changed approximately 4degrees by shifting

the trim

rod

one hole.

Adjusting

boat

trim

Wh

en theboat is on plane, a bo

w-

upattitude

22

Operation

resulls in less drag, grealer

sla

bilily and

eff

卜

ciency. Thisis generally whenIhe kee

lline

01

Ihe boal isup aboul 3

10

5 degrees. With

Ih

e

bow up,theboalmay have a greaterlenden-

cy

10

sleer

10

oneside or the olhe

r.

Compen-

sa

le

lor

this as you s

le

e

r.

The trim tab can

also be ad

ju

s

led

10

help offset this ellec

l.

When

Ih

e bow

01

Ihe boatis down, ilis easier

10

accelerale Irom a standing start onto

plane.

们C:>

7

BowUp

Too much Irim-oul puts the bow

01

Ihe boat

100high inIhewate

r.

Performance

an

d econ-

omy are decreased because the hull

01

Ihe

boat is pushing the wa

ler

and there is more

air drag. Excessive Irim-out can also cause

Ihepropeller

10

venlilate, which reduces per-

lormance lurther, and the boat

may

平时

,

poise" (hop in Ihe water), which could throw

Ihe operator arid passengers overboard.

23

O~

~\一一一

Bow

Oown

Too much trim-in causes Ihe

boallo

"plow"

through Ihe water, decreasing luel economy

and making

il

hard

10

increase speed. Oper-

ating wilh excessive

Ir

im-in

al

higherspeeds

also makes

Ih

e boal unstable. Resistance at

the bowisgreatiyincreased, heightening Ihe

danger 01"bow sleering" and making opera-

tion dillicull and dange

rou

s.

白人/

~~

NOTE

:

Depending

on

the Iype

01

boat, Ihe ou

lb

oa

rd

molorIrim angle mayhave little e

ll

ect on Ihe

trim

01

Ihe boal wh

en

operaling.

Tilting

Up and

down

1I

Iheengine wi

ll

be stopped

lor

somelime

or

il

Ihe boat is moored

in

shallows, Ihe out-

board motorshould be tilted up

to

prolectIhe

propeller and casing Irom damage by colli-

sion with obstruclion5, and also

10

reduce

5altcorrosion

r

,~

Be

sure

all people are

clear

of

the

out-

board

motor

when

tilting

up

and

down

,

also

be

careful

not

to

pinch

any

body

parts

between the

drive

unit

and

engine

bracke

t.

,,,

'n!'

;I

~II~[1

帽

Leaking fuel

is

a

fire

hazard.

If

there

is

a

fuel

joint

on

the

outboard

motor

,

discon-

nect

the fuel line

or

close

the fuel

cock

if

the

engine

will

be

tilted

for

more

than

a

few minutes. Otherwise fuel

may

leak.

销黯翻

这

• Before

tilting

the

outboard

motor

,

stop

the

engine

by

following

the

procedure

on

page 21. Never tilt

the

outboard

mo-

tor

while

the engine

is

running.

Severe

damage

from

overheating

can result.

•

00

not

tilt

up

the

engine

by

pushing

the

tiller

handle

(if

equipped)

because

this

could

break

the

handle.

Procedure

for

tilting

Up

(manual

tilt

models)

1. Place the gear shift lever

in

neu

lr

a

l.

J

2. Disconnecl the luel line Irom the oul-

board moto

r.

Operation

3.

Place the tilt lock lever

(i

l equipped) in

Ihe release/up posilion

4.

Pull up Ihe shallow wal

er

lever (il

equip

pe

d)

5. Hold Ihe rear

01

Ihe lop cowling with

one

hand and liltthe engine up lull

y.

6.

Push the lilt support

kn

ob in

lo

the clamp

brackel. OrtheliIIsupportbarw

illlurn

to

Ihe lock posilion automalically.

24

Oper

a_

tion

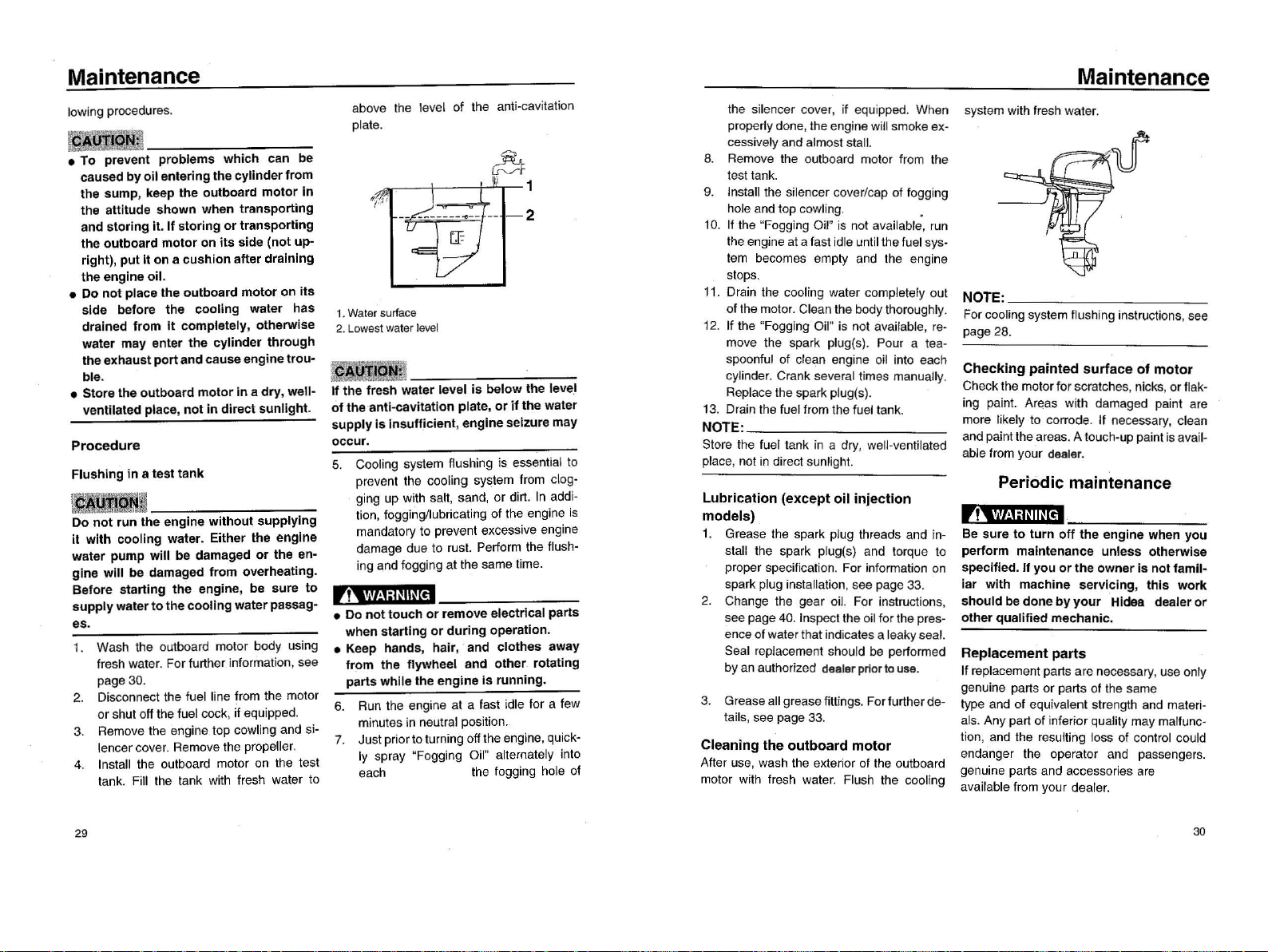

Procedure

for

tilting

down

(manual

tilt

models)

1. Pl

ace

the tilt lock lever

in

the lock posi-

tíon.

2.

Slightlyti

lt

the

engineupuntílthe tilt sup-

port bar is automatically released

3.

Slowly tilt the

engíne

down.

Cruising

in

shallow

water

The outboard motor can

be

tilted up partially

to allow operation

in

shallow water.

Cruising

in

shallow

water

(manual

tilt

models)

,

1

‘

,

'I'I!

1:

lm~[

帽

• Placethegearshiftin neutral before

us-

ingthe shallow water cruising system.

• Run the boat at the lowest possible

speed when using the shallow water

cruising system. The

tilt

lock

mecha-

nism does

not

work

while the shallow

water cruising system

is

being used.

Hitting an underwater obstacle

could

cause the outboard

motor

to

11ft

out

of

the water,resulting

in

loss

of

contro

l.

•

00

not

rotate the outboard

motor

180

。

and operate the boat

in

reverse. Place

the gear

shift

in

reverse

to

operate the

25

boat

in

reverse.

• Use extra care when operating

in

re-

verse. Too much reverse thrust can

cause the outboard

motor

to

lift

out

of

the water, increasing the chance

of

ac-

cident and personal injury.

• Returntheoutboard

motor

to

its

normal

position as soon

as

the boat

is

back

in

deeperwater.

翻黯翻

露

00

not

tilt

the outboard

motor

up

so that

thecoolingwater inleton the lower

unit

is

above the surface

of

the water when set-

ting

up

for

and cruising

in

shallow water.

。

therwise

severe damagefrom overheat-

ing can resul

t.

Procedure

1. Place the gear shift leverin neutral

2.

Place the ti

lt

lock lever

in

the release/up

position.

3.

Slightly tilt the outboard motor up. The

tilt support bar will lock automatically,

suppo

同

i

ng

the outboard motor

in

a par-

tially

ra

ised position.

NOTE:

Thisoutboard motor has 2 positions for shal-

low

wa

ter cruising.

4.

To return the outboard motor to the nor-

mal running position, place the gearshift

leverin neutral,

th

en place the tiltlock le-

ver in Ihe

lo

ckldown

posi

甘

on

.

5.

Slighlly lilt Ihe oulboard motor up until

Ihe till support bar automalically returns

10

Ihe free position.

6.

Sl

ow

ly lower Ihe outboa

rd

motor to the

normal position.

Operation

Cruising

in

other

condltlons

Cruising

in

salt

water

After operating in salt water, wash out the

cooling water passages with fresh water

10

prevent them from becoming clogged with

saltdeposits.

NOTE:

Forcooling system flushing instructions, see

page 28.

Cruising in

turbid

water

strongly recommends Ihat you use

the optional chromium-plaled waterpump kit

(not availa

ble

for some models)

if

yo

u

use

Ihe outboa

rd

molor in turbid

(m

uddy) water

co

nditions.

26

EF20:14.7kW@5000-5500r/min

EF30: 22kW@5000-5500r/min

EF20 :1000 / EF30: 1118

EF20:427 / EF30: 430

EF20:(S)1080 (L)1207 / EF30: (S)1155(L)1282

EF2 0:(S)381(L)508 / EF30: (S)431(L)558

EF20:(S)58kg (L) 60kg / EF30:(S)84kg(L)89kg

1050

EF20:323.0cm³ EF30:498cm³

or atomizer

Maintenance

lowing procedures.

剧目黯""警句盹掌重哩

Q

宝宝晒

撞

到国画姐随

袭

瓷将

强~

'!i.扁.......如硝烟盹

•

To

prevent problems

which

can be

caused

by

oil

enteringthe

cylinder

from

the

sump

, keep the outboard

motor

in

the attltude

shown

when

transpo

此

ing

and

storing

It.

If

storing

or

transp

。此

ing

the

outboard

motor

on

its

side

(not

up-

rlght),

put

It

on a

cushion

afterdraining

the

englne

oi

l.

•

00

not

place

the

outboard

motor

on

its

slde before

the

cooling water

has

dralned

from

It

comptetely, otherwlse

water

may

enter the

cylinder

through

theexhaust

port

andcauseengine

trou-

ble

.

• Store

the

outboard

motor

in

a

d町,

well

ventilated place,

not

in

direct

sunligh

t.

Procedure

Flushlng

in

a

test

tank

翻

翻

眼镇

建

00

not

run

the

englne

without

supplying

it

wlth

cooling

water. Either the engine

water

pump

will

be damaged

or

the

en-

glne

will

be damaged

from

overheating.

Before

starting the engine,

be

sure

to

supply

water

to

the

cooling

water

passag-

es

.

1. Wash the outboard motor body using

fresh water. For further information, see

page 30.

2. Disconnect the fuel line Irom the motor

or shut offthe luel cock,

il

equipped.

3.

Remove the engine top cowling and si-

lencer cover. Remove the propeller

4.

In

stall the outboard motor on the test

tank. Fill the tank with fresh water

10

29

Maintenance

above the level of the anti-cavitation

plate. system with Iresh water

Ihe silencer cover,

il

equipped. When

prope

叫y

done,theengine will smoke ex-

cessively and almost stall.

8.

Remove the o

ut

board motor Irom the

aρ

test tank

9.

Install the silencer cover/cap

01

logging

hole and top cow

li

ng.

•

10.

1I

the "Fogging Oil" is not

ava

il

ab

怡,

run

the engine at a fast idle until the fuel sys-

tem

becomes empty and the engine

stops.

11.

Drain the cooling water completely out

ofthe moto

r.

Clean the body thoroughly

1

2.

1I the "Fogging Oil" is not àvailable,

re

-

move the spark plug(s). Pour a tea-

spoon

fu

l

01

clean eng

in

e

oil

into each

cylinde

r.

Crank seve

ra

l times manually

Replace the spark plug(s).

1

3.

Drain the luel lrom the luel tank

NOTE:

Store the luel tank

in

a dry, well-venlilated

place, not

in

direct sunl

igh

t.

1.

Water

surface

2.

Lowest

wa

t

er

level

翻

翻

翻

意

11

the

Iresh

water

level

is

below

the

level

01

the

anti

心

avitatlon

plate,

or

if

the

water

supply

Is

insufficient

,

engine

seizure may

occur

.

5. Cooling system Ilushing is essential to

prevent the cooling system Irom clog-

ging up with salt, sand, or dirt.

In

addi-

tion, fogging

/l

ubricating of the engine is

mandalory

10

prevent excesslve englne

damage due 10 rus

t.

Perform the flush-

ing and fogging at the sa

me

time.

Lubrication

(except

oil

injectlon

models)

1.

Grease the spark plug threads and in-

stall the spark plug(s) and torque to

proper specilication. For information

on

spark plug installation, see page 33

2.

Change the gear oi

l.

For instnuctions,

see page 40. Inspect the oil

lo

rthe pres-

ence

01

water that indicates a leakyseal.

Seal repiacement should be performed

byan authorized dealerprlor

to

use

.

r

,,

~l

h1

iWI~

[êJ

•

00

not

touch

or

remove electrical

pa

同

S

when

starting

or

during

operation.

• Keep hands,

hair

, and

clothes

away

from

the

flywheel and

other

. rotating

parts

whlle

the

engine

is

running.

6.

Run

the engine at a last idle

lor

a few

minutes in neutral position.

7. Justpriortoturning offthe engine, quick-

Iy

spray "Fogging Oil"

allern

啤

tely

into

each the logging hole 01

3.

Grease allgrease littings. Forfurtherde-

lails, see page 33

Cleaning

the

outboard

motor

After use, wash the exterior

01

the outboard

motor with Iresh water. Flu

sh

the cooling

NOTE:

Forcooling system flushing instructions,see

page 28.

Checking

painted

surface

of

motor

Checklhe motorfor scratches,nicks,

or

flak-

i

ng

pain

t.

Areas with damaged paint are

more li

ke

ly

10

corrode. If necessary, cl

ean

and paintthe areas. A touch-up paint is avail-

able from your dealer.

Periodic

maintenance

,帽

Be sure

to

turn

off

the

engine when

you

per

form

maintenance

unless

otherwlse

specified.

If

you

or

the

owner

is

not

famil-

iar

with

machine

servicing

,

this

work

should

be

done

by

your

Hidea dealer

or

other qualified mechanic.

Replacement

parts

If replacement parts

ar

e necessary,use only

genume

pa

川

s

or

parts

01

t

he

same

type and

01

equivalent strength and

mater

卜

als. Any part

01

inferiorquality may malfunc-

tion, and the resulting loss

01

contr

ol

could

endanger

th

e operator and passengers.

genuine parts and accessories are

available fr

om

your dealer.

30

Maintenance Maintenance

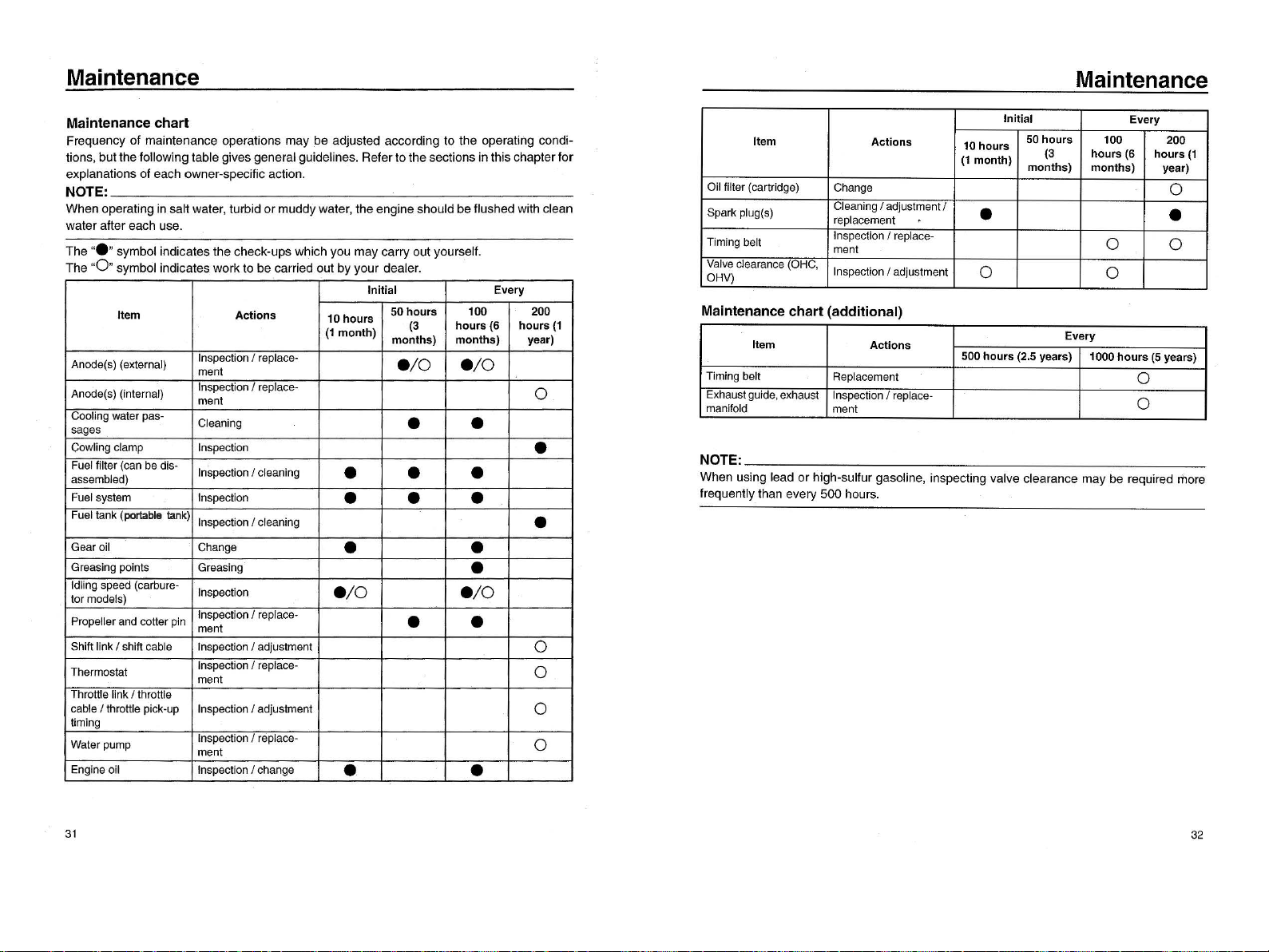

Maintenance

chart

Frequency

of

maintenance

operations

may

be

adjusted

according

to

the

operatiilg

condi-

tions

,

but

the

following

table

gives

general

guidelines.

Refer

to

the

sections

in

this

chapter

for

explanations

of

each

owner-specific

action.

NOTE:

When

operating

in

salt

water

,

turbid

or

muddy

water

,

the

engine

should

be

flushed

with

clean

water

after

each

use.

The

"."

symbol

indicates

the

check-ups

which

you

may

carry

out

yourself

The

"0"

symbol

indicates

work

to

be

carried

out

问

your

deale

r.

Initial

Every

Item

Actions

10

hours

50

hours

100 200

(1

month)

(3

hours

(6 hours

(1

months)

months)

year)

Oil filter (cartridge) Change

。

Spark

plug(S)

Clear

刊

ng

/ adjustment/ • •

replacement

Timing belt Inspection / replace-

。

。

门、

ent

Valve

clearance (OHC, Inspection / adjustment

。

。

OHV)

Initial Every

Item

Actions

10

hours

50

hours

100 200

(1

month)

(3

hours

(6

hours

(1

months) months)

year)

Anode(s) (external) Inspection I replace-

./0

./0

阿

lent

Anode(s) (internal) InspectionI replace-

。

町、

ent

Cooling water pas- Cleaning • •

sages

Cowling clamp Inspection •

Fuel filter (can be dis- Inspection/ cleaning • • •

assembled)

Fuel system Inspection • • •

Fuel tank

(阴阳

ble

恒

nk)

InspectionI cleaning •

Gearoil Change • •

Greasing points Greasing •

Idling speed (carbure- Inspection

./0 ./0

tormodels)