High Tech 3003 User manual

page 1

Instructions

Art-Nr:3003 Red backlights 4-axle up to 16 volt

1. These parts are not suitable for small children. There is a

danger of swallowing.

2. The product can be seen in figure 1. These instructions are

part of the product. Please retain them well.

3. The product is suited for direct and alternating current from 6 –

16 volt. The current consumption depends on the brightness of

the LED, usually a couple of milliampere.

4. The metal weight inside the wagon has been removed, the

built-in electronics weigh approximately the same, so the

weight of the model basically has not changed.

5. The installed backlights are ready to use, so you just can put

the car on the tracks and start running it. The lights will start

working as soon as they are connected to a current of the

above mentioned strength, no extra charging time is

necessary. The built-in electronics are able to bridge voltage

gaps up to a few seconds that are normal to occur when

working with model trains and due to the light weight of the

car. This has the effect that the backlights always shine with a

continous intensity when the car is moving.

6. Under normal circumstances the backlights are also working when the wagon is standing, e.g. if in a

digital system the tracks are always provided with current or when using our controller for analog

systems. But this cannot be guaranteed, since it is due to physical reasons that the current input is

not continous, but always interrupted for short intervals. If the wagon comes to a halt where the

contact of the current to the current collectors is interrupted, it is logical that the lights turn off after a

short afterglow. But as soon as the car starts to move again, the current collectors have contact to the

current again and the LEDs will be shining again continously as described above.

7. The LEDs are affixed underneath the upper platform of the wagon very firmly. Nevertheless it is

advisable to avoid mechanical impact, contact with screwdrivers or other tools, or getting stuck with

your fingernails. If the LED is broken off, this very often also damages the small wires.

8. Unlike the wheels moving along without current, these wheels are picking up a lot of dirt. We know

this problem from the locomotives. For working properly, they need to be cleaned from time to time.

For doing this, dismantle the wheels carefully using some tweezers. Avoid contact with the current

collectors by picking them up on the side opposite to the current collectors.

9. Never try to dismantle the bogie. There is a thin wire attached firmly to the car chassis and the bogie,

which will break in case of dismantling. For cleaning, always only dismantle the axles. As described

under point 8, do not damage the current collector.

10. Ultrasonic treatment and using a damp cloth are the best methods to clean the wheels, especially the

contact surfaces and the axle. According to our experience it is best to use ultrasonic treatment

and/or polish everything with a damp cloth. The contact surfaces should not be matt afterwards, but

shining like the ones of a new wheel. The cleaning process does not influence the abrasion of the

nickel layer. The abrasion of the nickel layer usually has a different reason, e.g. the different speed of

the wheels on each side when going through curves. But the nickel layer can also be damaged

unnecessarily when using a whire brush or fiber glass pen, so we strongly advise to use the method

described above for cleaning your wheels.

11. The best liquids for cleaning the wheels are benzine, alcohol, purified alcohol, surgical spirit, or simply

spirit, all of them mild cleaning liquids for metal. Just soak a cloth and wipe off the dirt. The wheels

should not be soaked and remain in these or other detergents for any length of time. Also do not use

any solvents or thinners that are used when working with paint. These are likely to damage the plastic

foam insulation on one side of the wheel and make it soft. As a consequence, the wheel starts to

flatter.

page 2

figure 2: A closer look at the backlights

figure 1: Red backlights in a motorvehicle transport car

page 2

Instructions

Art-Nr: 3003 Red backlights 4-axle up to 16 volt

10. For reassembling the wheels, use the tweezers again. The

model has to lie securely and backwards on the

locomotive repairing fixture. Put the axle on the spot where

it is usually held by the clamp, figure 3. Watch for the

correct polarity! Figure 6 and 7. Now use your tweezers to

bend open the clamp at the side away from the current

collector by pressure on the axle and push in the wheels,

figure 4. Finished – all done, figure 5.

11. For running your trains properly, the right polarity is very

important. Axles built in the wrong way cause short circuits

with high currents that can destroy the fine current

collector springs. An axle of a 4-axle wagon is built in

correctly if in one bogie both axles are built in the same

way. In this case you can see the uninsulated side of the

wheel, so the pure metal wheel, at the upper edge, figure 7.

In the other bogie the axles then have to be built in exactly

the opposite way. Remember this well, it is very important

for running your trains properly and avoiding major

damages.

12. The current collectors are our own design and patent

protected under German law. A compromise had to be

found between the elasticity of the metal and the contact

pressure of the spring. Of course a high contact pressure

guarantees a good current collection. This is no problem

with powered locomotives, the engine easily surmounts

this frictional resistance. With wagons pulled by a

locomotive things are a bit more difficult. Concerning our

current collector, we have given preference to the elasticity

of the metal, and so to a low contact pressure. The very

thin and flexible material has the ability to abut with a

strong bending, but with low pressure, evenly and securely

on the axle. This is why the spring is strongly bent

forward, see figure 8. It can happen that this bend

disappears in the course of time. So always check the

spring when cleaning the wheels and if necessary bend

the spring again as shown in figure 8. Don’t be afraid, the

material is suitable for this and due to the low contact

pressure the wagon, in spite of its light weight, won’t be

lifted by the spring.

13. High Tech Modellbahnen manufactures its products with

the greatest possible care. We issue a guarantee and

warranty according to legal regulation. Should you find any

new product you just bought defective, please contact your

local dealer.

14. If one of our products has been damaged or breaks,

please contact your local dealer as well. He often might be

able to save it, while own attemps to repair it might lead to

a total economic loss.

Now enjoy your new car with backlights.

High Tech Modellbahnen

97456 Hambach

www.z-hightech.de

figure 6: Left bogie: both axles with the isolated sides

facing upwards

figure 7: Right bogie: both axles with the uninsulated

side facing upwards.

Very important! Very important!

figure 8: The correct position of the current collector

springs without the axle

figure 3: The axle ready to be built in, lying on top of

the clamp

figure 4:

ushing the axle into the clamp with the help

of some tweezers.

figure 5: The axle has been pushed underneath the

clamp holding it in ist place.

Popular Toy manuals by other brands

Hasbro

Hasbro Transformers Robots in Disguise Mini-Con Deployers Autobot... Quick start quide

Faller

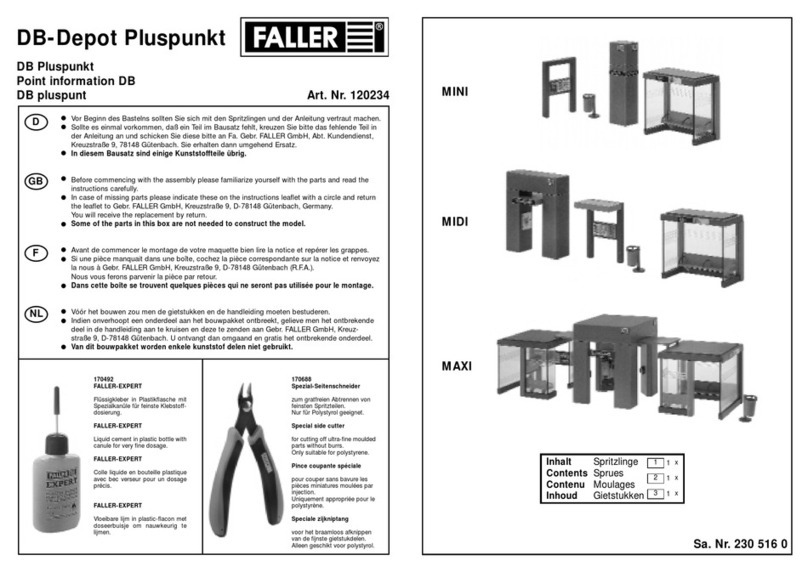

Faller 120234 manual

CNC Workshop

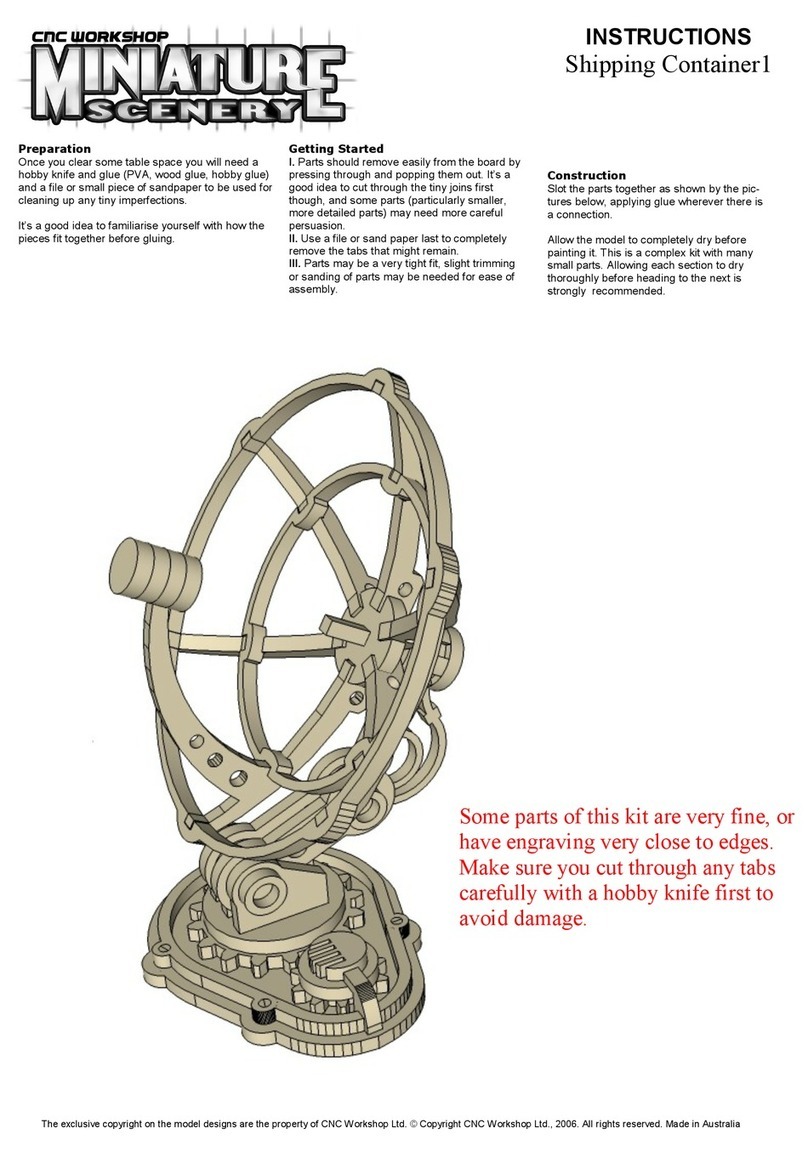

CNC Workshop MINIATURE SCENERY Shipping Container1 instructions

Faller

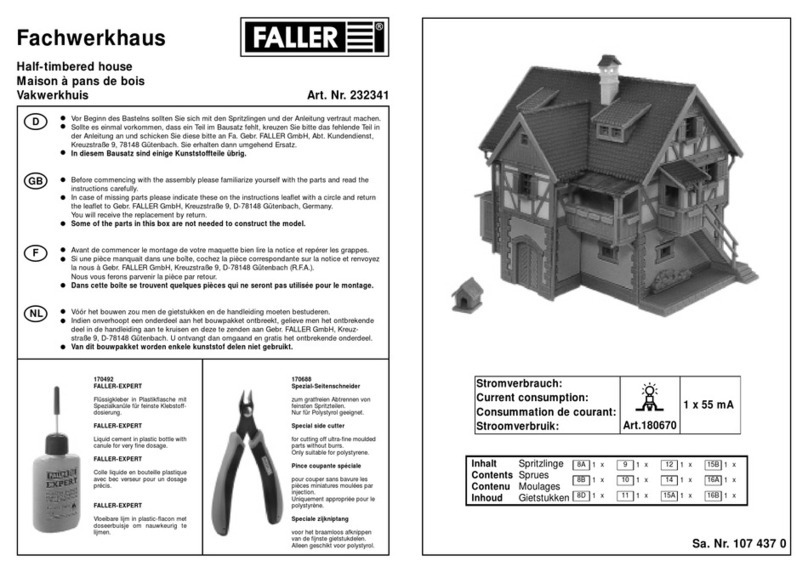

Faller HALF-TIMBERED HOUSE instructions

Bandits and Angels

Bandits and Angels YF2282 Assembly instructions

Fisher-Price

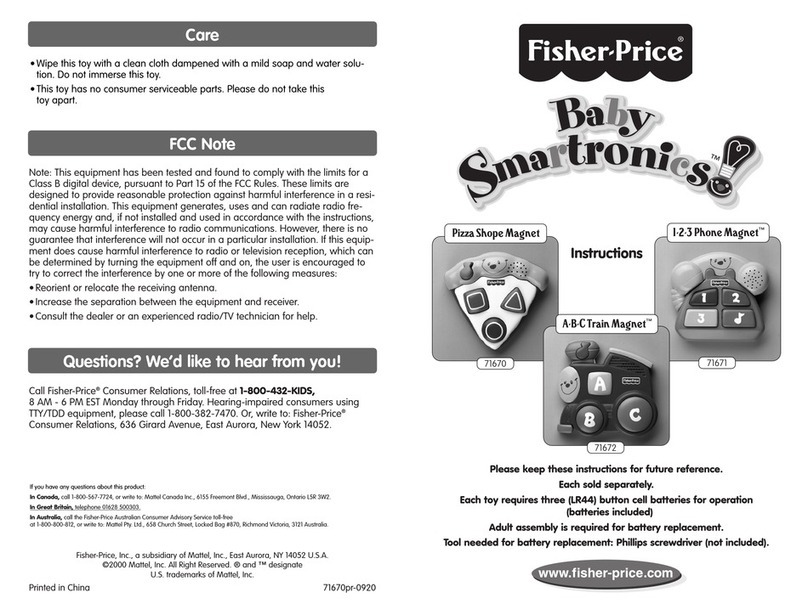

Fisher-Price Baby Smartronics instructions

Dynam

Dynam P-47D thunderbolt instruction manual

Pilot Communications

Pilot Communications 50CC Assembly manual

Krick

Krick COMTESSE Building Instruction

REVELL

REVELL German Heavy Cruiser Blucher Assembly manual

Faller

Faller Car Center Assembly instructions

Jupiter Creations

Jupiter Creations Flying Eagle 90100 instruction manual