HIKOKI WH 14DDL User manual

Other HIKOKI Impact Driver manuals

HIKOKI

HIKOKI DH3640DB User manual

HIKOKI

HIKOKI WH18DC User manual

HIKOKI

HIKOKI WR 22SE User manual

HIKOKI

HIKOKI WH 18DD User manual

HIKOKI

HIKOKI DS18DC User manual

HIKOKI

HIKOKI WH 7DL User manual

HIKOKI

HIKOKI WR18DH User manual

HIKOKI

HIKOKI WH 10DCL User manual

HIKOKI

HIKOKI WR 14VE User manual

HIKOKI

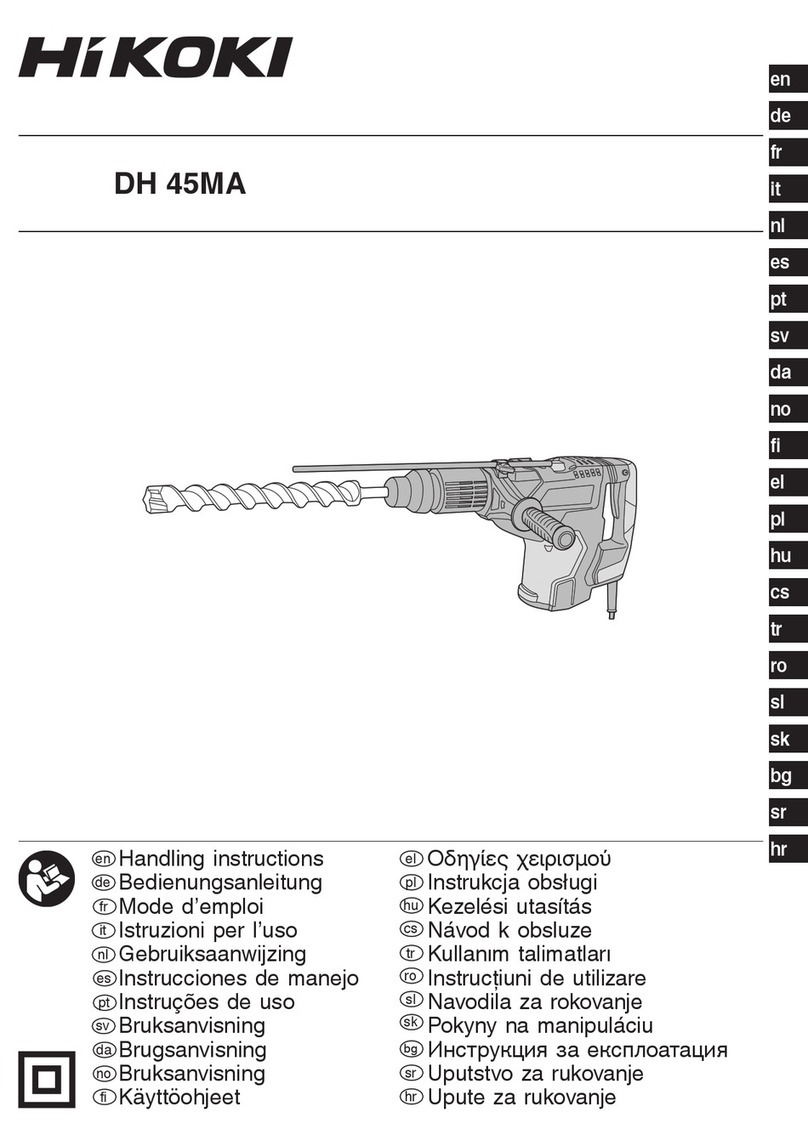

HIKOKI DH45MAWSZ User manual

HIKOKI

HIKOKI WH 12DD User manual

HIKOKI

HIKOKI WH 18DBFL2 User manual

HIKOKI

HIKOKI WW8A User manual

HIKOKI

HIKOKI WH 10DCL User manual

HIKOKI

HIKOKI WH 18DJL User manual

HIKOKI

HIKOKI WH 18DD User manual

HIKOKI

HIKOKI WH 12DAF2 User manual

HIKOKI

HIKOKI WR 16SE User manual

HIKOKI

HIKOKI WH 14DSDL User manual

HIKOKI

HIKOKI WH 10DL User manual