Hiniker 2751 User manual

STRAIGHT PLOW

Model Years 1996-1999

Electrical Troubleshooting Guide For

Models 2751, 2851, 2801, 2901

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 39300026 Rev. B

TITLE

Foreword

FOREWORD

This guide is intended to assist the trained

dealer mechanic in the repair of Hiniker Com-

pany snowplows. While it provides schematics,

tables, and other documentation, it is not a train-

ing manual and should not be considered a sub-

stitute for proper training in electrical, hydraulic,

or mechanical repair. Above all, it should not be

considered as a substitute for experience and

common sense.

The information in this guide has been checked

and is believed to be accurate. Hiniker Com-

pany, however, assumes no responsibility for

any errors, omissions, or other inaccuracies,

which may appear in this document or for any

damage or expense resulting from them. Nor

does Hiniker Company make any commitment

to update the information contained herein but

reserves the right to make changes at any time

without prior notice.

Hiniker Company reserves the right under its

product improvement policy to discontinue

equipment, or to change construction or design

details and furnish equipment when so altered

without reference to the illustrations or specica-

tions contained herein.

Trucks intended to be equipped with a snowplow

must comply with the vehicle manufacturer’s

specications for snowplow applications. Check

with the vehicle dealer for information on snow-

plow package availability, contents, and any ad-

ditional recommended options.

TITLE

TABLE OF CONTENTS

39300026 Rev. B 12/09 Manual/39300026RevB

INTRODUCTION..................................................................................................... 1

SAFETY ...............................................................................................................2-3

PLOW IDENTIFICATION ........................................................................................ 4

THEORY OF OPERATION...................................................................................5-6

INITIAL INSPECTION............................................................................................. 7

MOLDBOARD PROBLEMS ..............................................................................8-18

Will Not Angle Right........................................................................................... 8

Will Not Angle Left............................................................................................. 9

Will Not Raise.................................................................................................. 10

Will Not Lower..................................................................................................11

Constantly Angles Left..................................................................................... 12

Constantly Angles Right.................................................................................. 13

Operates Slowly.............................................................................................. 14

Will Not Stay Raised........................................................................................ 15

Will Not Hold Angle.......................................................................................... 15

Pump Will Not Run.......................................................................................... 16

No Plow Power................................................................................................ 17

No Controller Power........................................................................................ 18

LIGHTING PROBLEMS...................................................................................19-28

No Lights On Truck And Plow OK..............................................................19-20

No High Beam(s) On Truck And Plow OK...................................................... 20

No Low Beam(s) On Truck And Plow OK....................................................... 21

No Lights On Plow And Truck OK..............................................................22-23

No High Beam(s) On Plow And Truck OK...................................................... 24

No Low Beam(s) On Plow And Truck OK....................................................... 25

No Parking Lights On Plow ............................................................................. 26

No Left Turn Signal On Plow........................................................................... 26

No Right Turn Signal On Plow......................................................................... 27

No Lights On Truck And No Lights On Plow................................................... 28

LIGHTING CONVERSIONS.............................................................................29-32

General............................................................................................................ 29

99 Dodge Dual, P/N 25010617 ..................................................................29-30

99 Dodge Quad, P/N 25011011 .................................................................30-31

99 GM Quad, P/N 25010616........................................................................... 32

Table of Contents

Table of Contents

TEST PROCEDURES......................................................................................33-43

Hydraulic Solenoid .....................................................................................33-34

Motor Solenoid................................................................................................ 35

Controller......................................................................................................... 36

Under Hood Harness..................................................................................37-39

Plow Harness.............................................................................................40-41

Plow Headlight ...........................................................................................42-43

CIRCUIT DESCRIPTIONS...............................................................................44-56

REFERENCE ...................................................................................................57-77

Special Problems ............................................................................................ 57

Company Information...................................................................................... 58

Lighting Adapter Application Chart.............................................................58-59

Lighting Adapters........................................................................................60-63

Ground Switch Converters.........................................................................64-65

Hydraulic Solenoid Table................................................................................. 66

Power Unit Drawing......................................................................................... 66

Hydraulic Schematic........................................................................................ 67

Hydraulic Oil Selection Chart .......................................................................... 68

Hydraulic Solenoids......................................................................................... 69

Motor Solenoids .............................................................................................. 70

Spike Suppressors.....................................................................................71-72

Relays ............................................................................................................. 73

Relay Connections.......................................................................................... 74

Straight Plow Wiring Diagram ......................................................................... 75

Lighting Connectors ........................................................................................ 76

Harness Connectors........................................................................................ 77

System Schematic..............................................................................Back Page

TITLE

Introduction 1

INTRODUCTION

Thissection guidesyouthroughstepbysteppro-

cedures designed to help troubleshoot electrical

problems you might encounter while repairing

or installing a Hiniker straight plow, model years

1996 - 1999. It is intended to be used by quali-

ed service technicians at the dealer level.

This guide contains the following basic types of

information:

• Troubleshooting Procedures

• Testing Procedures

• Electrical Schematics

• Hydraulic Schematics

• Reference Information.

Troubleshooting procedures for various prob-

lems are listed in the table of contents. Select

the one that is closest to your situation. Many

problems overlap each other. If there was no

moldboard movement at all you could select

“PLOW WILL NOT ANGLE LEFT” as the prob-

lem.

The troubleshooting procedures are laid out in

a text based owchart form. Following the guide

consists of performing an action and checking

what happened (See below). For a “No” answer,

go down the left side of the page to the next ac-

tion. “Yes” answers have the next action directly

below them.

Perform action 1.

DID THIS HAPPEN?

No. Yes.

| Perform action 3.

| DID THIS HAPPEN?

| No. Yes.

| | Replace this.

| |

| Perform action 4.

| DID THIS HAPPEN?

|

Perform action 2.

Some of the actions performed are xed test

procedures covering the controller, under hood

harness, and plow harness. The troubleshooting

procedure is geared toward the problem you se-

lected. As an example:

If you have a “PLOW WILL NOT ANGLE LEFT”

problem and the under hood harness fails the

under hood harness test, it is assumed that it

failed because of “PLOW WILL NOT ANGLE

LEFT” problem. The trouble shooting procedure

will then focus on the part of the under hood har-

ness responsible for angle left movement.

Most test procedures require the use of the

Hiniker Snowplow Electrical System Tester part

# 36014014. The tester helps in quickly locating

problems with the system wiring and is required

for performing these tests. The tester is avail-

able from Hiniker Co.

During all testing, the plow should be resting on

the ground. When testing out by the plow, the

two-conductor power cable should be unplugged

at the grill. This will prevent any movement of

the plow and any risk of the plow causing harm

to anyone nearby.

Pull straight out on connectors when unplug-

ging, Do Not Twist. Before plugging connectors

together line them up with the notch or stripe lo-

cated on the connector

During testing it is good practice to check all

wires and connections for any kind of damage.

Corrosion can cause intermittent connections, it

is recommended that dielectric grease be used

on all harness connections.

Power should always be removed from the cir-

cuit that you will be testing before you unplug

or plug any connections.

TITLE

SAFETY INFORMATION

Operator safety is a principle concern in the de-

sign and distribution of equipment. Many ac-

cidents can be avoided by taking the time to

become familiar with the equipment and how to

operate it safely.

Do not use or operate any equipment until the

Operators Manual has been read and thorough-

ly understood.

This is the safety alert symbol. It alerts

an operator to instructions concerning

personal safety. Always read and fol-

low the instructions. Failure to do so could

result in serious injury or death.

Along with the safety alert symbol is a signal

word. It will be the word “CAUTION”, “WARN-

ING”, or “DANGER”. These signal words are

dened as follows.

CAUTION -A reminder for proper safety prac-

tices and directs attention to following them.

Equipment decals of this class are yellow

and black.

WARNING - A reminder for proper safety

practices and what can happen if they are

ignored. This has a more serious conse-

quence than CAUTION. Equipment decals of

this class are yellow and black.

DANGER - Denotes the most serious safety

hazard. It is a reminder for observing the

stated precautions and what can happen if

they are ignored. Equipment decals of this

class are red and white.

CAUTION: For your protection we

strongly recommend that you read,

understand, and heed the following

information.

1. If the operator’s manual is lost or missing

from any Hiniker equipment contact Hiniker

to obtain a replacement.

2. Read the operators manual thoroughly.

Make sure that you understand and know

how to safely operate the equipment. Snow-

plows can kill or injure an untrained or care-

less operator.

3. Do not attempt to service any equipment un-

less you know how to do it safely.

4. Do not be in a hurry. Take time to ensure

proper procedures have been followed.

PAY SPECIAL ATTENTION TO THE FOLLOW-

ING:

ALWAYS inspect lift system bolts and pins when-

ever attaching or detaching the plow, and before

traveling. Worn or damaged components could

result in the plow dropping while driving, causing

an accident.

NEVER place ngers in mounting holes to check

alignment. Sudden shifting of the plow could se-

verely injure a nger.

NEVER stand between the vehicle and mold-

board or directly in front of the moldboard when

it is being operated. Clearance between the

moldboard and vehicle changes as the mold-

board is operated. Serious injury can result from

the moldboard striking a body or dropping on

hands or feet.

NEVER work on the vehicle without having a

fully charged re extinguisher available. A 5 lb.

or larger CO2 or dry chemical unit specied for

gasoline, chemical, or electrical res is recom-

mended.

NEVER smoke while working on the vehicle.

Gasoline and battery acid vapors are extremely

ammable and explosive.

ALWAYS operate the vehicle in a well-ventilated

area. The carbon monoxide in exhaust fumes

is highly toxic. It can cause serious injury or

death.

2 Safety

Safety 3

NEVER allow hands, hair, or clothing to get near

any moving parts such as fan moldboards, belts,

and pulleys. Never wear neckties or loose tting

clothing when working on the vehicle.

NEVER wear wristwatches, rings, or other jewel-

ry when working on the vehicle. They can catch

on moving parts or cause an electrical short that

could result in serious personal injury.

ALWAYS wear suitable eye protection when

working on the vehicle to protect from battery

acid, gasoline, and dirt thrown from moving en-

gine parts.

ALWAYS be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYSwearsuitableeyeprotectionwhenstrik-

ing metal against metal. It is recommended that

a softer, non-chipping metal be used to cushion

the blow.

NEVER use your hands to check for hydraulic

uid leaks. Escaping uid under pressure can

be invisible and can penetrate the skin and can

cause serious injury. If any uid is injected into

the skin, see a doctor at once. A doctor familiar

with this type of injury must surgically remove

the injected uid or gangrene may result.

ALWAYS make sure the vehicle is parked on sol-

id, level ground and the plow moldboard is down

when not being operated.

ALWAYS unplug the two conductor power cable

at the grill when performing tests on the plow

harness, motor solenoid, hydraulic solenoids, or

any time you need to work on the moldboard.

TITLE

4 Plow Identification

PLOW IDENTIFICATION

The plow model # is located on the back, left

side of the moldboard. Use it with the chart be-

low to identify the model year.

Model# Year Type * Width

700 2005 S 7’

1850 1999 V 8.5’

1851 2000 V 8.5’

1852 2006 DAV 8.5’

1951 2000 V 9.5’

1952 2006 DAV 9.5’

2750 1995 S 7.5’

2751 1996-99 S 7.5’

2752 2000 S 7.5’

2800 1995 S 8’

2801 1996-99 S 8’

2802 2000 S 8’

2851 1996-99 S 8.5’

2852 2000 S 8.5’

2901 1996-99 S 9’

2902 2000 S 9’

3800 2000 C 8’

6800 2000 Scoop 8’

6900 2000 Scoop 9’

7800 2000 S 8’

7801 2000 S 8’

7900 2000 S 9’

7901 2000 S 9’

8800 2000 C 8’

8801 2000 C 8’

8900 2000 C 9’

8901 2000 C 9’

9850 2007 DAV 8.5’

9950 2007 DAV 9.5’

10321 2008 S 10’

10322 2008 S 10’

* C - C - Moldboard Plow

DAV - Dual Acting Vee Moldboard Plow

S - Straight Moldboard Plow

V - Single Acting Vee Moldboard Plow

1995 - This was the rst year for Hiniker plows. Only

straight plows were manufactured. The plow con-

troller used up/down and left/right rocker switches

to control the moldboard. The under hood harness

had one large relay for switching headlights from

truck to plow. Plugging the plow into the grill con-

nector would cause the headlights to switch to the

plow. The wiring of the under hood harness was

covered by tightly woven, black, webbed loom.

The motor solenoid for this year had three termi-

nals and was mounted out on the plow pump mo-

tor.

1996-99 - Straight plows were manufactured dur-

ing this period, with the V plow being added in

1999. The straight plow controller used a joystick

style switch to control moldboard movements.

The V plow controller used the same joystick style

switch with the addition of two pushbuttons. The

under hood harness had a black box with a fuse

and two relays mounted on it. The wiring consisted

of gray cables. The motor solenoid had three ter-

minals and was mounted under the vehicle hood.

The automatic headlight switching system was re-

placed with a slide switch on the controller and a

power switch was also added.

2000 - Straight, Scoop, V, and C plows were man-

ufactured with the Scoop and C plow being new

for 2000. All four plows use a custom molded,

black plastic case with a joystick style switch and

additional pushbuttons where needed. The under

hood harness has a cluster of three relays for high

beams, low beams, and power switching. The wir-

ing is covered by black plastic corrugated loom.

The motor solenoid is mounted under the hood

and has a separate ground terminal added for a

total of four.

2006 - The V Plow was changed from a SingleAct-

ing hydraulic cylinder V plow to a Dual Acting hy-

draulic cylinder V plow. In a Single Acting V plow,

the wings are retracted by having the left and right

retract solenoids bleed off the hydraulic uid, al-

lowing the wings to retract under spring tension.

In a DualActing V plow, the wings are retracted by

turning on the hydraulic oil pump and having the

left and right retract solenoids route the pumped oil

to the front of the wing cylinders. This causes the

wings to retract under hydraulic pressure rather

than spring tension.

TITLE

Theory of Operation 5

THEORY OF OPERATION

MOLDBOARD MOVEMENTS

Over View

Pushing the joystick to one of the moldboard

movement positions causes the controller to

send +12 volts out to the appropriate solenoid(s)

that interface with the hydraulic system. This,

in turn, causes the movement to be performed.

The solenoids are as follows:

Motor Solenoid - This controls the hydraulic

pump motor, which pumps hydraulic oil.

Down Solenoid - This bleeds off the hydraulic

oil in the up cylinder causing the moldboard to

lower.

Left Solenoid - This changes the ow path of

pumped hydraulic oil. Instead of going to the up

cylinder, the ow is sent to the left cylinder.

Right Solenoid - This changes the ow path of

pumped hydraulic oil. Instead of going to the up

cylinder, the ow is sent to the right cylinder.

Raise Movement

To raise the plow, the controller simply turns on

the motor solenoid. With both the left and right

solenoid off, oil is pumped into the up cylinder,

raising the moldboard. When the joystick is re-

leased, a check valve prevents the oil from ow-

ing backward to the oil tank. A raise movement

will also cause the controller to turn off the down

solenoid if the moldboard was in oat mode.

Lower Movement

To lower the plow, the controller turns on the

down solenoid. This bleeds the oil from the up

cylinder, back into the oil tank as the weight of

the plow moldboard pushes against it. When this

movement is performed the down solenoid is

latched on, also called oat mode, so that the

moldboard can rise and fall with the surface be-

ing plowed. A raise movement will turn off the

down solenoid and cancel the oat mode.

Moldboard Left Movement

To perform a moldboard left movement the con-

troller turns on both the motor solenoid and the

moldboard left solenoid. With the moldboard left

solenoid on, the oil, instead of going to the up

cylinder, is sent to the moldboard left cylinder.

The cylinder extends pushing the right side of

the moldboard forward which angles the mold-

board left. The moldboard left movement also

supplies a bleed back path for the oil in the mold-

board right cylinder so that it can collapse.

Moldboard Right Movement

To perform a moldboard right movement the con-

troller turns on both the motor solenoid and the

moldboard right solenoid. With the moldboard

right solenoid on, the oil, instead of going to the

up cylinder, is sent to the moldboard right cylin-

der. The cylinder extends pushing the left side of

the moldboard forward, which angles the mold-

board right. The moldboard right movement also

supplies a bleed back path for the oil in the mold-

board left cylinder so that it can collapse.

6 Theory of Operation

PLOW LIGHTING

Over View

The purpose of the plow lighting system is to

control the normal vehicle lighting functions and

extend them out to the top of the plow where

they will not be blocked by the plow moldboard.

Head Lights

In order to control the headlights the connec-

tion between the existing vehicle wiring and the

headlights is broken. Lighting adapters are then

used to match the under hood harness to the

various types of vehicle lighting systems.

The under hood harness uses a high and low

beam relay to switch the headlights to either

TRUCK or PLOW depending on the light selec-

tion switch on the controller. Disconnecting the

controller will automatically switch the lights to

the truck.

Parking Lights

The parking lights for the plow are tapped from

the existing vehicle wiring using a quick connect

bullet receptacle. The receptacle mates with the

parking light bullet connector coming from the

under hood harness. It does not change the nor-

mal operation of the vehicle parking lights.

Turn Signals

The left and right turn signals for the plow are

tapped from the vehicle turn signal wiring using

quick connect bullet receptacles. The recepta-

cles mate with the turn signal bullet connectors

coming from the under hood harness. It does not

change the normal operation of the vehicle turn

signals.

TITLE

Step Action

1. Personally observe how, and when, the problem occurs on the customer’s plow.

2. Make sure vehicle is on a solid, level surface, in park, and parking brake is set.

3. Lower plow moldboard before servicing any part of hydraulic or electrical system.

If moldboard will not lower then support it with a oor jack or other suitable means.

4. Insure battery is fully charged.

5. Insure battery terminals and connections are clean, corrosion free, and tight.

6. Insure battery ground to vehicle frame is clean, corrosion free, and tight.

7. Insure alternator belt is in good condition.

8. Insure alternator belt has correct tension.

9. Verify alternator provides 13.6 volts minimum with the engine running and no accessories on.

10. Verify that capacity of alternator meets minimum requirements for operating the snowplow.

11. Insure snowplow ground and power connections are clean, corrosion free, and tight.

12. Check harness connectors for corrosion, dirt, damage, or pushed pins or sockets that do not

fully connect.

13. Check fuses and circuit breakers in the system for the need to be replaced or reset.

14. Verify that the correct hydraulic uid is being used in the unit and that it is adequately lled.

CAUTION! NEVER use your hands to search for hydraulic uid leaks. Use a piece of paper or wood.

15. Check all hoses and cylinders for proper condition and leaks.

Initial Inspection 7

INITIAL INSPECTION

The initial inspection is intended to eliminate

system problems that could occur and should

be performed prior to any troubleshooting. The

troubleshooting procedures assume that the

initial inspection has been performed and will

not address system problems such as a low hy-

draulic uid level.

TITLE

8 Moldboard Problems

MOLDBOARD PROBLEMS

PLOW WILL NOT ANGLE RIGHT

Perform angle right.

DID PUMP MOTOR RUN?

No. Yes.

| Perform Controller Test Procedure.

| DID CONTROLLER TEST OK?

| No. Yes.

| | Perform Under Hood Harness Test Procedure.

| | DID UNDER HOOD HARNESS TEST OK?

| | No. Yes.

| | | Perform Plow Harness Test Procedure.

| | | DID PLOW HARNESS TEST OK?

| | | No. Yes.

| | | | Locate right hydraulic solenoid (See Power Unit Drawing).

| | | | Perform Hydraulic Solenoid Test Procedure.

| | | | DID RIGHT SOLENOID TEST OK?

| | | | No. Yes.

| | | | | Hydraulic problem (See Hydraulic Unit Service Manual).

| | | | |

| | | | Replace right solenoid (See Hydraulic Unit Service Manual).

| | | |

| | | Check ORANGE wire from J1 - 4 (plow harness) to right solenoid.

| | | DID THIS FIND THE PROBLEM?

| | | No. Yes, done.

| | | |

| | | See Special Problems.

| | |

| | Check wiring between P2 - 6 (controller) to P1 - 4 (grill).

| | Note: Wire color changes from BLUE between P2 - 6 & Relay Box,

| | to ORANGE between Relay Box & P1 - 4.

| | DID THIS FIND THE PROBLEM?

| | No. Yes, done.

| | |

| | See Special Problems.

| |

| DID TEST SHOW NO POWER TO CONTROLLER?

| No. Yes.

| | See No Controller Power.

| |

| Check J2 - 6 (controller) for damage.

| DID THIS FIND THE PROBLEM?

| No. Yes, done.

| |

| Replace the controller.

|

See Pump Will Not Run.

Moldboard Problems 9

PLOW WILL NOT ANGLE LEFT

Perform angle left.

DID PUMP MOTOR RUN?

No. Yes.

| Perform Controller Test Procedure.

| DID CONTROLLER TEST OK?

| No. Yes.

| | Perform Under Hood Harness Test Procedure.

| | DID UNDER HOOD HARNESS TEST OK?

| | No. Yes.

| | | Perform Plow Harness Test Procedure.

| | | DID PLOW HARNESS TEST OK?

| | | No. Yes.

| | | | Locate left hydraulic solenoid (See Power Unit Drawing).

| | | | Perform Hydraulic Solenoid Test Procedure.

| | | | DID LEFT SOLENOID TEST OK?

| | | | No. Yes.

| | | | | Hydraulic problem (See Hydraulic Unit Service Manual).

| | | | |

| | | | Replace left solenoid (See Hydraulic Unit Service Manual).

| | | |

| | | Check GREEN wire from J1 - 5 (plow harness) to left solenoid.

| | | DID THIS FIND THE PROBLEM?

| | | No. Yes, done.

| | | |

| | | See Special Problems.

| | |

| | Check wiring between P2 - 5 (controller) to P1 - 5 (grill).

| | Note: Wire color is GREEN between P2 - 5 & Relay Box

| | and GREEN between Relay Box & P1 - 5.

| | DID THIS FIND THE PROBLEM?

| | No. Yes, done.

| | |

| | See Special Problems.

| |

| DID TEST SHOW NO POWER TO CONTROLLER?

| No. Yes.

| | See No Controller Power.

| |

| Check J2 - 5 (controller) for damage.

| DID THIS FIND THE PROBLEM?

| No. Yes, done.

| |

| Replace the controller.

|

See Pump Will Not Run.

10 Moldboard Problems

PLOW WILL NOT RAISE

Perform up.

DID PUMP MOTOR RUN?

No. Yes.

| Locate down hydraulic solenoid (See Power Unit Drawing).

| Check if constantly on (See Hydraulic Solenoid Tests).

| IS DOWN SOLENOID CONSTANTLY ON?

| No. Yes.

| | Perform the Controller Test Procedure.

| | DID CONTROLLER TEST OK?

| | No. Yes.

| | | Perform Under Hood Harness Test Procedure.

| | | DID UNDER HOOD HARNESS TEST OK?

| | | No. Yes.

| | | | Perform Plow Harness Test Procedure.

| | | | DID PLOW HARNESS TEST OK?

| | | | No. Yes.

| | | | | Problem may be intermittent.

| | | | | See Special Problems.

| | | | |

| | | | Check BROWN wire between J1 - 3 & down solenoid

| | | | for short to +12.

| | | | DID THIS FIND THE PROBLEM?

| | | | No. Yes, done.

| | | | |

| | | | See Special Problems.

| | | |

| | | Check RED wire between P2 - 2 & Relay Box for short to +12.

| | | Check BROWN wire between Relay Box & P1 - 3 for short to +12.

| | | DID THIS FIND THE PROBLEM?

| | | No. Yes, done.

| | | |

| | | See Special Problems.

| | |

| | Replace the controller.

| |

| Hydraulic problem (See Hydraulic Unit Service Manual).

|

See Pump Will Not Run.

Moldboard Problems 11

PLOW WILL NOT LOWER

Perform the Controller Test Procedure

DID CONTROLLER TEST OK?

No. Yes.

| Perform Under Hood Harness Test Procedure.

| DID UNDER HOOD HARNESS TEST OK?

| No. Yes.

| | Perform Plow Harness Test Procedure.

| | DID PLOW HARNESS TEST OK?

| | No. Yes.

| | | Locate down hydraulic solenoid (See Power Unit Drawing).

| | | Perform Hydraulic Solenoid Test Procedure.

| | | DID DOWN SOLENOID TEST OK?

| | | No. Yes.

| | | | Hydraulic problem (See Hydraulic Unit Service Manual).

| | | |

| | | Replace down solenoid (See Hydraulic Unit Service Manual).

| | | DID THIS FIND THE PROBLEM?

| | | No. Yes, done.

| | | |

| | | See Special Problems.

| | |

| | Check BROWN wire from J1 - 3 (plow harness) to down solenoid.

| | DID THIS FIND THE PROBLEM?

| | No. Yes, done.

| | |

| | See Special Problems.

| |

| Check wiring between P2 - 2 (controller) to P1 - 3 (grill).

| Note: Wire color changes from RED between P2 - 2 & Relay Box,

| to BROWN between Relay Box & P1 - 3.

| DID THIS FIND THE PROBLEM?

| No. Yes, done.

| |

| See Special Problems.

|

DID TEST SHOW NO POWER TO CONTROLLER?

No. Yes.

| See No Controller Power.

|

Check J2 - 2 (controller) for damage.

DID THIS FIND THE PROBLEM?

No. Yes, done.

|

Replace the controller.

12 Moldboard Problems

PLOW CONSTANTLY ANGLES LEFT

Locate left hydraulic solenoid (See Power Unit Drawing).

Check if constantly on (See Hydraulic Solenoid Test Procedure).

IS LEFT SOLENOID CONSTANTLY ON?

No. Yes.

| Perform Controller Test Procedure.

| DID CONTROLLER TEST OK?

| No. Yes.

| | Perform Under Hood Harness Test Procedure.

| | DID UNDER HOOD HARNESS TEST OK?

| | No. Yes.

| | | Perform the Plow Harness Test Procedure.

| | | DID PLOW HARNESS TEST OK?

| | | No. Yes.

| | | | See Special Problems.

| | | |

| | | Check GREEN wire from J1 - 5 (plow harness) to left solenoid for short to +12.

| | | DID THIS FIND THE PROBLEM?

| | | No. Yes, done.

| | | |

| | | See Special Problems.

| | |

| | Check wiring between P2 - 5 (controller) to P1 - 5 (grill) for short to +12.

| | Note: Wire color is GREEN between P2 - 5 & Relay Box

| | and GREEN between Relay Box & P1 - 5.

| | DID THIS FIND THE PROBLEM?

| | No. Yes, done.

| | |

| | See Special Problems.

| |

| Replace the controller.

|

Hydraulic problem (See Hydraulic Unit Service Manual).

Moldboard Problems 13

PLOW CONSTANTLY ANGLES RIGHT

Locate right hydraulic solenoid (See Power Unit Drawing).

Check if constantly on (See Hydraulic Solenoid Test Procedure).

IS RIGHT SOLENOID CONSTANTLY ON?

No. Yes.

| Perform Controller Test Procedure.

| DID CONTROLLER TEST OK?

| No. Yes.

| | Perform Under Hood Harness Test Procedure.

| | DID UNDER HOOD HARNESS TEST OK?

| | No. Yes.

| | | Perform Plow Harness Test Procedure.

| | | DID PLOW HARNESS TEST OK?

| | | No. Yes.

| | | | See Special Problems.

| | | |

| | | Check ORANGE wire between J1 - 4 (plow harness ) & right solenoid

| | | for short to +12.

| | | DID THIS FIND THE PROBLEM?

| | | No. Yes, done.

| | | |

| | | See Special Problems.

| | |

| | Check wiring between P2 - 6 (controller) to P1 - 4 (grill) for short to +12.

| | Note: Wire color changes from BLUE between P2 - 6 & Relay Box,

| | to ORANGE between Relay Box & P1 - 4.

| | DID THIS SOLVE THE PROBLEM?

| | No. Yes, done.

| | |

| | See Special Problems.

| |

| Replace the controller.

|

Hydraulic problem (See Hydraulic Unit Service Manual).

PLOW OPERATES SLOWLY

The plow should take approximately two seconds to perform moldboard movements.

DOES IT DO THIS?

No. Yes, done.

|

IS THE PLOW BEING USED AT EXTREMELY COLD TEMPERATURES?

No. Yes.

| See chart for recommended oils at various temperatures.

| DID THIS FIND THE PROBLEM?

| No. Yes, done.

| |

|______|

|

See No Plow Power.

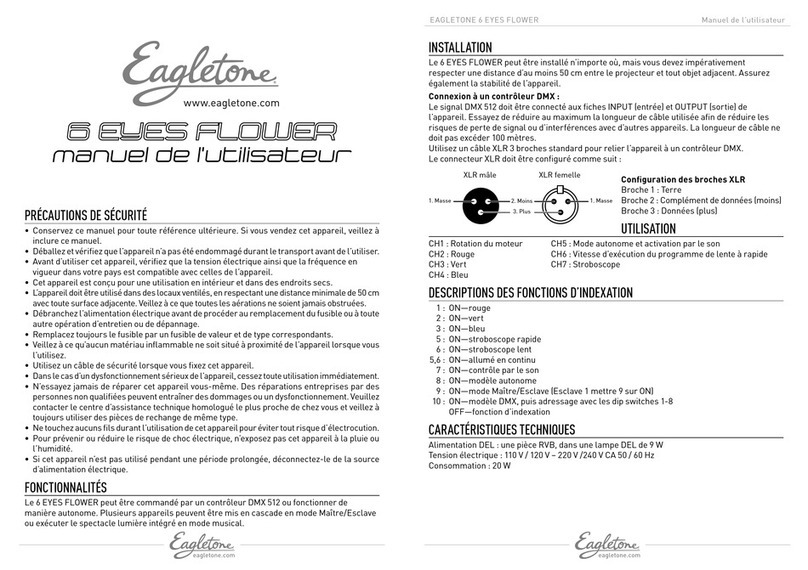

HYDRAULIC OIL SELECTION CHART

14 Moldboard Problems

The following chart shows various hydraulic oils

and their recommended temperature range. Se-

lect an oil that is appropriate for your location

and plowing conditions. Old or contaminated hy-

draulicoilcancausemanyoperationalproblems.

Hydraulic oil should be changed every year for

best performance.

Refer to the Operators Manual for specic in-

structions on changing oil.

CAUTION: Do not mix different types

of hydraulic uid. Some uids are not

compatible and may cause perfor-

mance problems and product damage.

DWG NO. 3991A

RECOMMENDED OILS AT VARIOUS TEMPERATURES

OIL TEMPERATURE - - DEGREES FAHRENHEIT

-60 -40 -20 0 20 40 60 80 100

-100 -50 0 50 100 150 200

UNIVIS J26

MIL-5606

SAE 5

ISO VG 22

SAE 10

ATF

OIL TEMPERATURE - - DEGREES CENTIGRADE

MAX. RECOMMENDED PUMP

OPERATING TEMPERATURE.

HYDRAULIC OIL SELECTION CHART

This manual suits for next models

3

Table of contents