Hiniker AR-2000 User manual

MODEL AR-2000

FLAIL SHREDDER

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 79203019 Rev. A

TITLE

Section 1

Table of Contents 1

TABLE OF CONTENTS

79203019RevA 3/11 Manual/79203019RevA

ASSEMBLY ..........................................................................................................................................43-54

Accessories

End Transport.................................................................................................................................... 49

After Market Hydraulics..................................................................................................................... 50

Optional Hydraulics ......................................................................................................................50-51

Warning Light Package.................................................................................................................52-53

Skid Shoes ........................................................................................................................................54

Grass Divider..................................................................................................................................... 54

Basic Machine..............................................................................................................................43-49

Off-loading......................................................................................................................................... 43

FIELD PREPARATION......................................................................................................................... 11-19

3 Point Hitch................................................................................................................................. 11-14

PTO’s...................................................................................................................................... 11, 14-16

Rockshaft & Wheels.....................................................................................................................16-17

Towing ..........................................................................................................................................18-19

Trailing Hitch...................................................................................................................................... 14

Tractor ................................................................................................................................................11

GENERAL

Specications ....................................................................................................................... 55

To Purchaser.......................................................................................................................... 2

Storage................................................................................................................................. 22

LUBRICATION........................................................................................................................23-26

OPERATION...........................................................................................................................20-22

General............................................................................................................................20-21

Height Adjustment...........................................................................................................21-22

SAFETY....................................................................................................................................3-10

Before Operation.................................................................................................................... 4

Decal Location...................................................................................................................7-10

During Operation.................................................................................................................... 5

General................................................................................................................................3-4

Service ................................................................................................................................5-6

Towing.................................................................................................................................... 5

SERVICE................................................................................................................................28-42

Belts ..................................................................................................................................... 30

Drive Shaft Bearings ............................................................................................................ 35

Gearbox...........................................................................................................................36-38

Hardware.............................................................................................................................. 28

Knives..............................................................................................................................28-29

PTO’s ..............................................................................................................................39-42

Rotor Bearings ................................................................................................................30-33

Sheaves ..........................................................................................................................33-35

Wheel Bearings...............................................................................................................35-36

TROUBLESHOOTING ................................................................................................................ 27

WARRANTY................................................................................................................................ 57

2 Section

TITLE

2 To The Purchaser

TO THE PURCHASER

This product is designed and manufactured to

give years of dependable service, when properly

maintained and used for the purpose for which

it is intended. Never allow anyone to operate

this equipment until they fully understand the

complete contents of this manual. It is the re-

sponsibility of owner’s, who do not operate this

equipment, to insure the operator is properly in-

structed and is fully aware, and understands, the

contents of this manual. It is also the owner’s re-

sponsibility to insure that anyone operating this

equipment is mentally and physically capable of

so doing.

Important information is contained in this manual

tohelpinsuresafeandefcientoperation.

If you have any questions about this manual, or

the equipment discussed therein, contact your

HINIKER dealer.

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED,

THESE INSTRUCTIONS, OTHERWISE DEATH,

OR SERIOUS INJURY CAN RESULT!

All references to LEFT or RIGHT means view-

ing the equipment from the rear and facing the

tractor.

Additional copies of this manual are available

from your Hiniker Dealer

ALWAYS OBTAIN ORIGINAL HINIKER SER-

VICE PARTS BECAUSE SUBSTITUTE PARTS

COULD ADVERSELY AFFECT EQUIPMENT

PERFORMANCE AND WARRANTY.

All photos in this manual refer to paragraph(s)

preceding the photo.

ATRIPLICATE(3COPIES)DELIVERYREPORT

IS TO BE FILLED OUT BY YOUR HINIKER

DEALER WHEN YOU ACCEPT THIS EQUIP-

MENT.

ONE COPY IS TO BE GIVEN TO YOU. DO NOT

ACCEPT THIS EQUIPMENT UNTIL YOU ARE

SATISFIEDALLITEMS THEREON HAVE BEEN

CHECKED, AND YOU UNDERSTAND THEM.

Check that your dealer has forwarded the

HINIKER delivery report copy, along with the

machine serial number, because it helps main-

tain maximum service and warranty benets.

This does not put you on any mailing list and

information thereon is not available to others.

FIGURE 1 PHOTO NO. 3540

Record the following information for later

reference when obtaining service parts:

Purchase Date:________________________

Purchaser’s Name:_____________________

Dealer’s Name:________________________

Machine Serial #:_______________________

TITLE

Section 3

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED,

THESE SYMBOLS AND INSTRUCTIONS, OTH-

ERWISE DEATH, OR SERIOUS INJURY CAN

RESULT!

Operatorsafety is a principle concern in equipment

design and distribution. However, many accidents

occur because a few seconds of thought, and a

more careful approach to handling, were ignored.

ACCIDENTS CAN BE AVOIDED BY KNOWING,

AND, FOLLOWING, THE PRECAUTIONS CITED

IN THIS MANUAL.

For better viewing, certain photos may show a

safety shield open or removed. This equipment

should never be operated without factory installed

shields in place.

Replace any decals that are not readable, or miss-

ing. Their ordering numbers and proper location

are shown in the DECAL LOCATION section of

this manual. Keep decals free of dirt, grease, etc.

Throughout this manual, and on all safety related

decals, a safety alert symbol, along with the signal

word CAUTION, WARNING or DANGER will be

found.Thesearedenedasfollows:

CAUTION: A reminder for proper safety

practices and directs attention to fol-

lowing them. Decals of this class are

yellow and black.

WARNING: A reminder for proper safety

practices and what can happen if they

are ignored. This has a more serious

consequence than CAUTION. Decals of this

class are orange and black.

DANGER: Denotes a most serious safe-

ty hazard. It is a reminder for observing

the stated precautions and what can

happen if they are ignored. Decals of this class

are red and white.

Safety 3

SAFETY

There are other decals, and copy, in this manual

that pertain to protecting the equipment. They are

not directly related to operator safety. These have

black letters on a white background to distinguish

them from safety decals. They lack the safety alert

symbol, but carry the words NOTICE or IMPOR-

TANTdenedasfollows:

NOTICE: INFORMS THE READER OF SOME-

THING THAT CAN CAUSE MINOR MACHINE

DAMAGE, OR POOR PERFORMANCE, IF IG-

NORED.

IMPORTANT: WARNS THE READER OF PO-

TENTIALLY MORE SERIOUS MACHINE DAM-

AGE, OR POOR PERFORMANCE IF IGNORED.

GENERAL

1. Additional copies of this operator’s manual

are available from your HINIKER dealer. If you

sell this equipment, insure the new owner ac-

knowledges receipt of this manual.

2. Read this manual thoroughly. Make sure the

operator understands it and knows how to op-

erate this equipment safely. Farm equipment

can kill or injure an untrained, or careless, op-

erator.

3. Do not attempt to handle and service this

equipment, or direct others to do the same,

unless you know how to do it safely.

4. Keep all shields and guards in place.

5. Keep hands, feet, hair and clothing away from

moving parts.

6. Disengage PTO, stop tractor engine, set

brakes and wait for all motion to stop before

adjusting, or servicing, this equipment.

7. Keep off, keep others off, and insure everyone

is clear before starting, actuating hydraulics,

and during equipment operation.

4 Safety

8. Do not service, or otherwise handle, a shred-

der in a raised position unless it is securely

blocked against unexpected falling.

9. Keepallfrontippershieldsinplaceandfree

swinging.

10. Never shred in areas littered with glass, rocks,

metal, etc. Use cab tractor if operating in un-

familiar areas. Keep cab windows clean to

maintain good visibility.

11. Escapinghydraulic/dieseluidunderpressure

can penetrate the skin causing serious injury.

DO NOT use your hand to check for leaks. Use a

piece of cardboard.

Stop tractor and relieve pressure before connect-

ing/disconnecting lines.

Tighten all connections before pressurizing hy-

draulic lines.

Ifuidisinjectedintotheskin,getmedicalatten-

tion to prevent serious infection.

12. Discipline yourself to always visually inspect

this equipment for any excessively worn, dam-

aged, or cracked parts before starting use.

Replace these with genuine HINIKER parts.

13. Stalk shredding often involves a combustible

environment.Carryareextinguisherandrst

aid kit with tractor.

14. OSHA requires farm employers to meet cer-

tain safety standards. Become familiar with,

and comply with them.

15. Do not alter this equipment to the extent of

compromising safety and performance.

16. Do not substantially operate tractor in a closed

building.

17. Ag chemicals can be dangerous. Always fol-

low the manufacturer’s label safety precau-

tions when using them.

18. Do not assume everyone is as safety con-

scious as yourself.

BEFORE OPERATION

1. Insure unit’s PTO assembly is fully engaged

with gearbox and tractor shafts and SLID-

ING COLLARS ARE RETURNED TO THEIR

LOCKED POSITIONS.

2. NEVER allow improperly supervised minors,

or anyone else, to operate this equipment. It is

your responsibility to insure that any operator

is mentally and physically capable of so do-

ing.

3. Do not operate a 1000 RPM shredder with a

540 RPM tractor.

4. Do not “jump start” the tractor from along side

it. Start tractor only from seat.

5. For trail hitch units, lock any swinging tractor

drawbar before hooking up. Use a cross re-

tainer in end of the hitch pin.

6. For 3 point hitch units, it is CRITICALLY IM-

PORTANTNOTTOOPERATEWITHATRAC-

TOR OF INSUFFICIENTSIZEAND/OR WITH

OUTADEQUATEFRONTEND WEIGHTS. Ig-

noring this can result in dangerously unstable

front steering!

7. Disengage PTO, stop tractor engine, and re-

move key before hooking up shredder PTO.

8. Clear area of people, and debris, before en-

gaging tractor PTO Be alert for blind areas of

operator. Slow down PTO and “feather” into

engagement to prevent unnecessary stress

on shredder’s driveline.

9. DO NOT OPEN MACHINE SHIELDS WITH

TRACTOR ENGINE RUNNING.

10. Do not stand close to, immediately behind or

in front of, a running shredder.

11. Four different PTO’s, involving 2 different

hitches, are available. INSURE YOU UNDER-

STAND CORRECT SHREDDER HOOKUP

FOR YOUR TRACTOR USAGE (SEE “FIELD

PREPARATION” in this manual).

Safety 5

DURING OPERATION

1. Gradually bring unit up to operating speed

and check for any abnormal vibration, or per-

formance. IF ABNORMAL VIBRATION IS

PRESENTATANY TIME, IMMEDIATELY DIS-

ENGAGE PTO, STOP TRACTOR ENGINE,

REMOVE KEYAND DETERMINE/ CORRECT

CAUSE BEFORE PROCEEDING.

2. Disengage PTO, stop tractor engine, remove

key and allow EQUIPMENT TO COME TO A

COMPLETE STOP before:

- Cleaning, unclogging, lubricating, inspecting,

or otherwise servicing, any part of this equip-

ment.

- Connecting or disconnecting the shredder from

the tractor.

- Allowing anyone else near the equipment.

- Dismounting from the tractor seat and parking

the equipment.

- Placing any part of your body in dangerous

proximity to shredder.

3. When parking this equipment, lower it to full

“down” position. Set the tractor brakes and

block wheels if on an extreme slope.

TOWING

1. When towing on public highways:

- Use a safety chain between the shredder hitch

and the towing vehicle (The 10,000# safety

chain is part number 85501539).

- Useatractorofsufcientsize,andweight,re-

quiredforeldoperation.

- Do not tow faster than 25 MPH (40 kph).

- BE AWARE THE TRAIL HITCH WIDTH, WITH

END TRANSPORT KIT, IS 132” (11’) WIDE.

THE 3 POINT HITCH WIDTH, WITH END

TRANSPORT KIT, IS 107” (8’-11”) WIDE.

THESE WIDTHS ARE WITH THE PTO RE-

MOVED. If these widths are not permitted, or

advisable, under your circumstances, the hitch

of either machine must be removed.

- Check local regulations on towing width and

warning lights.

2. Nevertowtrailingshreddersineldmodewith

the PTO detached from the tractor and hooked

to the gearbox.

3. HINIKER shredders are provided with (1)

ASAE SMV (slow moving vehicle) emblem and

(2) mounting sockets there for. One socket is

for towing in FIELD mode and one socket is for

towing with the END TRANSPORT accessory.

4. At sundry locations, RED (rear facing) andAM-

BER (forward facing) reectors are provided.

Insure these do not become defaced or cov-

ered with debris.

SERVICE

1. Service information herein is intended for deal-

ers and others correspondingly competent.

If you are not experienced and/or capable of

handling such service, do not attempt it.

2. Disengage PTO, stop tractor engine, re-move

key and allow EQUIPMENT TO COME TO A

COMPLETE STOP before:

- Cleaning, unclogging, lubricating, inspecting,

or otherwise servicing, any part of this equip-

ment.

- Connecting or disconnecting the shredder from

the tractor.

- Allowing anyone else near the equipment.

- Placing any part of your body in dangerous

proximity to shredder.

3. Donotservice,orotherwisehandle,ashred-

der in a raised position unless it is securely

blocked against unexpected falling.

6 Safety

4. Stalk shredders operate in a naturally vi-

bratory environment. Discipline yourself to

always visually inspect this equipment for

any excessively worn, damaged, or cracked

parts before starting use. Replace these

with genuine HINIKER parts.

5. DO NOT SERVICE END DRIVE BELTS

WHEN TRACTOR IS RUNNING!

6. Replace all shields removed for service, and

check PTO shield for free rotation, before

operating this equipment.

REMEMBER - ACCIDENT PREVENTION IS

PART OF YOUR JOB!

TITLE

Section 7

DECAL LOCATION

Decal Location 7

It is an owner’s and dealer’s responsibility to

ensure clear, complete decals are maintained

on equipment, whether operating or offered for

sale.

Information herein is provided for proper decal

ordering and placement.

Decal surfaces should be free of dirt, grease,

etc. Temperatures should be above 50° F. To ap-

ply, remove the smaller part of the decal backing

paper and apply this part of the exposed adhe-

sive to the desired location. Peel the other part

of the backing paper slowly off and smooth out

the entire decal.

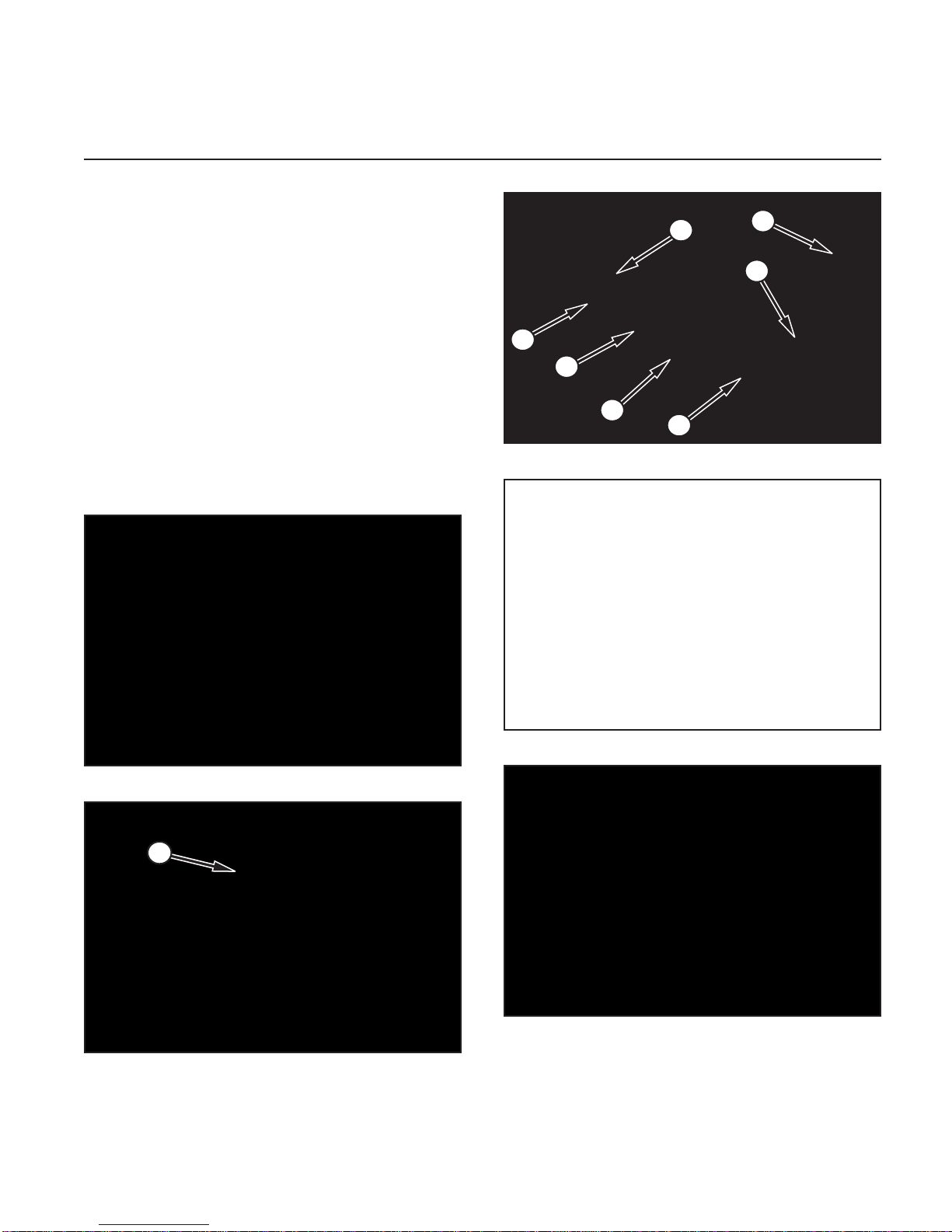

FIGURE 1 PHOTO NO. 2992B

22

FIGURE 1 PHOTO NO. DSCN4637A

99

13

26

8

20 19

FIGURE 2 PHOTO NO. 3541B

FIGURE 3 PHOTO NO. 3542

FIGURE 4 PHOTO NO. 3543A

8 Decal Location

10

20

14

28

FIGURE 5 PHOTO NO. DSCN4654A

FIGURE 6 PHOTO NO. 3545B

FIGURE 7 PHOTO NO. 3546B

FIGURE 7A PHOTO NO. 2998A

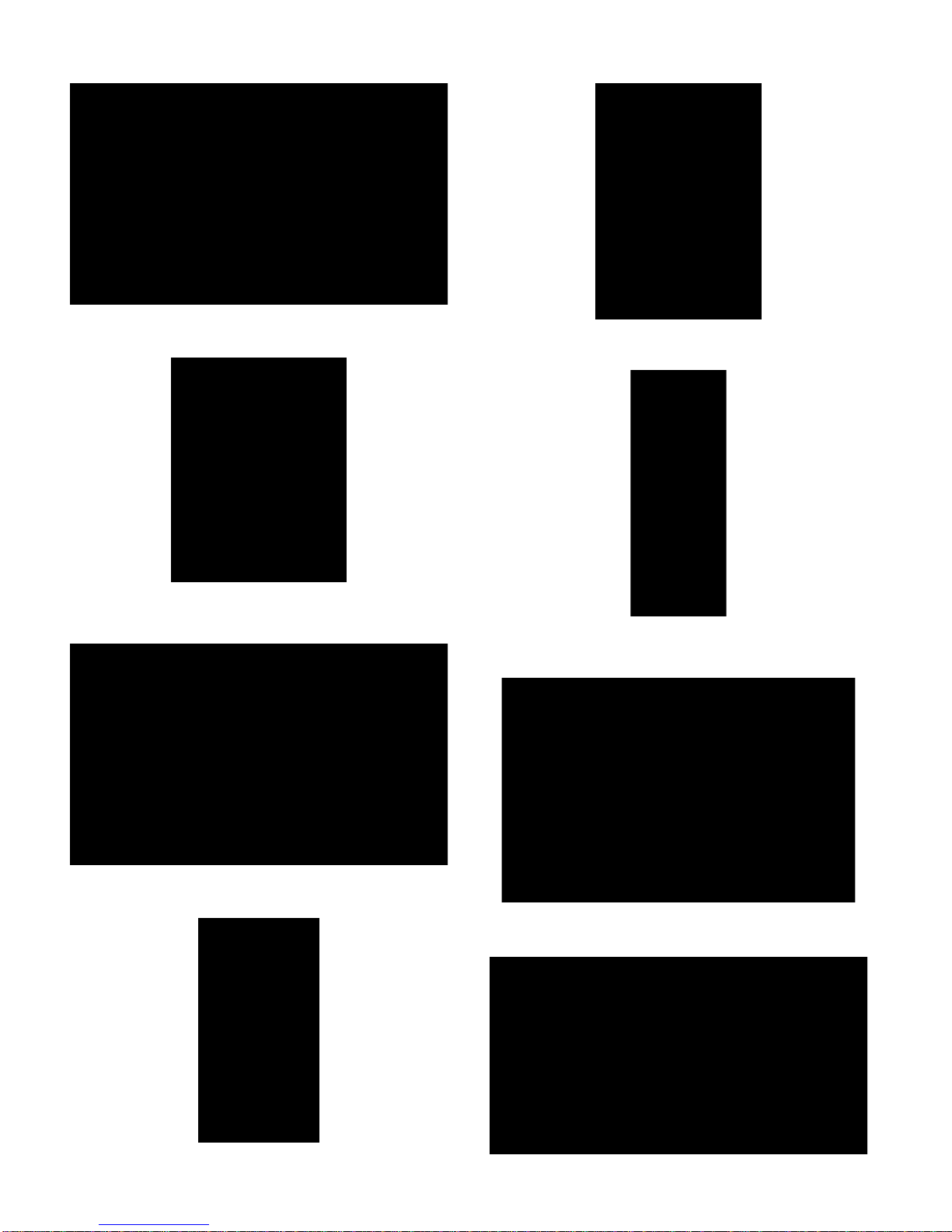

FIGURE 8 79202299 LOGO AR-2000

FIGURE 9 71505168 LOGO HINIKER

AR-2000

FIGURE 10 79202337 LOGO AR-2000

FIGURE 14 79203023 IMPORTANT: MAINTAIN BELTS...

FIGURE 16 71504126 IMPORTANT: OPERATE MACHINE...

Decal Location 9

FIGURE 17 71504133 IMPORTANT: HITCH...

FIGURE 18 715-03174 IMPORTANT: LIFT...

FIGURE 19 850-001-285 TAPE YELLOW REFLECTOR

FIGURE 20 850-001-305 TAPE RED REFLECTOR

FIGURE 21 715-04132 CAUTION: READ MANUAL...

FIGURE 22 85501787 CAUTION: SAFETY CHAIN...

FIGURE 23 71504129 CAUTION: 1000 RPM

FIGURE 24 715-03056 CAUTION: REVERSE 25 MPH...

10 Decal Location

FIGURE 26 71505169 WARNING: LOOK AND LISTEN...

FIGURE 27 71505171 WARNING: KEEP HANDS, ETC...

FIGURE 28 71505170 WARNING: DO NOT OPERATE...

FIGURE 29 WARNING: DO NOT EXCEED...

FIGURE 30 520-03138 DANGER: ROTATING DRIVE...

FIGURE 31 520-03139 DANGER: SHIELD MISSING...

FIGURE 32 71504131 DANGER: KEEP FLIPPERS...

FIGURE 33 71505172 WARNING: WEIGHT..

TITLE

Section 11

Field Preparation 11

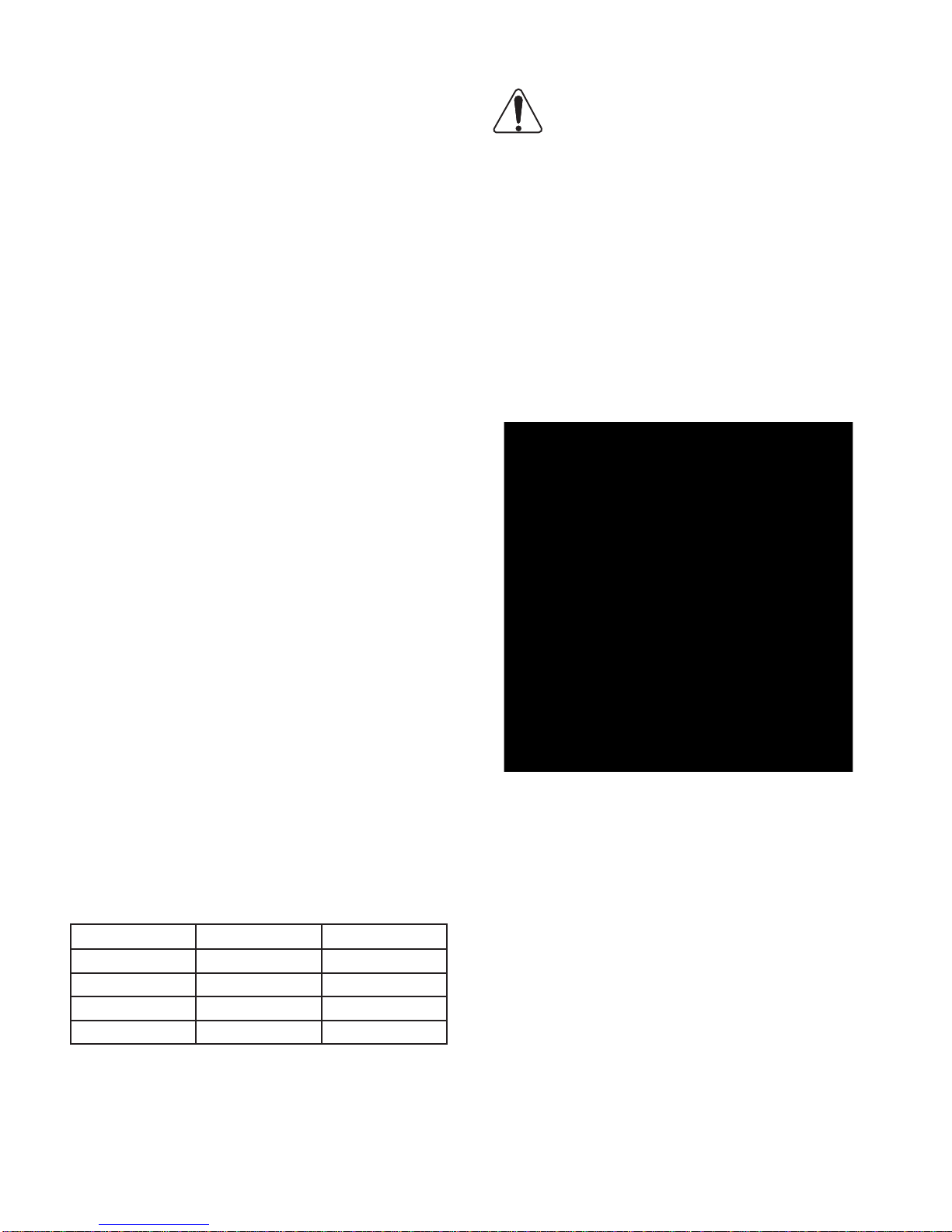

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. BEFORE FIELD

PREPARATION, READ SAFETY-GEN-

ERAL, BEFORE OPERATION, DURING OP-

ERATION AND TOWING AT FRONT OF THIS

MANUAL.

TRACTOR-GENERAL

IMPORTANT: IT IS CRITICAL TO KNOW WHAT

SHREDDER CONFIGURATION IS INVOLVED

BEFORE TRACTOR HOOKUP. CONVERSELY,

IF THE TRACTOR CONFIGURATION IS A GIV-

EN, THE SHREDDER MUST CONFORM TO IT,

OTHERWISE POTENTIAL EQUIPMENT DAM-

AGE CAN RESULT.

HINIKER shredders are available with:

TWO DIFFERENT hitches (trail and 3 point)

for all widths. Upon choice of hitch, DETER-

MINE THE TRACTOR’S PTO OUTPUT. This

will be 1 of 2 choices:

1000 RPM 1 3/8”-21 spline

1000 RPM 1 3/4”-20 spline

All TRAILING units use ONLY CV (constant

velocity) PTO’s. These are identied by ex-

tended front yokes separated by a large guide

hub between them.

All 3 POINT units use ONLY NON CV PTO’s.

Theseareidentiedbyfrontyokesjoinedwith

a conventional (simple) front cross.

IMPORTANT: IDENTIFY CORRECT SHRED-

DER PTO FOR TRACTOR USED BY CHECK-

ING FORWARD YOKE SPLINE AND NOTING

WHETHER THE PTO IS A CV OR NON CV.

DO NOT INTERMIX FRONT AND REAR PTO

HALVES BETWEEN DIFFERENT PTO’s.

FIELD PREPARATION

REFERENCE: COMPRESSED O.A. LENGTH

EACH AVAILABLE PTO.

SIZE RPM TYPE & ACC.* NO. LENGTH

1 3/8” (1000) 21 Spline Trailing

79202278 * – 55”

1 3/4” (1000) 20 Spline Trailing

79202277 * – 55”

1 3/8” (1000) 21 Spline 3 Point

520-02157 * – 38 1/16”

1 3/4” (1000) 20 Spline 3 Point

520-02159 * – 39 1/4”

* Accessory

CAUTION: DEATH OR SERIOUS INJURY

CAN RESULT. NEVER USE 1 3/8” TO

1 3/4” PTO “ADAPTER” EXTENSIONS.

TRACTOR 3-POINT GEOMETRY

Adjust the tractor’s lower links sway stops to

provide no more than “moderate” sway. That is,

do not operate with full, or no, lower link sway.

During shredding, maintain the tractor’s 3 point

lift system in POSITION CONTROL mode.

HINIKER 3 point hitch shredders are designed

to operate with Cat. II, III and IIIN free link (di-

rect) hitches and integral Cat. II, III and IIIN

quick hitches, having standard (ASAE S217.12

and S278.7) dimensions:

Category

II III & IIIN

Horizontal distance from end of

1 3/8” PTO to lower hitch

points in horizontal position. 20” – 22”

Horizontal distance from end of

1 3/4” PTO to lower hitch

points in horizontal position. 24” – 26”

Upper hitch pin diameter. 1” 1 1/4”

Lower hitch pin diameter. 1 1/8” 1 7/16”

12 Field Preparation

These shredders will also satisfactorily operate

with “add on” Cat. II, III and IIIN quick hitches, pro-

vided the horizontal distance from end of PTO’s to

lower hitch points in horizontal position does not

exceed:

1 3/8” PTO 27”

1 3/4” PTO 28”

Some tractors, with free links only (ie. without a

quick hitch), may have less than the above mini-

mums. In such circumstance, it is recommended

to use an “add on” quick hitch.

IMPORTANT: FAILURE TO VERIFY TRACTOR’S

CONFORMITY TO THESE DIMENSIONS CAN

DAMAGE BOTH TRACTOR AND SHREDDER

DRIVELINE. IF THIS IS NEGLECTED, HINIKER

OFFERS NO ASSURANCE THE DRIVELINE

WILL PROPERLY FUNCTION. BEFORE OPER-

ATING, CAREFULLY CHECK THAT YOUR PTO

HOOK UP NEITHER “BOTTOMS”, NOR EXCES-

SIVELY “DECOUPLES”.

IMPORTANT: BE SURE TO SET MAXIMUM UP

STOP ON 3-POINT POSITION CONTROL LE-

VER TO AVOID AN EXCESSIVE UNIVERSAL

OPERATING ANGLE. ANY ANGLE IN EXCESS

OF 30 DEGREES GREATLY REDUCES THE

FUNCTIONAL LIFE OF DRIVE LINE.

For 3 point hitch hookups, it is:

IMPORTANT: REALIZE THE OVERHUNG MA-

CHINE MOMENT (WEIGHT) SUBSTANTIALLY

VARIES FROM THE NARROWEST (15’) TO THE

WIDEST (25’) SHREDDERS.

Typical minimum unit’s weights are:

WIDTH LBS. KG.

15 foot 3375 1531

18 foot 3866 1754

20 foot 4163 1888

25 foot 5200 2360

DANGER: DEATH OR SERIOUS INJURY

CANRESULT.DONOTOPERATE3POINT

HITCH UNITS WITHOUT ADEQUATE

TRACTOR FRONT END WEIGHTS. USING AN

UNDERSIZE, OR INADEQUATELY FRONT END

WEIGHTED TRACTOR, WILL RESULT IN DAN-

GEROUS LOSS OF STEERING CONTROL.

FOR ROAD TRAVEL, ALLOW WHEELS TO RUN

IN GROUND CONTACT.

TRACTOR-TRAILING GEOMETRY

IMPORTANT: INSURE TRACTOR PTO AND

DRAWBAR CONFORM TO DIMENSIONS BE-

LOW.

DWG. NO. 71504133

IMPORTANT: AFTER TRACTOR HOOKUP, AL-

WAYS STORE HITCH JACK ON PEDESTAL AT

TOP OF GEARCASE.

SHREDDER 3-POINT HITCH

Three point hitch shredders have furnished 2 low-

er link pins (Item 1) and 1 upper link pin (Item 2).

These are sized for Cat. II; thus, may be used di-

rectly for that mode. Refer to Photo 2965.

Pins (Item 1) also have 2 spacers on each. These

are 1 3/4” O.D. (Item 3) and 1 7/16” O.D. (Item 4).

The larger spacer is factory installed furthermost

from the hitch centerline.

The inner 1 7/16” O.D. spacers should be removed

when operating in Cat. II mode.

Field Preparation 13

Pin (Item 2) has a 1 1/4” O.D. factory installed

spacer (Item 5) and PTO transport support (Item

6) thereon. The spacer should be removed for Cat.

II mode.

To operate in Cat. III mode, the lower link pins

spacers should be reversed from factory instal-

lation (ie. larger spacer (Item 3) innermost and

smaller spacer (Item 4) outermost).

To operate in Cat. IIIN mode, leave the lower link

pins spacers as factory installed (ie. larger spacer

(Item 3) outer-most and smaller spacer (Item 4)

innermost).

PHOTO NO. 2965

The 3 point hitch has lower link pin holes (Item 1

& 2). These are 4” apart and allow varying tractor

tire sizes and/or 3 point lift ranges. EITHER HOLE

MAY BE USED FOR BOTH CAT. II, III AND IIIN

MODES.

Generally, the LOWERMOST link pin hole (Item 1)

is appropriate for tractors with smaller tires and/

or less lift range. The UPPERMOST link pin hole

(Item 2) is generally appropriate for tractors with

larger tires and/or greater lift range. Refer to Photo

2965A.

Three upper link pin holes (Item 3, 4 & 5) are also

4” apart each. Refer to Photo 2965A.

IF OPERATION IS IN CAT. II MODE AND:

LOWERMOST lower link pin hole (Item 1) is

used, install upper link pin in hole (Item 3) or if,

UPPERMOST lower link pin hole (Item 2) is

used, install upper link pin in hole (Item 4).

IF OPERATION IS IN CAT. III OR IIIN MODE

AND:

LOWERMOST lower link pin hole (Item 1) is

used, install upper link pin in hole (Item 4) or if,

UPPERMOST lower link pin hole (Item 2) is

used, install upper link pin in hole (Item 5).

IMPORTANT: INITIAL LOWER LINK PIN LO-

CATIONS MAY HAVE TO BE REPOSITIONED

AFTER FIRST FIELDING THE TRACTOR AND

SHREDDER

FIGURE 36 PHOTO NO. 2965A

Support stand assembly (Item 1) is for hook up and

machine storage. FOR SHREDDER OPERATION

AND TRANSPORT, lower hole (Item 2) for cross

pin (Item 3) is used. Refer to Photo 3031A.

PHOTO NO. 3031A

IMPORTANT: AFTER TRACTOR HOOK UP,

RAISE AND LOCK SUPPORT STAND BY IN-

STALLING CROSS PIN AND Q.A. PIN IN LOW-

ER STAND HOLE.

14 Section

14 Field Preparation

After initial elding, the wheel legs rockshaft

position is normally adjusted with the ratchet

jack(s) and left unchanged unless eld condi-

tions change.

SHREDDER-TRAILING HITCH

Trailing shredders have an adjustable hitch

height adjustment (Item 1) to match various trac-

tor drawbar heights. Refer to Photo 3555A.

IMPORTANT: CORRECT TRAILING HITCH

DRAFT LINK LENGTH ADJUSTMENT CAN-

NOT BE MADE UNTIL AFTER THE SHRED-

DER IS INITIALLY FIELDED.

Raise the shredder with hitch jack until the hitch

yoke corresponds with the tractor’s drawbar and

insert hitch pin.Always store the hitch jack (Item

1) as shown in Photo DCP0603.

IMPORTANT: ALWAYS USE A 1” DIAMETER

HITCH PIN.

CAUTION: DEATH OR SERIOUS IN-

JURY CAN RESULT. ALWAYS INSERT

THE HITCH PIN POINT DOWN WITH A

CROSS LOCKING PIN THROUGH ITS LOWER

END.

PHOTO NO. 3555A

SHREDDER-PTO’s

IMPORTANT: IT IS CRITICAL TO KNOW WHAT

TRACTOR CONFIGURATION IS INVOLVED

BEFORE HOOKUP. THE PROPER SHREDDER

PTO MUST BE USED, OTHERWISE UNSATIS-

FACTORY PERFORMANCE WILL RESULT.

Hitch jack (Item 1), Photo DCP0603 is not needed

on 3 point hitch units, except when an end trans-

port accessory is used. Its storage position is on

pedestal on top the gearcase.

The “lost motion” slot (Item 1) provides ground

oatwhenthetractor’supperlink(Item2)isprop-

erly length adjusted. Normally, cross pin (Item 3)

should operate in the REAR SECTOR of the slot.

That is, from the slot’s center position to about 1”

from its rear. Actual adjustment herein is made

by VARYING THE TRACTOR’S UPPER LINK

LENGTH.

1

PHOTO NO. DCP0603

IMPORTANT:CORRECT“LOSTMOTION”AND

TRACTOR UPPER LINK ADJUSTMENT CAN

NOT BE MADE UNTIL AFTER THE SHRED-

DER IS INITIALLY FIELDED AND FINAL FIELD

SETTINGS ARE MADE.

PHOTO NO. 2972

No hose support is furnished with 3 point hitch

units because generally remote hydraulics are

not needed in this mode.

Section 15

Field Preparation 15

HINIKER shredders are available with:

TWO DIFFERENThitches (trail and 3 point) for all

widths. Upon choice of hitch, DETERMINE THE

TRACTOR’S PTO OUTPUT. This will be 1 of 2

choices:

1000 RPM 1 3/8”-21 spline

1000 RPM 1 3/4”-20 spline

All TRAILING UNITS use ONLY CV (constant

velocity) PTO’s. These are identied by ex-

tended front yokes separated by a large guide

hub between them.

All 3 POINT UNITS use ONLY NON CV PTO’s.

Theseareidentiedbyfrontyokesjoinedwith

a conventional (simple) front cross.

IMPORTANT: IDENTIFY CORRECT SHRED-

DER PTO FOR TRACTOR USED BY CHECK-

ING FORWARD YOKE SPLINE AND NOTING

WHETHER IT IS A CV OR NON CV. FRONT AND

REAR CV PTO HALVES CAN BE SWAPPED IN

THE FIELD, IF THE PTO’S HAVE BLACK PLAS-

TIC SHIELDS.

See reference table, page 11 for identifying cor-

rect PTO.

All shredder PTO’s have similar sliding yoke cou-

plers at the tractor and gearbox ends. GEARBOX

ENDS ARE IDENTIFIED BY AN OVERRUNNING

CLUTCH (Item 1).

Clean gearbox spline of any encrusted dirt or

grease and lightly oil it. Slide outer PTO collar

(Item 2) toward its adjacent yoke (Item 3) and slide

PTO over the gearbox spline. Reverse the sliding

collar to lock the assemblies together.

PHOTO NO. 2969A

NOTICE: TO FACILITATE PTO HOOK UPS,

CHECK TRACTOR SPLINE FOR BURRS, OR

OTHER DAMAGE. IF SHREDDER’S LOCKING

COLLAR IS DIFFICULT TO PROPERLY EN-

GAGE, CLEAN AND LIGHTLY OIL SPLINE.

The tractor PTO spline engages similar to above.

Slide outer collar (Item 1) toward its adjacent yoke

(Item 2) and slide PTO over the tractor spline. Re-

verse the sliding collar to lock the assemblies to-

gether.

PHOTO NO. 2966A

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. NEVER OPERATE

A SHREDDER UNLESS BOTH ENDS OF

THE PTO ARE PROPERLY LOCKED TO THEIR

INTENDED SPLINES.

Check the decal on gearbox shield to insure prop-

er tractor/shredder RPM matching.

DWG. NO. 71504129

DANGER: DEATH OR SERIOUS INJURY

CAN RESULT. KEEP AWAY AND KEEP

OTHERS AWAY FROM AN OPERAT-

ING PTO. DO NOT OPERATE WITHOUT ALL

SHIELDS IN PLACE. INSURE PTO SHIELDS

FREE WHEEL AND BOTH PTO’S ENDS ARE

SECURELY ATTACHED.

16 Field Preparation

IMPORTANT: NEVER TOW A TRAILING

SHREDDER UNLESS THE PTO IS PROPER-

LY HOOKED UP TO BOTH TRACTOR AND

SHREDDER. OTHERWISE, IT CAN BE DAM-

AGED. IF NECESSARY TO OTHERWISE TOW,

DETACH ENTIRE PTO ASSEMBLY (1) FROM

GEARBOX AND SECURE IT BEHIND A DRIVE

SHAFT SHIELD (2).

PHOTO NO. 3547

Three point hitch shredders may be eld mode

towed with the PTO detached from the tractor,

PROVIDED support chain (Item 1) is wrapped

around the PTO and hooked up. Before opera-

tion, always insure this chain is removed from

the PTO, wrapped around the “A” frame and re-

hooked on itself. Refer to Photo 3016.

PHOTO NO. 3016

SHREDDER ROCKSHAFT & WHEELS

If the shredder has been delivered without acces-

sory ratchet jack(s), or aftermarket hydraulics, in-

stall either at this time. See ASSEMBLY, page 45

or 50. It is not necessary to use hydraulics on 3

point hitch shredders.

If optional hydraulics are used on a trailing unit,

pass hoses through the hose support ring and en-

gage hose couplers with tractor’s remote hydraulic

outlets.

Insert tractor quick couplers to give shredder a

DOWNWARD movement when tractor hydraulic

lever is shoved FORWARD and vice versa.

CAUTION: DEATH OR SERIOUS INJURY

CAN RESULT. STOP TRACTOR ENGINE

AND RELIEVE HYDRAULIC PRESSURE

BEFORE CONNECTING OR DISCONNECTING

HYDRAULIC LINES.

DO NOT USE YOUR HAND TO CHECK FOR

HYDRAULIC LEAKS. HIGH PRESSURE FLUID

CAN PENETRATE THE SKIN.

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. DISENGAGE PTO,

STOPTRACTORENGINE,SETBRAKES,

REMOVE KEY AND ALLOW EQUIPMENT TO

COME TO A COMPLETE STOP BEFORE:

CLEANING, UNCLOGGING, LUBRICATING, IN-

SPECTING, OR OTHERWISE SERVICING, ANY

PART OF THIS EQUIPMENT.

DO NOT INSPECTAND/OR SERVICEA SHRED-

DER IN A RAISED POSITION UNLESS IT HAS

BEEN SECURELY BLOCKED FROM UNEX-

PECTED DROPPING.

HINIKER shredders are shipped with a 5/8” diam-

eter lockup bolt(s) through rockshaft bracket(s)

(Item 2) and “lost motion” link(s) (Item 3) at (Item

1).

IMPORTANT: TO PREVENT ROCKSHAFT

TWISTING ON 18’AND 20’ UNITS:

ACTUATE BOTH RATCHET JACKS UNIFORM-

LY OR,

INSTALL IDENTICAL LENGTH OF STOP COL-

LARS ON EACH CYLINDER ROD OR,

IDENTICALLY SET BOTH HYDRAULIC CYLIN-

DER INTEGRAL TRIPS.

Field Preparation 17

2

1

3

4

PHOTO NO. DCP0545

To adjust transverse spacing of a trailing unit’s

wheels, raise it with either the ratchet jack(s), or

hydraulic cylinder(s). Do this with the shredder

hitched to a tractor of adequate size to operate the

unit; thus, stabilizing it.

CAUTION: DEATH OR SERIOUS INJURY

CAN RESULT. MAKE ADJUSTMENTS

ONLY ON A LEVEL SURFACE. SET THE

TRACTOR’S BRAKES AND, SHUT OFF THE

ENGINE BEFORE PROCEEDING.

BLOCK UNIT OFF GROUND

AS SPECIFIED BELOW.

Insert approximately 8” high SECURE blocks

under each side of the shredder at its rear.

Lower shredder onto these blocks and continue

retracting either the ratchet jack(s), or hydrau-

lic cylinder(s), until the tires come free of the

ground.

Dimns. 30” Rows 36” Rows

15 foot units (outer) (1) 90” 72”

(inner) (2) 60” 36”

18 foot units (outer) (1) 90” 108”

(inner) (2) 60” 72”

20 foot units (outer) (1) 120” 108”

(inner) (2) 60” 72”

25 foot units (outer) (1) 150” 144”

(inner) (2) 90” 72”

Loosen the 6 5/8” leg bolts for each wheel and

transversely slide the entire assembly to the fol-

lowing tire centerline (as applicable). Tire cen-

terline spacings should be EQUALIZED on each

side of the shredder’s centerline.

For other row spacings, adjust the above set-

tings accordingly. Torque up each wheel leg’s 6

clamping bolts by uniformly tightening the lower

3tosnugt.Subsequently,torque,andretorque

top 3 to 146-206 Ft/lbs. (198-279 N/m.). Raise

the shredder, remove blocks and lower the unit.

Toadjustthetransversespacingofa3pointhitch

shredder’s wheels, a similar procedure is used.

Except, the shredder is raised with the tractor’s

3 point hitch and subsequent steps followed.

PHOTO NO. 2995

SHREDDER TIRES

Recommended tires on 5” wide rims are 7.60 x 15-

8PR L1 (implement) or equivalent. When equipped

with 8” wide rims 9.5L x 15 8 ply (implement) tires

are recommended. The shredder will perform bet-

ter, especially under ridged conditions, if tire pres-

sures are kept no greater than recommended. (If

the shredder tends to “yaw”, or climb ridged rows,

decrease pressure in the outside tires to the lower

range cited and recheck that tire centerlines are

running in the row middles.

18 Field Preparation

SHREDDER-FIELD MODE TOWING

Shredders are furnished with 1 SMV emblem (Item

1) and sockets (Item 2 & 3) Photo 2993A therefor.

If it is to be towed on public highways, WITHOUT

AN END TRANSPORTACCESSORY, install SMV

emblem in socket (Item 2). If it is to be towed on

public highways, WITH AN END TRANSPORT

ACCESSORY, install SMV emblem in socket (Item

3). The SMV’s reective surface should face the

rear.

CAUTION: DEATH OR SERIOUS INJURY

CAN RESULT. WHEN TOWING ON PUB-

LIC HIGHWAYS:

USE A TRACTOR OF SUFFICIENT SIZE, AND

WEIGHT, REQUIRED FOR FIELD OPERATION.

DO NOT TOW AT SPEEDS IN EXCESS OF 25

MPH (40 KPH).

USE AN AFTERMARKET SAFETY TOWING

CHAIN BETWEEN TOWING VEHICLE AND

SHREDDER.

USETHESMVEMBLEMASSPECIFIEDABOVE.

CHECK LOCAL REGULATIONS ON TOWING

WIDTH AND WARNING LIGHTS.

TOW 3 POINT HITCH UNITS WITH WHEELS

RUNNING IN GROUND CONTACT.

IMPORTANT: NEVER TOWA TRAILING SHRED-

DERUNLESS THEPTOIS PROPERLYHOOKED

UP TO BOTH TRACTOR AND SHREDDER.

OTHERWISE, IT CAN BE DAMAGED. IF NEC-

ESSARY TO OTHERWISE TOW, DETACH EN-

TIRE PTO ASSEMBLY FROM GEARBOX AND

SECURE IT BEHIND A DRIVE SHAFT SHIELD.

Three point hitch shredders may be towed with

the PTO detached from the tractor, PROVIDED its

support chain is used.

PHOTO NO. 2993A

Use a safety towing chain (Item 1) between the

shredder and towing vehicle. Hook chain around

bracket (Item 2) and pass forward through after-

market clevis (Item 3). Fix chain’s forward end

(Item 4) to tractor.

PHOTO NO. 3550

Shredder- Warning Light Package

Install the warning lights into the two SMV style

sockets provided on the end panels of the shred-

der. Route the warning light cable from each light

assembly to the center of the machine. Run the ca-

ble forward over the top of the shredder and down

along the hitch until the connector reaches the trac-

tor 7 pin lighting connector. Secure the cable with

plastic cable ties. Important- Make sure the cable

will not be tangled in the PTO when making

sharp turns.

Checkthelightstobesuretheyareconnectedprop-

erlysothatturnsignalashersoperatecorrectly.

Other manuals for AR-2000

1

Table of contents

Other Hiniker Paper Shredder manuals