Hiniker AR-2000 User manual

MODEL AR-2000

30 FT. FLAIL SHREDDER

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 79203563

TITLE

Section 1

Table of Contents 1

TABLE OF CONTENTS

79203563 2/13 Manual/79203563

ASSEMBLY ..........................................................................................................................................33-39

Skid Shoes ........................................................................................................................................38

Grass Divider..................................................................................................................................... 39

Basic Machine..............................................................................................................................33-38

Off-loading......................................................................................................................................... 33

FIELD PREPARATION.........................................................................................................................10-13

End Transport Towing........................................................................................................................ 12

PTO’s................................................................................................................................................. 10

Rockshaft & Wheels...........................................................................................................................11

Trailing Hitch...................................................................................................................................... 10

Tractor ............................................................................................................................................... 10

GENERAL

Specications ....................................................................................................................... 40

To Purchaser.......................................................................................................................... 2

Storage................................................................................................................................. 16

LUBRICATION............................................................................................................................. 18

OPERATION...........................................................................................................................14-17

End Transport Towing........................................................................................................... 15

General................................................................................................................................. 14

Trailing Hold Height Adjustment........................................................................................... 15

SAFETY......................................................................................................................................... 9

Before Operation.................................................................................................................... 4

Decal Location........................................................................................................................ 6

During Operation.................................................................................................................... 4

General................................................................................................................................... 3

Service ................................................................................................................................... 5

Towing.................................................................................................................................... 5

SERVICE................................................................................................................................23-32

Belts ..................................................................................................................................... 25

Drive Shaft Bearings ............................................................................................................ 29

Gearbox................................................................................................................................ 30

Hardware.............................................................................................................................. 23

Knives................................................................................................................................... 23

Rotor Bearings ..................................................................................................................... 25

Sheaves ............................................................................................................................... 28

Wheel Bearings.................................................................................................................... 29

TROUBLESHOOTING ................................................................................................................ 22

WARRANTY................................................................................................................................ 41

2 Section

TITLE

2 To The Purchaser

TO THE PURCHASER

This product is designed and manufactured to

give years of dependable service, when properly

maintained and used for the purpose for which

it is intended. Never allow anyone to operate

this equipment until they fully understand the

complete contents of this manual. It is the re-

sponsibility of owner’s, who do not operate this

equipment, to insure the operator is properly in-

structed and is fully aware, and understands, the

contents of this manual. It is also the owner’s re-

sponsibility to insure that anyone operating this

equipment is mentally and physically capable of

so doing.

Important information is contained in this manual

tohelpinsuresafeandefcientoperation.

If you have any questions about this manual, or

the equipment discussed therein, contact your

HINIKER dealer.

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED,

THESE INSTRUCTIONS, OTHERWISE DEATH,

OR SERIOUS INJURY CAN RESULT!

All references to LEFT or RIGHT means view-

ing the equipment from the rear and facing the

tractor.

Additional copies of this manual are available

from your Hiniker Dealer

ALWAYS OBTAIN ORIGINAL HINIKER SER-

VICE PARTS BECAUSE SUBSTITUTE PARTS

COULD ADVERSELY AFFECT EQUIPMENT

PERFORMANCE AND WARRANTY.

All photos in this manual refer to paragraph(s)

preceding the photo.

3 COPIES OF THE DELIVERY REPORT ARE

TO BE FILLED OUT BY YOUR HINIKER DEAL-

ER WHEN YOU ACCEPT THIS EQUIPMENT.

ONE COPY IS TO BE GIVEN TO YOU. DO NOT

ACCEPT THIS EQUIPMENT UNTIL YOU ARE

SATISFIEDALLITEMS THEREON HAVE BEEN

CHECKED, AND YOU UNDERSTAND THEM.

Check that your dealer has forwarded the

HINIKER delivery report copy, along with the

machine serial number, because it helps main-

tain maximum service and warranty benets.

This does not put you on any mailing list and

information thereon is not available to others.

FIGURE 1 DWG NO. 6864

Record the following information for later

reference when obtaining service parts:

Purchase Date:________________________

Purchaser’s Name:_____________________

Dealer’s Name:________________________

Machine Serial #:_______________________

TITLE

Section 3

THIS IS THE SAFETY ALERT SYMBOL.

IT ALERTS AN OPERATOR TO INFOR-

MATION CONCERNING PERSONAL

SAFETY. ALWAYS OBSERVE, AND HEED,

THESE SYMBOLS AND INSTRUCTIONS, OTH-

ERWISE DEATH, OR SERIOUS INJURY CAN

RESULT!

Operatorsafety isaprinciple concern inequipment

design and distribution. However, many accidents

occur because a few seconds of thought, and a

more careful approach to handling, were ignored.

ACCIDENTS CAN BE AVOIDED BY KNOWING,

AND, FOLLOWING, THE PRECAUTIONS CITED

IN THIS MANUAL.

For better viewing, certain photos may show a

safety shield open or removed. This equipment

should never be operated without factory installed

shields in place.

Replace any decals that are not readable, or miss-

ing. Their ordering numbers and proper location

are shown in the DECAL LOCATION section of

this manual. Keep decals free of dirt, grease, etc.

Throughout this manual, and on all safety related

decals, a safety alert symbol, along with the signal

word CAUTION, WARNING or DANGER will be

found.Thesearedenedasfollows:

CAUTION: A reminder for proper safety

practices and directs attention to fol-

lowing them. Decals of this class are

yellow and black.

WARNING: A reminder for proper safety

practices and what can happen if they

are ignored. This has a more serious

consequence than CAUTION. Decals of this

class are orange and black.

DANGER: Denotes a most serious safe-

ty hazard. It is a reminder for observing

the stated precautions and what can

happen if they are ignored. Decals of this class

are red and white.

Safety 3

SAFETY

There are other decals, and copy, in this manual

that pertain to protecting the equipment. They are

not directly related to operator safety. These have

black letters on a white background to distinguish

them from safety decals. They lack the safety alert

symbol, but carry the words NOTICE or IMPOR-

TANTdenedasfollows:

NOTICE: INFORMS THE READER OF SOME-

THING THAT CAN CAUSE MINOR MACHINE

DAMAGE, OR POOR PERFORMANCE, IF IG-

NORED.

IMPORTANT: WARNS THE READER OF PO-

TENTIALLY MORE SERIOUS MACHINE DAM-

AGE, OR POOR PERFORMANCE IF IGNORED.

GENERAL

1. Additional copies of this operator’s manual

are available from your HINIKER dealer. If you

sell this equipment, insure the new owner ac-

knowledges receipt of this manual.

2. Read this manual thoroughly. Make sure the

operator understands it and knows how to op-

erate this equipment safely. Farm equipment

can kill or injure an untrained, or careless, op-

erator.

3. Do not attempt to handle and service this

equipment, or direct others to do the same,

unless you know how to do it safely.

4. Keep all shields and guards in place.

5. Keep hands, feet, hair and clothing away from

moving parts.

6. Disengage PTO, stop tractor engine, set

brakes and wait for all motion to stop before

adjusting, or servicing, this equipment.

7. Keep off, keep others off, and insure everyone

is clear before starting, actuating hydraulics,

and during equipment operation.

4 Safety

8. Do not service, or otherwise handle, a

shredder in a raised position unless it is

securely blocked against unexpected falling.

9. Keepallfrontippershieldsinplaceandfree

swinging.

10. Never shred in areas littered with glass, rocks,

metal, etc. Use cab tractor if operating in

unfamiliar areas. Keep cab windows clean to

maintain good visibility.

11. Escapinghydraulic/dieseluidunderpressure

can penetrate the skin causing serious injury.

DO NOT use your hand to check for leaks. Use a

piece of cardboard.

Stoptractorandrelievepressurebeforeconnecting/

disconnecting lines.

Tighten all connections before pressurizing

hydraulic lines.

Ifuidisinjectedintotheskin,getmedicalattention

to prevent serious infection.

12. Discipline yourself to always visually inspect

this equipment for any excessively worn,

damaged, or cracked parts before starting

use. Replace these with genuine HINIKER

parts.

13. Stalk shredding often involves a combustible

environment. Carry a re extinguisher and

rstaidkitwithtractor.

14. OSHArequiresfarmemployerstomeetcertain

safety standards. Become familiar with, and

comply with them.

15. Do not alter this equipment to the extent of

compromising safety and performance.

16. Do not substantially operate tractor in a closed

building.

17. Agchemicalscanbedangerous.Alwaysfollow

the manufacturer’s label safety precautions

when using them.

18. Do not assume everyone is as safety

conscious as yourself.

BEFORE OPERATION

1. Insure unit’s PTO assembly is fully engaged

with gearbox and tractor shafts and SLIDING

COLLARS ARE RETURNED TO THEIR

LOCKED POSITIONS.

2. NEVER allow improperly supervised minors,

or anyone else, to operate this equipment. It is

your responsibility to insure that any operator

is mentally and physically capable of so doing.

3. Do not operate a 1000 RPM shredder with a

540 RPM tractor.

4. Do not “jump start” the tractor from along side

it. Start tractor only from seat.

5. Lock any swinging tractor drawbar before

hooking up. Use a cross retainer in end of the

hitch pin.

6. Disengage PTO, stop tractor engine, and

remove key before hooking up shredder PTO.

7. Clear area of people, and debris, before

engaging tractor PTO Be alert for blind areas

of operator. Slow down PTO and “feather” into

engagement to prevent unnecessary stress

on shredder’s driveline.

8. DO NOT OPEN MACHINE SHIELDS WITH

TRACTOR ENGINE RUNNING.

9. Do not stand close to, immediately behind or

in front of, a running shredder.

DURING OPERATION

1. Gradually bring unit up to operating speed

and check for any abnormal vibration, or

performance. IF ABNORMAL VIBRATION

IS PRESENT AT ANY TIME, IMMEDIATELY

DISENGAGE PTO, STOP TRACTOR

ENGINE, REMOVE KEY AND DETERMINE/

CORRECT CAUSE BEFORE PROCEEDING.

2. Disengage PTO, stop tractor engine, remove

key and allow EQUIPMENT TO COME TO A

COMPLETE STOP before:

- Cleaning, unclogging, lubricating, inspecting,

or otherwise servicing, any part of this

equipment.

Safety 5

- Connecting or disconnecting the shredder

from the tractor.

- Allowing anyone else near the equipment.

- Dismounting from the tractor seat and parking

the equipment.

- Placing any part of your body in dangerous

proximity to shredder.

3. When parking this equipment, lower it to full

“down” position. Set the tractor brakes and

block wheels if on an extreme slope.

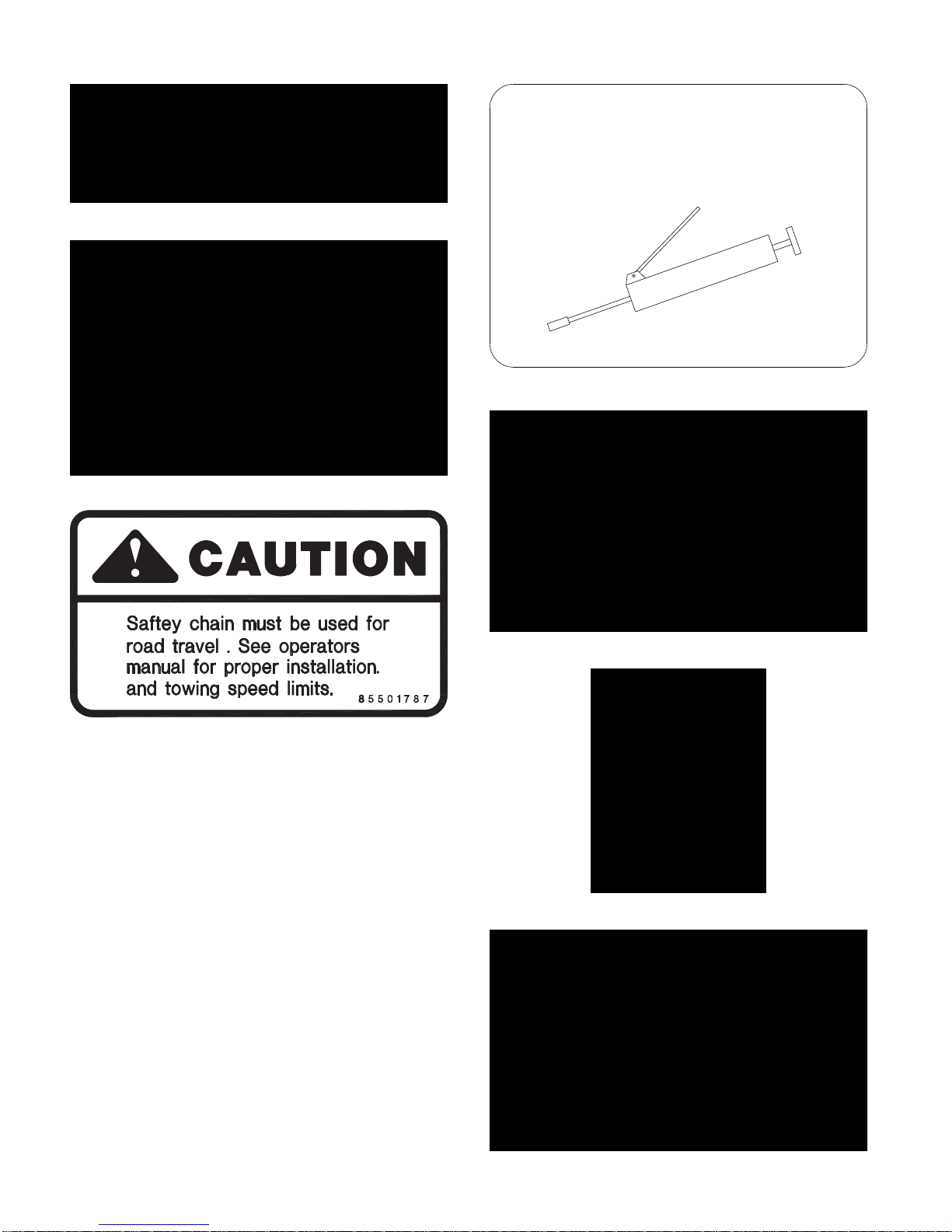

TOWING

1. When towing on public highways:

- Use a safety chain between the shredder hitch

and the towing vehicle (The 10,000# safety

chain is part number 85501539).

- Be sure end transport hydraulic cylinder locks

are in place.

- Use a tractor of sufcient size, and weight,

requiredforeldoperation.

- Do not tow faster than 25 MPH (40 kph).

- BEAWARE THETRAILHITCH WIDTH, WITH

END TRANSPORT KIT, IS 138” (11 1/2’)

WIDE. THESE WIDTHSARE WITH THE PTO

REMOVED. If these widths are not permitted,

or advisable, under your circumstances, the

hitch must be removed.

- Check local regulations on towing width and

warning lights.

2. Never tow trailing shredders in eld mode

with the PTO detached from the tractor and

hooked to the gearbox.

3. Ensure ASAE SMV (slow moving vehicle) is

visible when towing down public roadways.

4. At sundry locations, RED (rear facing) and

AMBER (forward facing) reectors are

provided.Insurethesedonotbecomedefaced

or covered with debris.

SERVICE

1. Service information herein is intended

for dealers and others correspondingly

competent. If you are not experienced and/

or capable of handling such service, do not

attempt it.

2. Disengage PTO, stop tractor engine, re-

move key and allow EQUIPMENTTO COME

TO A COMPLETE STOP before:

- Cleaning, unclogging, lubricating,

inspecting, or otherwise servicing, any part

of this equipment.

- Connecting or disconnecting the shredder

from the tractor.

- Allowing anyone else near the equipment.

- Placing any part of your body in dangerous

proximity to shredder.

3. Do not service, or otherwise handle, a

shredder in a raised position unless it is

securely blocked against unexpected falling.

4. Stalk shredders operate in a naturally

vibratory environment. Discipline yourself

to always visually inspect this equipment for

any excessively worn, damaged, or cracked

parts before starting use. Replace these

with genuine HINIKER parts.

5. DO NOT SERVICE END DRIVE BELTS

WHEN TRACTOR IS RUNNING!

6. Replace all shields removed for service, and

check PTO shield for free rotation, before

operating this equipment.

REMEMBER - ACCIDENT PREVENTION IS

PART OF YOUR JOB!

6 Section

TITLE

6 Decal Location

DECAL LOCATION

It is an owner’s and dealer’s responsibility to

ensure clear, complete decals are maintained

on equipment, whether operating or offered for

sale.

Information herein is provided for proper decal

ordering and placement.

Decal surfaces should be free of dirt, grease,

etc. Temperatures should be above 50° F. To ap-

ply, remove the smaller part of the decal backing

paper and apply this part of the exposed adhe-

sive to the desired location. Peel the other part

of the backing paper slowly off and smooth out

the entire decal.

15

7

3

2

81

14

PHOTO NO. ARS040A

11

PHOTO NO. DSCN4637B

14

3

2

2

20

PHOTO NO. ARS004A

17

6

10

12

5

19

21

PHOTO NO. 100-4282A

13

9

8

18

PHOTO NO. 100-4283A

Section 7

Decal Location 7

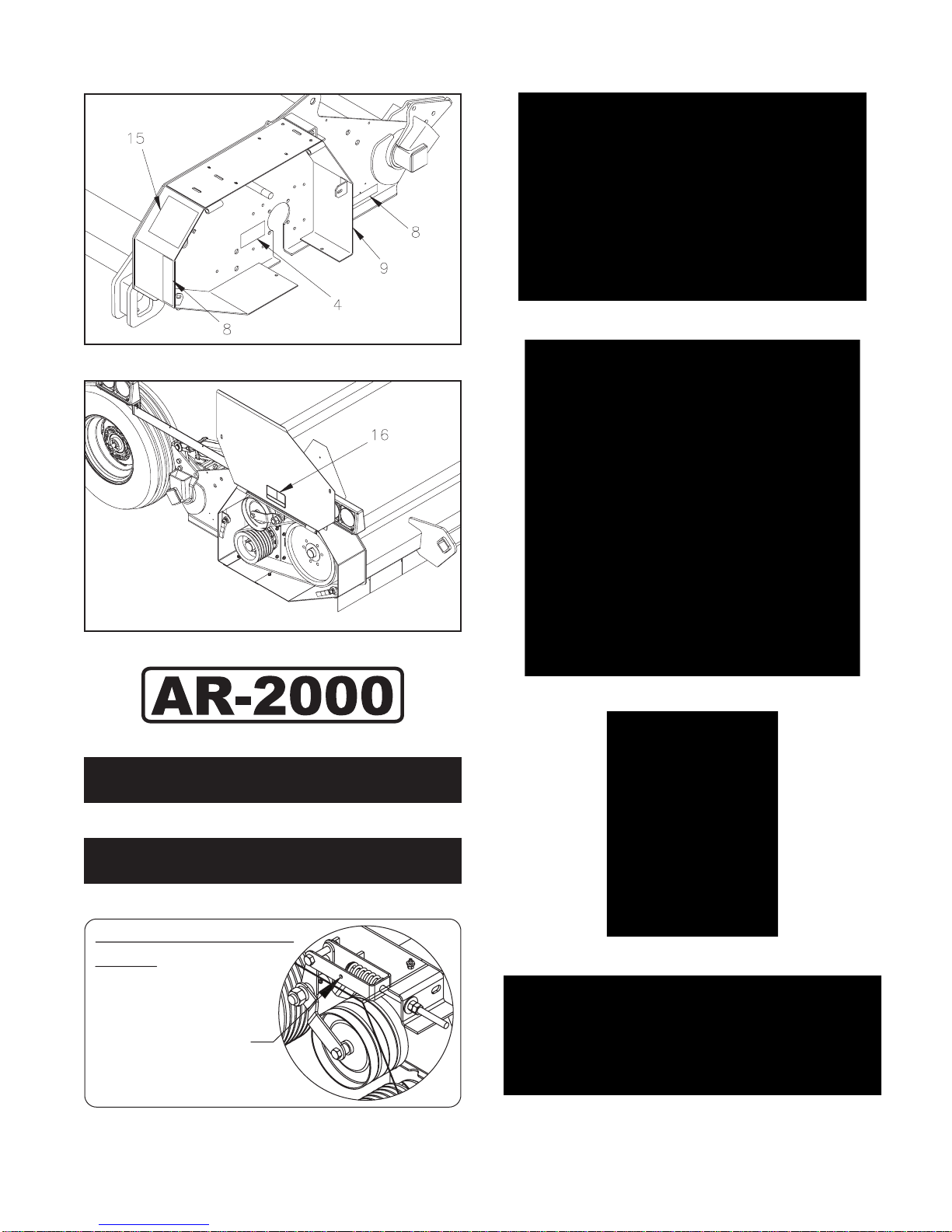

DWG NO. 6865

DWG NO. 6866

FIGURE 1 79202299 LOGO AR-2000

FIGURE 2 71505168 LOGO HINIKER

AR-2000

FIGURE 3 79202337 LOGO AR-2000

No Rotation. Read Operators Manual.

IMPORTANT: Maintain Belt Tension

Stop unit completely for maintenance.

Compress spring until

washer can be seen

through sight hole

PART NO. 79203548

FIGURE 4 79203548 IMPORTANT: MAINTAIN BELTS...

FIGURE 5 71504126 IMPORTANT: OPERATE MACHINE...

FIGURE 6 71504133 IMPORTANT: HITCH...

FIGURE 7 715-03174 IMPORTANT: LIFT...

FIGURE 8 850-001-285 TAPE YELLOW REFLECTOR

8 Decal Location

FIGURE 9 850-001-305 TAPE RED REFLECTOR

FIGURE 10 715-04132 CAUTION: READ MANUAL...

FIGURE 11 85501787 CAUTION: SAFETY CHAIN...

FIGURE 12 71504129 CAUTION: 1000 RPM

GREASE

FIGURE 13 79203259 GREASE:

FIGURE 14 71505169 WARNING: LOOK AND LISTEN...

FIGURE 15 71505171 WARNING: KEEP HANDS, ETC...

FIGURE 16 71505170 WARNING: DO NOT OPERATE...

Decal Location 9

FIGURE 17 520-03138 DANGER: ROTATING DRIVE...

FIGURE 18 520-03139 DANGER: SHIELD MISSING...

FIGURE 19 71504131 DANGER: KEEP FLIPPERS...

IMPORTANT

Maintain tires at 15-20 psi

on level land.

See operator's manual for

ridged operation.

71504136

FIGURE20 71504136 IMPORTANT: MAINTAINTIRES...

FIGURE 21 520-03138 WARNING: DO NOT EXCEED...

10 Section

TITLE

10 Field Preparation

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. BEFORE FIELD

PREPARATION, READ SAFETY-GEN-

ERAL, BEFORE OPERATION, DURING OP-

ERATION AND TOWING AT FRONT OF THIS

MANUAL.

TRACTOR-GENERAL

IMPORTANT: IT IS CRITICAL TO KNOW WHAT

SHREDDER CONFIGURATION IS INVOLVED

BEFORE TRACTOR HOOKUP. TRACTOR

MUST HAVE 1 3/4-20 SPLINE OUTPUT SHAFT.

Hiniker shredders are only available with a PTO

output option of: 1000 RPM 1 3/4”-20 spline

Part# 79202277

All units use ONLY CV (constant velocity) PTO’s.

These are identied by extended front yokes

separated by a large guide hub between them.

SHREDDER-TRAILING HITCH

Trailing shredders have an adjustable hitch

height adjustment (Item 1) to match various trac-

tor drawbar heights. Refer to Photo 100-4282B.

1

PHOTO NO. 100-4282B

IMPORTANT: CORRECT TRAILING HITCH

DRAFT LINK LENGTH ADJUSTMENT CAN-

NOT BE MADE UNTIL AFTER THE SHRED-

DER IS INITIALLY FIELDED.

FIELD PREPARATION

Raise the shredder with hitch jack until the hitch

yoke corresponds with the tractor’s drawbar and

insert hitch pin. Always store the hitch jack (ar-

row 1) as shown in Photo DCP0603.

1

PHOTO NO. DCP0603

IMPORTANT: ALWAYS USE A 1” DIAMETER

HITCH PIN.

CAUTION: DEATH OR SERIOUS IN-

JURY CAN RESULT. ALWAYS INSERT

THE HITCH PIN POINT DOWN WITH A

CROSS LOCKING PIN THROUGH ITS LOWER

END.

SHREDDER-PTO’s

IMPORTANT: IT IS CRITICAL TO KNOW WHAT

TRACTOR CONFIGURATION IS INVOLVED

BEFORE HOOKUP. THE PROPER SHREDDER

PTO MUST BE USED, OTHERWISE UNSAT-

ISFACTORY PERFORMANCE WILL RESULT.

TRACTOR MUST HAVE 1 3/4-20 SPLINE OUT-

PUT SHAFT.

All shredder PTO’s have similar sliding yoke

couplers at the tractor and gearbox ends. GEAR-

BOX ENDS ARE IDENTIFIED BY AN OVER-

RUNNING CLUTCH (Item 1).

Clean gearbox spline of any encrusted dirt or

grease and lightly oil it. Slide outer PTO collar

(Item 2) toward its adjacent yoke (Item 3) and

slide PTO over the gearbox spline. Reverse the

sliding collar to lock the assemblies together.

Field Preparation 11

PHOTO NO. 2969A

NOTICE: TO FACILITATE PTO HOOK UPS, CHECK

TRACTOR SPLINE FOR BURRS, OR OTHER DAM-

AGE. IF SHREDDER’S LOCKING COLLAR IS DIF-

FICULT TO PROPERLY ENGAGE, CLEAN AND

LIGHTLY OIL SPLINE.

The tractor PTO spline engages similar to above.

Slide outer collar (Item 1) toward its adjacent yoke

(Item 2) and slide PTO over the tractor spline. Re-

verse the sliding collar to lock the assemblies togeth-

er.

PHOTO NO. 2966A

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. NEVER OPERATE

A SHREDDER UNLESS BOTH ENDS

OF THE PTO ARE PROPERLY LOCKED TO

THEIR INTENDED SPLINES.

Check the decal on gearbox shield to insure

proper tractor/shredder RPM matching.

DWG. NO. 71504129

DANGER: DEATH OR SERIOUS IN-

JURY CAN RESULT. KEEP AWAY AND

KEEP OTHERS AWAY FROM AN OP-

ERATING PTO. DO NOT OPERATE WITH-

OUT ALL SHIELDS IN PLACE. INSURE PTO

SHIELDS FREE WHEEL AND BOTH PTO’S

ENDS ARE SECURELY ATTACHED.

IMPORTANT: NEVER TOW A TRAILING

SHREDDER UNLESS THE PTO IS PROPER-

LY HOOKED UP TO BOTH TRACTOR AND

SHREDDER. OTHERWISE, IT CAN BE DAM-

AGED. IF NECESSARY TO OTHERWISE TOW,

DETACH ENTIRE PTO ASSEMBLY (1) FROM

GEARBOX AND SECURE IT BEHIND A DRIVE

SHAFT SHIELD (2).

PHOTO NO. 3547

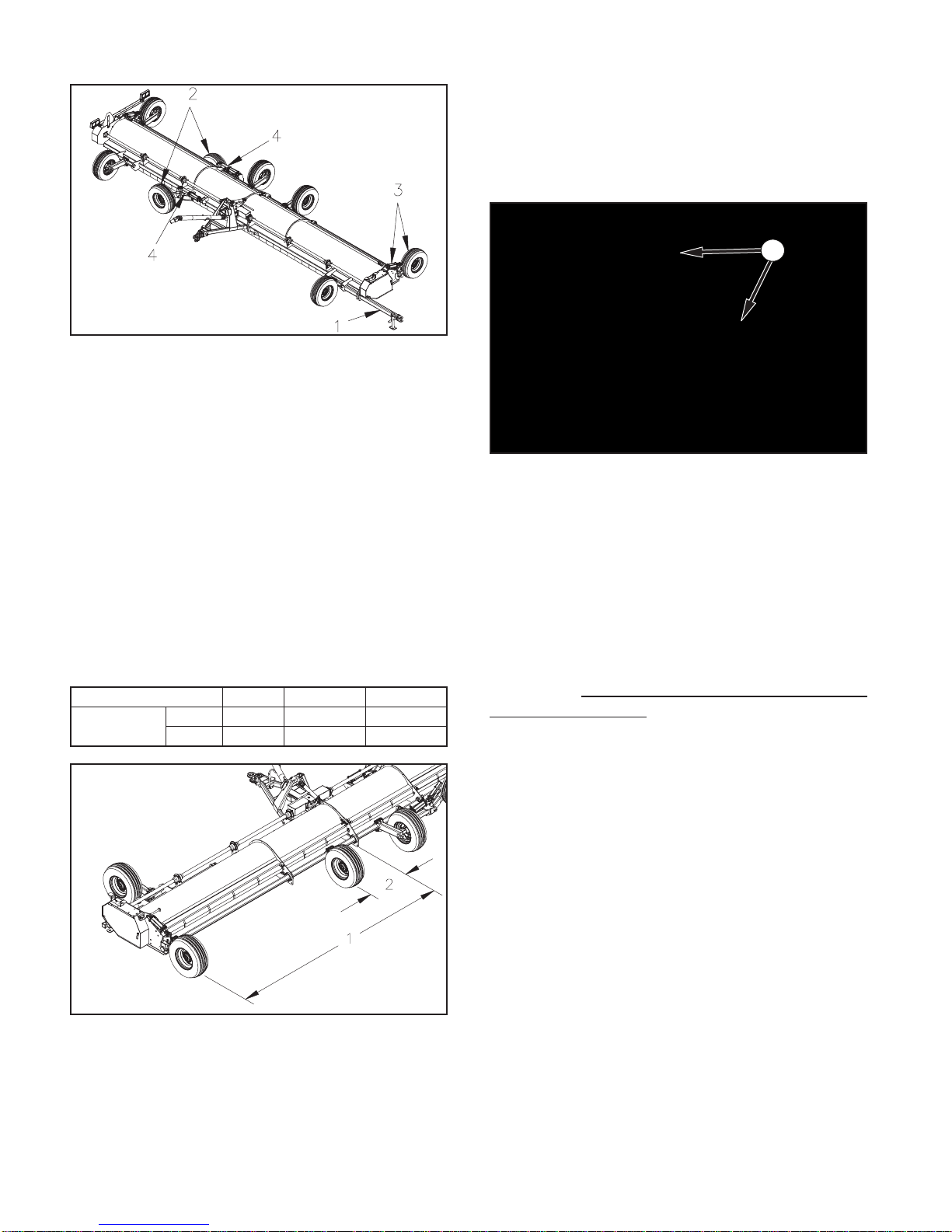

SHREDDER ROCKSHAFT & WHEELS

Toadjusttherockshafteldwheelspacingthe

end transport wheels can be used. Insert trac-

tor quick couplers to give machine a down-

ward movement when tractor hydraulic lever is

pushed forward.

12 Field Preparation

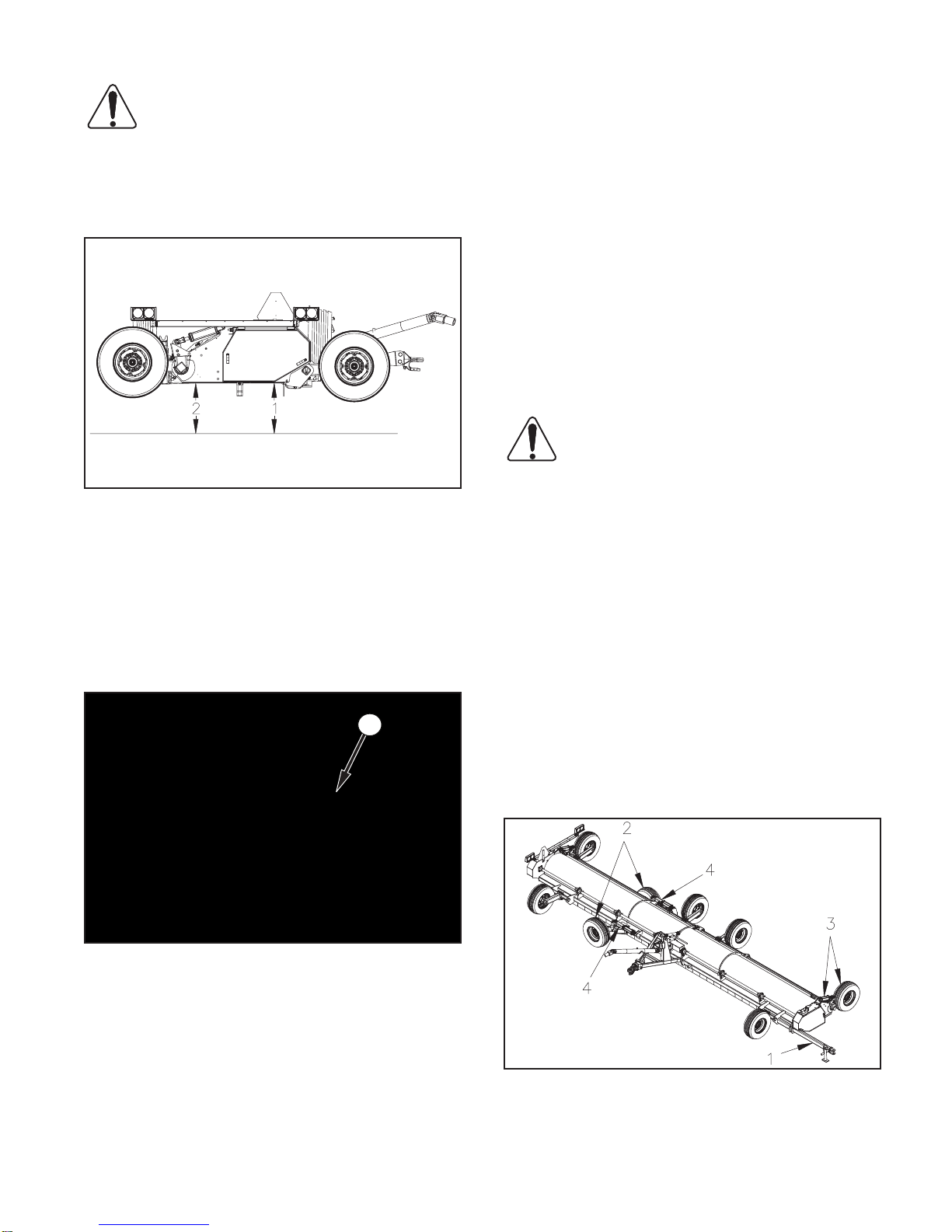

DWG NO. 6668

To adjust wheel spacing on rear rock shaft wheels,

attach a tractor of adequate size to operate unit

totheeldhitch.Slideendtransporthitchoutand

pin in position (arrow 1). Attach jack to spud on

hitch. Using tractor hydraulics lower end transport

wheels(arrow2)andraiseeldwheels(arrow3).

Rotate locking channels (arrow 4) over end trans-

port hydraulic cylinder shafts to prevent cylinder

contracting.

Loosen wheel bolt clamps and slide wheels into

correctdimensionsforeldoperation.Thecor-

rect spacing for 30” and 36” row and is provided

in the table below.

Dimns. 30” Rows 36” Rows

30 foot units (outer) (1) 180” 180”

(inner) (2) 30” 36”

DWG NO. 6667

For other row spacings, adjust the above set-

tings accordingly. Torque up each wheel leg

clamping bolts by uniformly tightening the lower

boltstoasnugt.Then,torque,andre-torque

top bolts to 146-206 Ft/lbs.

Once correct spacing is set up unlock end

transport cylinder locks. Lower eld wheels all

the way down. Raise end transport cylinders and

slide end transport hitch in and re-pin in position.

Store jack in its storage position.

1

PHOTO NO. 1000-4284A

Hydraulic cylinder control segments (arrow 1)

are provided to hold machine at desired cutting

height.

SHREDDER TIRES

Recommended tires are 9.5L x 15 8 ply

(implement) tires with 8” rims. The shredder

will perform better, especially under ridged

conditions, if tire pressures are kept no greater

than recommended. (If the shredder tends to

“yaw”, or climb ridged rows, decrease pressure

in the outside tires to the lower range cited and

recheck that tire centerlines are running in the

row middles.

SHREDDER-END TRANSPORT TOWING

Hiniker 30 Ft. shredders are designed for end

transport only down public roadways. Implement

lights (arrow 1) and SMV sign (arrow 2) are

standard equipment and mounted on rear of

machine.

Field Preparation 13

1

2

PHOTO NO. ARS048A

CAUTION: DEATH OR SERIOUS INJU-

RY CAN RESULT. WHEN TOWING ON

PUBLIC HIGHWAYS:

USE A TRACTOR OF SUFFICIENT SIZE, AND

WEIGHT, REQUIRED FOR FIELD OPERATION.

DO NOT TOW AT SPEEDS IN EXCESS OF 25

MPH (40 KMH).

USE A TOWING CHAIN BETWEEN TOWING

VEHICLE AND SHREDDER.

THE SMV’S REFLECTIVE SURFACE MUST

BE VISIBLE FROM THE REAR OF UNIT.

CHECK LOCAL REGULATIONS ON TOWING

WIDTH AND WARNING LIGHTS.

THE FRONT HITCH, PTO AND PTO HOLDER

MAY BE REMOVED TO REDUCE THE END

TRANSPORT WIDTH IF REQUIRED.

Use a safety towing chain (Item 1) between the

shredder and towing vehicle. Hook chain around

bracket (Item 2) and pass forward through after-

market clevis (Item 3). Fix chain’s forward end

(Item 4) to tractor.

PHOTO NO. 3550

Checkthelightstobesuretheyareconnectedprop-

erlysothatturnsignalashersoperatecorrectly.

14 Section

TITLE

OPERATION

WARNING: DEATH OR SERIOUS IN-

JURY CAN RESULT. BEFORE OPER-

ATING, READ SAFETY-GENERAL,

BEFORE OPERATION, DURING OPERATING

AND TOWING AT FRONT OF THIS MANUAL.

GENERAL

DWG. NO. 71504131

DWG. NO. 71504132

Always operate tractor at standard 1000 RPM

PTO. Use transmission up, or down, shift to

vary forward speed. CONSISTENTLY OVER-

SPEEDING THE PTO WASTES FUELAND AG-

GRAVATES KNIFE WEAR.

Avoid “jackrabbit” PTO engagement at full speed

because it overstresses the shredder’s driveline.

Engage PTO at slow speed and throttle up to

operating speed.

Insert quick couplers to give shredder a DOWN-

WARD movement when tractor hydraulic lever is

shoved FORWARD and vice versa.

IMPORTANT: FOR TRAILING HITCH END

TURNS ACROSS RIDGED ROWS, SLOW

FORWARD SPEED AND RAISE MACHINE

TO MINIMIZE EXCESSIVE BOUNCING AND

SCALPING.

CAUTION: DEATH OR SERIOUS INJURY CAN

RESULT. FOR TRAILING UNITS, SOME

TRACTOR MASTER PTO SHIELD’S

MAY CONTACT SHREDDER’S FRONT

PTO SHIELD ON TURNS. BE ALERT FOR

THIS AND MAXIMIZE TURNING RADII. RE-

PLACE SHREDDER FRONT PTO SHIELD IF IT

BECOMES DAMAGED.

IMPORTANT: INITIALLY START SHREDDING

WITH UNIT SET SUBSTANTIALLY HIGHER

THAN THE RECOMMENDED MINIMUM KNIFE/

ROW CLEARANCE OF 3”.

Shred a short distance and check performance.

The higher knife/row clearance may not give sat-

isfactory results; therefore, lower unit and check

again. Progressively lower unit until good results

are obtained. DO NOT OPERATE WITH LESS

THAN 3” KNIFE CLEARANCE TO HIGHEST

GROUND POINT WITHIN SHREDDED WIDTH.

Once optimum height is set, insert equal amount

of hydraulic cylinder stop segments over the

rods of the lift cylinders to hold machine at de-

sired height.

IMPORTANT: “SCALPING” ROWS WASTES

FUEL AND RAPIDLY AGGRAVATES KNIFE

WEAR. THIS IS PARTICULARLY TRUE IN

ROCKY FIELDS. IF YOUR FIELD HAS PRO-

TRUDING ROCKS, KEEP UNIT’S HEIGHT

SUFFICIENT FOR KNIVES TO CLEAR THEM.

STALK SHREDDERS ARE NOT INTENDED TO

BE USED AS A “ROCK PICKER”, OR A “RO-

TOTILLER”.

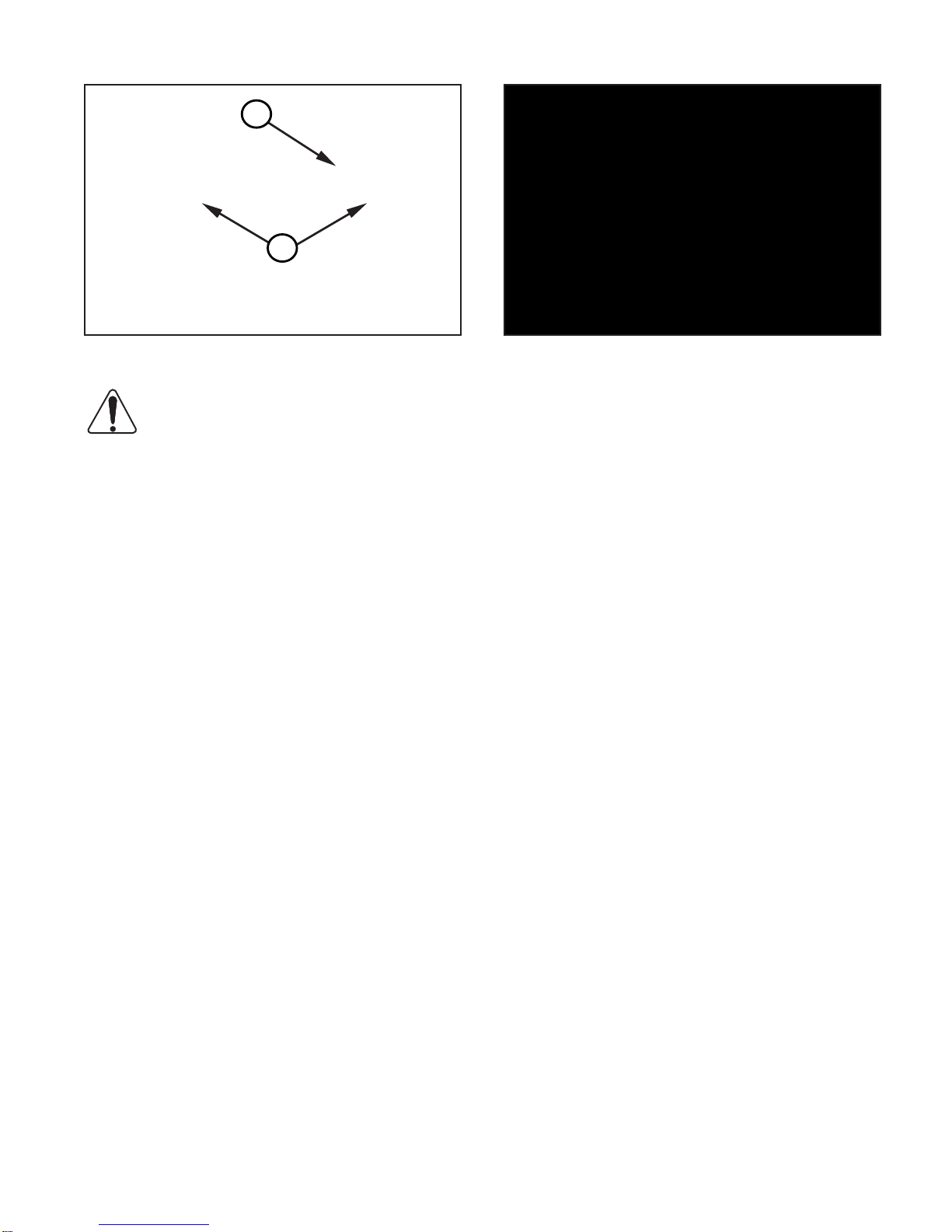

Operate the shredder approximately LEVEL.

That is, front (Item 1) of main frame should clear

ground about the same as the rear (Item 2).

14 Operation

Operation 15

CAUTION: DEATH OR SERIOUS

INJURY CAN RESULT. EXCESSIVE

FRONTFRAME/GROUNDCLEARANCE

CAUSES MORE DEBRIS TO THROW

FORWARD UNDER THE TRASH SHIELDS.

NEVER STAND NEAR, AND AHEAD OF, A

RUNNING MACHINE.

DWG NO. 6869

TRAILING HITCH HEIGHT ADJUSTMENT

1. Position unit astraddle rows and insure

wheels are centered in row middles before

making any adjustments. Rotate

rockshaft/wheels until knives clear rows by

GREATER than 3”.

1

PHOTO NO. 100-4277A

With unit attached to tractor, adjust turn-

buckle (arrow 1) to raise machine front up

or down to desired height.

2. Recheck knives/row clearance and read-

just rockshaft/wheels, as well as draft link

length, if necessary.

3. Shred a short distance, stop and check

stubble to insure knives are properly clear-

ing rows and satisfactory performance is ob-

tained. If necessary, reset rockshaft/wheels

and drawbar’s underneath draft link.

4. Ensure cylinder stop collars, are of equal

height on lift cylinders.

END TRANSPORT TOWING

The 30 Ft. AR shredder can only be towed down

public highways in end transport mode. Towing

theshredderineldmodedownpublichighways

will violate local regulations and is prohibited.

CAUTION: DEATH OR SERIOUS INJU-

RY CAN RESULT. WHEN TOWING ON

PUBLIC HIGHWAYS:

USE A TRACTOR OF SUFFICIENT SIZE, AND

WEIGHT, REQUIRED FOR FIELD OPERATION.

DO NOT TOW AT SPEEDS IN EXCESS OF 25

MPH (40 KMH).

USE THE PROVIDED SAFETY TOWING

CHAIN BETWEEN TOWING VEHICLE AND

SHREDDER/WINDROWER.

USE THE SMV EMBLEM AS SPECIFIED AND

STORE PTO SHAFT IN PTO HOLDER.

CHECK LOCAL REGULATIONS ON TOWING

WIDTH AND WARNING LIGHTS.

DWG NO. 6868

To put the machine in end transport. With tractor

attachedtotheeldhitchSlideoutendtransport

tongue (arrow 1) and pin in position.

Rotate jack into position. Lower end transport

wheelsall the way down (arrow2). Raise eld

wheels all the way up (arrow 3). Rotate hydraulic

cylinder channel locks (arrow 4) into position to

hold cylinders in the fully extended position. Us-

ing jack raise front end of tractor until the cast

hitch on shredder comes off the draw bar of the

tractor.

DWG NO. 6870

Disconnect hydraulic lines and store in hydrau-

lic tip holder (arrow 5). Flip up PTO holder (ar-

row 6). Disconnect PTO and lay in PTO holder.

Raise or lower end transport hitch so it can be

attached to tractor drawbar.Attach tractor of suf-

cientsizeforoperationtoendtransporttongue.

Storejackoneldhitchstoragelocation.

DWG NO. 6871

Wrap safety Chain around hitch tube and pass

through the large chain end loop and welded on

c-channel.

2

1

PHOTO NO. 3550B

Attach safety chain on end transport hitch to

tractor.

Insert electrical connector into tractor. Verify

warning lights and turn indicators all work cor-

rectly. Verify SMV sign is visible from rear of ma-

chine.

STORAGE

CAUTION: DEATH OR SERIOUS

INJURY CAN RESULT. DISENGAGE

PTO, STOP TRACTOR ENGINE,

SET BRAKES, REMOVE KEY AND ALLOW

EQUIPMENT TO COME TO A COMPLETE

STOP BEFORE:

CLEANING, UNCLOGGING, LUBRICATING,

INSPECTING, OR OTHERWISE SERVICING,

ANY PART OF THIS EQUIPMENT.

The following will insure equipment is in top

operating condition at start of next season.

1. Open end shields and thoroughly clean

out dirt and trash. Clean out any other

trash hanging on unit. Check drive shaft

and gearbox bearing seals for trash

entanglement.

2. Back off backwrap belt idlers to relax tension

on “V” belts. Inspect belts for wear.

3. Clean debris from PTO ends and insure

safety shield freely rotates.

16 Operation

Operation 17

4. Relube machine and check gearbox lube

level.

5. Clean rust off exposed surfaces and repaint

any surface requiring it. Also check for any

loose hardware.

6. Inspect both rotor assemblies for lost,

broken, or worn out knives. Replace

these as required. Also, replace any other

deteriorated parts, especially decals and

reectors.

18 Section

TITLE

LUBRICATION

WARNING: DEATH OR SERIOUS INJU-

RY CAN RESULT. BEFORE LUBRICAT-

ING, READ SAFETY-GENERAL AND

SERVICE AT FRONT OF THIS MANUAL.

CAUTION: DEATH OR SERIOUS IN-

JURY CAN RESULT. DISENGAGE PTO,

STOP TRACTOR ENGINE, REMOVE

KEY AND ALLOW EQUIPMENT TO COME TO

A COMPLETE STOP BEFORE: CLEANING,

UNCLOGGING, LUBRICATING, INSPECTING,

OR OTHERWISE SERVICING, ANY PART OF

THIS EQUIPMENT. SECURELY BLOCK UNIT

BEFORE SERVICING TO PREVENT UNEX-

PECTED FALLING.

HINIKER shredders have been factory checked

and lubricated. However, re-check and relubri-

cateaunitpriortorsteldoperation.

Shredders operate in an extremely dirty (ne

dust) environment. Proper maintenance atten-

tion to the anti-friction bearings will save money!

IMPORTANT: WIPE ALL ZERKS AND GUN

TIPS BEFORE LUBRICATING.

IMPORTANT: WHEN LUBRICATING BEAR-

INGS ADHERE TO 1 PUMP PER FITTING ON

A DAILY INTERVAL.

When lubricating, couplers, pivots, and PTO lu-

bricate until you see grease. Items (8 & 15) CV

double yoke needs 15 to 20 pumps.

IMPORTANT: INNER ROTOR COUPLER (ITEM

29) NEEDS 20-25 PUMPS DAILY FOR PROP-

ER OPERATION.

Replace any damaged ttings and use a good

grade of lithium base grease.

Gearbox should be checked at least seasonally.

After300hoursoperation,drainandrell.

A 1000 rpm gearbox is checked by measuring

3 7/8” to 4” depth to lube level below ll hole

thread top or use check plug at rear. Clean plug

before removing. Use a.P.I. 80W90 synthetic ex-

treme pressure lubricant.

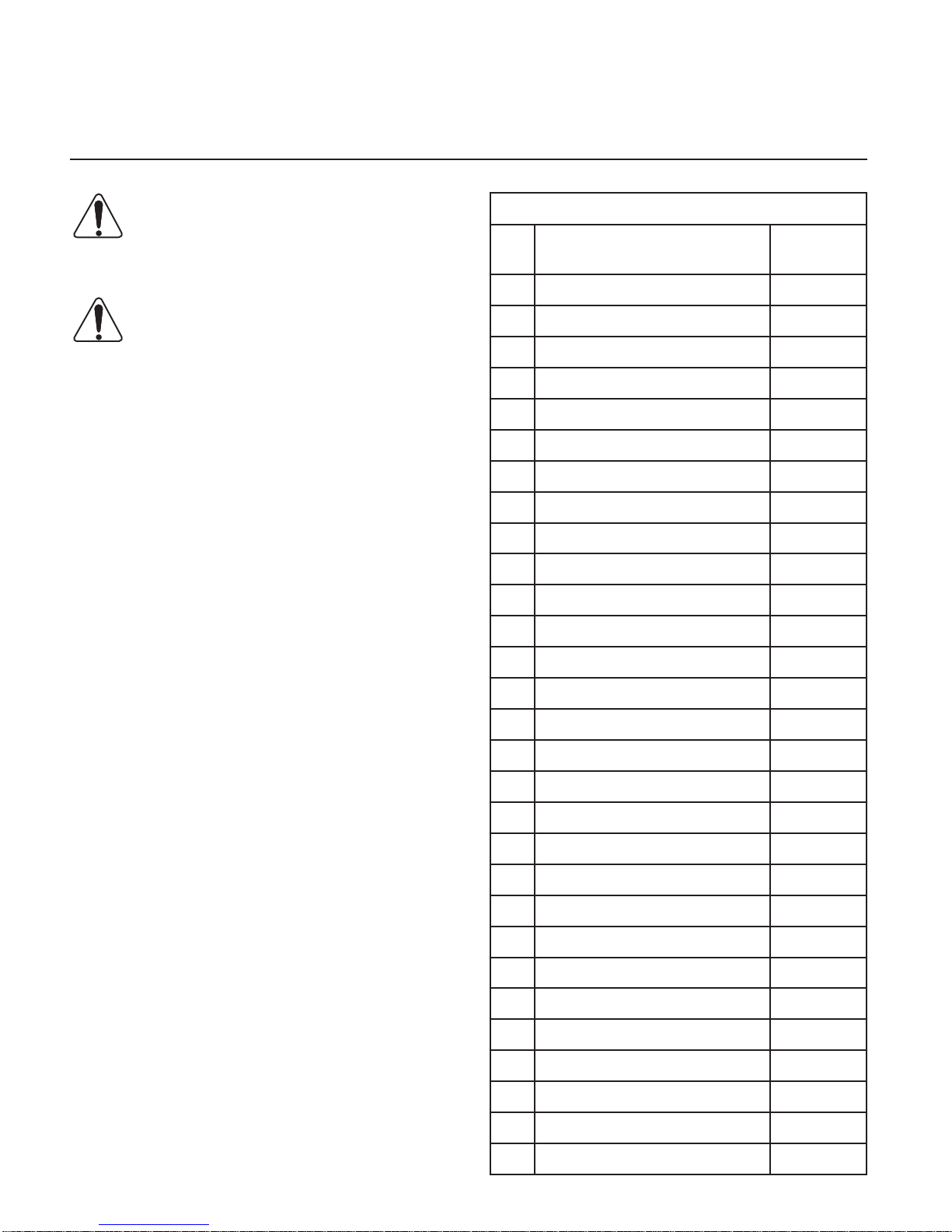

Lubrication Chart

Ref.

No. Description Interval

1. Front Cross & Bearing Daily

2. Front Shield Bearing Daily

3. Sliding Tube Daily

4. Rear Shield Bearing Daily

5. Rear Cross & Bearing Daily

6. Overrunning Clutch Daily

7. Front Shield Bearing Daily

8. CV Cross Daily

9. CV Cone Shield & Bearing Daily

10. Front Cross & Bearing Daily

11. End Transport Pivot Daily

12. Overrunning Clutch Daily

13. Rear Cross & Bearing Daily

14. Rear Shield Bearing Daily

15. CV Flange (15-20 Pumps) Daily

16. Line Shaft Coupler (15-20 Pumps) Daily

17. Outer Rotor Bearing Daily

18. Rockshaft Bearing Weekly

19. Center Bearings Daily

20. Wheel Hub Weekly

21. Ratchet Jack Seasonal

22. Gearbox Drain 300 Hours

23. Center Rotor Bearings Daily

24. Outer Lineshaft Bearing Daily

25. Mid Lineshaft Bearing Daily

26. Idler Pivot Weekly

27. Gearbox Breather -----------

28. Gearbox Oil Level Check Plug -----------

29. Rotor Coupler (20-25 Pumps) Daily

18 Lubrication

Other manuals for AR-2000

1

Table of contents

Other Hiniker Paper Shredder manuals