Hiniker 2754 User manual

PICKUP TRUCK SNOWPLOW

STEEL STRAIGHT PLOW

Models 2754, 2804, 2854

ASSEMBLY INSTRUCTIONS

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 25014882

Please visit www.snowplows.hiniker.com to access the most recent version

TABLE OF CONTENTS

GENERAL PLOW ASSEMBLY...................................................................................................... 2

FRAME TO MOLDBOARD ASSEMBLY........................................................................................ 3

HYDRAULICS ASSEMBLY ........................................................................................................... 4

PLOW ELECTRONICS ASSEMBLY ............................................................................................. 5

TRUCK ELECTRONICS & MOUNT KIT ASSEMBLY.................................................................... 7

SYSTEM CHECKOUT................................................................................................................. 10

CONTROLLER CONFIGURATION ............................................................................................. 12

HEADLAMP AIMING PROCEDURE ........................................................................................... 13

WARRANTY ................................................................................................................................ 14

Table of Contents 1

25014882 8/2023 Hiniker/25014882

GENERAL PLOW ASSEMBLY

WARNING: To prevent personal injury or

death, be certain to keep clear of any parts

that may drop when removing bun-

dling straps, wires or brackets. Sup-

port heavy sections with hoist or

blocks before removing wires or straps.

In the following instructions, left and right ma-

chine references are defined as being viewed

from the cab of the truck.

Be certain that hydraulic hoses and electrical

wires are safely routed and allow full motion of

moving parts. Secure loose wires with plastic tie

straps.

Some components are fastened at incorrect lo-

cations for shipping purposes.

All hardware should be tightened only enough

to ensure safety during assembly. Torque hard-

ware to specied values, as shown in the fol-

lowing chart, only after assembly has been com-

pleted.

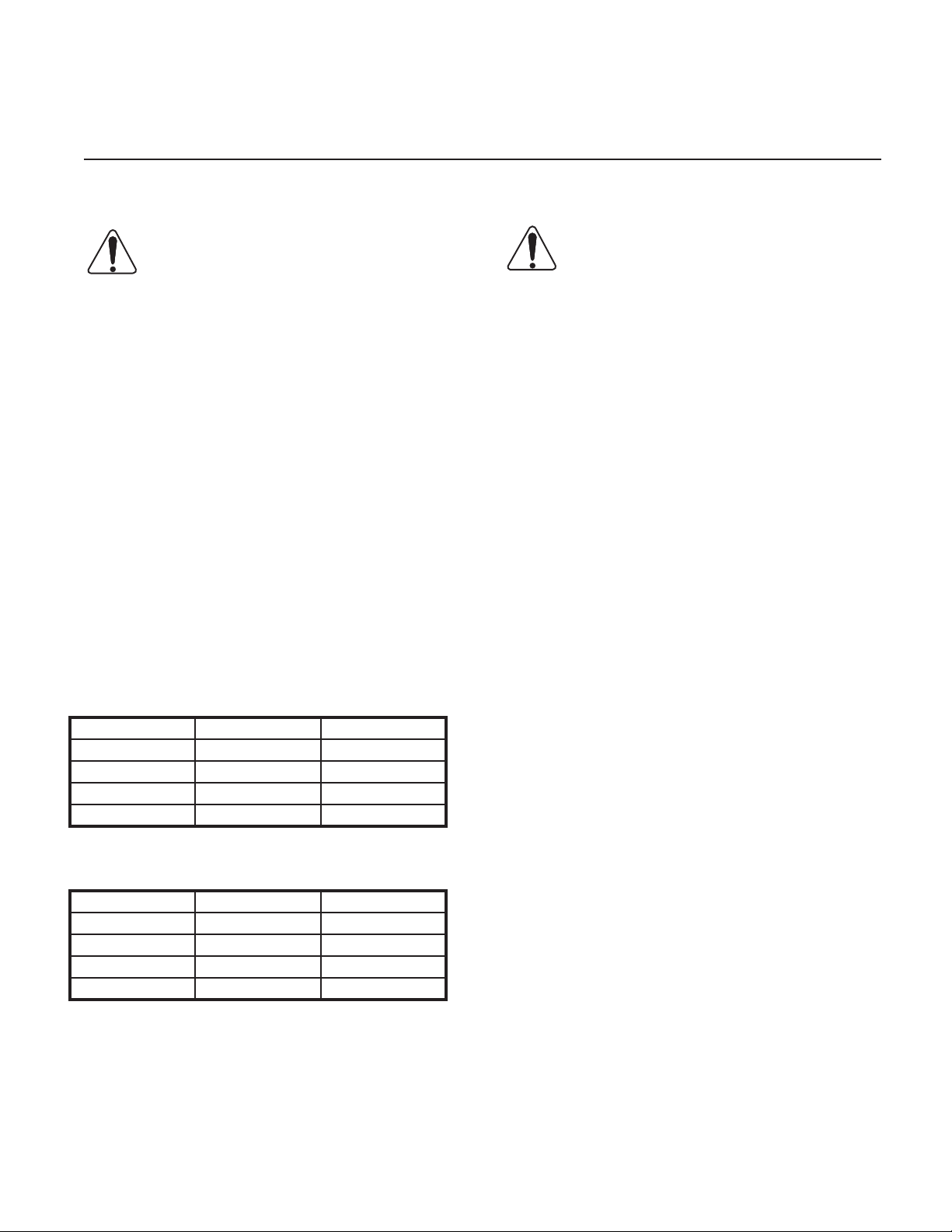

GRADE 5 TYPE B & F LOCK NUT

TORQUE VALUES

Size Ft-lbs. N-m

5/16” 13-18 17-25

3/8” 23-33 31-44

1/2” 58-82 79-112

5/8” 117-165 158-223

GRADE 5 BOLT TORQUE VALUES*

Size Ft-lbs. N-m

1/4” 8-12 11-16

3/8” 29-41 39-56

1/2” 73-103 99-140

5/8” 146-206 198-279

* applications without lock nuts

Replace worn bolts and lock nuts with

grade 5 bolts and equivalent type B and type F

lock nuts. Type B lock nuts are plain hex; type F

lock nuts are flanged hex.

WARNING: Snow plow has O-ring hydraulic

fittings on the pump, hoses and hydraulic

cylinders. DO NOT use pipe sealant or

over tighten during assembly.

After assembly validate all hydraulic connec-

tions are tight. Factory installed connections

may loosen during shipping.

NOTE: New hydraulic cylinders will leak a small

amount of oil until packings become saturated

and produce a good seal. If leakage is exessive,

or if leaking continues after initial cycling, tighten

the packing nut in 1/8 turn increments until leak-

ing stops.

NOTE: Discard any lock nuts removed while

transitioning the plow from shipping congura-

tion to nal conguration. Utilize new lock nuts

provided in Op manual bag.

2 General Plow Assembly

Frame to Moldboard Assembly 3

FRAME TO MOLDBOARD ASSEMBLY

1. Place moldboard face down on cardboard

or other padding that will prevent scratches

in the paint.

Remove two side markers and four ship-

ping straps from the ends of the moldboard.

NOTE: Additional compression springs are in-

cluded with 8 1/2’ moldboards. Remove springs

and set aside for reassembly.

2. Open the frame box and set aside the hard-

ware bag, power unit box and electronics box

for later assembly. Remove the frame as-

sembly from the shipping box to a piece of

cardboard or other padding that will prevent

scratches in the paint.

NOTE: If assembling an 8 1/2’ plow, remove

endcaps from compression springs and install

an extra spring inside each existing spring.

Place endcaps on springs and tighten 3/4” lock

nuts on pullrods until the outer springs measure

13” long. Do not overtighten springs.

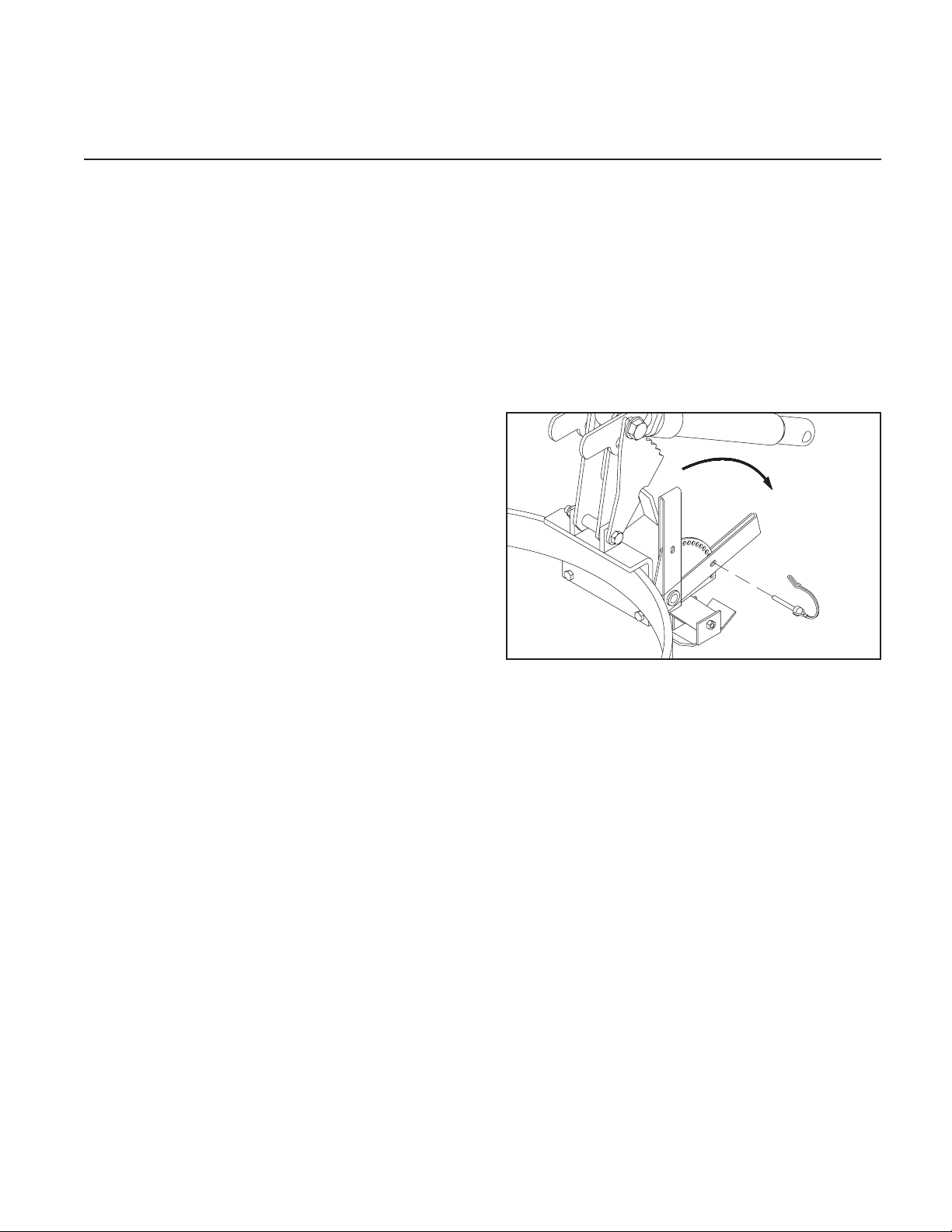

3. Gently tip the plow assembly to its working

position with a hoist or forklift. Pin the

parking stand to hold the square tubes of

the push frame parallel to the ground.

DWG NO. 4201A

NOTE: The bottom surface inside the two prong

receiver channels should measure about 10”

above the ground in the working position.

Carefully lift the frame assembly by wrap-

ping straps or padded chains around both

ends of the 2 1/2” square tube at the rear of

the frame. Attach the frame assembly to the

moldboard by lining up the three bushings

on the frame with the three sets of bushings

on the moldboard.

Apply commercially available anti-seize lu-

bricant (not supplied) to the hinge pins to

prevent future corrosion, and reinstall the

hinge pins through the bushings. Secure

the hinge pins with spring pins.

Remove 3/4” lock nuts from the back of

each compression spring and discard. Align

each pullrod bushing with the upper set of

holes in the moldboard ribs and reinstall

5/8” bolts and lock nuts. Tighten lock nuts

only until snug against ribs.

Assemble new 3/4” lock nuts back onto

pullrods and tighten until compression

springs measure 13” long. Do not overtight-

en springs.

HYDRAULIC ASSEMBLY

1. For Halogen lights Only: Before assembling

the power unit on the lift frame, scrape a

small amount of paint from the two mount

holes in the lift frame to provide a good

electrical ground for the turn signals and

parking lights.

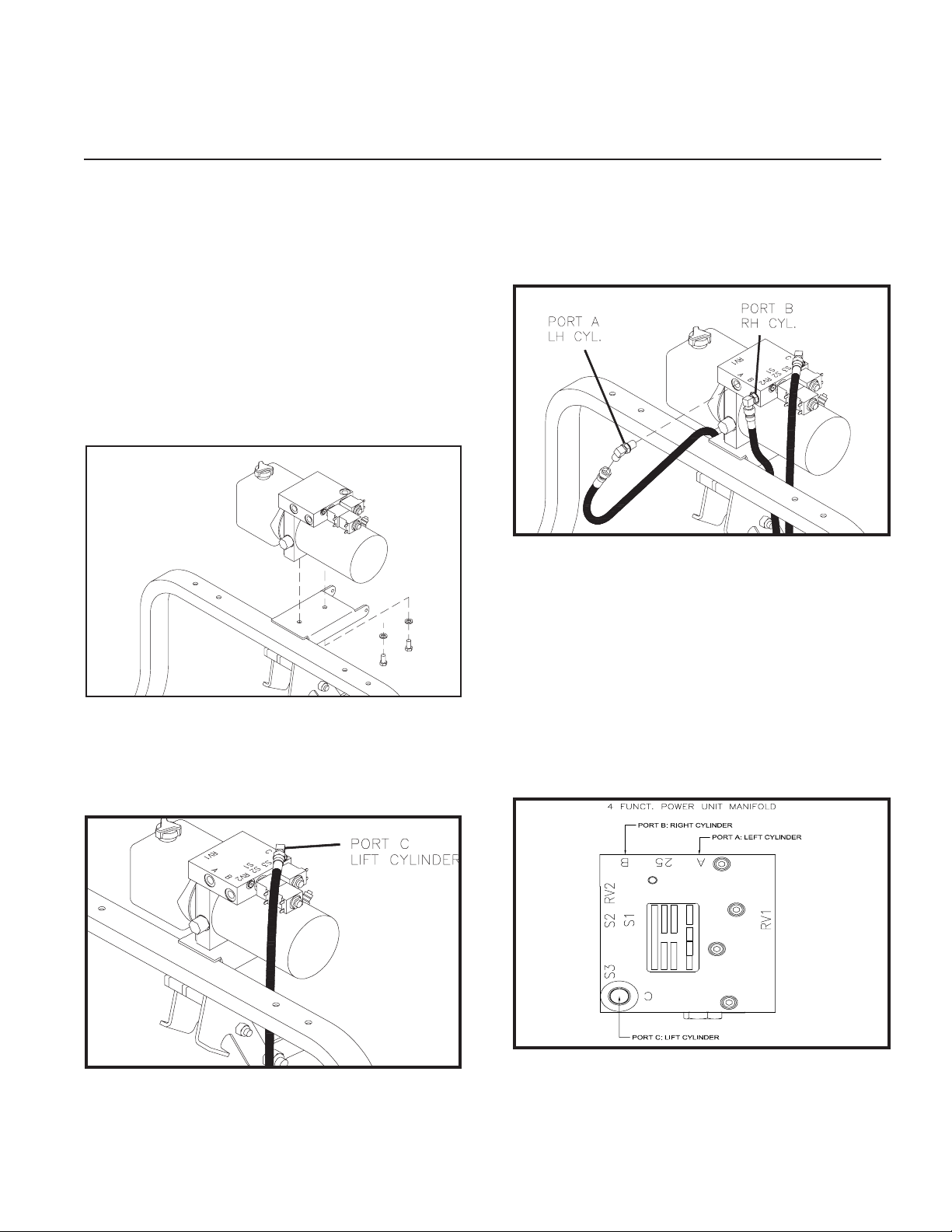

2. Mount the power unit on the lift frame with

two 3/8” x 3/4” hex bolts and two 3/8” lock

washers. The plastic reservoir of the power

unit should be to the left side of the plow,

see following illustration.

DWG NO. 6595A

DWG. NO. 6484A

3. Install the adapters into power unit, then

fasten the hoses to the adapters matching

the letter ends to the letters on the mani-

fold.

DWG NO. 6485A

4. Ensure factory installed ttings are tight.

Then secure hoses ensuring they clear the

lift links and latch handle.

NOTE: The tting in the LH side angling cylin-

der may have to be adjusted slightly to route the

hydraulic hose to best avoid interference with

the latch handle and the lift links. Use plastic tie

straps to secure all hydraulic hoses away from lift

link stops.

DWG NO. 4fct Manifold

4 Hydraulic Assembly

Plow Electronics Assembly 5

PLOW ELECTRONICS ASSEMBLY

NOTE: Check 1/4” bolts provided in LED head-

light box. If they do not have a pre applied Loc-

tite patch, apply anti-sieze to the bolts to pre-

vent galling.

NOTE: Do not use an impact driver, tighten

bolts by hand to prevent galling and damage to

headlight housing.

1. Mount the headlamp brackets to the lift

frame tube with hardware provided in light

parts box.

Remove the LH and RH headlamps from their

box and mount on the brackets with the pro-

vided hardware.

Refer to section titled “Headlamp Aiming

Procedure” for aiming instructions.

DWG. NO. 6012F

2. Take the 38” power cable (38812008) from

the electronics parts box and the plow side

harness (38813155 for LED) or (38813098

for Halogen) from the headlight parts box.

NOTE: To prevent corrosion lightly coat all elec-

trical connections, ring and spade terminals with

dielectric grease prior to assembly.

3. Fasten the ring terminal of the solid black wire

of the power cable assembly to the stud that

the solenoid ground cables are running to on

the motor.

4. Attach the ring terminal of the red striped wire

of the power cable assembly to the unoccu-

pied terminal on the motor.

5. Connect the RH headlamp to the har-

ness end labeled “PSNGR SIDE” and the

LH headlamp to the end labeled “DRIVER

SIDE”.

6 Plow Electronics Assembly

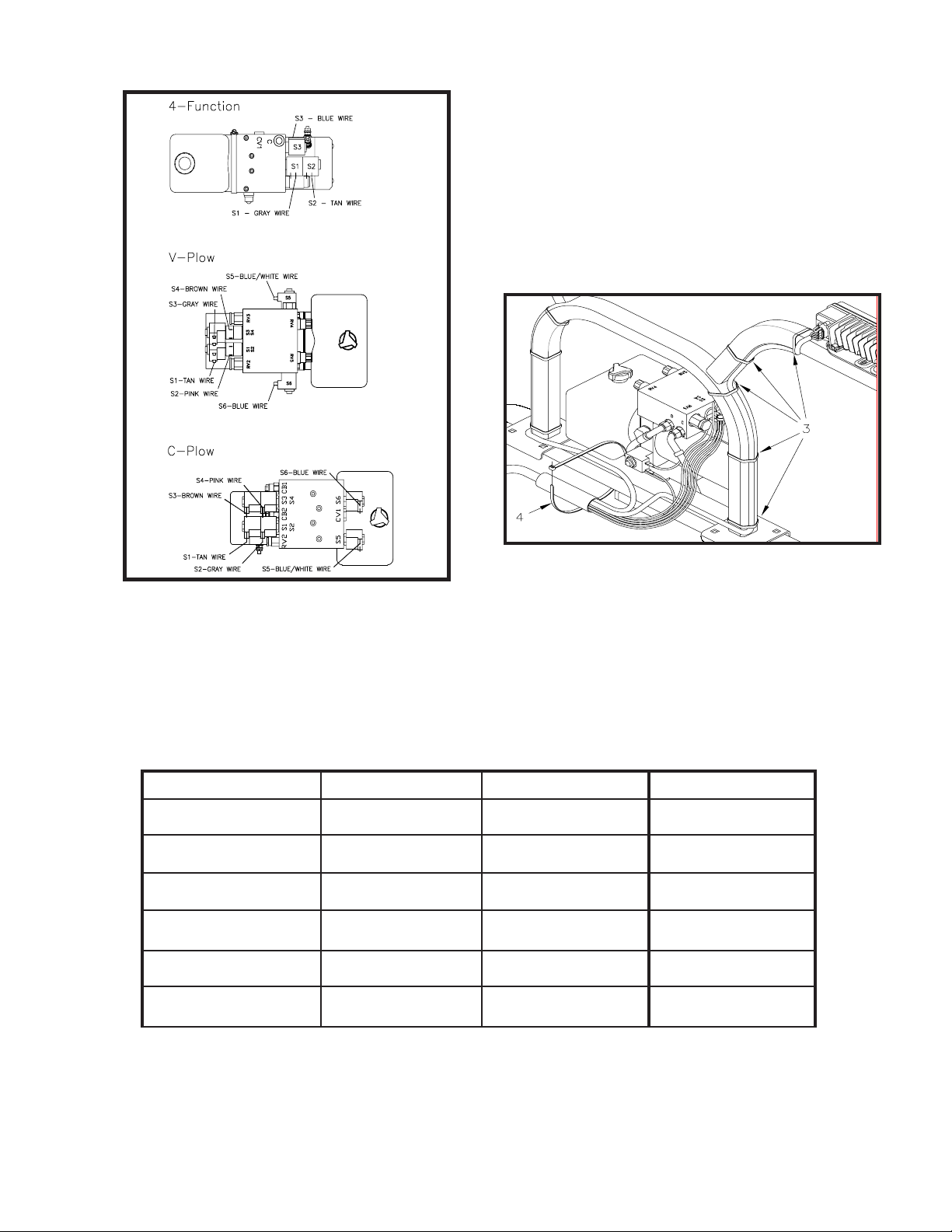

Wire to Solenoid Chart

4 Function V-Plow C-Plow

Tan S2 S1 S1

Pink not used S2 S4

Gray S1 S3 S2

Blue w/ White not used S5 S5

Blue S3 S6 S6

Brown not used S4 S3

NOTE: Install the plow harness so that water

does not run down the wires and pool inside the

“Y” connection. Position the harness so that any

trapped water can easily drain away.

7. Refer to drawing 6013F. Use plastic tie

straps to secure plow wiring harness to lift

frame tube and headlamp bracket at the lo-

cations shown by arrows 3 and 4.

DWG. NO. 6013F

DWG. NO. 8007

6. Refer to drawing 8007 and the chart below

to connect the plow wiring harness to the

power unit solenoids.

TRUCK ELECTRONICS & MOUNT KIT ASSEMBLY

Truck Battery On Passenger Side

WARNING: Disconnect truck battery before

beginning electrical installation to avoid

shock hazard.

Open the electronics parts box and validate you

have all components, harnesses, and hardware

per the checklist inside the box.

NOTE: To prevent corrosion, apply a light coat

of dielectric grease on all connectors and termi-

nals before installation.

1. Refer to drawing 8000 & 8001 for a general

guide on routing the HTBX electrical system

harnesses. Not all engine compartments

are compatible with the routing shown in

the drawings 8000 & 8001. Installers must

use their best judgement to route the har-

nesses ensuring everything is secured from

hot or moving components.

2. If there is no access hole in the driver’s

side rewall then drill a 1” diameter hole.

Route the 12 pin rectangular connector of

the controller harness (38828011) from the

HTBX controller through the rewall into the

cab compartment. If required, install the 4”

grommet in the hole.

CAUTION: Ensure that the electrical system

will clear any hood lift/spring mecha-

nisms before installation.

Truck Electronics & Mount Kit Assembly 7

Wire to Solenoid Chart

4 Function V-Plow C-Plow

Tan S2 S1 S1

Pink not used S2 S4

Gray S1 S3 S2

Blue w/ White not used S5 S5

Blue S3 S6 S6

Brown not used S4 S3

NOTE: Install the plow harness so that water

does not run down the wires and pool inside the

“Y” connection. Position the harness so that any

trapped water can easily drain away.

7. Refer to drawing 6013F. Use plastic tie

straps to secure plow wiring harness to lift

frame tube and headlamp bracket at the lo-

cations shown by arrows 3 and 4.

DWG. NO. 6013F

DWG. NO. 8007

6. Refer to drawing 8007 and the chart below

to connect the plow wiring harness to the

power unit solenoids.

8 Truck Electronics & Mount Kit Assembly

Truck Battery On Driver Side

3. Splice the yellow wire to the vehicle’s 12

volt auxiliary electrical circuit. This will pre-

vent operation of the plow without the ve-

hicle’s key being on.

4. Connect the dark blue end of the cab har-

ness (38828030) to the controller harness

(38828012) inside the truck cab. Then con-

nect the black & white end of the cab har-

ness to the universal controller (38828019),

Refer to the controller conguration section

for instruction on how to congure the con-

troller with the correct plow setting, and the

operators preferred joystick conguration.

Once congured, secure the case together

with the provided hardware.

CAUTION: To prevent injury or property dam-

age caused by unintentional plow

movement when the key is removed

from the vehicle, the yellow wire must

be connected to a switched power source on

the vehicle. Connecting to a power source

not controlled by the ignition switch will allow

movement of the plow with the vehicle key re-

moved.

DWG. NO. 8006

CAUTION: Ensure that the electrical system

will clear any hood lift/spring mecha-

nisms before installation.

NOTE: Do not over tighten nuts on the motor

solenoid terminals. Over-tightening causes pre-

mature solenoid failure. Refer to torque specica-

tions on the solenoid.

5. Select an area within 16” of the vehicle

battery for the motor solenoid placement.

Using the solenoid bracket as a template,

mark and drill two 3/16” diameter holes then

fasten the solenoid with two 1/4” x 1/2” long

self tapping screws provided in the electri-

cal parts box.

6. Safely route the 16 pin plow harness

(38828012) from the HTBX controller

through the grill of the vehicle to a location

that will be easily accessible with the plow

attached.

7. Refer to drawings 8000 or 8001 for con-

necting the power cable and harness:

a. Connect the black terminal from the 9’

battery cable (38813066) and the black

wire from the power harness (38828016) to

the minus(-) post of the vehicle’s battery or

the vehicle’s designated ground stud.

b. Connect the red striped terminal from the

9’ battery cable (38813066) to the motor so-

lenoid then route the battery cable through

the grill near the 16 pin plow connector.

c. Connect the 24” red cable to the motor

solenoid.

d. Connect the red fused wire from the pow-

er harness (3882016) and the free end of

the 24” red cable to the plus(+) terminal of

the battery or battery access post.

e. Connect the black wire & the blue wire

from the power harness (38828016) to the

small posts of the motor solenoid, polarity is

not important.

8. See instruction sheet provided with vehicle

specific harness for hooking up the HTBX

system to the vehicle’s headlights.

9. To complete the electrical installtion: con-

nect all harnesses to the HTBX controller

and secure all harnesses & cables away

from hot or moving components with the

provided cable ties.

10. See instruction sheet provided with the ve-

hicle specific mount kit to finalize the ve-

hicle part of the plow installation.

NOTE: Prongs from the mount kit should be at a

height that will slightly lift the plow frame when

attaching the plow. General rule of thumb is 9”

from the ground to the underside of the prong.

This can vary if the truck has a modified sus-

pension.

NOTE: Powdered graphite can be used on the

prongs to help the plow slide on and off more

easily.

NOTE: Prong receivers on the plow frame must

be parallel to the ground before attaching the

plow. Always follow the attaching and detaching

instructions that are decaled on the rear side of

the plow blade.

Truck Electronics & Mount Kit Assembly 9

10 System Checkout

SYSTEM CHECKOUT

1. Prongs from the truck mount kit should

be at a height that will slightly lift the plow

frame when attaching the plow. Prong re-

ceivers on the plow frame should be paral-

lel to the ground when attaching the plow.

Apply powered graphite on the truck prongs

to help the plow to slide on and o more

easily.

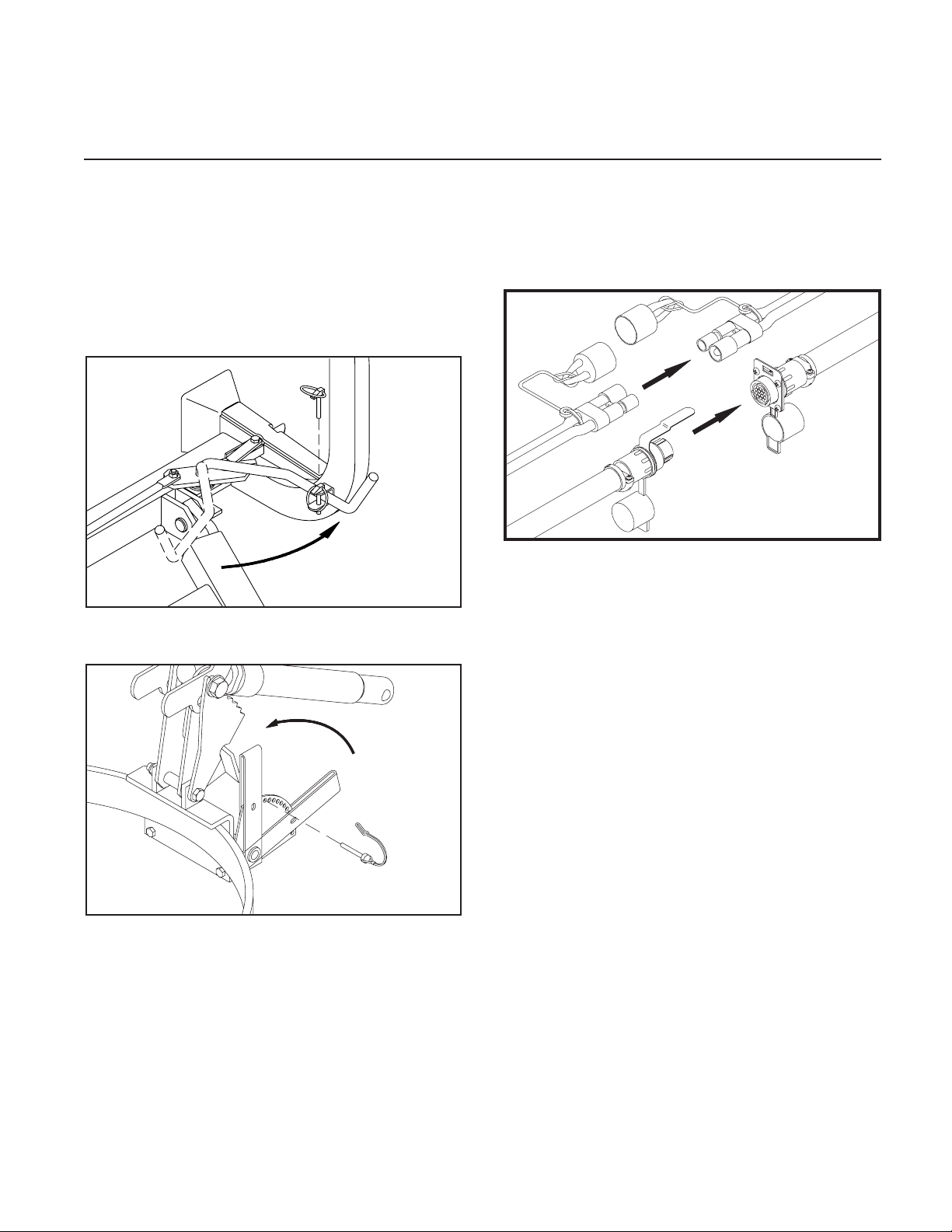

Handle Pinned With Plow on Truck DWG NO. 4199

DWG NO. 5286A

2. Connect the electrical cables from the plow

to their corresponding receptacles on the

truck. Validate the power connection is red

stripe to red stripe and black to black.

DWG. NO. 6697

3. Select Hiniker Cold Flow Hydraulic Oil or

an equivalent oil that meets military speci-

fication 5606, for plowing in extremely cold

temperatures.

Pour hydraulic oil into the power unit oil

reservoir until the reservoir is half full.

Angle the plow full left or right with the cab

control box inside the truck to fill the an-

gling cylinder with oil. Add more oil until the

reservoir is about 3/4 full. Do not over-fill

the reservoir.

Cycle the plow left and right and up and

down to purge any air trapped in the hy-

draulic system.

Check the oil level with the plow on the

ground. Add oil to the fill line, if necessary,

but do not over fill the reservoir.

NOTE: New hydraulic cylinders will leak a small

amount of oil until packings become saturated

and produce a good seal. If leakage is exces-

sive, or if leaking continues after initial cycling,

tighten the cylinder packing nut in 1/8-turn in-

crements until leaking stops.

4. Fasten the power unit cover assembly to the

lift frame bracket with two 1/4” x 3/4” screws,

at washers and lock nuts from the hardware

bag in the power unit box. Tighten the lock

nuts so that the assembly is secure, yet the

cover hinges freely.

DWG. NO. 6310

NOTE: When the cover is closed, rods from the

latch handles should extend behind the light

brackets to hold the cover in place.

DWG. NO. 6014D

5. Assemble side markers on the ends of the

moldboard with 5/16” bolts, at washers

and lock nuts.

DWG. NO. 6006

NOTE: The power cable and wiring harness

must be connected between the snowplow and

truck to test the functions of the headlights and

power unit. Vehicle ignition must be switched

on.

6. Move the headlight switch on the joystick con-

troller to the “TRUCK” position and turn on

the vehicle headlights. High and low beams

should operate on the truck.

7. Turn the vehicles headlight switch to its o

position then move the switch to the “PLOW”

position. Plow lights should operate in both

high and low beams. Vehicle headlights

should be o.

8. Test the parking lights and turn signals. Lights

on the plow and truck should operate at the

same time.

9. In an area clear of bystanders, test joystick

functions by raising and lowering the plow

and angling side to side.

NOTE: To reverse the angle functions, exchange

the tan and gray wires on the power unit.

Refer to the section titled “Controller Congura-

tion” for instructions on inverting the raise and

lower functions.

System Checkout 11

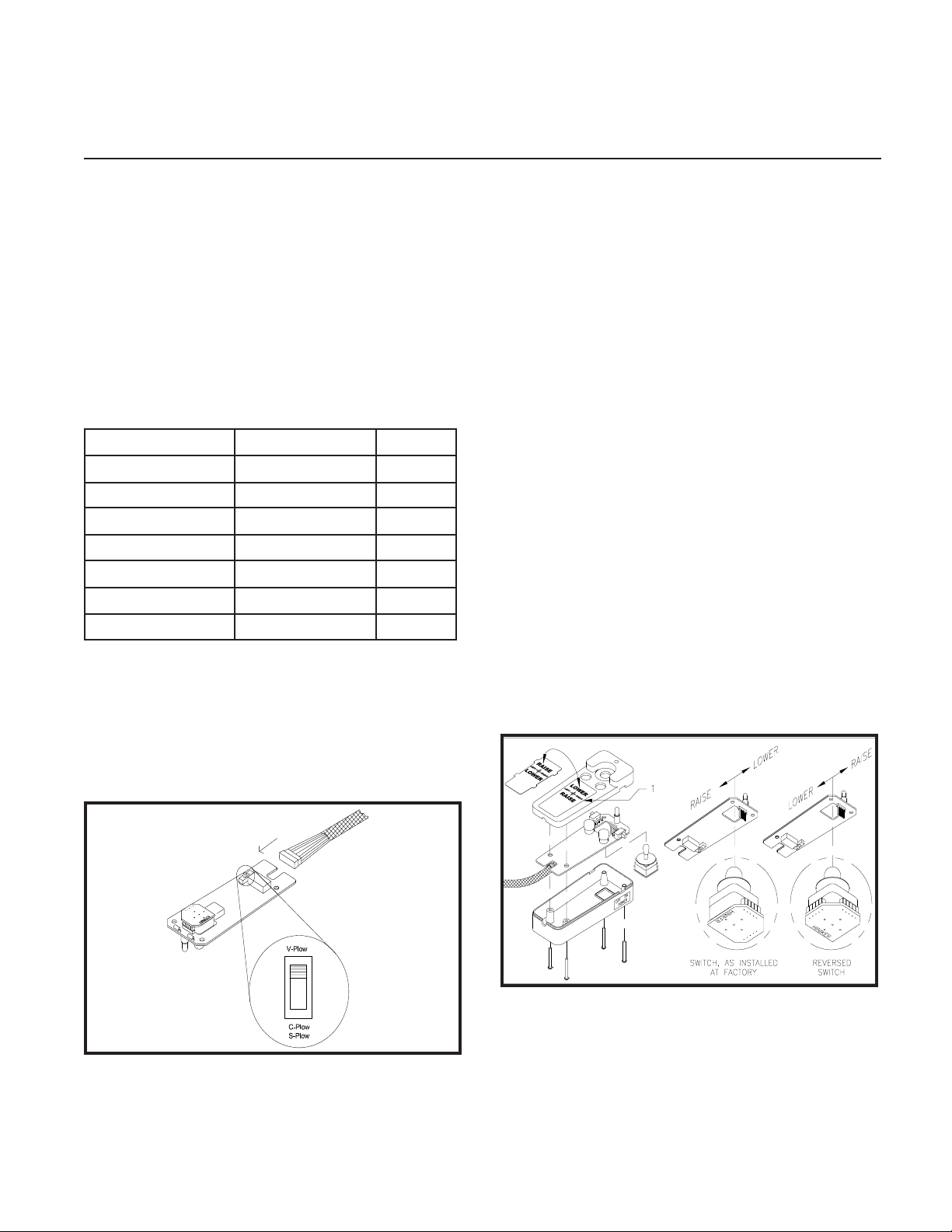

CONTROLLER CONFIGURATION

NOTE: The 2 pin power cable and 16 pin plow har-

ness must be connected, and the vehicle’s ignition

switch must be switched on in order to test the

functions of the headlights and power unit.

1. Ensure the black and white 12 pin connec-

tor from the cab harness is attached to the

controller.

2. Use the plow selection switch to select

whether you have a V-Plow or a Straight

Blade.

Model Plow Type Postion

9585, 9595 Torsion V Up

9863, 9963, 9710 Compression V Up

2754, 2804, 2854 Steel Straight Down

8804, 8904 CDown

6814, 6914 Scoop Down

7814, 7914 Poly Straight Down

703, 753 Mid Size Straight Down

NOTE: As supplied from the factory, the snow-

plow controller raises the plow when the joystick

is pulled backward and lowers the plow when

the joystick is pushed forward. If you wish to re-

verse this follow steps 3 through 5. If not, skip

to step 6.

DWG. NO. 8006

3. Pry the face plate of the controller by insert-

ing a small screwdriver along the side of the

plate of the plate at location 1 in drawing

5855A. Flip the plate over, then reinstall by

gently sliding the 4 tabs into the slots in the

controller top.

4. To reverse the joystick switch, gently pull on

the edges of the small circuit board at the

base of the joystick switch to remove the

switch from the 5 pins on the main circuit

board.

5. Rotate the switch 90 degrees then gently

push the switch back onto the 5 pins.

6. Insert the main circuit board into the case

top ensuring the joystick is properly seated

and the harness strain relief is inside the

case.

7. Assemble the case with the provided

screws.

8. Test the controller on the snow plow to ver-

ify that raise and lower functions are what

the operator desires.

DWG. NO. 5855A

12 Controller Conguration

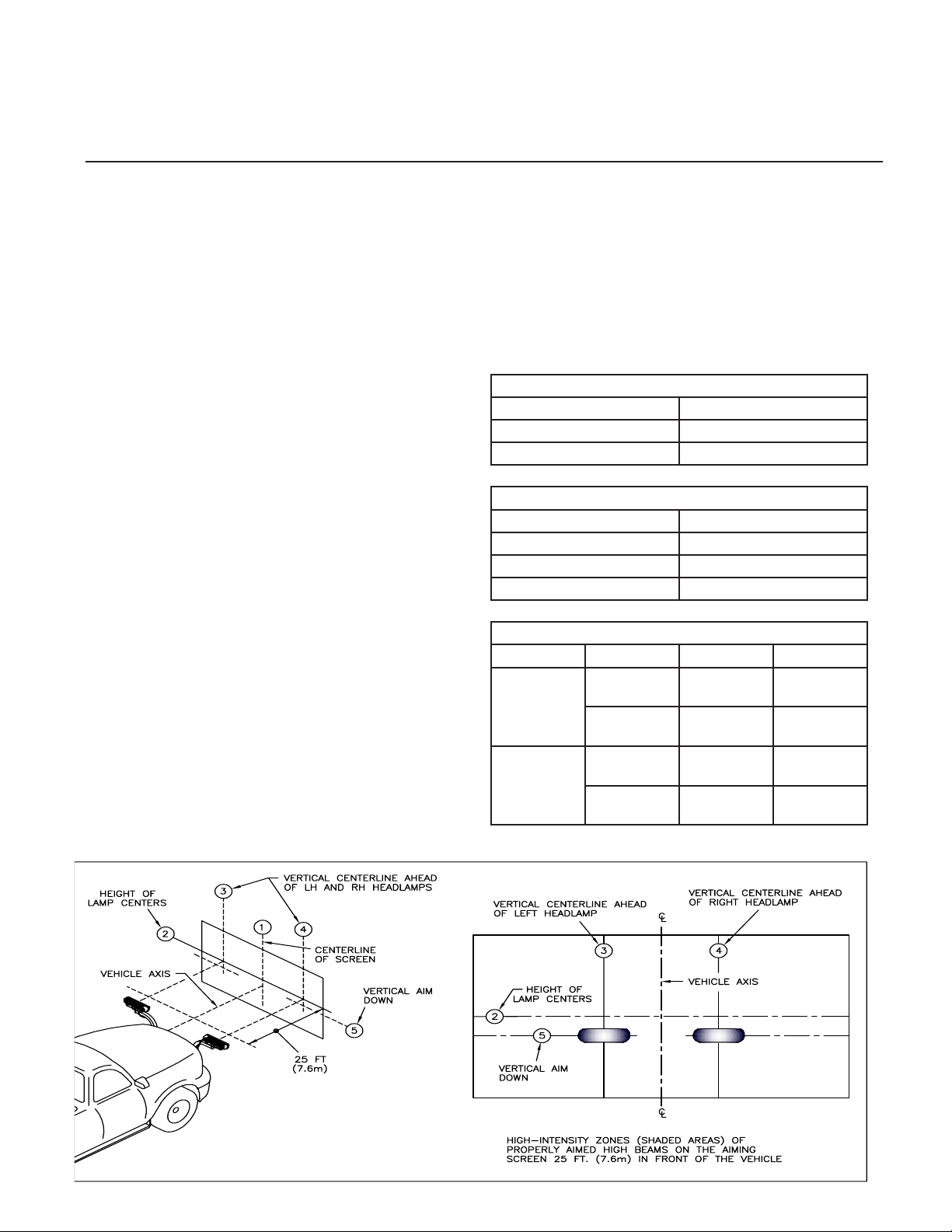

HEADLAMP AIMING PROCEDURE

NOTE: Headlamp aiming should be done while

plow is in a raised position.

NOTE: This procedure should be done with no

load on the vehicle other than the driver, snow-

plow, and rear ballast weight, inspect the vehicle

for proper tire in ation and broken or sagging sus-

pension components. Check functioning of any

automatic vehicle leveling systems and any spe-

ci c manufacturer’s instructions pertaining to ve-

hicle preparation for headlamp aiming. Stabilize

the suspension by rocking the vehicle sideways.

1. Park the vehicle with the plow attached on

a level surface 25’ (7.6 m) from a at, unob-

structed light-colored wall.

1. Centerline of vehicle.

2. Height of Lamp Centers.

3. LH Headlight Center (see Table 1 for di-

mensions from Line 1).

4. RH Headlight Center (see Table 1 for di-

mensions from Line 1).

5. Vertical Aim Down Height (see Table 2

for dimension from Line 2)

2. Mark the wall with black tape according to

drawing 5698B.

3. Wipe the lamp lenses clean and check for

proper switching and function.

4. Activate the plow lamp HIGH beams to illumi-

nate toward the wall.

5. Focus the center of the LH light beam on the

intersections of lines 3 and 5.

6. Focus the center of the RH light beam on the

intersections of lines 4 and 5.

7. Tighten the headlamp hardware according to

the table below.

Table 1: Lines 3 & 4 Dimensions

Type Line 3 & 4 Dimension

LED 19 in (48 cm)

Halogen 22 in (56 cm)

Table 2: Line Dimension

Height from Ground Dimension

22 to 36 in (56 to 90 cm) 0

36 to 48 in (90 to 120 cm) 2 in (5 cm)

48 to 54 in (120 to 140 cm) 4 in (6.4 cm)

Table 3: Hardware Torque

Type Size Ft-Lbs N-m

LED 1/2” (Bracket

to Bar)

58-82 79-112

1/4” (Light to

Bracket)

6-7 8-10

Halogen 1/2” (Bracket

to Bar)

58-82 79-112

3/8” (Light to

Bracket)

29-41 39-56

DWG NO. 5698B

Headlamp Aiming Procedure 13

HINIKER SNOWPLOW LIMITED WARRANTY

The only warranty Hiniker Company (Hiniker) gives and the only warranty that any Hiniker dealer is authorized to

give on behalf of Hiniker is as follows: (NO EMPLOYEE OR REPRESENTATIVE IS AUTHORIZED TO CHANGE

THIS WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY.)

Hiniker warrants to the original purchaser of a Hiniker snowplow that Hiniker will repair or replace any defects

in material and workmanship that occur within two years from date of retail delivery except the following items:

Hiniker warrants that it will repair or replace any defects in materials or workmanship with respect to the paint

nish, any accessories, and service parts and components for a period of one year from date of retail delivery.

Hiniker’s obligation and liability under this warranty is expressly limited to repairing or replacing, at Hiniker’s

option, at an authorized Hiniker dealer location, the defective parts at no charge to the original purchaser.

HINIKER MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED AND MAKES NO WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR ANY PARTICULAR PURPOSE.

HINIKER’S OBLIGATION UNDER THIS WARRANTY SHALL NOT INCLUDE ANY TRANSPORTATION

CHARGES TO OR FROM THE AUTHORIZED HINIKER DEALER LOCATION OR ANY LIABILITY FOR

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGE OR DAMAGES OF ANY KIND FOR LOST PROFITS

OR DELAY. If requested by Hiniker, products or parts for which a warranty claim is made are to be returned freight

prepaid to our factory. Any improper use, operation beyond rated capacity, substitution of parts not approved by

Hiniker Company, or any alteration or repair in such manner as in our judgment a ects the product materially and

adversely shall void this warranty.

Hiniker reserves the right to make improvements or changes to any of it’s products without notice. Such

improvements or changes shall not trigger any obligation by Hiniker to update, modify or change any products

previously sold by Hiniker.

HINIKER does not warrant the following:

1. Used products.

2. Any product that has been repaired, modi ed or altered in a way not approved by Hiniker Company.

3. Depreciation or damage caused by normal wear, lack of reasonable and proper maintenance, failure

to follow Operators Manual Instructions, misuse, lack of proper protection during storage, or accident.

4. Parts replacement and service necessitated by normal wear or maintenance including, but not limited

to, cutting edges, hoses, snowplow skid shoes, blade marker guides and hardware.

5. Paint nish damage caused by normal wear.

Hiniker does not assume any liability for any damage to a motor vehicle resulting from the attachment or use of

a Hiniker snowplow. Compliance with applicable motor vehicle regulations is the responsibility of the installer.

Attachment of a Hiniker snowplow to a motor vehicle is at the risk of the purchaser.

It is the responsibility of the original snowplow purchaser to verify the original date of purchase.

A DELIVERY REPORT FORM must be lled out and received by Hiniker with 30 days of retail delivery at the

address below to initiate the warranty coverage.

HINIKER COMPANY

58766 240th Street

Mankato, MN 56001

PHONE 800-433-5620 -- FAX (507) 625-5883

www.hiniker.com

HINIKER WARRANTY

14 Warranty

This manual suits for next models

13

Table of contents

Other Hiniker Snow Blower manuals

Popular Snow Blower manuals by other brands

Ariens

Ariens Sno-Thro 920021 compact 24 Operator's manual

Buhler

Buhler Farm king FK311 owner's manual

Wiedenmann

Wiedenmann SNOW MASTER VARIO FLEX 3370 Series TRANSLATION OF ORIGINAL OPERATING INSTRUCTION

Craftsman

Craftsman 247.881720 Operator's manual

Poulan Pro

Poulan Pro PR5524ES owner's manual

MTD

MTD Yardworks 31AS33BE515 Operator's manual