Hiniker 825 User manual

LIGHT TRUCK MATERIAL SPREADER

MODELS 825, 815, 625, 615

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 79202499 Rev. C

TABLE OF CONTENTS

TO THE PURCHASER.................................................................................................................. 2

SAFETY......................................................................................................................................... 3

OPERATING PROCEDURES .................................................................................................... 4-8

General Information................................................................................................................ 4

Sander Control Box................................................................................................................ 5

Spread Control ....................................................................................................................... 6

Swing Away Chute .............................................................................................................. 6-7

Storage................................................................................................................................... 8

MAINTENANCE & SERVICE PROCEDURES......................................................................... 9-13

General................................................................................................................................... 9

Chain Tension....................................................................................................................... 10

Throttle Control Actuator .......................................................................................................11

Lubrication....................................................................................................................... 11-12

Electric Clutch, Trouble Shooting Clutch Problems.............................................................. 13

INSTALLATION INSTRUCTIONS .......................................................................................... 14-15

OPTIONAL EQUIPMENT ....................................................................................................... 16-18

PARTS BREAKDOWN ........................................................................................................... 19-24

Engine Assembly.................................................................................................................. 19

Electrical Assembly .............................................................................................................. 20

Discharge Chute Assembly .................................................................................................. 21

Hopper Assembly ............................................................................................................ 22-23

Front Shaft & Apron Chain ................................................................................................... 24

SPECIFICATIONS....................................................................................................................... 25

ELECTRICAL SCHEMATIC DIAGRAM....................................................................................... 26

WARRANTY ................................................................................................................................ 27

Table of Contents 1

79202499 Rev. C 3/10 Hiniker/79202499RevC

TO THE PURCHASER

2 To The Purchaser

This product is designed and manufactured to

give years of dependable service, when prop-

erly maintained and used for the purpose for

which it is intended. Never allow anyone to op-

erate this equipment until they fully understand

the complete contents of this manual. It is the

responsibility of owners who do not operate this

equipment to ensure the operator is properly in-

structed and understands the contents of this

manual. It is also the owner’s responsibility to

ensure that anyone operating this equipment is

mentally and physically capable of so doing.

Important information is contained in this manu-

al to help ensure safe and efficient operation.

If you have any questions about this manual, or

the equipment discussed herein, contact your

Hiniker dealer.

This is the safety alert symbol. It alerts

an operator to information concerning

personal safety. Always observe and

heed these instructions, otherwise death, or

serious injury can result!

All references to LEFT or RIGHT mean viewing

the spreader from the rear and facing the truck.

This Operator’s manual is shipped with this

equipment. Contact your Hiniker dealer for ad-

ditional copies.

Always obtain original Hiniker service parts.

Substitute parts could adversely affect equip-

ment performance and warranty.

Check that your dealer has forwarded the

Hiniker delivery report copy and the machine

serial number to maintain maximum service and

warranty benefits. This does not put you on any

mailing list and information thereon is not avail-

able to others.

Your spreader’s identification number plate is at

the location shown below.

DWG. NO. 6018

Record the following information for later ref-

erence when obtaining service parts:

Purchase Date

Purchaser’s Name

Dealer’s Name

Machine Serial No.

This is the safety alert symbol. It alerts an

operator to information concerning per-

sonal safety. Always observe and heed

these instructions, otherwise death or serious

injury can result!

Operator safety is a principle concern in equipment

design and distribution. However, many accidents

occur because a few seconds of thought, and a more

careful approach to handling, were ignored.

Accidents can be avoided by knowing and following

the precautions cited in this manual.

GENERAL SAFETY

1. Read this manual thoroughly. Make sure the op-

erator understands it and knows how to operate

this equipment safely. This equipment can kill or

injure an untrained or careless operator and by-

standers. If you sell this equipment, ensure the

new owner acknowledges receipt of this manu-

al.

2. Make sure the engine cover is securely fastened

to the spreader before starting the engine and

operating the spreader.

3. Do not attempt to handle or service this equip-

ment, or direct others to do the same, unless

you know how to do it safely and have the prop-

er tools for the job.

4. Keep hands, feet, hair, and clothing away from

moving parts. Flying material can cause bodily

injury. Wear eye protection.

5. Do not alter the equipment to the extent of com-

promising safety or performance.

6. Material to be spread can be dangerous. Im-

proper selection, application, use or handling

may be a hazard to persons, vehicle or other

property. Follow instructions and precautions

given by the material manufacturer.

7. Do not over-load your vehicle beyond payload

limits. If there are any questions, contact the ve-

hicle manufacturer.

8. Do not use side extensions on your spreader to

increase salt storage capacity. Using side exten-

sions may damage hopper and cause injury to

personnel.

SAFETY

9. Do not drive motor vehicle with swing away

chute open or unlatched. Make sure swing away

chute is fully engaged in its working position or

damage to your spreader chute may occur.

10. Make sure the spreader is securely fastened to

the vehicle in accordance with this manual.

BEFORE OPERATION

1. Discipline yourself to visually check for worn,

damaged or cracked parts before starting use.

Replace these with genuine Hiniker parts.

2. Check all controls and operating functions of the

machine in a safe area before starting to work.

3. Do not lubricate, adjust or clean the machine

while it is running. After making adjustments,

check machine thoroughly for loose parts, hard-

ware and tools.

DURING OPERATION

1. Drive carefully and always wear seat belts when

operating a motor vehicle.

2. Ensure everyone is clear of the machine, espe-

cially away from blind areas of the operator, be-

fore starting or operating this equipment.

3. Stay out of hopper when conveyor power source

is engaged. If machine becomes blocked, do not

attempt to remove blockage until machine has

been shut off and conveyor and spinner move-

ment have stopped.

Use a shovel or other long-handled tool to reach

inside the hopper. Never attempt to break up

material inside the hopper with hands or feet.

4. Do not ride in any part of spreader while vehicle

is in motion.

5. Set the brakes and stop the truck’s engine be-

fore adjusting or servicing your spreader.

AFTER OPERATION

1. Inspect the spreader for components that have

become excessively worn or damaged and must

be repaired or replaced.

2. Develop a regular maintenance schedule to en-

sure safe, dependable spreader operation.

Safety 3

OPERATING PROCEDURES

GENERAL INFORMATION

Hiniker spreaders are capable of dispersing a

variety of dry materials for control of ice on road-

ways, walkways and parking lots.

Vehicle load carrying capacity limits the maxi-

mum load that can be safely transported, which

could be less than the volumetric capacity of the

spreader. Check the vehicle’s load rating certi-

cation sticker and DO NOT overload the vehicle

beyond its Gross Vehicle Weight Rating (GVWR)

or its Gross Axle Weight Rating (GAWR). Spread-

ers are recommended to be mounted on trucks

over 8,500 lb. GVWR.

Use the following tables to calculate vehicle pay-

load when material is loaded in the spreader.

VOLUMETRIC CAPACITY:

(Cubic Yards, Approx.)

LEVEL HEAPED

Standard 8’ Box 1.8 2.27

Standard 6 1/2’ Box 1.5 1.84

WEIGHT: (Pounds, Approx.)

8’ SS Standard Box 537

8’ Standard Box 602

6 1/2’ SS Standard Box 494

6 1/2’ Standard Box 550

Short Spinner Kit 33

Long Spinner Kit 42

Hinged Hopper Grids, 8’ Box 55

Hinged Hopper Grids, 6 1/2’ Box 45

Adjustable Inverted “V”, 8’ Box 26

Adjustable Inverted “V”, 6 1/2’ Box 20

MATERIAL WEIGHTS:

(Pounds Per Cubic Yard, Approx)

Very Coarse Rock Salt 950

Coarse Rock Salt 1,215

Coarse Sand - Dry 2,565

Coarse Sand - Wet 3,240

Calculate total material weight by multiplying

pounds per cubic yard by cubic yards of mate-

rial.

Local, state and federal regulations may require

flashing lights, center high mounted stop light,

or other additional equipment for operation on

public roadways. It is the owners responsibil-

ity to know and follow laws as they apply in his

area.

Always examine the spreader for worn or dam-

aged components prior to operation. During

operation, listen for unusual noise from the

spreader that might indicate component failure.

Never run a machine in need of repair.

Start the spreader for a short period of time be-

fore loading material to test for proper function

of moving parts.

After loading, run the spreader in an isolated

area, clear of people, to become familiar with

the controls and to verify the correct spread pat-

tern. Adjust deflectors on the discharge chute to

achieve the desired spread.

WARNING: Stop the conveyor and set

the vehicle parking brake before leav-

ing the vehicle to make adjustments.

If loading the hopper the night before an im-

pending snowfall or ice storm, park the spreader

indoors, if possible, to help prevent freeze-up of

material before morning.

4 Operating Procedures

Operating Procedures 5

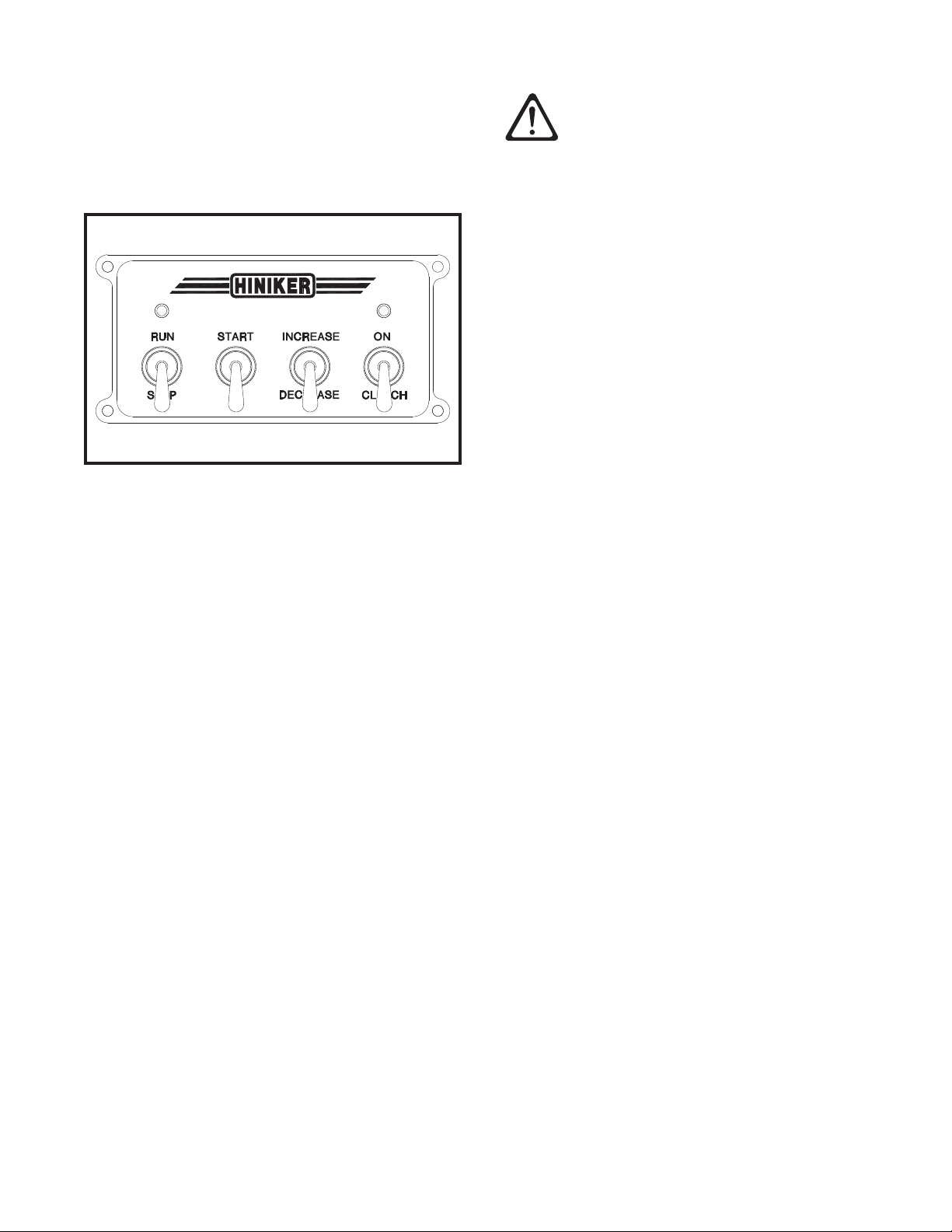

Sander Control Box

The spreader cab control consists of a power/

kill switch, a start switch, a throttle speed con-

trol switch, and a clutch on/off switch.

DWG. NO. 3184

Before starting the engine, check that the clutch

switch is in the OFF position.

To start the engine, first turn the power switch

to RUN, then hold the throttle control switch at

INCREASE for 3 seconds to choke the engine.

Hold the start switch at START until the engine

is running.

IMPORTANT: Do not hold the start switch

for longer than 15 seconds at a time when

attempting to start the engine. Allow the

starter motor to cool for 2 minutes between

attempts.

Once the engine has started, move the throttle

control switch to DECREASE until the engine

runs at the desired speed.

IMPORTANT: Prolonged operation of the en-

gine at full or partial choke may cause pre-

mature engine wear or failure due to gaso-

line diluted oil or fouled spark plug.

The engine can also be started by using the re-

coil starter with the power switch in the RUN

position.

CAUTION: If the battery has been re-

moved and machine is to be hand

started, be sure the positive cable

(red) at the battery end has the terminal

taped to prevent sparking to ground when

the engine is running.

The electric clutch can be engaged or disen-

gaged at any engine speed. However, since

engagement time and torque is almost instanta-

neous, to prevent premature spinner chain fail-

ure and chain tension loss, it is recommended

that the electric clutch be engaged at the lowest

possible engine speed without killing the en-

gine.

Burnishing the clutch is necessary to achieve

rated torque capacity. Never perform burnishing

while drive is loaded. New clutches and clutches

that have not been used for a long time, should

be burnished before full load operation by the

following procedure:

1. Rotate the clutch and check for rubbing or

interference. Reinstall chain, do not over

tighten.

2. Run at 50% throttle.

3. Engage and disengage the clutch 25 times.

(10 seconds on/10 seconds off).

4. Increase to 75% throttle.

5. Engage and disengage the clutch 25 times.

(10 seconds on/10 seconds off).

Disengage the clutch and move the power

switch to the STOP position when done using

the spreader.

6 Operating Procedures

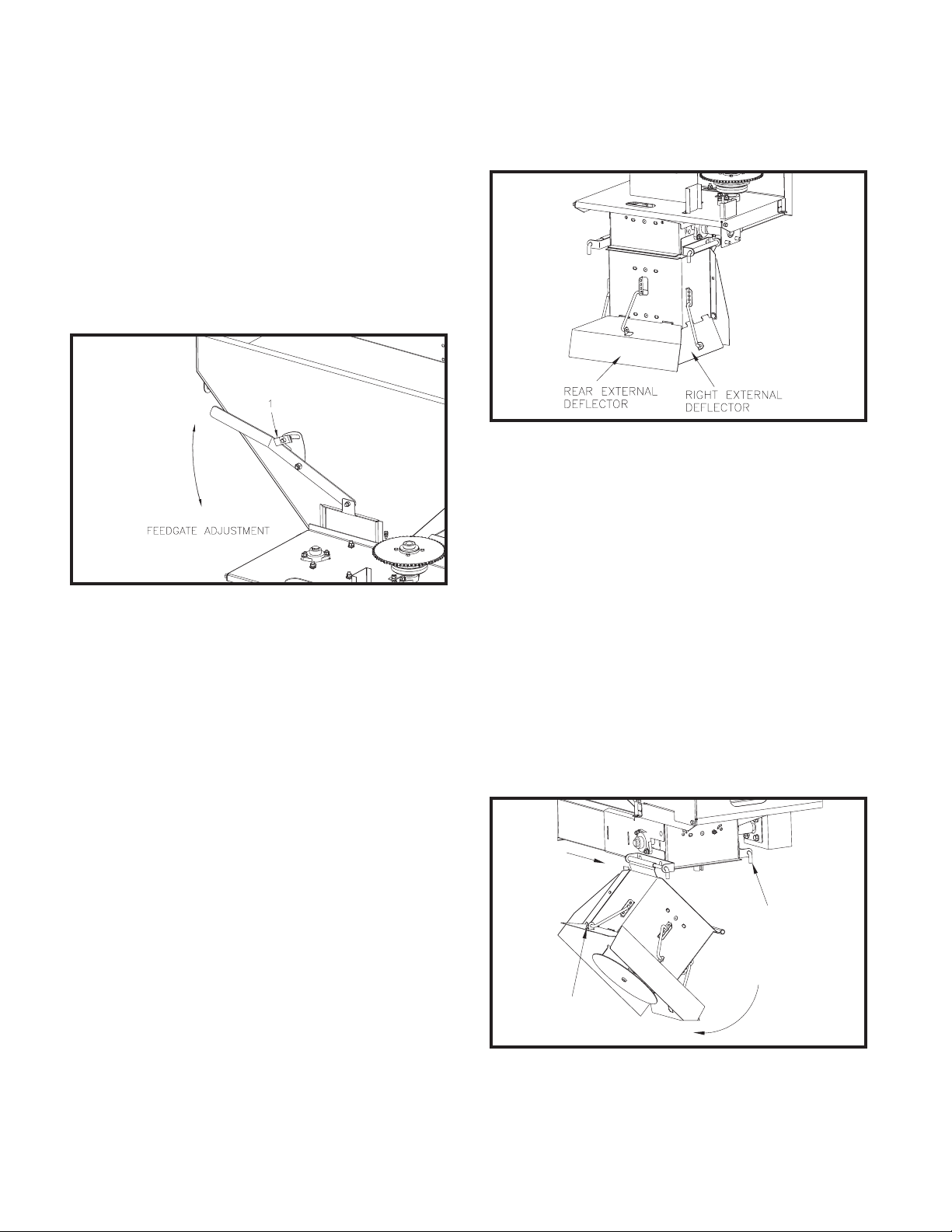

2. Deflector Positions:

The three external deflectors control the

size of the spread.

DWG. NO. 6020

Raising any of the three external deflectors

at the bottom of the discharge chute will pro-

duce a wider, thinner distribution of material to

that same side. Adjust the various speeds and

settings one at a time to produce the desired

spread pattern.

SWING AWAY CHUTE

Hiniker spreaders are equipped with a swing

away chute making cleaning of the hopper and

storage much easier. The swing away chute is

for clean out and storage only. Do not drive mo-

tor vehicle with swing away chute open or not

fully engaged in its working position.

SLIDE

REARWARD

1

2

DWG. NO. 6021

SPREAD CONTROL

Thickness of material cover is controlled by four

variables:

1. Feedgate Setting:

Raising or lowering the feedgate will in-

crease or decrease the amount of mate-

rial delivered to the spinner for any given

conveyor speed. Gate openings range from

3/8” to 4 1/4”.

DWG. NO. 6019

To set the feedgate position loosen the nut

at location 1. Use the feedgate handle to

move the feedgate into the desired posi-

tion. Lock the handle into position by re-

tightening the nut.

2. Conveyor Speed:

A faster conveyor speed will deliver more

material to the spinner.

3. Truck Speed:

The slower the vehicle travels, the more

material covers the ground.

4. Width of Spread:

A wide spread pattern produces a thinner

material cover.

Spread width is controlled by two variables:

1. Spinner Speed (determined by conveyor

speed):

A faster spinner speed produces a wider

pattern.

Operating Procedures 7

SHORT SPINNER OPERATION

To utilize this option pull the pin at location 1

and allow the chute to swing open. This disen-

gages the spinner from the spreader. The spin-

ner may need to be rotated slightly to fully dis-

engage the spinner. Slide the chute rearward

about 1 1/2 inches. Pull the hair pin cotter at

location 2. Disengage the deflector pin from the

hole in the deflector

DWG. NO. 6022

Rotate the chute assembly approximately 180

degrees. Insert the pin (arrow 1) from the exter-

nal deflector into the hole of the top chute mount

at location 2. Insert the hair pin cotter into the

pin behind the top chute mount to secure the

chute in this position.

DWG. NO. 6023

To realign the shafts for spreading, reverse the

above steps. When the chute has been secured

to the spreader, check that the coupler has fully

engaged the spring pin on the spinner shaft.

If it is not engaged turn the spinner shaft until

the spring pushes the coupler over the spinner

shaft and the coupler engages the spring pin.

A fully engaged spinner will look like the above

drawing.

SLIDE REARWARD

2

3

1

DWG. NO. 6024

LONG SPINNER OPERATION

To utilize this option pull the pin at location 1 and

allow the chute to swing open. This disengages

the spinner from the spreader. The spinner may

need to be rotated slightly to fully disengage the

spinner. Slide the chute rearward about 1 1/2

inches. Pull the (2) hair pin cotters at location 2.

Remove the left deflector pin from the chute as-

sembly. Insert one end of the pin into the hole in

the top chute mount at location 3. Insert the hair

pin cotter into the pin hole behind the top chute

mount to secure the pin in position.

DWG. NO. 6025

Rotate the chute assembly approximately 180

degrees. Insert the other end of the pin (arrow

1) from the external deflector into the formed

tab of the spinner assembly at location 2.

8 Operating Procedures

Insert the hair pin cotter to secure the chute as-

sembly in position.

To realign the shafts for spreading, reverse the

above steps. When the chute has been secured

to the spreader, check that the coupler has fully

engaged the spring pin on the spinner shaft. If

it is not engaged turn the spinner shaft until the

spring pushes the coupler over the spinner shaft

and the coupler engages the spring pin. A fully

engaged spinner will look like drawing 6023.

STORAGE

Store the spreader in a dry protected area when

it will not be used for an extended period of time.

Perform the following maintenance procedures

at the end of the season to ensure that the ma-

chine remains in good operating condition.

1. Disconnect and remove the battery from

the spreader. Apply a light coat of dielectric

grease to all electrical terminals, and cap or

tape loose terminals to prevent damage or

corrosion.

2. Wash the spreader to ush out any remain-

ing material.

3. Inspect for worn or damaged components.

Repair or replace as needed.

4. Grease all bearings. Grease points are

identied in the Maintenance & Service

section of this manual.

5. Oil conveyor and roller chains.

Maintain the spreader engine according to the

Briggs & Stratton owner’s manual that is shipped

with the spreader. Engine warranty is described

in the Briggs & Stratton manual.

If service or repair is required, contact an au-

thorized Briggs & Stratton service center. The

service center will ask for the model, type and

code number of the engine.

Locate the nearest service center in the “Yellow

Pages” or use the dealer locator at

www.briggsandstratton.com.

Maintenance & Service Procedures 9

MAINTENANCE & SERVICE PROCEDURES

Dependable spreader operation is the result of

following good maintenance procedures. Inspect

your spreader frequently to ensure that all parts

are working smoothly, and develop a schedule

for maintenance at required intervals.

GENERAL

Prior to operation of a new spreader, or one that

has been stored, inspect all hardware and verify

proper torque on all bolts and nuts in accordance

with the recommended torque specifications.

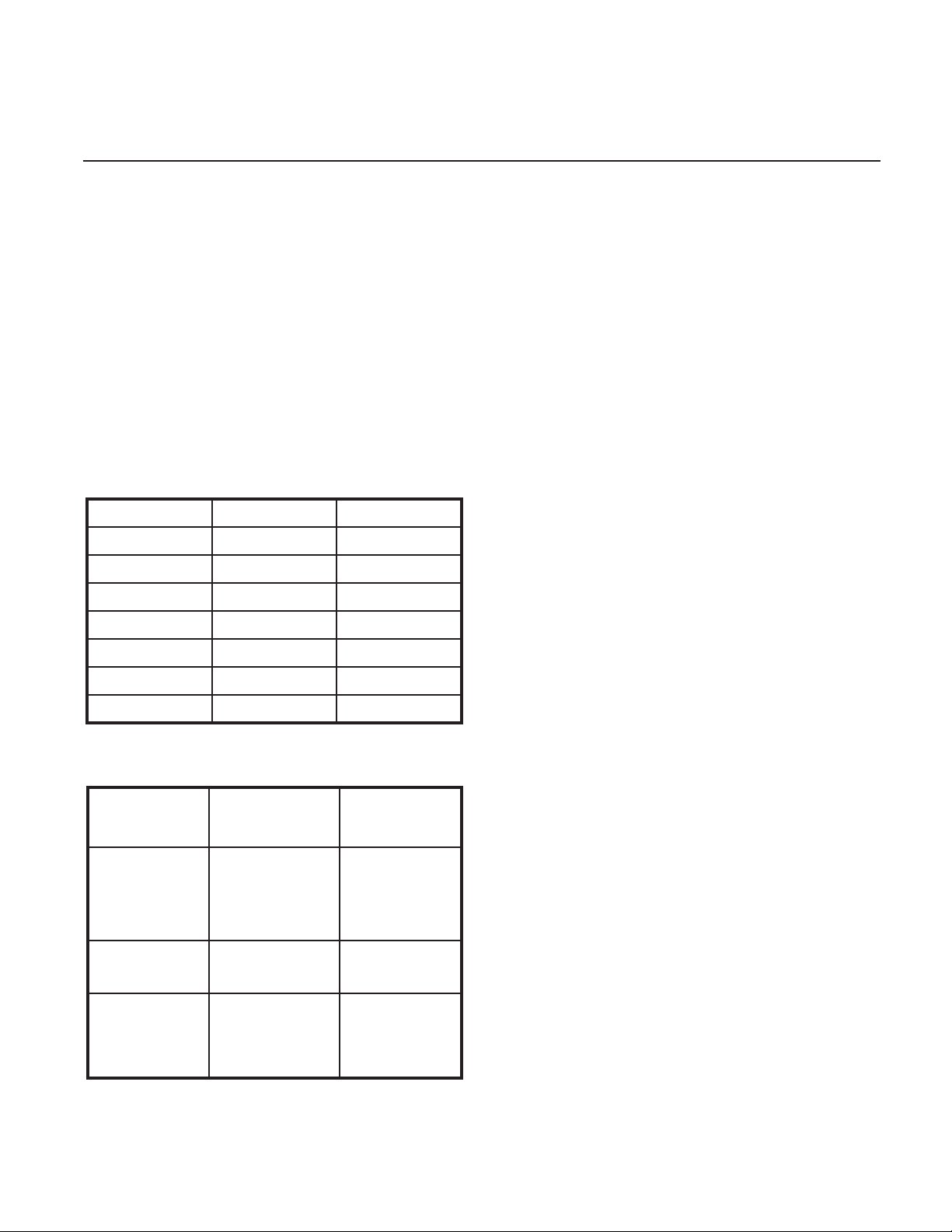

GRADE 5 TYPE B & F LOCKNUT TORQUES

Diameter Ft-lbs. N-m

1/4” 6-10 8-13

5/16” 13-18 17-25

3/8” 23-33 31-44

7/16” 38-54 51-73

1/2” 58-82 79-112

5/8” 117-165 158-223

3/4” 206-292 280-396

SET SCREW SEATING TORQUE

Socket

Head

Torque

In.-lbs.

(Ft-lbs)

Torque

N-m

#8

#10

1/4

5/16

20 (1.6)

36 (3)

87 (7.25)

165 (13.5)

2.25

4

9.8

18.6

Square

Head

#10

1/4

5/16

100 (8.8)

212 (17.7)

420 (35)

11.3

24

47.5

Loose bolts can cause hole elongation and part

failure resulting in dangerous operating condi-

tions and equipment breakdown.

Check all hardware periodically during opera-

tion and keep tightened to specified torques.

Replace worn bolts and locknuts with Grade 5

bolts and equivalent type B or F locknuts. Type

B locknuts are plain hex; type F locknuts are

flanged hex.

Fill electrical connectors with dielectric grease

to prevent corrosion of contacts when the con-

nectors are unplugged, and to make connecting

and disconnecting plugs easier.

Wash salt and dirt off the spreader before stor-

age.

Maintain the spreader engine according to the

Briggs & Stratton owner’s manual that is shipped

with the spreader. Engine warranty is described

in the Briggs & Stratton manual.

If service or repair is required, contact an au-

thorized Briggs & Stratton service center. The

service center will ask for the model, type and

code number of the engine.

Locate the nearest service center in the “Yellow

Pages” or use the dealer locator at

www.briggsandstratton.com

10 Maintenance & Service Procedures

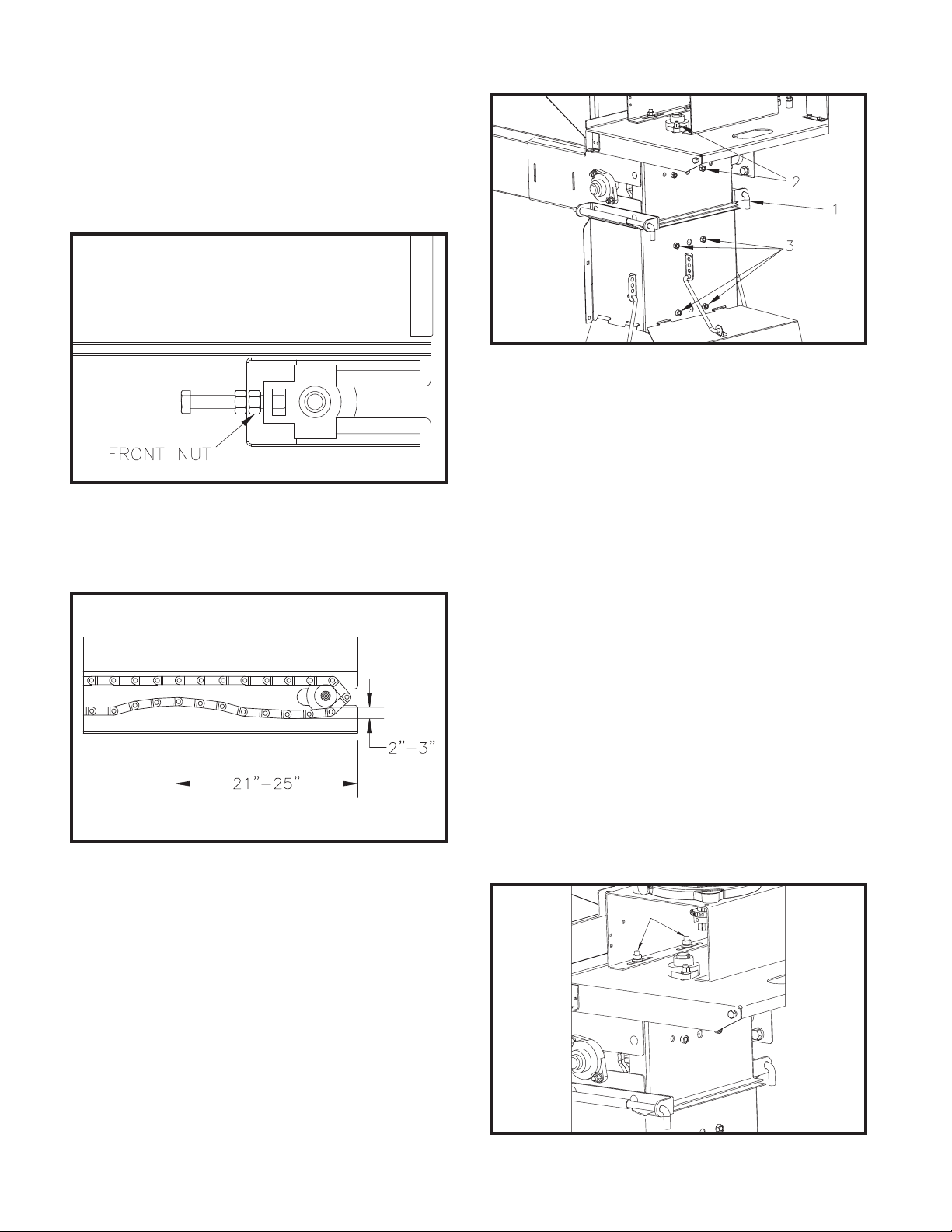

CHAIN TENSION

Tighten the conveyor chain periodically to com-

pensate for the chain stretching. Adjust both

sides the same amount to equalize the load on

the chain.

DWG. NO. 6026

Loosen the front nut, then turn the adjustment

bolt to take up the slack.

DWG. NO. 6596

Retighten the front nut after the chain is adjust-

ed. A properly tensioned chain can be pulled up

2-3 inches about 24 inches from the back of the

spreader side rails. A chain that is too tight will

cause excess stress on drive components.

DWG. NO. 6027

To adjust tension in the roller chain between the

gearbox and the spinner shaft first pull the pin at

location 1 and allow the spinner to swing open.

Loosen the (4) nuts, at location 2, that secure

the upper bearings which hold the upper spin-

ner shaft. Slide the top spinner shaft away from

the gearbox to tighten the chain. Make sure the

shaft is vertical before retightening the hard-

ware.

Rotate the chute assembly and reinsert the pin

at location 1. Loosen the (4) nuts, at location 3,

that secure the bearings which hold the bottom

spinner shaft. Slide the bottom shaft until it is

aligned with the top shaft.

When the shafts are aligned, the coupler on the

upper shaft will slide over the bottom shaft and

the spring pin will engage the slot in the cou-

pler. The bottom shaft may need to be rotated

slightly to align the slot in the coupler with the

spring pin. Make sure the bottom shaft is verti-

cal before retightening all hardware.

1

DWG. NO. 6028

Maintenance & Service Procedures 11

Tighten the engine drive chain by loosening the

four nuts (arrow 1)holding the engine plate, then

slide the entire engine assembly. Retighten nuts

to secure the engine plate

THROTTLE CONTROL ACTUATOR

Reassemble the throttle actuator as follows:

FORWARD

1

2

3

DWG. NO. 6040

1. Assemble the actuator on the bracket.

2. Advance the actuator arm (arrow 1) forward

with a 9V battery until the arm is stopped

by the bracket.

3. Place the plastic block (arrow 2) on the ac-

tuator arm and loosely bolt the bracket (ar-

row 3) on the engine plate.

4. Slide the governor control rack on the en-

gine fully ahead, then pin to the plastic

block.

5. Fully tighten the bracket to the engine

plate.

6. Cycle the actuator to verify that the arm is

stopped by the bracket, not by the engine

mechanism.

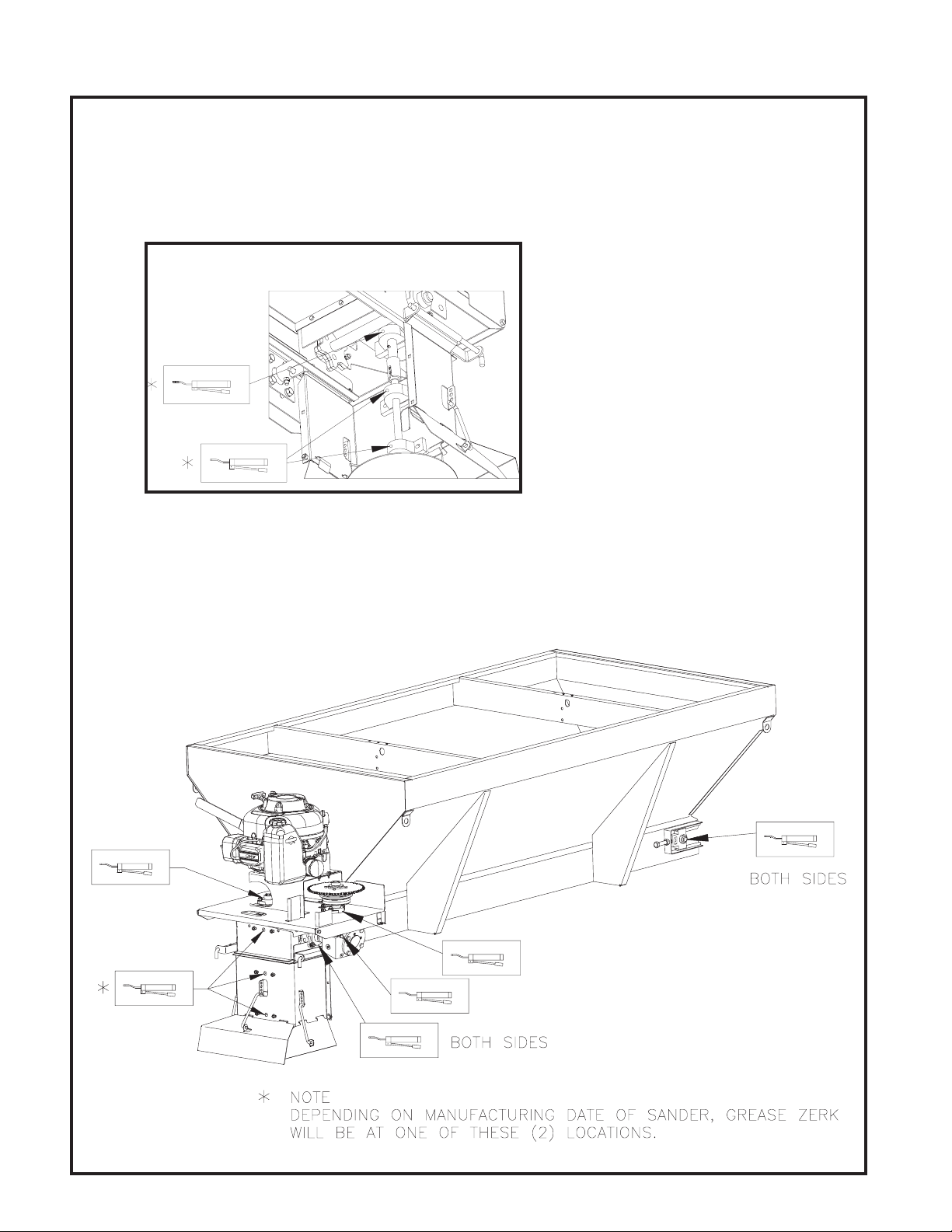

LUBRICATION

CAUTION: Do not lubricate, adjust or

clean the machine while it is running.

Death or serious injury can result.

Prior to operation of a new machine, or one that

has been stored, grease all bearing points with

a high quality SAE multi-purpose grease and oil

the roller chains.

Throughout the season, grease bearings at

about 10 hour intervals and oil roller chains of-

ten.

NOTE: Over-greasing may cause seal damage

to bearings. Use only one pump of grease per

fitting.

Replace gear box oil annually with SAE 90 gear

lubricant. Prevent debris from entering the gear

box by cleaning dirt from plug area and wiping

plugs prior to reinstallation.

DWG. NO. 6031

Remove the drain plug at location 1 to drain old

oil into a quart or larger container and discard.

Reinstall the drain plug and remove the breath-

er at location 2 and the oil level plug at location

3. Fill the gearbox through the breather port un-

til oil appears at the level port. Reinstall the oil

level plug, add another 1/4 quart then reinstall

the breather. Capacity is about 5/8 quart (0.6

liters).

12 Maintenance & Service Procedures

GREASE POINT LOCATIONS

DWG. NO. 6029

DWG. NO. 6030

Spinner Grease Point Locations

Maintenance & Service Procedures 13

ELECTRIC CLUTCH

The following procedures are recommended to

maximize the life of the electric clutch:

- Remove and clean the electric clutch at

the end of the snow season.

- After cleaning the clutch, coat both mat-

ing surfaces with oil or light grease.

- Remove oil and grease before using the

clutch the following season.

DWG. NO. 6041

When servicing worn clutch components, the

rotor and armature must be replaced as a pair.

TROUBLESHOOTING CLUTCH PROBLEMS

A. Symptom: Clutch will not Engage

PROBLEM POSSIBLE CAUSES

- Low voltage

supply

- Zero voltage

- Defective battery

- Faulty charging system

- Bad wiring or connectors

- Broken lead wire

- Open clutch coil, check

coil resistance

- Faulty switch

B. Symptom: Noisy Clutch

PROBLEM POSSIBLE CAUSES

- Failed bearing

- Adapter plate

rattles against

antirotation pin

- Loose mounting

- Operating Temperature

above 250OF

- Bearing Preloaded Axi-

ally

- Some noise is normal: to

reduce noise level, iso-

late antirotation pin from

frame with rubber.

C. Symptom: Clutch Slips

PROBLEM POSSIBLE CAUSES

- Low voltage

supply

- Contaminat-

ed friction

surfaces

- Clutch loose

on shaft

- Clutch not

mounted

square

- Broken rivet

joints

- Defective battery

- Faulty charging system

- Bad wiring or connectors

- Oil or grease on clutch

- Eccentric collar not locked

onto the shaft

- Mounting shoulder not

square

- Clutch integral key hitting

end of keyway

- Loose mounting

Replace clutch

14 Installation Instructions

GRADE 5 TYPE B & F LOCKNUT TORQUES

Diameter Ft-lbs. N-m

1/4” 6-10 8-13

5/16” 13-18 17-25

3/8” 23-33 31-44

7/16” 38-54 51-73

1/2” 58-82 79-112

5/8” 117-165 158-223

3/4” 206-292 280-396

SET SCREW SEATING TORQUE

Socket

Head

Torque

In.-lbs.

(Ft-lbs)

Torque

N-m

#8

#10

1/4

5/16

20 (1.6)

36 (3)

87 (7.25)

165 (13.5)

2.25

4

9.8

18.6

Square

Head

#10

1/4

5/16

100 (8.8)

212 (17.7)

420 (35)

11.3

24

47.5

MOUNTING THE SPREADER

1. Remove the tailgate from the truck according

to instructions from the vehicle manufacturer.

WARNING: Never attempt to lift a

spreader with material in the hopper.

Verify that the lifting device is capable

of handling at least 1,000 LB. loads before try-

ing to lift the spreader.

2. Lift the spreader by hooking the slot in the

rear-most (toward rear of the truck) hopper

cross member.

The lifting slot is placed at the approximate

balance point of the spreader. Residual mate-

rial, gasoline, oil, battery, top screen, inverted

vee may affect this balance point.

INSTALLATION INSTRUCTIONS

3. Center the spreader on the truck with the

rear rails extending about 12-14 inches be-

hind the furthest point of interference (back

of the truck, bumper, trailer hitch, etc.) Verify

the rear legs of the spreader rest securely

on the bed of the truck.

Place lumber as needed between the back

of the truck cab and the front of the spread-

er to help hold the sander in position and

protect the truck from damage due to shift-

ing of the spreader.

4. Attach the sander to the truck bed using 3/8”

hardware through the slot in the sanders (4)

legs. Ratchet tie-down straps must be used

to secure the spreaders (4) tie down eyes

located at each corner of the spreader to

the vehicles factory installed anchor points.

Ratchet tie down straps must be used to

properly secure hopper to vehicle. Do not

use cam buckle or other forms of straps

where adequate tension to secure hopper

against load shifting cannot be achieved.

NOTE: Inspect hold-downs and tie down straps

periodically for wear or loosening, and retighten

or repair as required.

Installation Instructions 15

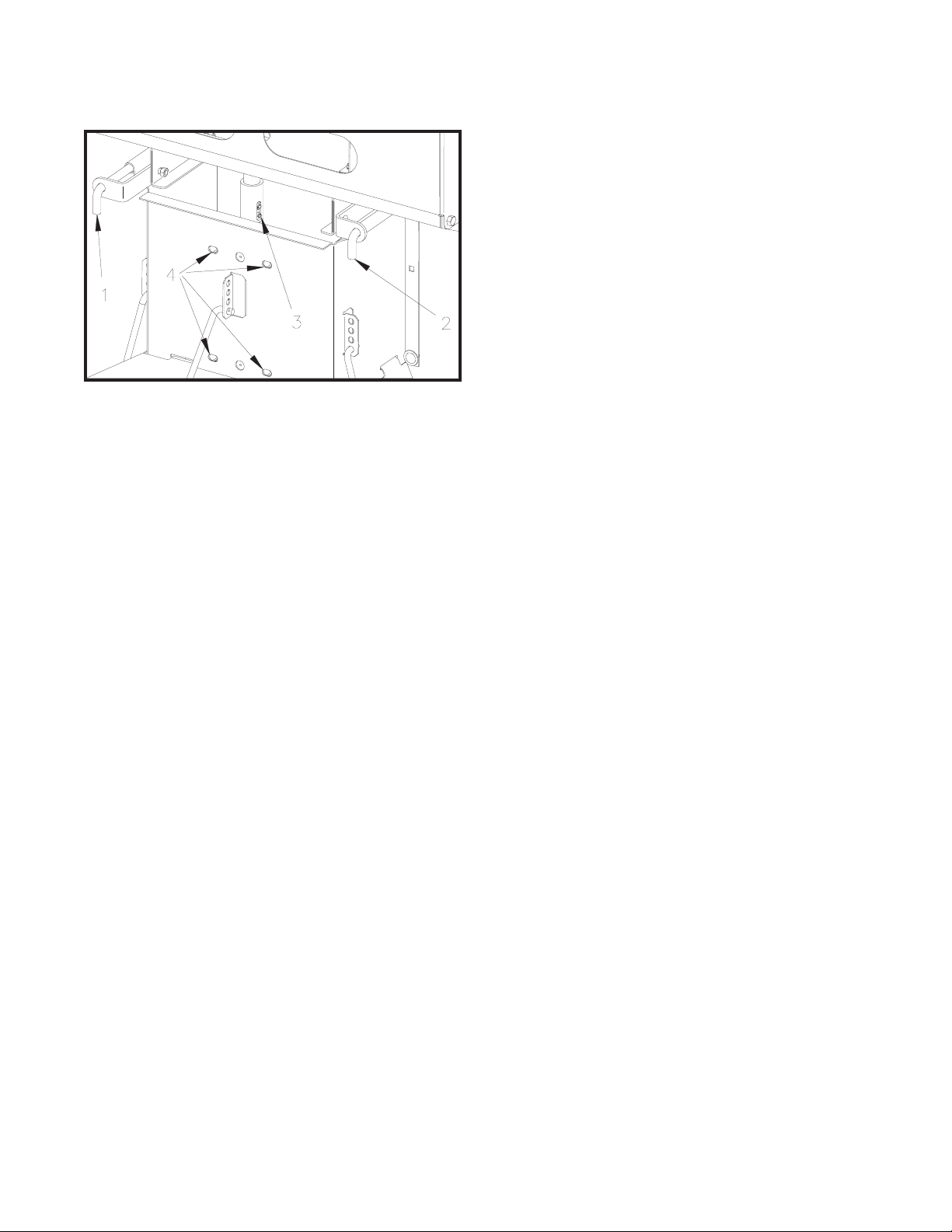

CHUTE ASSEMBLY

DWG. NO. 6032

1. Attach the chute assembly to the spreader

by inserting the long pin through the clevis

and chute hinge at location 1.

Rotate the chute assembly and insert the

pin at location 2. Check and see if the two

shafts are aligned. The slot on the coupler

should be pointing toward the side of the

machine for ease of assembly.

When the shafts are aligned the coupler on

the upper shaft will slide over the bottom

shaft and the spring pin, at location 3, will

engage the slot in the coupler. The bottom

shaft may need to be rotated slightly to align

the slot in the coupler with the spring pin.

2. If the shafts are not aligned, loosen the (4)

nuts at location 4 holding the lower spinner

shaft bearings to the chute. Slide the bot-

tom shaft until it is aligned with the top shaft

and the coupler engages the spinner shaft

spring pin.

Again, when the shafts are aligned, the cou-

pler on the upper shaft will slide over the

bottom shaft and the spring pin will engage

the slot in the coupler. The bottom shaft

may need to be rotated slightly to align the

slot in the coupler with the spring pin.

Check that the bottom shaft is vertical be-

fore retightening all hardware.

INSTALLATION OF

CAB CONTROL & ELECTRICAL WIRING

Use the bracket and hardware provided to

mount the cab control box at a convenient loca-

tion for the operator.

Connect the extension cable to the engine har-

ness. Route the extension cable along the RH

side of the hopper.

Determine the best location for running the ex-

tension cable into the truck cab. If a hole must

be drilled to pass the cable through the cab wall,

protect wires from sharp edges around the hole

with a grommet.

Connect the cab control box cable to the exten-

sion cable for operation of the spreader.

16 Optional Equipment

OPTIONAL EQUIPMENT

REF.

NO.

PART

NUMBER DESCRIPTION QTY.

REF.

NO.

PART

NUMBER DESCRIPTION QTY.

1

2

79201998

79202566

79202135

79202567

400-15052

79202565

Inverted V, 8’ Hopper

Inverted V, 8’ Hopper SS

Inverted V, 6 1/2’ Hopper

Inverted V, 6 1/2’ Hopper SS

Strap

Strap SS

1

1

1

1

2

2

3

4

5

950-001-089

031-09103

951-005-003

951-003-013

79202743

79202744

Hex Head Cap Screw 3/8-16 x 3/4

Hex Head Cap Screw 3/8-16 x 3/4 SS

Lock Nut 3/8-16 Nylon Insert

Lock Nut 3/8-16 Nylon Insert SS

Inverted V Gusset

Inverted V Gusset SS

12

12

12

12

2

2

DWG. NO. 6305

Adjustable Inverted V Kit No. 79202394 6 1/2 FT. Hopper, SS

Adjustable Inverted V Kit No. 79202042 8 FT. Hopper

Adjustable Inverted V Kit No. 79202395 8 FT. Hopper, SS

Inverted V Options

Optional Equipment 17

HINGED HOPPER GRIDS OPTION

DWG. NO. 6015

79202391 Hinged Hopper Grids Kit, 6 1/2 Ft. Hopper

79202392 Hinged Hopper Grids Kit, 8 Ft. Hopper

REF.

NO.

PART

NUMBER DESCRIPTION QTY.

REF.

NO.

PART

NUMBER DESCRIPTION QTY.

1

2

3

79202561

79202562

79202009

950-001-113

Screen, 8 Ft. Hopper

Screen, 6 1/2 Ft. Hopper

Screen Holdown

Hex Head Cap Screw 5/16-18 x 3/4 Gr. 5

2

2

2

6

4

5

6

7

951-005-036

79203146

950-001-089

951-002-003

Lock Nut 5/16-18 Mac Lock

Middle Grid Support

Hex Head Cap Screw 3/8-16 x 3/4 Gr. 5

Whiz Lock Nut 3/8-16

6

1

2

2

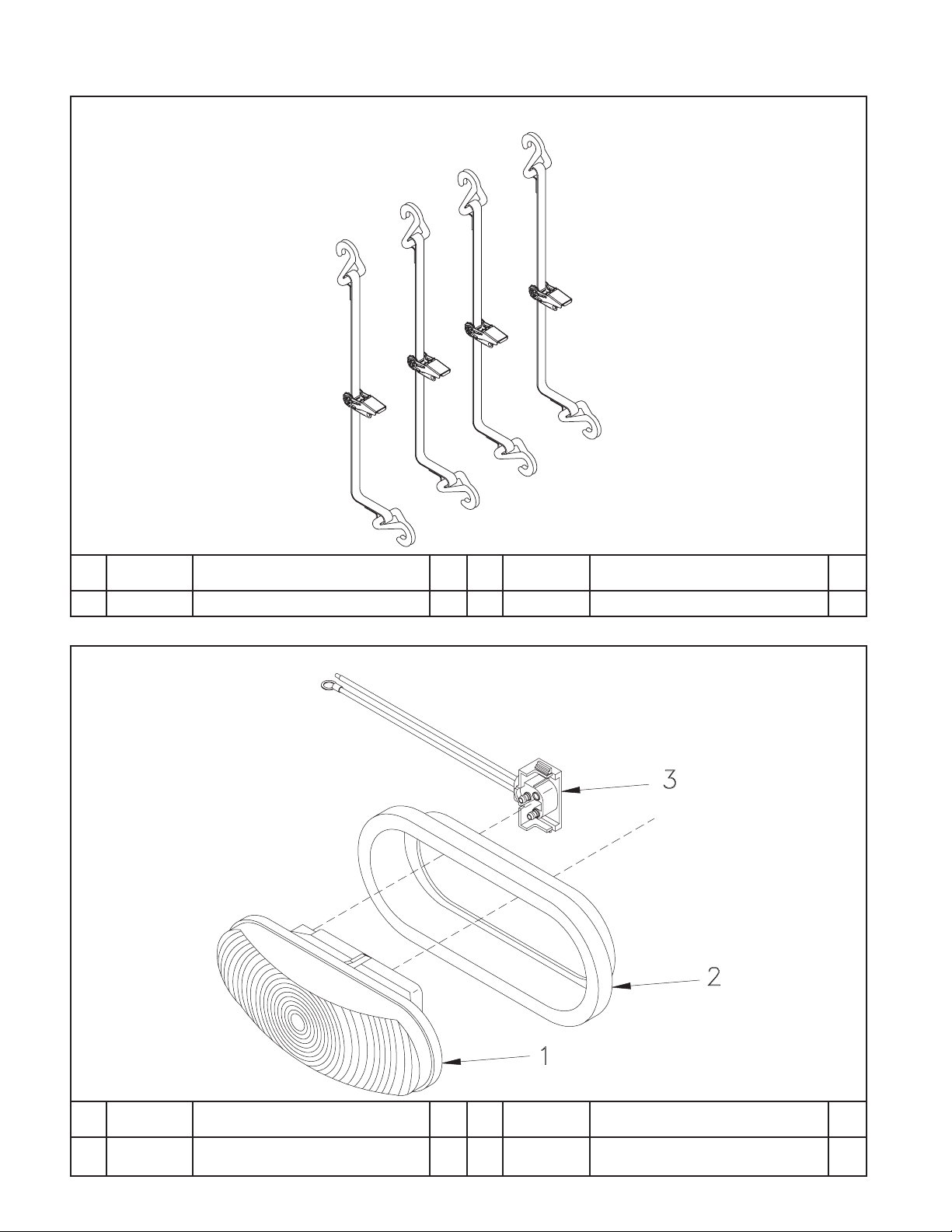

TARP KIT

DWG. NO. 6460

79203036 6 1/2 Foot Sander Tarp Assembly

79203037 8 Foot Sander Tarp Assembly

REF.

NO.

PART

NUMBER DESCRIPTION QTY. REF.

NO.

PART

NUMBER DESCRIPTION QTY.

1

2

3

79203033

79203032

79203031

79203029

Tarp Shurco 8’ Sander

Tarp Shurco 6 1/2’ Sander

Tarp Hook

LH Tarp Bracket

1

1

4

4

4

5

6

7

79203030

030-16041

033-12007

951-005-036

RH Tarp Bracket

Carriage Bolt 5/16-18 x 3/4 Gr. 5

SAE Flat Washer 5/16 Inch

Mac Lock Nut 5/16-18

4

4

4

4

18 Optional Equipment

TIE DOWN KIT

DWG. NO. 603979202393 Truck Hold Down Kit

REF.

NO.

PART

NUMBER DESCRIPTION QTY. REF.

NO.

PART

NUMBER DESCRIPTION QTY.

1 79202400 Ratchet Tiedown 4

BRAKE LIGHT KIT

DWG. NO. 367479202581 Brake Light Assembly

REF.

NO.

PART

NUMBER DESCRIPTION QTY. REF.

NO.

PART

NUMBER DESCRIPTION QTY.

1

2

79202091

79202092

Lamp

Grommet

1

1

3 79202093

79202089

Plug

Brake Light Assembly

1

This manual suits for next models

3

Table of contents

Other Hiniker Spreader manuals

Popular Spreader manuals by other brands

Gardena

Gardena Spreader L operating instructions

Brinly

Brinly PS10-70BH owner's manual

Earth Way

Earth Way 2600A-Plus Estate Assembly and operating instructions

Tube-Line

Tube-Line NITRO 575RS Operator's manual

Earth Way

Earth Way EV-N-SPRED C24HD Assembly and operating instructions

AIRFLO

AIRFLO PSV Operator and parts manual