September 11, 2014 [AIR-FLO MANUFACTURING CO., INC.]

UP SPREADER OPERATOR AND PARTS MANUAL

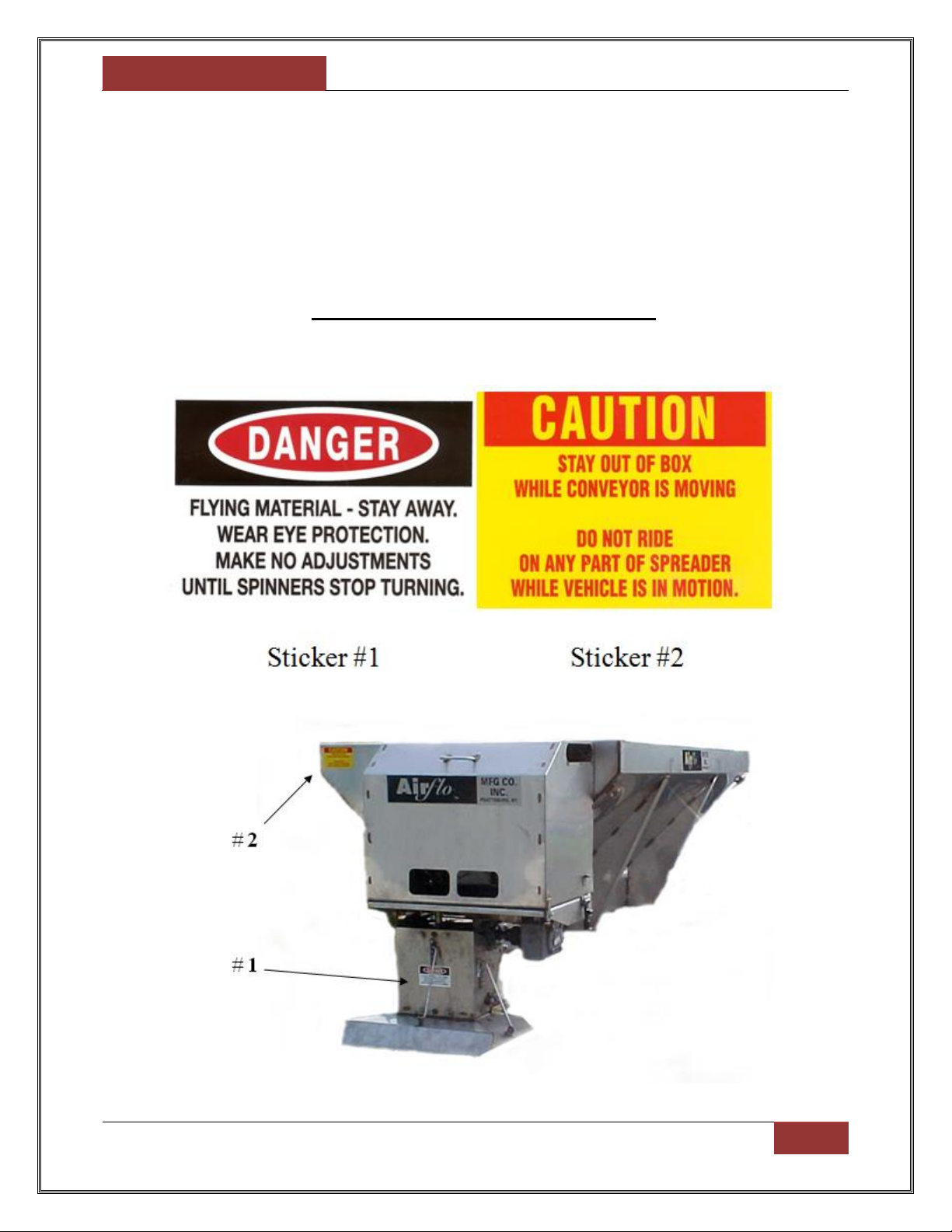

2.) Mounting the Spinner/Chute Assembly

a.) Attach the spinner/chute assembly to the spreader using the four (4)

3/8-16 X 5/8”hex head bolts, lock washers, and nuts. The head of the bolt is

to be placed on the inside of the chute assembly. Push the chute assembly

towards the cab of the vehicle. Loosely attach the hardware, but do not

tighten at this time.

b.) Install the roller chain between the sprocket mounted to the spinner/chute

assembly and the gearbox sprocket. Make sure both sprockets are in line with

one another. Tighten the gearbox sprocket set screw. Install the roller chain

master link.

c.) To adjust the roller chain tension, loosen the spinner shaft bearing bolts and

slide the shaft away from the gearbox sprocket. Be sure to maintain the

vertical alignment of the spinner shaft and the bearings before tightening the

hardware. The correct chain tension should allow for a 5/16”deflection

midway between both chain sprockets.

CAUTION! Do not over-tighten the chain tension. This can cause damage to

the chain, bearings, and gearbox.

d.) Install the chain guard using the three (3) 1/4-20 X 3/4”hex head bolts, lock

washers, and nuts

e.) Tighten all hardware to the recommended torque specifications as shown in

this manual.

SPREADER OPERATION:

NOTE: Before starting engine, follow all safety precautions.

1.) Control Panel Description:

a.) The clutch switch is a three position switch with the following functions:

1. “OFF”Position: While this switch is in this position and the engine is running,

the spreader feed chain and the spinner disk will remain non-operational.

(Meaning the ice control material will not be dispensed)

2. “ON”Position: While this switch is in this position and the engine is running,

the spreader feed chain and the spinner disk will dispense the ice control

material at the normal regulated rate.