Hiniker 600P User manual

POLY RECEIVER HITCH SPREADER

MODEL: 600P & 1000P

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

Please visit www.snowplows.hiniker.com to access the most recent version

PART NUMBER 25014940

TABLE OF CONTENTS

TO THE PURCHASER.................................................................................................................. 2

SAFETY...................................................................................................................................... 3-4

OPERATING PROCEDURES .................................................................................................... 5-9

General Information................................................................................................................ 5

Sander Control Box................................................................................................................ 5

Spread Control ....................................................................................................................... 7

Transporting Spreader ........................................................................................................... 7

Spreader Optional Equipment................................................................................................ 7

Swing Away Kit....................................................................................................................... 8

Vibrator Kit.............................................................................................................................. 8

Storage................................................................................................................................... 9

MAINTENANCE & SERVICE PROCEDURES............................................................................ 10

TROUBLE SHOOTING ................................................................................................................11

INSTALLATION INSTRUCTIONS .......................................................................................... 12-14

SPECIFICATIONS....................................................................................................................... 15

WARRANTY ................................................................................................................................ 17

Table of Contents 1

25014940 10/23 Hiniker/25014940

TO THE PURCHASER

2 To The Purchaser

This product is designed and manufactured to

give years of dependable service, when properly

maintained and used for the purpose for which

it is intended. Never allow anyone to operate

this equipment until they fully understand the

complete contents of this manual. It is the

responsibility of owners who do not operate this

equipment to ensure the operator is properly

instructed and understands the contents of this

manual. It is also the owner’s responsibility to

ensure that anyone operating this equipment is

mentally and physically capable of so doing.

Important information is contained in this manual

to help ensure safe and efficient operation.

If you have any questions about this manual, or

the equipment discussed herein, contact your

Hiniker dealer.

This is a safety alert symbol. It alerts

an operator to information concerning

personal safety. Always observe and

heed these instructions, otherwise death, or

serious injury can result!

All references to LEFT or RIGHT mean viewing

the spreader from the rear and facing the truck.

This Operator’s manual is shipped with this

equipment. Contact your Hiniker dealer for

additional copies.

Always obtain original Hiniker service parts.

Substitute parts could adversely affect

equipment performance and warranty.

Check that your dealer has forwarded the

Hiniker delivery report copy and the machine

serial number to maintain maximum service

and warranty benefits. This does not put you on

any mailing list and information thereon is not

available to others.

Your spreader’s identification number plate is at

the location shown below.

Record the following information for later

reference when obtaining service parts:

Purchase Date

Purchaser’s Name

Dealer’s Name

Machine Serial No.

This is a safety alert symbol. It alerts

an operator to information concerning

personal safety. Always observe and

heed these instructions, otherwise death or

serious injury can result!

Operator safety is a principle concern in

equipment design and distribution. However,

many accidents occur because a few seconds

of thought, and a more careful approach to

handling, were ignored.

Accidents can be avoided by knowing and

following the precautions cited in this manual.

GENERAL SAFETY

1. Read this manual thoroughly. Make sure

the operator understands it and knows

how to operate this equipment safely.

This equipment can injure an untrained or

careless operator and bystanders. If you

sell this equipment, ensure the new owner

acknowledges receipt of this manual.

2. Make sure all safety guards are securely

mounted in place before operating this

spreader.

3. Do not attempt to handle or service this

equipment, or direct others to do the same,

unless you know how to do it safely and

have the proper tools for the job.

4. Keep hands, feet, hair, and clothing away

from moving/rotating parts. Flying material

can cause bodily injury. Wear eye protection.

5. Do not alter the equipment to the extent of

compromising safety or performance.

6. Material to be spread can be dangerous.

Improper selection, application, use or

handling may be a hazard to persons,

vehicle or other property. Follow instructions

and precautions given by the material

manufacturer.

SAFETY

7. Do not over-load your vehicle beyond

payload limits. If there are any questions,

contact the vehicle manufacturer.

8. Make sure spreader is securely fastened to

vehicle in accordance with this manual.

9. Do not operate a spreader in need of

maintenance or repair.

BEFORE OPERATION

1. Discipline yourself to visually check for

worn, damaged or cracked parts before

starting use. Replace these with genuine

Hiniker parts.

2. Check all controls and operating functions

of machine in a safe area before starting to

work.

3. Do not adjust or clean machine while it

is running. After making adjustments,

check machine thoroughly for loose parts,

hardware and tools.

4. Always disconnect wiring harness before

removing or replacing any electrical

components.

5. Verify hardware attaching safety cable to

cover and hopper is tight.

6. Make sure cover rubber latches are securely

fastened before driving motor vehicle.

Safety 3

4 Safety

DURING OPERATION

1. Drive carefully and always wear seat belts

when operating a motor vehicle. Braking

distance may be increased and handling

characteristics impaired due to extra weight

of spreader.

2. Ensure everyone is clear of machine,

especially away from blind areas of the

operator, before starting or operating this

equipment.

3. Stay out of hopper when auger power

source is engaged. If machine becomes

plugged or material bridges, do not attempt

to remove blockage until machine has been

shut o and auger and spinner movement

have stopped.

Use a shovel or other long-handled tool to

reach inside hopper. Never attempt to break

up material inside hopper with hands or feet.

4. Set brakes and stop truck’s engine before

adjusting or servicing your spreader.

AFTER OPERATION

1. Inspect spreader for components that have

become excessively worn or damaged and

must be repaired or replaced.

2. Develop a regular maintenance schedule

to ensure safe, dependable spreader

operation.

3. Never use swing away hopper feature with

material in spreader.

4. Never remove spreader with material in

hopper.

5. Disconnect power before servicing

equipment.

6. DO NOT leave unused material in hopper.

Material will freeze up or solidify causing

unit to malfunction. Empty and clean after

each use.

OPERATING PROCEDURES

GENERAL INFORMATION

Hiniker spreaders are capable of dispersing

a variety of dry materials for control of ice on

roadways, walkways and parking lots.

Vehicle load carrying capacity limits the

maximum load that can be safely transported,

which could be less than the volumetric capacity

of the spreader. Check the vehicle’s load rating

certication sticker and DO NOT overload

the vehicle beyond its Gross Vehicle Weight

Rating (GVWR) or its Gross Axle Weight Rating

(GAWR). Check carrying capacity of 2” receiving

hitch on vehicle. Be sure not to overload hitch.

Overloading could result in an accident or

damage to vehicle and spreader.

An alternator rated for 135 amps or higher is

recommended.

Use the following tables to calculate vehicle

payload when material is loaded in the spreader.

VOLUMETRIC CAPACITY:

(Cubic Feet, Approx.)

LEVEL

Hopper Capacity Model 600P 6

Hopper Capacity Model 1000P 10

WEIGHT: (Pounds, Approx.)

Hopper Assembly Model 600P 120

Hopper Assembly Model 1000P 136

MATERIAL WEIGHTS:

(Pounds Per Cubic Feet, Approx)

Rock Salt, Dry 80 - 90

Salt Sand Mix, Dry * 95 - 120

* A 1:1 ratio recommended for salt/sand mix to

prevent material from freezing.

Calculate total material weight by multiplying

pounds per cubic foot by cubic foot of material.

Always examine spreader for worn or damaged

components prior to operation. During operation,

listen for unusual noise from spreader that

might indicate component failure. Never run a

machine in need of repair.

Verify cover rubber latches are secure and

safety cable hardware is tight before operating

and driving of motor vehicle.

Start spreader for a short period of time before

loading material to test for proper function of

moving parts.

After loading, run spreader in an isolated area,

clear of people, to become familiar with controls

and to verify correct spread pattern.

Do not load material the night before or material

may take in moisture and solidify before

operation. Load material right before use to

avoid material solidifying.

If material bridges or solidifies remove all

material from hopper.

Do not leave unused material in hopper

overnight. Remove all material from hopper

after each day’s use.

SANDER CONTROL BOX

Hiniker controllers are equipped with variable

material feed, blast control, and a push button for

an optional vibrator. The variable speed knob is

clearly marked with full counterclockwise(CCW)

being minimum speed/power and full clockwise

(CW) being maximum speed/power.

Operating Procedures 5

6 Operating Procedures

To turn on controller, push and hold power

button until push button illuminates red in color.

The Hiniker controller will pulse the drive motor

on and off a few times then drive motor at full

power for a short duration to loosen material

in hopper. The motor will then go to operator’s

preset speed. The speed will be shown by which

numbers are illuminated red on the dial.

Example: If numbers up to 5 are red in color,

spreader is set for speed setting 5.

An optional vibrator is available which helps

keep a steady flow of material onto spinner. It

also slightly increases rate at which material is

applied because a vibrator helps to put maximum

amount of material onto conveying mechanism.

To activate vibrator, push vibrator button until

light beside “Vibrator” button is illuminated

green in color.

Important: Vibrator should be used only when

necessary. Excessive use of vibrator may

damage hopper. Vibrator is recommended to

only be used when hopper is about 1/2 to 1/3

full until empty. Vibrator is also necessary when

material is damp. Vibrator should be turned

on for short durations of time to help with

material flow but is not recommended to be ran

continuously at any time.

Blast feature is used for slippery spots that need

excess salt/sand. When blast button is held

down material feed drive system runs at full

power applying maximum amount of material.

Light beside “Blast” button will illuminate green

when blast feature is active. Once button is

released blast feature will stop, and normal

preset application will resume.

Hiniker has safety features built into the controller

to protect its electrical components and motors.

When a potentially damaging overload occurs

the controller variable speed knob will flash

red. The controller will then reduce the amount

of voltage allowed to the motor and pulse the

motor for 1 minute.

This is an attempt to loosen frozen, wet, or

clumping material. If the motor is still drawing

too many amps after 1 minute the controller will

then stop sending power to motor and controller

will continue to flash red.

Operating Procedures 7

When this happens the spreader is most likely

jammed with frozen, wet, or clumping material.

The operator will need to get out of truck to

investigate cause of jam.

Before checking hopper be sure controller is

turned off and vehicle is off and in park with

ignition key in operator’s pocket.

Hiniker spreaders are equipped with a bottom

hopper slide gate to make checking material

jams easier. This gate is also used to empty

material out of hopper after each days use or to

empty hopper if frozen, wet, or solidied material

is in hopper.

To open bottom slide gates rst loosen wing nut

on both slide gates. Pull on outer formed edge

of both gates simultaneously to open. Remove

blockage and then slide gates until they are

almost touching auger tube and retighten wing

nuts. Dry material may now be put into hopper.

Controller will need to be shut o and back on to

resume material spreading.

SPREAD CONTROL

Spread pattern is controlled by (2) variables

motor speed and vehicle speed. The drive and

spinner motor are coupled together making them

run at the same RPM. As the drive motor is sped

up the material feed rate is increased. This also

increases the speed of the spinner making a

wider less populated spread pattern. If the motor

is ran at a slower speed the feed rate decreases.

This will decrease the spinner speed and cause

a smaller but heavier populated spread pattern.

The other variable is vehicle speed, a slower

vehicle speed results in heavier populated

spread pattern.

TRANSPORTING SPREADER

When transporting Hiniker spreaders it is

essential that the spreader is tied down using

ratcheting tie down straps to the rear corners of

the spreader (as shown).

It is recommended to attach tie downs so they

are pulling at a frontward and upward angle.

This will help take some of the weight off the

receiver hitch as well as stabilizing the spreader.

It is recommended to attach the ratchet straps

to the tie downs in the bed of the truck.

WARNING: Verify cover is secure to

hopper before transporting vehicle or

death, injury, or vehicle damage could

occur.

It is important to verify cover is secured to

hopper using rubber latches before transporting

spreader or a potentially dangerous situation

may occur. Also verify safety cable hardware is

tight and cables are in good working condition.

8 Operating Procedures

SWING AWAY KIT (Optional)

Hiniker Swing Away Kit makes loading of pallets

of bagged material into the back of a vehicle

easier. The swing away option can only be used

when the hopper is completely empty.

For loading material into back of vehicle remove

pin. Lift up on rear of spreader hopper frame

while pulling out or away from vehicle to unhitch

hopper from swing away frame. Swing hopper

out of bed area to allow material to be loaded

into rear of vehicle.

To relock hopper in place, swing hopper until

prong touches receiver tube. Lift up on back

of spreader hopper frame and push prong into

receiver tube. Push hopper in until hitch pin can

be inserted locking hopper to receiver frame.

Insert hitch pin and secure with hairpin.

DWG NO. 7272

VIBRATOR KIT (Optional)

Hiniker vibrator kit is to eliminate bridging and

assure continuous ow of dry material to the

auger.

Important: Vibrator should be used only when

necessary. Excessive use of vibrator may

damage hopper. Vibrator is recommended to

only be used when hopper is about 1/2 to 1/3

full until empty. Vibrator is also necessary when

material is damp. Vibrator should be turned

on for short durations of time to help with

material flow but is not recommended to be ran

continuously at any time.

Operating Procedures 9

STORAGE

Store spreader in a cool dry protected area

when it will not be used for an extended period

of time. Never attempt to remove spreader with

material in hopper. Perform these maintenance

procedures at end of season to ensure machine

remains in good operating condition:

1. Unload hopper completely and wash to

ush out any remaining material to prevent

material buildup. Do not pressure wash

motor or electrical components or damage

will occur.

2. Disconnect and remove controller from

spreader. Store in a cool dry place. Summer

temperatures and climate could damage

circuit boards and void warranty.

3. Apply a light coat of dielectric grease to all

electrical terminals, and cap or tape loose

terminals to prevent damage or corrosion.

4. Inspect for worn or damaged components.

Repair or replace as needed.

10 Maintenance & Service Procedures

MAINTENANCE & SERVICE PROCEDURES

Dependable spreader operation is a result

of following good maintenance procedures.

Inspect your spreader frequently to ensure that

all parts are working smoothly, and develop a

schedule for maintenance at required intervals.

GENERAL

Always disconnect power from wiring harness

before servicing or replacing any electrical

components. Prior to operation of a new

spreader, or one that has been stored, inspect

all hardware and verify proper torque on all

bolts and nuts in accordance with recommended

torque specifications.

1 or 2 58

Manufacturer marks may very.

These are all SAE Grade 5 (3 - line).

DWG. NO. 1935

TABLE 1 RECOMMENDED TORQUE VALUES FOR INCH FASTENERS

(ZINC COATING & LUBRICATED)**

Nominal

Size

SAE 5

120,000 psi

Min Tensile Str

lbf - ft

SAE 8

150,000 psi

Min Tensile Str

lbf - ft

Dry Lubricated Dry Lubricated

1/4-20 8 6 12 9

5/16-18 17 13 25 18

3/8-16 30 23 45 35

1/2-13 75 55 110 80

5/8-11 150 110 220 170

** MACHINE DESIGN FASTENER AND JOINT REFERENCE ISSUE

Loose bolts can cause hole elongation and

part failure resulting in dangerous operating

conditions and equipment breakdown.

Check all hardware periodically during operation

and keep tightened to specified torques. Replace

worn bolts and locknuts, as needed.

Apply a light coat of dielectric grease to all

electrical connectors to prevent corrosion of

contacts when connectors are unplugged, and

to make connecting and disconnecting plugs

easier.

Remove all material from hopper and wash salt

and dirt off spreader before storage. Do not

pressure wash motor or electrical components

as damage may occur.

Never leave material in hopper overnight.

Material may freeze or solidify and seriously

damage spreader or components.

Controller is not serviceable. If controller does

not function a new one must be purchased.

Trouble Shooting 11

Preliminary Checks:

– Be sure all electrical connections are tight and clean.

– Be sure nothing is jammed in hopper or spinner.

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

No power to cab

Power switched to ON position

No illumination of indicator light

Controller plug is loose

Blown fuse

Check plug connection at cab

control

Replace fuse

Faulty battery Check battery voltage should be

between 13 - 15 Volts with vehicle

running

Vehicle wiring harness damaged

between battery and controller

Repair/Replace damaged wires

or harness as required.

Control Dial does not change

speed

Controller does not function

Malfunctioning cab control Replace controller

Wiring harness is damaged or

has a short between cab control

and spreader

Check plug connections at cab

controller and spreader motors

Material feed motor does not

operate

Controller display blinks red

Material feed jam Remove obstruction

Frozen material

Solidied or clumping material

Thaw material

Replace material

Slide gates too tight on auger

shaft

Increase clearance between slide

gates and auger shaft

Material jammed between slide

gates and auger tube

Remove jammed material

Motor doesn’t run Loose electrical connections Check/tighten all connections

Jammed material feed/spinner Remove obstruction

Motor seized Replace motor

Material not owing from hopper Wet or Frozen material Replace with Dry material

Material feed jammed Remove obstruction

Material bridge Remove bridge

12 Installation Instructions

1 or 2 58

Manufacturer marks may very.

These are all SAE Grade 5 (3 - line).

DWG. NO. 1935

TABLE 1 RECOMMENDED TORQUE VALUES FOR INCH FASTENERS

(ZINC COATING & LUBRICATED)**

Nominal

Size

SAE 5

120,000 psi

Min Tensile Str

lbf - ft

SAE 8

150,000 psi

Min Tensile Str

lbf - ft

Dry Lubricated Dry Lubricated

1/4-20 8 6 12 9

5/16-18 17 13 25 18

3/8-16 30 23 45 35

1/2-13 75 55 110 80

5/8-11 150 110 220 170

** MACHINE DESIGN FASTENER AND JOINT REFERENCE ISSUE

MOUNTING SPREADER

1. Remove spreader from shipping container.

2. Remove zip tie securing grid to hopper.

Carefully remove grid from hopper to access

parts box.

3. Remove Hiniker controller, wiring harness,

ratchet straps, etc from parts box.

Verify everything has been removed from inside

the hopper.

INSTALLATION INSTRUCTIONS

4. Reassemble hopper grid and hopper cover

onto hopper assembly. Securely fasten

rubber latches.

5. Assemble 2” receiver assembly onto front

side of hopper assembly using provided

1/2” hardware, if not already assembled.

6. With hopper near 2” receiver on vehicle. Tip

spreader back and align bottom edge of 2”

spreader tube with vehicle 2” receiver. Slide

2” tube partially in and lift up while pushing

in to fully mount spreader in vehicle.

7. Secure spreader in place using provided

5/8” hitch pin and hairpin.

Installation Instructions 13

8. Use ratcheting tie down straps to secure

hopper to truck bed built in tie downs.

CONTROL BOX AND VEHICLE

WIRING INSTALLATION

Locate wiring harness removed from inside

hopper assembly.

To insure good performance of your spreader,

check condition of trucks electrical system.

Using a voltmeter, check alternator and battery

voltage. With engine running and headlights and

heater fan on, a good voltage reading should fall

between 13.0 and 15.3 volts. If reading falls out

of this range, check and adjust your electrical

system.

Refer to drawing 7295 on following page. Lay

out a wiring path for spreader wiring harness.

Connect wiring harness connectors to their

mating connectors on drive motor and vibrator

(if equipped). Drill all necessary holes or use

existing ones to pass connectors into truck cab.

Attach harness to truck frame. Do not route

wiring harness near exhaust system, or harness

may melt and short electrical system.

Mount controller in a convenient location in truck

cab. Do not mount controller directly in front of

heater vents, as this will raise temperature of

controller significantly and may cause damage

to your spreader controller.

CAUTION: Do not install controller in

deployment path of an air bag. Refer

to vehicle manufacturer’s manual for

air bag deployment areas.

Attach mating connectors between wiring

harness and cab controller.

CAUTION: Make sure power switch

on controller is off before connecting

power cable.

Lay out a path for power cable in truck’s engine

compartment. Drill a hole in firewall or use

an existing one to pass wiring harness. It is

recommended to pass power cable from inside

of cab to battery due to a large high amperage

connector. Do not route close to engine or

exhaust system, or harness may melt and short

electrical system.

Refer to drawing 7295 on following page.

Connect black lead to battery ground (-) terminal.

White is attached to positive (+) post of battery.

Connect power cable to controller.

Push on/off button on controller to check for

power. When power has been confirmed turn

power off. Electrical installation now is complete.

Refer to “Operating Procedures Section” for

more information on controller function.

DWG. NO. 7295

14 Installation Instructions

Specifications 15

SPECIFICATIONS

DIMENSIONS: 600P HOPPER 1000P HOPPER

Overall Length 25 Inches 29 1/2 Inches

Overall Width 32 Inches 38 1/4 Inches

Overall Height 36 1/2Inches 39 Inches

Hopper Length 24 Inches 28 Inches

Hopper Width 30 Inches 35 1/2 Inches

CAPACITY: Cubic Foot

Level 610

Weight: Model Hopper Only 120 lbs. 136 lbs.

AUGER:

Auger Diameter: 6 Inches 6 Inches

Electric Drive

Drive Motor 1/3 HP 12 V DC Electric Motor

Spinner Diameter: 10 Inches 10 Inches

Shaft Diameter: 3/4 Inch 3/4 Inch

Spreader Pattern Up To 25 Feet Up To 25 Feet

16 Notes

NOTES:

Hiniker Warranty 17

HINIKER SPREADER LIMITED WARRANTY

The only warranty Hiniker Company (Hiniker) gives and the only warranty that any Hiniker dealer is authorized to

give on behalf of Hiniker is as follows: (NO EMPLOYEE OR REPRESENTATIVE IS AUTHORIZED TO CHANGE

THIS WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY.)

Hiniker warrants to the original purchaser of a Hiniker spreader that Hiniker will repair or replace any defects

in material and workmanship that occur within two years from date of retail delivery except the following items:

Hiniker warrants that it will repair or replace any defects in materials or workmanship with respect to the paint

nish, any accessories, and service parts and components for a period of one year from date of retail delivery.

Hiniker’s obligation and liability under this warranty is expressly limited to repairing or replacing, at Hiniker’s

option, at an authorized Hiniker dealer location, the defective parts at no charge to the original purchaser.

HINIKER MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED AND MAKES NO WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR ANY PARTICULAR PURPOSE.

HINIKER’S OBLIGATION UNDER THIS WARRANTY SHALL NOT INCLUDE ANY TRANSPORTATION

CHARGES TO OR FROM THE AUTHORIZED HINIKER DEALER LOCATION OR ANY LIABILITY FOR

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGE OR DAMAGES OF ANY KIND FOR LOST PROFITS

OR DELAY. If requested by Hiniker, products or parts for which a warranty claim is made are to be returned freight

prepaid to our factory. Any improper use, operation beyond rated capacity, substitution of parts not approved by

Hiniker Company, or any alteration or repair in such manner as in our judgment aects the product materially and

adversely shall void this warranty.

Hiniker reserves the right to make improvements or changes to any of it’s products without notice. Such

improvements or changes shall not trigger any obligation by Hiniker to update, modify or change any products

previously sold by Hiniker.

HINIKER does not warrant the following:

1. Used products.

2. Any product that has been repaired, modied or altered in a way not approved by Hiniker Company.

3. Depreciation or damage caused by normal wear, lack of reasonable and proper maintenance, failure

to follow Operators Manual Instructions, misuse, lack of proper protection during storage, or accident.

4. Parts replacement and service necessitated by normal wear or maintenance including, but not limited

to, auger ighting, electric motor, and spinner disc.

5. Paint nish damage caused by normal wear.

Hiniker does not assume any liability for any damage to a motor vehicle resulting from the attachment or use

of a Hiniker spreader. Compliance with applicable motor vehicle regulations is the responsibility of the installer.

Attachment of a Hiniker spreader to a motor vehicle is at the risk of the purchaser.

It is the responsibility of the original spreader purchaser to verify the original date of purchase.

Dealer must submit PRODUCT REGISTRATION and ll out a DELIVERY REPORT FORM online within 30 days

of retail delivery to initiate the warranty coverage.

HINIKER COMPANY

58766 240th Street

Mankato, MN 56001

PHONE 800-433-5620 -- FAX (507) 625-5883

https://snowplows.hiniker.com/

HINIKER WARRANTY

This manual suits for next models

1

Table of contents

Other Hiniker Spreader manuals

Popular Spreader manuals by other brands

Blizzard

Blizzard LP-10 owner's manual

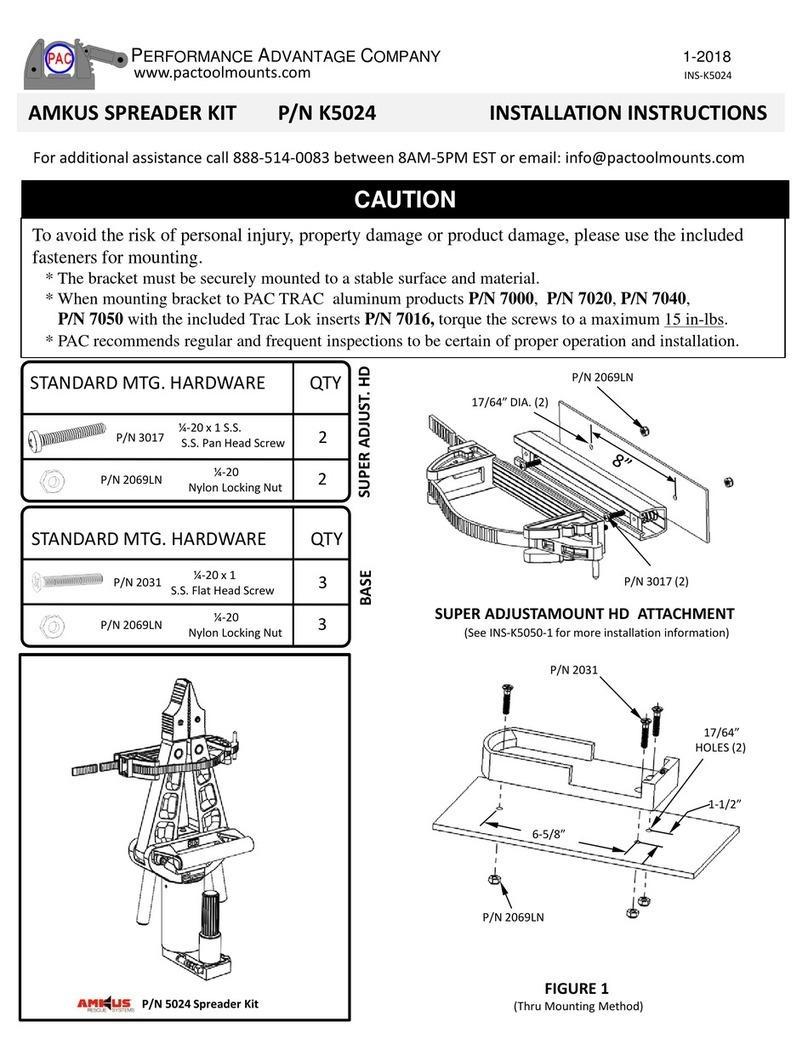

PERFORMANCE ADVANTAGE COMPANY

PERFORMANCE ADVANTAGE COMPANY K5024 installation instructions

Phoenix

Phoenix SPC10e instruction manual

AGREX

AGREX XDI 1500 User and maintenance manual

Echo

Echo RB-100S Operator's manual

New Leader

New Leader L5034 G4 Assembly/operators/parts manual