1. Safety Summary

3

even the specialized units cannot be used.

These products should not be installed in such

locations.

• Do NOT install this unit in any place where

silicon gases can coalesce. If the silicon gas

comes into contact with the surface of the heat

exchanger, the finned surfaces repel water. As a

result, moisture can enter from the condensate

pan into the electrical box, possibly causing

electrical failures.

• Do not place any flammable items or anything

that can cause a fire on or around the outdoor

unit. It may cause a fire.

• During the test run, check the unit’s operation

temperature. If the unit is used in an

environment where the temperature exceeds

the operation boundary, it may cause severe

damage. Check the working range in the

manual.

• The A-weighted emission sound pressure level

does not exceed 70 dB (A).

Installation Precautions

WARNING

To reduce the risk of serious injury or death,

the following installation precautions must be

followed.

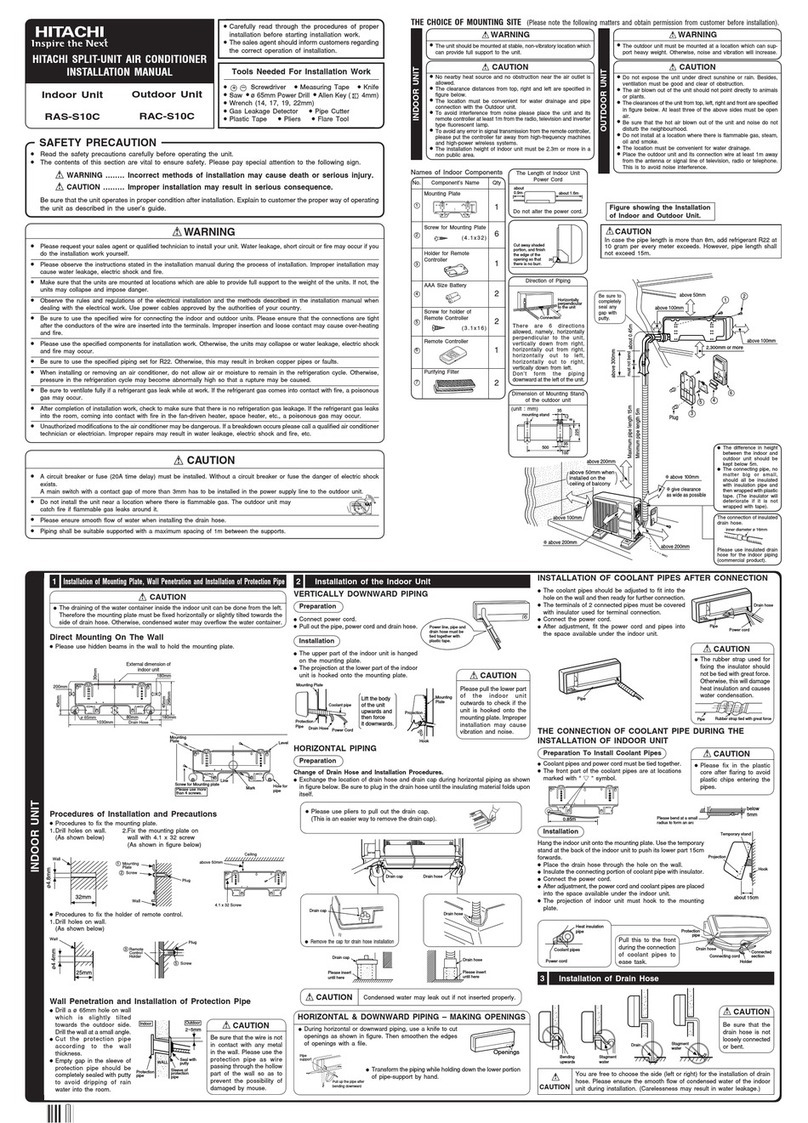

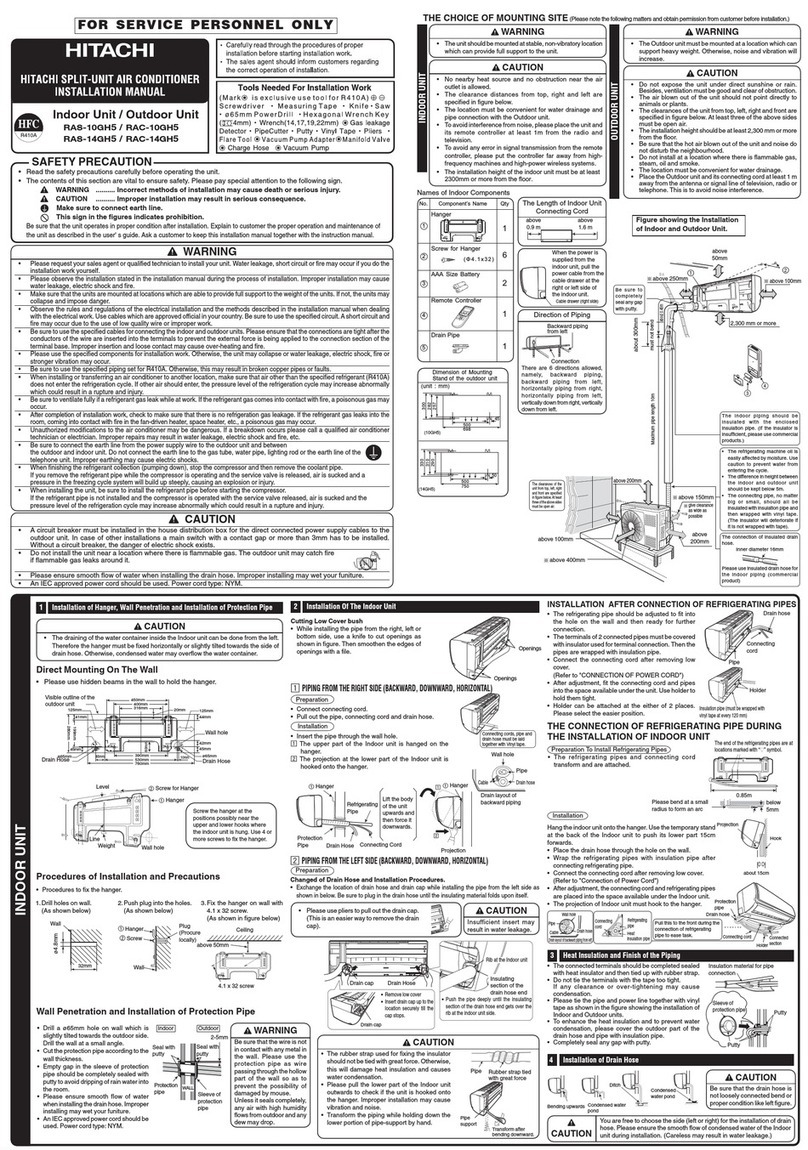

• When installing the unit into:

○A wall: Make sure the wall is strong enough

to hold the unit’s weight. It may be

necessary to construct a strong wood or

metal frame to provide added support.

○A room: Properly insulate any refrigerant

piping run inside a room to prevent

"condensation" that can cause dripping and

water damage to wall and floors.

○Damp or uneven areas: Use a raised

concrete pad or concrete blocks to provide

a solid, level foundation for the unit to

prevent water damage and abnormal

vibration.

○An area with high winds: Securely anchor

the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

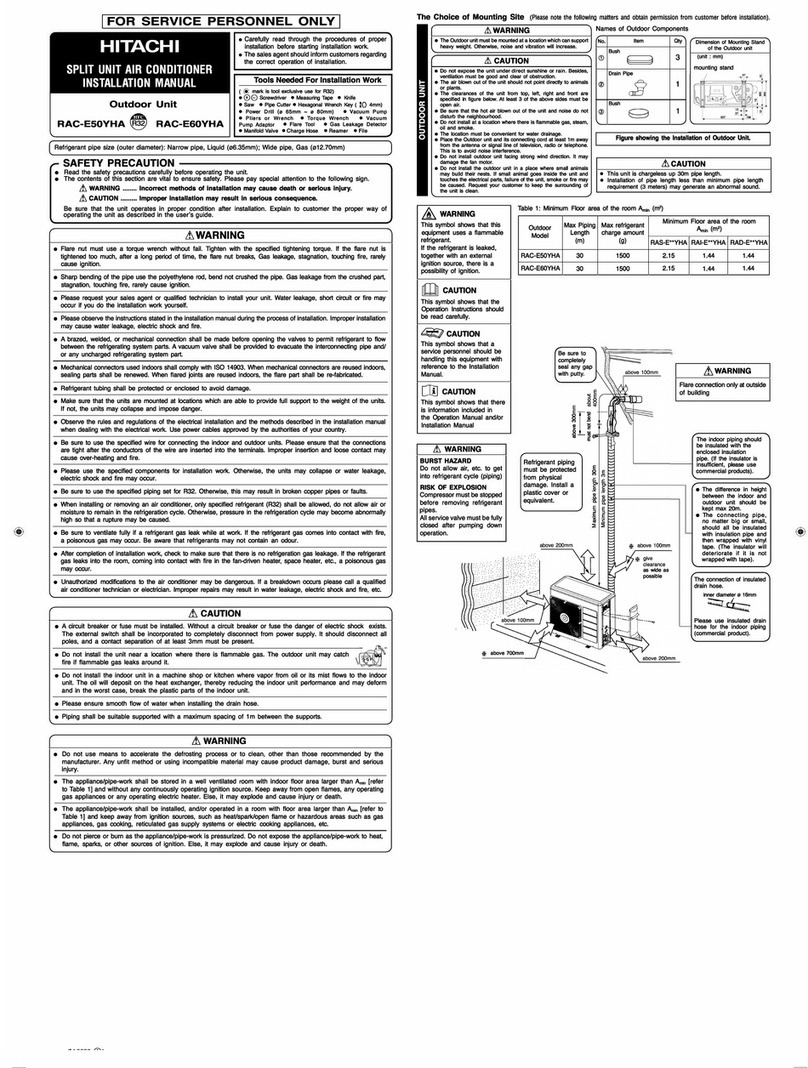

• Do NOT install the unit in the following places.

Doing so can result in an explosion, fire,

deformation, corrosion, or product failure.

○Explosive or flammable atmosphere

○Where a fire, oil, steam or powder can

directly enter the unit, such as nearby or

above a kitchen stove.

○Where oil (including machinery oil) may be

present.

○Where corrosive gases such as chlorine,

bromine, or sulfide can accumulate, such as

near a hot tub or a hot spring.

○Where dense, salt-laden airflow is heavy,

such as in coastal regions.

○Where the air quality is of high acidity.

○Where harmful gases can be generated from

decomposition.

• Do NOT position the condensate pipe for the

indoor unit near any sanitary sewers where

corrosive gases may be present. If you do, toxic

gases can seep into breathable air spaces and

can cause respiratory injuries. If the condensate

pipe is installed incorrectly, water leakage and

damage to the ceiling, floor, furniture, or other

possessions may result. If the condensate

pipe becomes clogged, water may drip from

the indoor unit. Do NOT install the indoor

unit where such dripping can cause moisture

damage or at uneven locations.

• During transportation, do NOT allow the

backrest of the forklift make contact with the

unit, otherwise, it may cause damage to the

heat exchanger and also may cause injury

when stopped or started suddenly.

• Before performing any brazing work, be sure

that there are no flammable materials or open

flames nearby.

• Remove gas inside the closing pipe when the

brazing work is performed. If the brazing filler

metal is melted with remaining gas inside, the

pipes will be blown off and it may cause injury.

• Be sure to use nitrogen gas for the airtight test.

If other gases such as oxygen gas, acetylene gas

or fluorocarbon gas are accidentally used, it

may cause an explosion or gas intoxication.

• Perform a test run to ensure normal operation.

Safety guards, shields, barriers, covers, and

protective devices must be in place while the

compressor/unit is operating. During the test

run, keep fingers and clothing away from any

moving parts.

• Do NOT install the indoor unit anywhere

discharge airflow can pass directly toward

nearby heating equipment (space heaters). It

may interfere with the combustion process in

these units.

• When the indoor unit is operating with heating

equipment, ventilate the room sufficiently. Any

leaked refrigerant gas that happens to come

into contact with any heat source can become