-8-

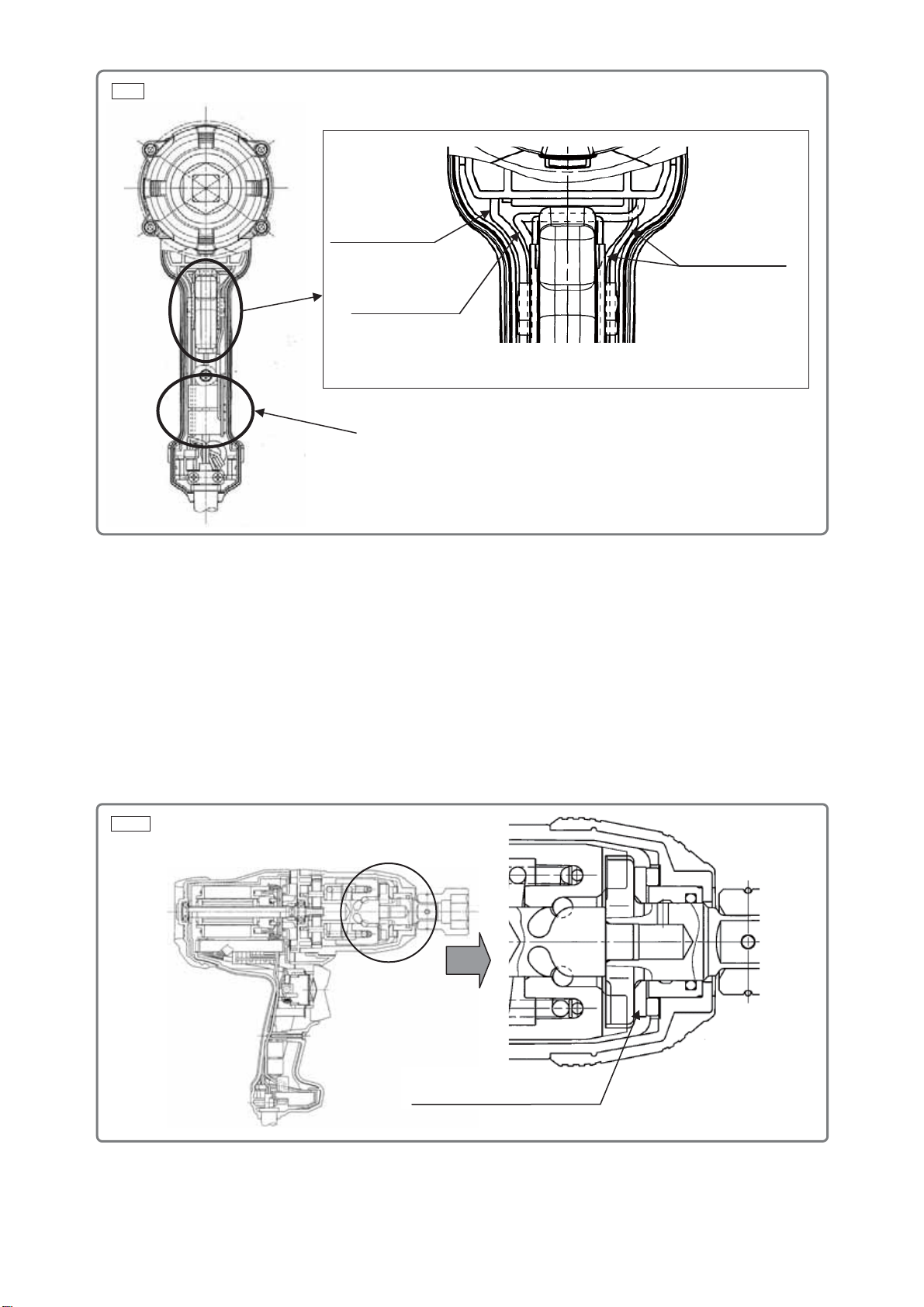

(1) Apply Nippeco SEP-3Agrease (Code No. 930035 (100 g)/930038 (2.5 kg)) to the following:

•Pinion tooth flanks of Rotor Ass’y (D) [29]

•Tooth flanks of the Ring Gear [23]

•Two Gear Shafts [19]

•Tooth flanks and inner circumference of the Idle Gear Set (2 pcs.) [21]

(2) Apply Doubrex 251 grease to the following:

•Between Hammer (D) [11] and Spring Seat [15]

•Inside of Hammer Case (D)Ass’y [1]

•Spindle [20]: Cam groove, sliding portion, and engaging portions with the Anvil [9] and Metal (E) [25]

•Cam groove and raised portions of Hammer (D) [11]

•Anvil [9]: 13 mm dia. hole, sliding portion with Washer (F) [8], claw, and sliding portion with the O-ring

•Two Steel Balls D7.14 [10]

•Thirty-eight Steel Balls D3.97 [12]

•Both end surfaces of Washer (D) [6] and Damper (D) [7]

•Seal Lock Hex. Socket Hd. Bolt M5 x 45 [3]----------------------------7.8 ± 1.5 N•m (80 ± 15 kgf•cm)

•Tapping Screw (W/Flange) D4 x 35 (Black) [37]-----------------------2.0 ± 0.5 N•m (20 ± 5 kgf•cm)

•Hex. Hd. Tapping Screw D4 x 60 [32] ------------------------------------2.0 ± 0.5 N•m (20 ± 5 kgf•cm)

•Button Bolt M4 [44]------------------------------------------------------------1.8 ± 0.4 N•m (18 ± 4 kgf•cm)

•Tapping Screw (W/Flange) D4 x 16 [46]---------------------------------2.0 ± 0.5 N•m (20 ± 5 kgf•cm)

Check the following after reassembly:

(1) Operate the Switch [39] and check that the switch moves smoothly and the switch operations (ON,

OFF, forward and reverse) are normal.

(2) Press the Switch [39] in “R” direction and slowly release the switch. Check that the switch returns to

the original position. Then press the Switch [39] in “L” direction and slowly release the switch. Check

that the switch returns to the original position.

(3) Check that the rotational direction of Anvil [9] matches the direction of rotation made when you press

the Switch [39]. When the Switch [39] is set to the “R” position, the Anvil [9] must rotate clockwise as

viewed from the rear (opposite to the Anvil [9].)

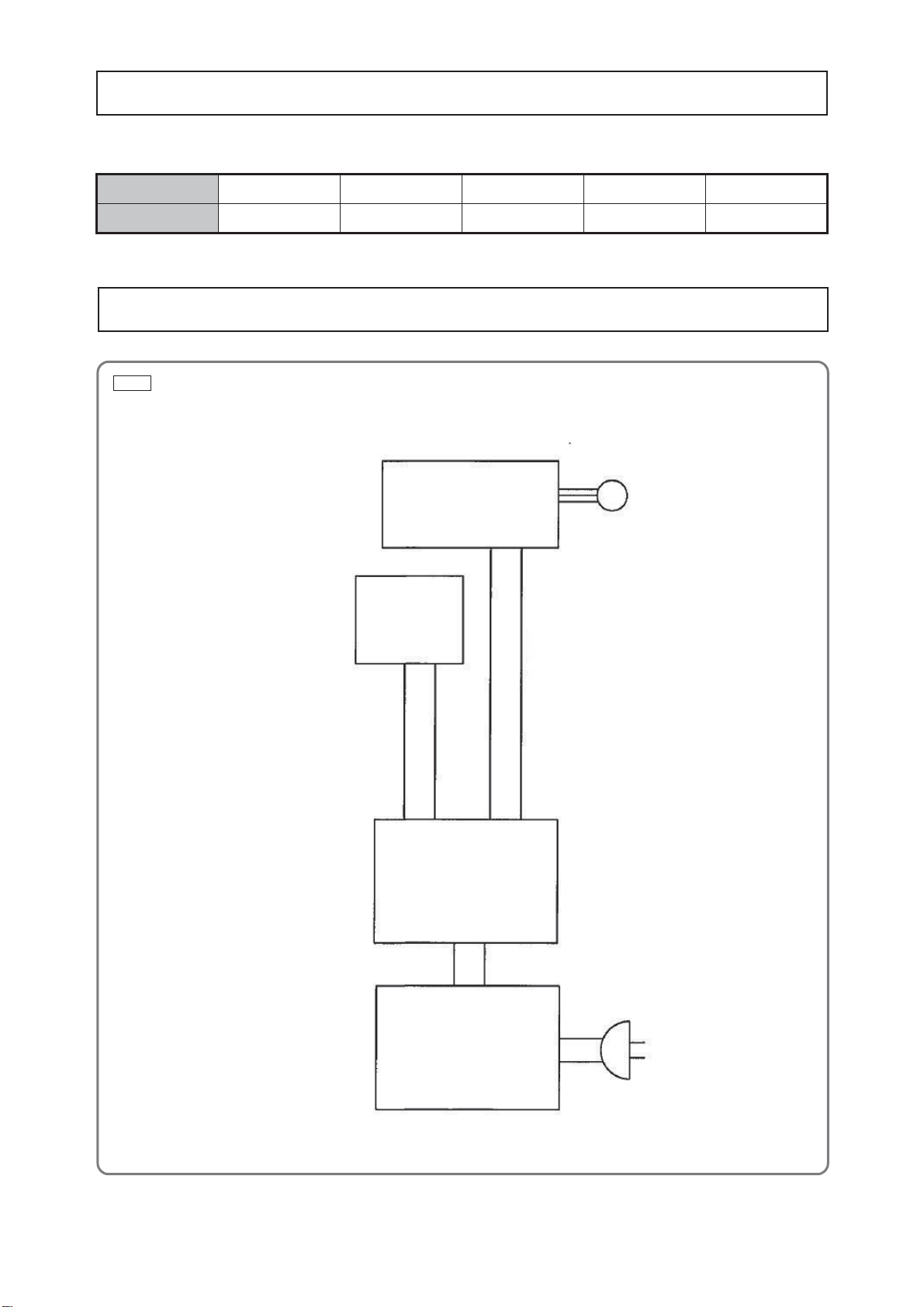

On completion of reassembly after repair, measure the insulation resistance and conduct the dielectric

strength test between the plug pins and the outside metallic parts such as the Anvil [9].

Insulation resistance: 7 Mȍor more

Dielectric strength: 2,500 V for 1 minute --------------------------------------- 110 V to 120 V

4,000 V for 1 minute --------------------------------------- 220 V to 240 V

Screw tightening torque

Checking after reassembly

Application of lubricant

Insulation test