Hitecsa pGD User manual

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

CONTROLLERS

pGD or Mini pGD

USER MANUAL

FOR UNITS: KRONO 3 (Kr3B)

Mini KRONO 3 (µKr3Bi)

2

Thank you for trusting the Hitecsa Products. Our company has been offering the market an extended range of

specialized equipment for air conditioning and cooling installations for over 35 years. Our approach is based on

efficiency, flexibility and practical solutions. This has been the hallmark of our product catalogue.

The versatility of our factory allows us to deliver solutions that can meet any requirement and we endeavour solving any

problem that may arise in designing and implementing air conditioning installations.

From all of us at Hiplus Aire Acondicionado, once again, thank you very much.

3

CONTROLLERS - CHILLERS and y HEAT PUMPS Air-Water

(Krono3; Mini Krono3)

INDEX

GENERAL SPECIFICATIONS...................................................................................................................4

INTERFACE CONNECTION......................................................................................................................5

OPERATION ..............................................................................................................................................6

USER INTERFACE................................................................................................................................................... 6

KEYS......................................................................................................................................................... 6

MAIN DISPLAY ......................................................................................................................................... 6

USER MENUS........................................................................................................................................... 7

MAIN MENU / SERVICE ..........................................................................................................................10

ALARMS ..................................................................................................................................................12

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

4

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

GENERAL SPECIFICATIONS

The controller (name: W-HiReg) is meant to optimising the water chiller performance (cooling only or heat pump) and

comprises three parts:

1. Input/output board or electronical device, built in the equipment.

2. Control software.

3. User interface terminal or remote thermostat.

The control device of each chiller comprises mainly the above mentioned first two items and the user interface is a serial

terminal or is part of a BMS System. The terminal is a physical device but it may be a virtual device too with a TCP/IP

connection to the internet or an internal network.

The controller works independently from the user interface. The differences depend mainly on the version of the

controller software, the unit’s configuration and the fitted options.

The general specifications of the Air-Water chiller control system are as follows:

Control according to the inlet (or outlet) water temperature.

Time scheduler.

Network connection (master-slave)

Defrost operation control.

Working hours register for maintenance purpose of the compressors and water pumps when the unit is equipped

with that option.

Display of the inlet temperature and the input and output positions.

Compressor start-up scheduler.

Anti-frost protection.

High pressure security protection.

Compressor electronical protection.

Outdoor fan protection.

Protection by water differential switch (water cond. mode).

Remote ON/OFF.

Electronical expansion valves control.

Alarm control.

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

5

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

INTERFACE CONNECTION

Terminal connection to a board with a 6 wire telephone cable (RJ12) at a max. 50 m distance. Connection between

several boards with a shielded pair.

For distances longer than 50 m and max. 200 m, proceed to interspersing with two TCONN devices.

PGD as

an option

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

6

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

OPERATION

Access to the parameters, variables, configuration etc. through the keyboard and display of the THERMOSTAT (the user

interface) or through BMS.

USER INTERFACE

KEYS

or

ALARM KEY: Press to display the alarms on the screen. The red illuminated key shows that there

is an active alarm.

or

PROGRAM KEY: Press to enter the programming menu. (Restricted access with a password).

“ESC”KEY: From any sub-menu press to go back one level. From the main menu, access to the

Help function.

UP ARROW KEY: Scrolling through menus or control parameters modification.

“ENTER”KEY: Confirmation of the entered values.

DOWN ARROW KEY: Scrolling through menus or control parameters modification.

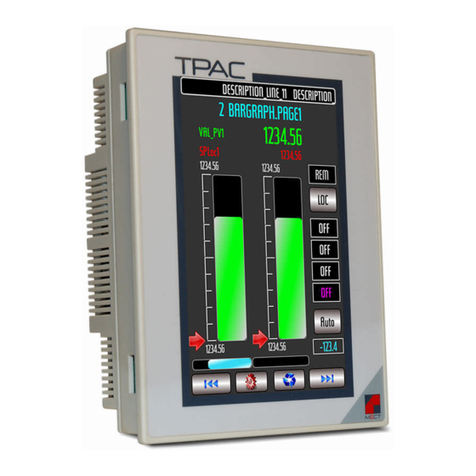

MAIN DISPLAY

Regulation

probe

Actual

Setpoint

Unit position

Operation mode

Date and hour

User menu

Modo de funcionamiento

Fecha y hora

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

7

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

OPERATION

USER MENUS

The symbol that represents one of the available menus is displayed in the lower right corner. Scroll through the various

available menus by pressing the up or down arrow keys. Press “Enter” to access the displayed menu.

If you need to see/modify a value or a parameter, scroll through the menu until you reach the display that includes the

required value. Then press “Enter” until the cursor shows the value (each time you press “Enter”, the pointer will move

alternately between the various values). Modify the selected value by pressing the up or down key, then press “Enter” to

change the cursor position and confirm the modification. Finally press “Esc” to leave.

The available menus are as follows:

SYMBOL

DESCRIPTION

POSSIBLE ACTIONS

STOP/START menu (ON/OFF)

Start or stop the unit

COOL/HEAT menu

Modify the operation mode of the unit.

SETPOINT/set menu

Modify the temperature setpoints.

INFO menu

Display various values and positions.

TIME SCHEDULE menu

Modify the date and hour.

Time scheduler

ON/OFF menu

Select and press “Enter”.

The unit is in the Off position (Stop). Change the position by using the arrow keys. “Esc” to leave.

Cool/heat menu

Select and press “Enter”.

Select alternately one of the two operation modes: Cool or Heat

The unit is working in the cooling mode (left) or heating mode (right). Change the mode by using the arrow keys. “Esc”

to leave.

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

8

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

OPERATION –User menus

TIME SCHEDULE menu

In addition to the mentioned basic operation modes, other functions are available from the time schedule menu.

Select and press “Enter”.

Follow the previously mentioned steps to complete the changes.

HOUR MODIFICATION

Modify the date and the actual hour.

TIME SCHEDULER

So as to enable time scheduling, proceed to changing from No to Yes. Once the programming function is enabled we

will be able to access the various options of the time Scheduler.

Temperature differential that will be applied depending on the various modes.

It is possible to program up to four events a day, each day of the week and four modes (OFF,

Comfort, Pre-Comfort and Economy) for each of the events. Change No to Yes to save the modifications. The selected

modes will be activated when the actual time matches the programmed hour and they will remain active until the next

scheduled event. The modes will be either Cooling or Heating depending on the selected modes for the hour when the

event starts.

Up to three annual periods may be scheduled. The selected mode for each period prevails over the daily mode that has

been selected.

A period of up to 6 days may be programmed with a single programmation. The selected mode for a special day will

prevail over the annual periods and the normal programmed days.

It is possible to select the “Auto” mode for a special day too.

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

9

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

OPERATION –User menus

Setpoints menu

Select and press “Enter”.

The temperature setpoints can be modified for both operation modes.

Operation modes:

The main two operation modes are the Cooling mode and the Heating mode. Both modes have three operation levels

that apply a compensation to the values of the temperature setpoints.

Comfort Mode: Standard mode that does not apply any compensation to the Setpoint value.

Pre-Comfort Mode: A differential (Offset) is applied to the temperature setpoints. This differential is positive for the

Cooling mode and negative for the Heating mode.

Economy Mode: Another differential is applied to the temperature values. This differential is positive for the Cooling

mode and negative for the Heating mode.

The Setpoint value that we want to modify and the actual active value will be displayed on the screen. If the time

Scheduler is active, the modified Setpoint value will be displayed too with the applied compensation after adding the

corresponding offset (Comfort, Economy, Pre-comfort).

Modification of the cool and heat setpoints (without compensation). If the scheduler is active, the compensated value of

the setpoint will be displayed acccording to the active mode.

Indication of the target outdoor temperature from Cool to Heat and vice versa.

Values that shall be compensated according to the different modes of the time schedule. The value will be added to the

Cool setpoint or will be deduced from the Heat setpoint depending on whether the cooling mode or the heating mode is

active.

INFO menu

Select and press “Enter”.

Access to various graphical displays including information about the different components of the system:

Water circuit

Circulation pumps

Circuit pressures

Compressors

Fans

Electrical resistances

Defrost operations

Controller

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

10

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

OPERATION

MAIN MENU / SERVICE

Enter the main menu by pressing the programming key “ ” o “ “. A password will be required to continue. The valid

password (service level) (only for installation) is “1996”.

MASTER-SLAVE CONFIGURATION

For interconnection of 2 to 5 units, the installer will need to configure one of them as the “Master” unit and the remaining

units will be “Slave” units.

Connect the pGD to the board of the chosen Master unit.

Enter the “Regulation” sub-menu. While keeping the “Enter” key pressed, go to “MS Type”.

While maintaining the cursor on “MS Type”, press the up/down arrow keys to change to “Master”.

Confirm and new fields will appear:

By pressing the “Enter” key we move to the field that we want to modify. Use the “up/down arrow” keys to change the

value.

(1) “Num. of units”: enter a number from 2 to 5.

(2) “RegType”: Chose the regulation type among the following options:

oAccording to the return temperature of the Master unit.

oAccording to the supply probe in the collector at the units’ outlet.

oAccording to the return probe of the most restrictive unit.

oAccording to the average data of the return probes of all the units.

Confirm the modifications by moving to “Update Config.?” and click to put the check mark “ ”.

After confirming by pressing “Enter”, we will need to confirm again from the following screen:

……..

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

11

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

OPERATION - THERMOSTAT AND CONTROL –MASTER / SLAVE

Register the remaining units as Slave units by connecting the pGD in each unit: select Slave in the “MS Type” cell

and allocate a different “ID Slave” number to each unit.

Once the selection is made, proceed to confirming the modifications as you did for the Master unit and go to the next

Slave unit.

… …

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

12

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

ALARMS

All the alarms displayed on the thermostat except the WARNING type alarms will make the unit stop.

Press the alarm key to access. It will display the active alarms first. Scroll through the various active alarms by using the

arrow keys. Press “Enter” from the last display to access the alarm history.

Alarm reset:

The Alarm key will be illuminated each time an alarm is active. Press that key to stop the sound alarm. By

pressing it again, the alarm will be deleted if the problem has been solved.

Please contact the technical assistance department if the alarm cannot be deleted.

How to reset the alarms:

Press (Alarm or ) to display information.

Press until the following screen appears:

Follow the displayed instructions:

Maintain the key pressed during three seconds to reset the alarms.

Description of the alarm messages:

ALARM MESSAGES

ACTION

Reset Alarms

-

Prb. Error - Water Inlet Temp.

Stops the whole unit

Prb. Error - Water Outlet Temp.

Stops the whole unit

Prb. Error - Water Outlet Temp. Circ.2

Stops the whole unit

Prb. Error - Water Tank Outlet Temp.

Stops the whole unit

Prb. Error - Exterior Temp.

Forces the fan setting to a fixed pressure (Factory).

Disables the defrost function of the fan and the tank resistance if

fitted.

Prb. Error - Flowmeter

Stops the whole unit

Prb. Error - Discharge Temp. Circ.1

Stops Circuit nº1

Prb. Error - Discharge Pressure Circ.1

Stops Circuit nº1

Prb. Error - Liquid Temp. Circ.1

-

Prb. Error - Suction Pressure Circ.1

Stops Circuit nº1

Prb. Error - Suction Temperature Circ.1

Stops Circuit nº1

Prb. Error - Discharge Temp. Circ.2

Stops Circuit nº2

Prb. Error - Discharge Press. Circ.2

Stops Circuit nº2

Prb. Error - Liquid Temp. Circ.2

-

Prb. Error - Suction Press. Circ.2

Stops Circuit nº2

Prb. Error - Suction Temp. Circ.2

Stops Circuit nº2

Prb. Error - Water Circuit Pressure

Stops the whole unit

DIN - Pump 1 Overload

Stops the unit unless there is rotation of the pumps. In that case

does not apply to that pump.

DIN - Pump 2 Overload

Stops the unit unless there is rotation of the pumps. In that case

does not apply to that pump.

DIN - Pump 3 Overload

Stops the unit unless there is rotation of the pumps. In that case

does not apply to that pump.

DIN - Compressor 1 Overload

Does not apply to that compressor

DIN - Compressor 2 Overload

Does not apply to that compressor

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

13

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

ALARM MESSAGES

ACTION

DIN - Compressor 3 Overload

Does not apply to that compressor

DIN - Compressor 4 Overload

Does not apply to that compressor

DIN - Fans 1 Overload

Stops Circuit nº1

DIN - Fans 2 Overload

Stops Circuit nº2

DIN - FlowSwitch - Pump ON no flow

Stops the whole unit

DIN - FlowSwitch - Pump OFF flow

Does not allow the unit to start.

DIN - High Press. Pressostat Circ.1

Stops Circuit nº1, proceed to resetting the pressure switch physically

DIN - High Press. Pressostat Circ.2

Stops Circuit nº2, proceed to resetting the pressure switch physically

ENV. - High discharge pres. Circ.1

Stops Circuit nº1

ENV. - High discharge temp. Circ.1

Stops Circuit nº1

ENV. - Low discharge pres. Circ.1

Stops Circuit nº1

ENV. - High motor current Circ.1

Stops Circuit nº1

ENV. - High pressure ratio Circ.1

Stops Circuit nº1

ENV. - Low delta pressure Circ.1

Stops Circuit nº1

ENV. - Low pressure ratio Circ.1

Stops Circuit nº1

ENV. - High suction pres. Circ.1

Stops Circuit nº1

ENV. - Low suction pres. Circ.1

Stops Circuit nº1

ENV. - High discharge pres. Circ.2

Stops Circuit nº2

ENV. - High discharge temp. Circ.2

Stops Circuit nº2

ENV. - Low discharge pres. Circ.2

Stops Circuit nº2

ENV. - High motor current Circ.2

Stops Circuit nº2

ENV. - High pressure ratio Circ.2

Stops Circuit nº2

ENV. - Low delta pressure Circ.2

Stops Circuit nº2

ENV. - Low pressure ratio Circ.2

Stops Circuit nº2

ENV. - High suction pres. Circ.2

Stops Circuit nº2

ENV. - Low suction pres. Circ2

Stops Circuit nº2

EVD1 - Battery discharge

Stops the whole unit

EVD1 - EEPROM alarm

Stops the whole unit

EVD1 - Incomplete closing

Stops the whole unit

EVD1 - Emergency closing

Stops the whole unit

EVD1 - Firmware not compatible

Stops the whole unit

EVD1 - Configuration error

Stops the whole unit

EEVA - Low SuperHeat Circ.1

Stops Circuit nº1

EEVA - LOP Circ.1

Stops Circuit nº1

EEVA - MOP Circ.1

Stops Circuit nº1

EEVA - Motor error Circ.1

Stops Circuit nº1

EEVA - Low suction temp. Circ.1

Stops Circuit nº1

EEVA - High condensing temp.

Stops Circuit nº1

EEVB - Low SuperHeat Circ.2

Stops Circuit nº2

EEVB - LOP Circ.2

Stops Circuit nº2

EEVB - MOP Circ.2

Stops Circuit nº2

EEVB - Motor error Circ.2

Stops Circuit nº2

EEVB - Low suction temp. Circ.2

Stops Circuit nº2

EEVA - Ineffective adaptive control

Stops Circuit nº1

EEVA - Emergency closing alarm

Stops Circuit nº1

EEVA - Parameter range error

Stops Circuit nº1

EEVB - High condensing temp.

Stops Circuit nº2

EEVB - Ineffective adaptive control

Stops Circuit nº2

EEVB - Emergency closing alarm

Stops Circuit nº2

EEVB - Parameter range error

Stops Circuit nº2

Antifreeze Alarm

Stops the whole unit, pump is maintained and resistances are

started up

Antifreeze warning

Warning with the unit stopped, start-up of pump and resistances

Antifreeze Alarm Circ.1

Stops Circuit nº1, pump is maintained and resistances are started up

Antifreeze Alarm Circ.2

Stops Circuit nº1, pump is maintained and resistances are started up

High Pres. Alarm Circ.1

Stops Circuit nº1

Low Pres. Alarm Circ.1

Stops Circuit nº1

Minimum Pres. Alarm Circ.1

Stops Circuit nº1

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

14

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

ALARM MESSAGES

ACTION

Refrigerant Leak Alarm Circ.1

Stops Circuit nº1

High Discharge Pres. Alarm Circ.2

Stops Circuit nº2

Low Suction Pres. Alarm Circ.2

Stops Circuit nº2

Minimum Suction Pres. Alarm Circ.2

Stops Circuit nº2

Refrigerant Leak Alarm Circ.2

Stops Circuit nº2

High Discharge Temp. Alarm Circ.1

Stops Circuit nº1

High Discharge Temp. Alarm Circ.2

Stops Circuit nº2

Water Flow Out of Limits

Stops the whole unit

Water Pressure Out of Limits

Stops the whole unit

Master Unit Offline

-

Slave Board Offline

-

EVD Drive Offline

Stops the whole unit

Energy Meter Offline

-

Fan 1 Offline

-

Fan 2 Offline

-

Fan 3 Offline

-

Fan 4 Offline

-

c.PCOe Offline

-

Slave Unit 1 Offline

-

Slave Unit 2 Offline

-

Slave Unit 3 Offline

-

Slave Unit 4 Offline

-

Maintenance Pump 1

-

Maintenance Pump 2

-

Maintenance Pump 3

-

Maintenance Comp 1

-

Maintenance Comp 2

-

Maintenance Comp 3

-

Maintenance Comp 4

-

Maintenance VE Circ.1

-

Maintenance VE Circ.2

-

Maintenance E.Heater Exchanger Circ.1

-

Maintenance E.Heater Exchanger Circ.2

-

Maintenance E.Heater W.Tank

-

Maintenance E.Heater Crankcase Circ.1

-

Maintenance E.Heater Crankcase Circ.2

-

Severe High Discharge Pres. Alarm Circ.1

Stops Circuit nº1, manual reset

Severe Low Suction Pres. Alarm Circ.1

Stops Circuit nº1, manual reset

Severe Minimum Suction Pres. Alarm Circ.1

Stops Circuit nº1, manual reset

Severe Refrigerant Leak Alarm Circ.1

Stops Circuit nº1, manual reset from factory

Severe High Discharge Pres. Alarm Circ.2

Stops Circuit nº2, manual reset

Severe Low Suction Pres. Alarm Circ.2

Stops Circuit nº2, manual reset

Severe Minimum Suction Pres. Alarm Circ.2

Stops Circuit nº2, manual reset

Severe Refrigerant Leak Alarm Circ.2

Stops Circuit nº2, manual reset from factory

Severe High Discharge Temp. Alarm Circ.1

Stops Circuit nº1, manual reset

Severe High Discharge Temp. Alarm Circ.2

Stops Circuit nº2, manual reset

Severe - FlowSwitch - Pump ON no flow

Stops the whole unit, manual reset

ENV. - Severe Low pressure ratio Circ.1

Stops Circuit nº1, manual reset

ENV. - Severe Low pressure ratio Circ.2

Stops Circuit nº2, manual reset

Severe - Water Flow Out of Limits

Stops the whole unit, manual reset

Severe - Antifreeze Alarm

Stops the whole unit, manual reset

Severe - Antifreeze Alarm Circ.1

Stops Circuit nº1, manual reset

Severe - Antifreeze Alarm Circ.2

Stops Circuit nº2, manual reset

Severe - Water Pressure Out of Limits

Stops the whole unit, manual reset

ZiehlFan MB 1 - Communication Error

Stops fan

ZiehlFan MB 1 - Motor Start Error

Stops fan

ZiehlFan MB 1 - Temperature Error

Stops fan

ZiehlFan MB 1 - Safety Shutdown

Stops fan

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

15

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

ALARM MESSAGES

ACTION

ZiehlFan MB 1 - Sinefilter

Stops fan

ZiehlFan MB 1 - Peak Current

Stops fan

ZiehlFan MB 1 - Motor Blocked

Stops fan

ZiehlFan MB 1 - Hallsensor Error

Stops fan

ZiehlFan MB 1 - TB Error

Stops fan

ZiehlFan MB 1 - Line Fault

Stops fan

ZiehlFan MB 1 - UIN LO

Stops fan

ZiehlFan MB 1 - UIN HI

Stops fan

ZiehlFan MB 1 - UZK LO

Stops fan

ZiehlFan MB 1 - UZK HI

Stops fan

ZiehlFan MB 1 - Earth to ground fault

Stops fan

ZiehlFan MB 1 - IGBT Fault

Stops fan

ZiehlFan MB 1 - Functional Safety - Full Safe Mode

Stops fan

ZiehlFan MB 1 - Motorcontrol Sys Warning

Stops fan

ZiehlFan MB 1 - User App Sys Failure

Stops fan

ZiehlFan MB 1 - Vibration Error

Stops fan

ZiehlFan MB 1 - Lifetime Error

Stops fan

ZiehlFan MB 1 - Direction Error

Stops fan

ZiehlFan MB 1 - Limitations active

Stops fan

ZiehlFan MB 2 - Communication Error

Stops fan

ZiehlFan MB 2 - Motor Start Error

Stops fan

ZiehlFan MB 2 - Temperature Error

Stops fan

ZiehlFan MB 2 - Safety Shutdown

Stops fan

ZiehlFan MB 2 - Sinefilter

Stops fan

ZiehlFan MB 2 - Peak Current

Stops fan

ZiehlFan MB 2 - Motor Blocked

Stops fan

ZiehlFan MB 2 - Hallsensor Error

Stops fan

ZiehlFan MB 2 - TB Error

Stops fan

ZiehlFan MB 2 - Line Fault

Stops fan

ZiehlFan MB 2 - UIN LO

Stops fan

ZiehlFan MB 2 - UIN HI

Stops fan

ZiehlFan MB 2 - UZK LO

Stops fan

ZiehlFan MB 2 - UZK HI

Stops fan

ZiehlFan MB 2 - Earth to ground fault

Stops fan

ZiehlFan MB 2 - IGBT Fault

Stops fan

ZiehlFan MB 2 - Functional Safety - Full Safe Mode

Stops fan

ZiehlFan MB 2 - Motorcontrol Sys Warning

Stops fan

ZiehlFan MB 2 - User App Sys Failure

Stops fan

ZiehlFan MB 2 - Vibration Error

Stops fan

ZiehlFan MB 2 - Lifetime Error

Stops fan

ZiehlFan MB 2 - Direction Error

Stops fan

ZiehlFan MB 2 - Limitations active

Stops fan

ZiehlFan MB 3 - Communication Error

Stops fan

ZiehlFan MB 3 - Motor Start Error

Stops fan

ZiehlFan MB 3 - Temperature Error

Stops fan

ZiehlFan MB 3 - Safety Shutdown

Stops fan

ZiehlFan MB 3 - Sinefilter

Stops fan

ZiehlFan MB 3 - Peak Current

Stops fan

ZiehlFan MB 3 - Motor Blocked

Stops fan

ZiehlFan MB 3 - Hallsensor Error

Stops fan

ZiehlFan MB 3 - TB Error

Stops fan

ZiehlFan MB 3 - Line Fault

Stops fan

ZiehlFan MB 3 - UIN LO

Stops fan

ZiehlFan MB 3 - UIN HI

Stops fan

ZiehlFan MB 3 - UZK LO

Stops fan

ZiehlFan MB 3 - UZK HI

Stops fan

ZiehlFan MB 3 - Earth to ground fault

Stops fan

ZiehlFan MB 3 - IGBT Fault

Stops fan

CONTROLLER

CHILLERS and HEAT PUMPS Air-Water

16

USM_CONTROL_KRONO 3-MINI KRONO 3_208064_220501_EN

ALARM MESSAGES

ACTION

ZiehlFan MB 3 - Functional Safety - Full Safe Mode

Stops fan

ZiehlFan MB 3 - Motorcontrol Sys Warning

Stops fan

ZiehlFan MB 3 - User App Sys Failure

Stops fan

ZiehlFan MB 3 - Vibration Error

Stops fan

ZiehlFan MB 3 - Lifetime Error

Stops fan

ZiehlFan MB 3 - Direction Error

Stops fan

ZiehlFan MB 3 - Limitations active

Stops fan

ZiehlFan MB 4 - Communication Error

Stops fan

ZiehlFan MB 4 - Motor Start Error

Stops fan

ZiehlFan MB 4 - Temperature Error

Stops fan

ZiehlFan MB 4 - Safety Shutdown

Stops fan

ZiehlFan MB 4 - Sinefilter

Stops fan

ZiehlFan MB 4 - Peak Current

Stops fan

ZiehlFan MB 4 - Motor Blocked

Stops fan

ZiehlFan MB 4 - Hallsensor Error

Stops fan

ZiehlFan MB 4 - TB Error

Stops fan

ZiehlFan MB 4 - Line Fault

Stops fan

ZiehlFan MB 4 - UIN LO

Stops fan

ZiehlFan MB 4 - UIN HI

Stops fan

ZiehlFan MB 4 - UZK LO

Stops fan

ZiehlFan MB 4 - UZK HI

Stops fan

ZiehlFan MB 4 - Earth to ground fault

Stops fan

ZiehlFan MB 4 - IGBT Fault

Stops fan

ZiehlFan MB 4 - Functional Safety - Full Safe Mode

Stops fan

ZiehlFan MB 4 - Motorcontrol Sys Warning

Stops fan

ZiehlFan MB 4 - User App Sys Failure

Stops fan

ZiehlFan MB 4 - Vibration Error

Stops fan

ZiehlFan MB 4 - Lifetime Error

Stops fan

ZiehlFan MB 4 - Direction Error

Stops fan

ZiehlFan MB 4 - Limitations active

Stops fan

Subject to modification without prior notice.

This manual suits for next models

1

Table of contents

Other Hitecsa Controllers manuals