Hitzer Energy Master II 710 User manual

Page 1

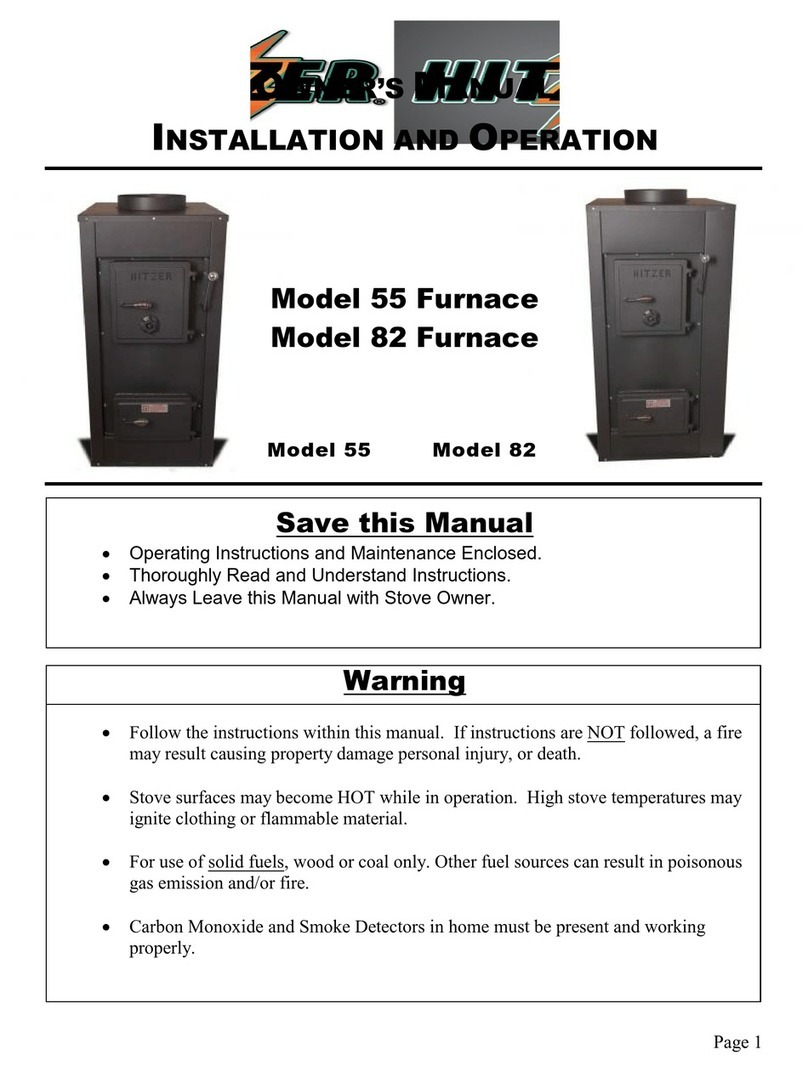

Hitzer Energy Master II Stoker Furnace

Model 710

Owner’s Manual

Installation and Operation

Save this Manual

Operating Instructions and Maintenance Enclosed.

Thoroughly Read and Understand Instructions.

Always Leave this Manual with Stove Owner.

Warning

FOLLOW THE INSTRUCTIONS WITHIN THIS MANUAL. IF

INSTRUCTIONS ARE NOT FOLLOWED, A FIRE MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY, OR EVEN DEATH. REFER

TO MARKINGS ON THE FURNACE FOR ADDITIONAL INFORMATION.

CARBON MONOXIDE AND SMOKE DETECTORS/ALARMS MUST BE

INSTALLED IN THE HOME AND WORKING PROPERLY

DANGER –RISK OF FIRE OR EXPLOSION

DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL, OR OTHER

FLAMMABLE LIQUIDS. DO NOT USE CHEMICALS OR FLUIDS TO

START FIRE

BURN RICE SIZE ANTHRACITE COAL ONLY

STOVE SURFACES MAY BE HOT WHILE IN OPERATION. KEEP

CHILDREN AWAY. DO NOT TOUCH DURING OPERATION.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE

DO NOT OPERATE WITH FLUE DRAFT EXCEEDING .06 WC (14.945 Pa)

Page 2

Table of Contents

I. Welcome to Hitzer Family

A. Safety Notice

II. Location of Stove & Installation

A. Pre Installation Information

B. Location

C. Clearances To Combustibles/Floor Protection

D. Requirements In Regards To Installation

E. Connecting Furnace To Chimney

III. Typical Installation

A. Illustrations

B. Supply Duct

C. Return Air

D. Combustion Air

E. Installation In A Confined Space

IV. Flue Systems

A. Masonry System

B. Factory Built Systems

C. Chimney Requirements

D. Flue Size

E. Chimney Height Requirements

F. Power Vent System

V. Basic Regulations for Safe Operations

A. Cautions

B. Local Codes

VI. Stove Start Up & Operation

A. Install Coal-Trol Thermostat

B. Start Up

C. Adjusting Chimney Draft

D. Measuring Furnace Compatibility

VII. MAINTENANCE

A. Daily

B. Weekly

C. Two Months

D. End Of The Season

E. Power Outages

VIII. TROUBLESHOOTING

IX. Further Information

Page 3

I. Welcome to Hitzer Family

Hitzer Inc. welcomes you to a proud and unified team of Hitzer stove owners. Thank You for your recent

purchase of a Hitzer Energy Master II Stoker Furnace. We can assure that your Hitzer furnace has the

finest Swiss Amish Craftsmanship. Your Hitzer Energy Master II Furnace is built with premium quality

materials to ensure safety, durability, and performance. These are all top priorities in the Hitzer line of

products.

We would like to personally thank you again and welcome you into our continually growing Hitzer Family.

We wish you and your family an extended amount of warmth and comfort, provided by your new Hitzer

Furnace. Thanks for choosing Hitzer where our motto is:

“Our Stoves Make Warm Friends.”

Safety Notice

Safety Notice: If this Hitzer Stove is not properly installed a house fire may result. For your safety and to

reduce the risk of fire, follow the installation instructions carefully. Failure to follow these instructions may

result in property damage, bodily injury, or even death. Contact your local building inspector or fire

officials about the need for a permit, restrictions, or installation inspection required in your area. Refer to

makings on your furnace for more information. Save these instructions for future reference.

Safety Notice: Always have working carbon monoxide and smoke detectors installed when using this

equipment. It is recommended to have one on each floor of the house and outside of sleeping rooms.

UL Tested/Label: Follow the information and clearance charts located on each Hitzer Stove Model. This

furnace has been tested to UL 391-2006 & CSA B366.1-M91, approved, and labeled on the rear of each

stove.

It is strongly recommended to have this Hitzer Furnace installed by an educated and certified professional

heating contractor. Please refer to a NFI (National Fireplace Institute) Certified Installer for your

installation needs and questions. Locate an NFI professional at www.nficertified.org.

Page 4

II. Location of Stove & Installation

Pre Installation Information:

Your Energy Master Furnace is intended for use in residential buildings. Do not install in a mobile home.

Do not install in a garage.

IMPORTANT: Always check with local authorities and obtain the necessary permits prior to

installing this furnace. This furnace must be installed in accordance with local, state, and national

codes and regulations.

Before installation some questions must be addressed.

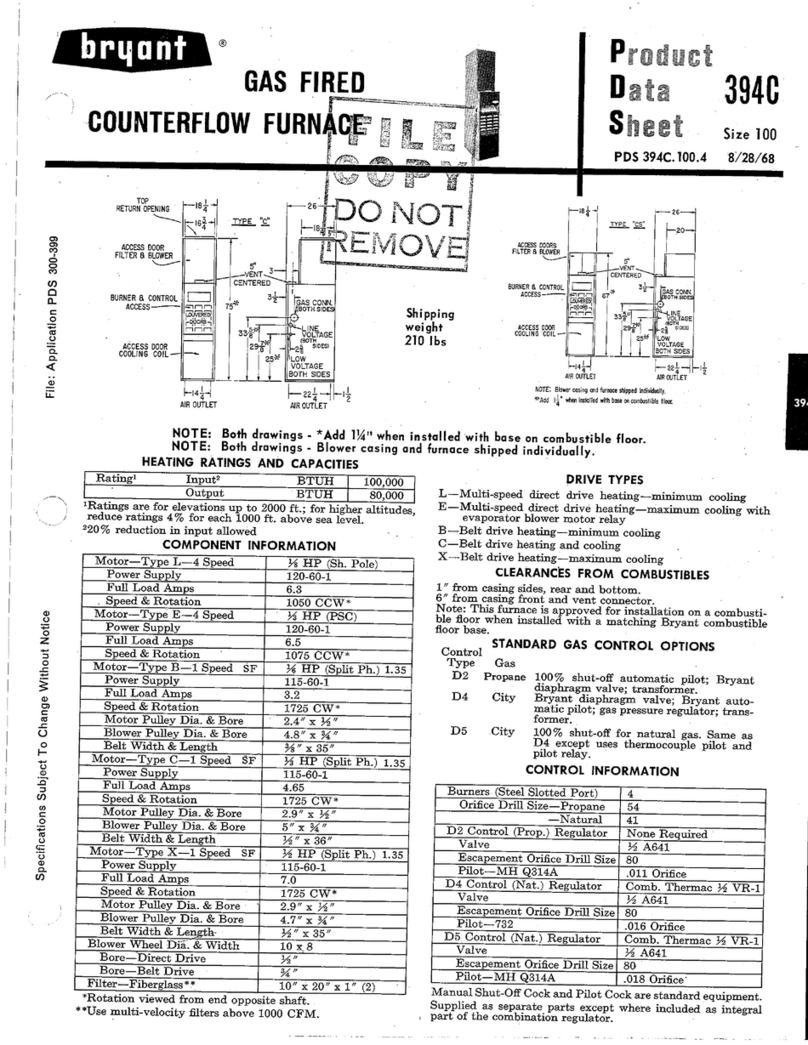

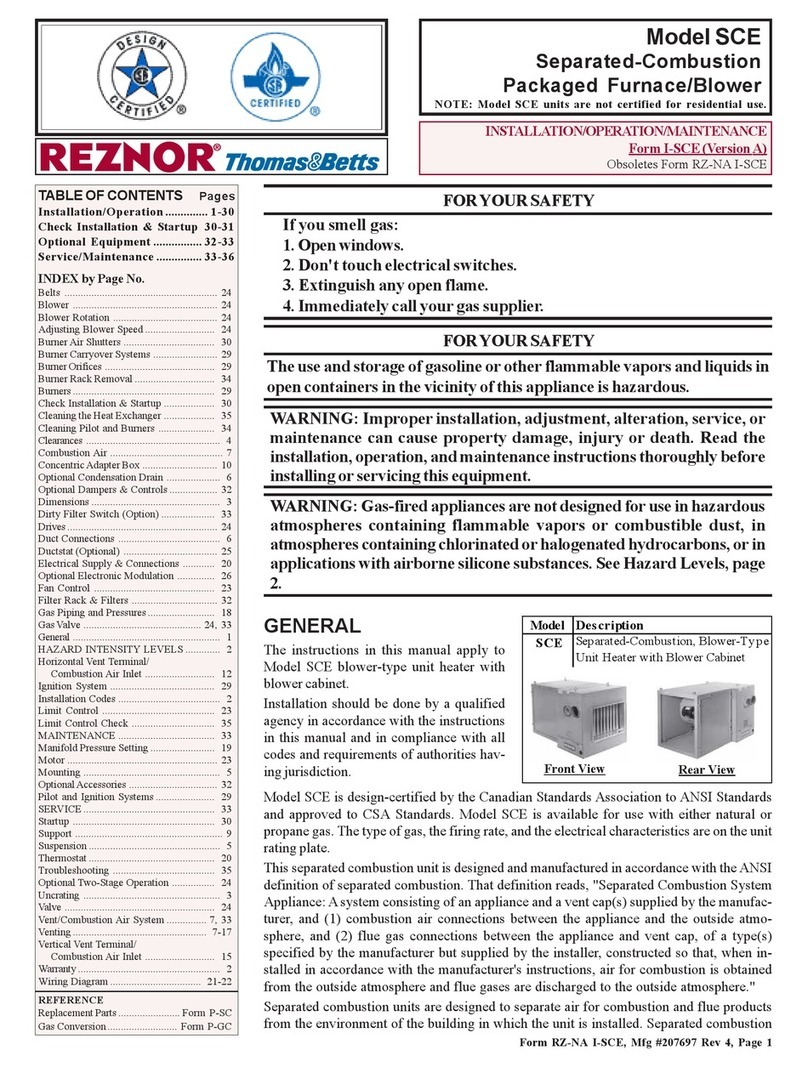

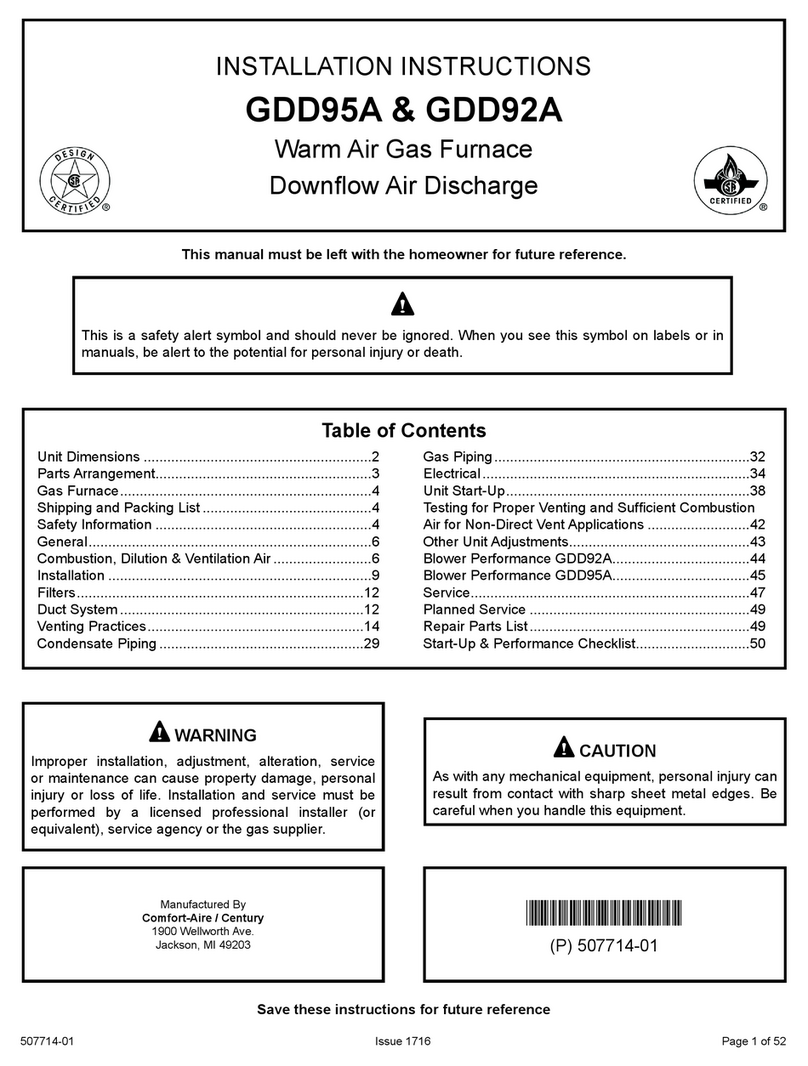

1. Will your Energy Master Furnace be used as a primary (central) furnace, or will it be installed as an

add-on to your existing central heating system?

2. If your Energy Master Furnace is to be installed as an add-on, is it compatible with your existing

furnace? Your Energy Master Furnace is designed to be used with a listed gas-, oil-fired furnace

however not all furnaces will accept add-on applications. Some small furnaces, and especially counter-

flow or down-flow furnaces, can not be used in an add-on installation. The CFM (cubic feet per minute)

capability between the blower on the existing furnace and the add-on furnace must be compatible. If all

these conditions are met then the combined static pressure must not exceed the maximum static

pressure listed on the nameplate on either furnace. Before installing your Energy Master Furnace consult

your Hitzer dealer or heating contractor and your local, state and national building codes and regulations

to determine if your central heating system is compatible with your Hitzer Energy Master Furnace. Once it

is determined your existing furnace will accept an add-on installation a parallel installation with return air

(outlined later in this manual) is recommended.

3. Can the furnace be vented properly?

a. Is the chimney appropriate for this installation? This furnace requires installation in a masonry

chimney with a clay flue liner or a metal all-fuel chimney listed to UL103 (CAN/ULC-S629-M87) Type HT.

Do not connect this furnace to a chimney serving another appliance!

b. Has your chimney been inspected? It is important that your chimney is clean and structurally sound

(free from defect or damage) before installing your Energy Master Furnace.

c. If you are power venting your furnace is there a place to mount the power vent away from

obstacles? Refer to power vent placement chart with power vent instructions.

4. Is there easy access to outside combustion air should your furnace require it?

5. Can the furnace be installed safely?

a. This furnace must not be installed in a location where it could come in contact with walls, carpeting,

curtains/drapes, or other combustible surfaces.

b. The clearances listed in this manual and on the furnace are minimum clearances. Any reduction

must be approved by the regulatory authority and is not recommended by Hitzer Inc.

c. Will this location require floor protection?

d. Furnace must not be installed in a sleeping room.

6. How close is the electrical source and does it conform to requirements listed?

7. Are there any local, state, or national codes or regulations concerning the use and placement of your

furnace?

8. Are there any structural reasons why the furnace cannot be located where you want it?

9. Will the furnace be easily accessible for refueling, cleaning, maintenance, and repair?

Page 5

Location:

The location of the stove is very important for optimum stove performance as well as safety assurance.

When searching for the location of the stove be sure to strictly follow manufactures guidelines,

clearance to combustible material requirements, local building, and fire codes. Failure to follow

manufacture’s instruction and local jurisdiction codes may result in bodily injury, property

damage, fire, or death. Locate the stove where there is sufficient air supply for proper operation to

occur. It is vitally important to locate the stove next to existing forced air furnace as well as next to the

chimney, or exterior wall for power vent systems. The closer placement to these two items the better the

stove will perform, and achieve maximum heat flow. The longer the chimney connector pipe (stovepipe)

and farther away the furnace is from the chimney or power vent the less performance is achieved from

the furnace. Please consider the construction and layout of the home to be heated and make placement

of the Energy Master Furnace to achieve maximum heat benefit it can produce.

Clearances To Combustibles/Floor Protection:

This furnace must be placed on a non-combustible floor. If the floor is a combustible material floor

protection must be placed underneath it and extend at least 8 inches on each side of the fuel or ash door.

It must also extend 16 inches out from the front of the furnace. The floor protection must also be placed

underneath the chimney connector (stove pipe) and extend at least 2 inches on either side of the chimney

connector. This protection is for hot ash and sparks. It is not needed for heat protection. If your furnace is

installed on a concrete basement floor, it is recommended to install on a 2 inch thick nonflammable

material. This will reduce contact with the damp floor that can cause possible rust and corrosion.

Back wall

2”

Minimum Clearance to Combustible Material: Floor Protection:

Unit to Side Wall: 2 inches Front: 16 inches

Unit to Back Wall: 6 inches Side: 8 inches from

Chimney Connecter to Back Wall: 18 inches either side of the

Chimney Connecter to Side Wall: 18 inches fuel and ash door

Rear: 2 inches

Furnace

Floor Protection

16 “

8”

6”

2”

Page 6

CAUTION: It is mandatory to abide by clearance to combustibles regulations provided on the

furnace label and in this instruction manual. Failure to abide by the clearance requirements may

result in a fire.

Requirements In Regards To Installation:

DO NOT connect to a chimney serving another appliance. Only one appliance is to be used per

chimney.

Flue must be the same size as stove flue collar or larger within requirements of flue size

maximums.

Chimney connector pipe (stove pipe) must be made of at least 24 gauge metal and be attached

with crimped ends facing the stove. A minimum of 3 screws is required at each connection point.

Masonry or manufactured thimble must be longer than the thickness of the wall and does not

intrude past the inner face of the chimney liner.

Thimble may be constructed of approved clay liner thimble tested and labeled. With a 12” non-

combustible clearance zone on each side of thimble. Please use NFPA 211 instructions and

requirements in regarding thimble information.

Thimble may be a manufactured thimble or class A chimney pipe. A manufactured component

must be installed with listed components accessories and meet manufacturer’s specifications.

It is required to have thimble clearances to combustible material as required by manufacturer and

NFPA 211.

NFPA 211 codes must be followed and an 18” clearance to combustible material is required for

chimney connectors.

This unit must be installed on a noncombustible floor according to the measurements above.

DO NOT install in a garage.

Connecting Furnace To Chimney:

Connection of your Energy Master Furnace to the chimney should be made as direct as possible. It is not

recommended to use more then 2 elbows for venting. The pipe connecting the furnace to the chimney

should be at least 24 gauge single wall pipe. Thicker gauges and double wall pipe may be used. A ½

inch slope, back toward the furnace, per foot of horizontal run is required. This allows any condensation

forming in the pipe to flow back toward the furnace. The connection pipe should be installed so the upper

pipe fits inside the lower pipe. Horizontal run pipe should have the seam turned up. Note the point at

which the flue passes through a wall to the chimney. This penetration must be made with an approved

through the wall thimble or class A chimney pipe and used with the listed proper accessories according to

manufacturer’s instructions. Chimney connector (stove pipe) CANNOT pass through a ceiling, wall, or any

concealed space. Three screws must be attached at each connection point of the chimney connector.

When the Class A chimney pipe connects to the masonry, it must be cemented to the chimney, or a

thimble must be connected to the chimney and the pipe should be tightly inserted into the thimble without

cementing.

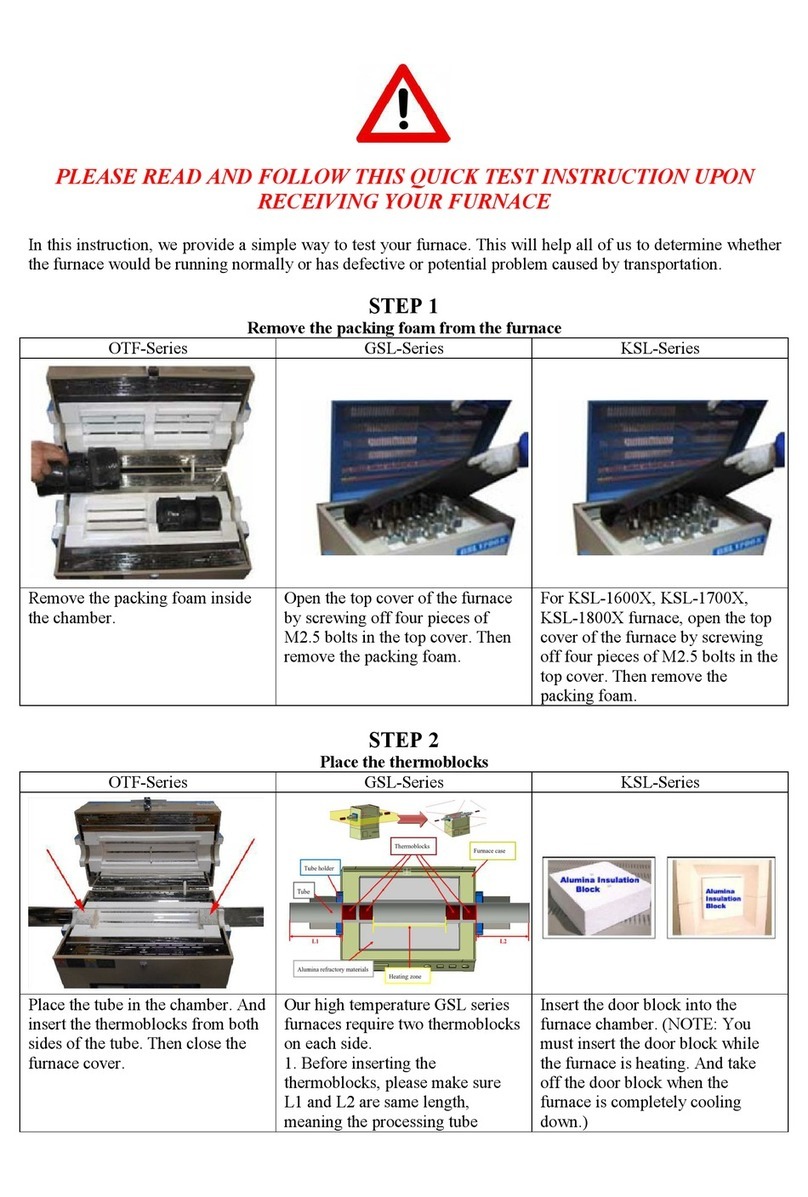

III. Typical Installations

Illustrations:

Below are typical ways of installation formats. Note: these illustrations reflect typical installations and are

for design purposes only. Illustrations and diagrams are for informational purposes only. These diagrams

are not drawn to scale. Actual installation procedures may vary.

NOTE: It is always best to run the supply duct up. The supply duct must be constructed of material with

a minimum 250°temperature rating. With the supply duct up, this will allow gravity heat to still rise into

the system. The plenum on the furnace must be constructed of metal.

Page 7

Page 8

Notice: Installations are drawn with a masonry chimney. Manufactured metal chimney listed to UL 103

(CAN/ULC-S629-M87) Type HT or a Hitzer approved power vent system may also be used. Follow

manufacturer’s instructions/guidelines when using these products.

Page 9

Supply Duct:

In order to achieve maximum performance it is important to have the correct size of duct work that

corresponds with your Hitzer ENERGY MASTER Stoker Furnace. Your furnace is equipped with a 1009

CFM Blower. In order to achieve maximum performance and heat, it is important to make sure the duct

work is sized properly and not too small for the blower assembly. If the duct work is too small your furnace

won’t achieve full potential. Duct sized excessively large will also be detrimental to the operation of your

furnace. NOTE: These calculations are based on a .10 static pressure.

Supply Duct Size Shape Approximate Capacity(CFM)

6” round 120

8”round 240

10” round 420

12” round 680

14” round 1000

8”x12” rectangle 480

8”x16” rectangle 700

8”x 20” rectangle 910

8”x 22” rectangle 1000

8”x 24” rectangle 1200

Return Air:

Return air is very important and MUST BE incorporated into the system. Without adequate return air

supplied to your furnace the warm air distributed into your home will be restricted. This will decrease the

efficiency of your furnace. You could also cause the furnace to overheat because of reduced air flow

causing damage to your unit and voiding your warranty. If your furnace is installed in a basement or utility

room that is fairly air tight the blowers on the furnace could depressurize the room and pull toxic flue

gasses from the furnace or other burning appliance in the area. These toxic fumes could then be

distributed throughout the house causing a very dangerous situation.

The return air can be provided by installing a separate duct system or by tying into the cold air return duct

of the existing furnace. Without a return air system warm air will be drawn into your basement,

unnecessarily heating unused portions of your home. The return duct should be a minimum of 16” x 20”

or equivalent (320sq.in.). The return duct may be attached to the rear of the stoker furnace. Make sure if

you are attaching the duct to the rear of the furnace you do not inhibit the removal and replacement of the

furnace filters. These filters should be checked and cleaned/replaced regularly to maintain the proper air

flow.

Combustion Air:

All fires need air to burn. The incomplete combustion that takes place in an “air starved” situation causes

carbon monoxide (CO) to be produced in quantities that can be dangerous inside a well sealed house.

Having a source of combustion air from outside the home will prevent “air starvation” of the furnace. You

must provide enough fresh air to assure proper combustion. Outside air is required to replace air used to

take the byproducts of combustion out the chimney. Outside air is also required to replace air exhausted

by kitchen/bathroom fans, and any other furnace, or water heater chimneys or fans.

Outside air may be needed if:

The solid-fuel-fired appliance does not draw steadily, smell, experiences smoke roll-out, burns

poorly, or back-drafts whether or not there is combustion present.

Any of the above symptoms are alleviated by opening a window slightly on a calm day.

The house is equipped with a well-sealed vapor barrier and tight fitting windows and/or has any

powered devices which exhaust house air.

There is excessive condensation on windows in the winter.

A ventilation system is installed in the house.

Installation In A Confined Space:

When the furnace is installed in a utility/storage room or other enclosed areas you must install two open

grills. They should be placed in a wall or door opening into the rest of the house. One will supply

combustion air. Locate it near the floor. The other is for ventilation and be located near the ceiling. Each

Page 10

grill must have free area. This open area should not be less than 1 square inch for each 1000 BTU/hr of

the total input rating of all the appliances in the confined space.

CAUTION: ANY FANS/BLOWERS INSTALLED IN THE ROOM WITH YOUR ENERGY MASTER

STOKER FURNACE MUST NOT CREATE A NEGATIVE PRESSURE IN THAT ROOM

Typical Wrong Installation

Do not have supply hot air flow downward as this will not allow the Hitzer Furnace to operate properly.

Do not have the supply air flow back into the blower of existing oil or gas furnace. This could damage the

existing furnace controls and/or void any warranty.

Do not have hot air from gas or oil furnace flow downward into the Hitzer Furnace and flow out the Hitzer

Furnace to existing duct work.

Additional Safety Requirements for Canadian Supplemental (add-on) Furnace Installations:

Do not use duct elbows having an inside radius of less than 6in (150mm) on the (oil, gas,

electric) furnace.

Do not connect to a down flow furnace.

Do not connect ductwork so that a reverse flow is possible.

Operate the (gas, oil, electric) furnace periodically to ensure it will operate satisfactorily when

needed.

Certified for installation with the ductwork configurations shown previously.

Do not relocate or bypass any of the safety controls in the original (gas, oil, electric) furnace

installation.

Do not connect to any furnace that has not been certified initially as complying with CAN/CGA-

2.3

The operation of the gas furnace must be verified for acceptable operation before and after

installation of the add-on appliance by a gas fitter who is recognized by the regulatory

authority.

DO NOT connect to any gas furnace that is not equipped with an air-circulation blower,

DO NOT connect to or a chimney or vent serving a gas furnace or gas appliance.

Page 11

This installation should comply with requirements of CAN/CSA-B365, and changes are made

to the central furnace, changes must comply with CSA B139 (for oil-fired), C22.1 (for electric),

or CAN/CGA-B149.1 or CAN/CGA-B149.2 (for gas-fired).

This add-on furnace must only be installed on a furnace duct system and chimney that are in

good operating condition.

IV. Flue Systems

Masonry Flue System: A good chimney is essential. A masonry chimney must be built with a low heat

masonry material. It is important to make sure that the masonry chimney is structurally sound and on a

solid foundation. The masonry chimney must have a liner installed within the chimney construction. An

unlined chimney is not safe with solid fuel systems, and may result in a house fire. The liner may be a

structurally sound clay liner or a stainless steel liner. If using an existing masonry chimney, be sure to

have the chimney examined and cleaned by a chimney professional. The structural foundation of the

chimney and liner are important. If the existing clay liner is cracked or damaged, it is recommended to re-

line the chimney with a stainless steel liner or other chimney relining system. Be sure the masonry

chimney is compatible with the local building codes and requirements. It is important to note that you can

only have one appliance per chimney, and it is not permissible to connect your Hitzer Energy Master II

furnace to a chimney that is servicing another appliance.

Factory Built System:

A good chimney is essential. The factory built chimney must be a Class A: High Temperature chimney UL

listed to UL 103 (CAN/ULC-S629-M87) Type HT. It is required for this Class A chimney to be listed and

labeled under the UL standards. If using an existing factory built Class A chimney it must be inspected

and cleaned by a certified chimney professional, before use. With Factory Built Chimneys, clearances

and distance requirements are required per chimney style. Be sure to follow the manufacturer’s

clearances and regulations. It is also important to abide by the rules and regulations of local jurisdictions

upon chimney installation. Like masonry chimneys, you can only have one appliance per chimney, and it

is not permissible to connect your Hitzer Energy Master II furnace to a chimney that is servicing another

appliance.

Flue Requirements: It is required to have a chimney that is built according to the chimney

manufacturer’s specifications and meets local building codes. It is also required to have your chimney

inspected and cleaned by a certified chimney professional before your Hitzer Energy Master II furnace

installation, and periodically during the heating season. When wood is burned slowly, it produces tar and

other organic vapors, which combine with expelled moisture to form creosote. The creosote vapors

condense in the relatively cool chimney of a slow-burning fire. As a result, creosote residue accumulates

on the flue lining. When ignited, this creosote makes an extremely hot fire, the results of which can be

tragic. If material has accumulated, it should be removed immediately to reduce the risk of a chimney fire.

An Anthracite coal fire, as a general rule, does not produce creosote so it should not add to a creosote

buildup. It can however get hot enough to ignite an existing buildup thus causing a chimney fire.

IF A CHIMNEY FIRE DOES OCCUR: Notify all the occupants of the house and call the fire department

immediately. Turn the power to the furnace turned off, and any draft controls should be closed. The

barometric damper should be blocked then exit the house at once!

Flue Size: The proper flue size is very important. The proper flue size is essential in order to have the

correct amount of draft required to operate the Hitzer Furnace. The diameter of the flue size including

chimney liner should never be less than the diameter of the flue exhaust collar on the Hitzer Furnace. The

flue size for the Stoker Furnace should be a minimum of 6 inches in diameter

The flue size also has a maximum size of inches in order to sustain the desired draft. For an interior

chimney the flue and chimney liner size cannot be larger than 3 times the square inches of the flue

exhaust collar on the Hitzer stove. For an exterior chimney that has at least one side exposed to the

exterior of the house the flue and chimney liner cannot be more than 2 times the square inches of the

flue exhaust collar of the Hitzer Furnace. Also keep in mind the warmer the chimney is the better the

draft.

Page 12

Model Flue Size (Sq. Inch) Minimum (Sq. inch) Maximum (Sq. Inch)Int/Ext

Stoker 6” 28 sq. in. 6” 28 sq. in. 84 sq. in. interior

Furnace 6” 28 sq. in. 6” 28 sq. in. 56 sq. in. exterior

Chimney Height Requirements: The minimum height of a chimney system for the Hitzer Stove is 15

feet. The chimney must exceed the roof of a house a minimum of 3 feet at any point of exit. In pitched

roof installation the chimney must be at least 2 feet higher than anything within a 10 foot radius of the

chimney. It is important to have a chimney draft of .03 - .06 wc. Never operate your furnace at a flue draft

exceeding .06 wc (14.945 Pa) or less than .03wc (7.473 Pa). It is required to abide by the manufacture’s

instructions on class A chimney’s as well as local building codes.

All of these requirements must be followed to ensure the best chances for good draft. There are however

many environmental factors that can effect your draft. A few of these include wind speed and direction,

obstructions diverting winds, barometric pressure and humidity. This is why it is essential to have a

barometric damper and carbon monoxide detectors/alarms installed and working properly.

Power Vent System:

A Hitzer approved power vent may be used in place of a chimney. BE SURE TO READ YOUR POWER

VENTER INSTALLATION AND OPERATION INSTRUCTION MANUAL BEFORE USING THE POWER

VENTER. Follow the instructions that come with the power venter, for cutting the hole, and mounting the

venter to the wall. Connect your Hitzer Energy Master II Stoker Furnace to the power vent using a 6 inch

stove pipe and a barometric damper. You need to make certain that the pipe joints are tight together and

screwed with a minimum of three sheet metal screws per joint. Once you have the vent system

installed you can then install the wall control thermostat system according to the COAL-TROL

DIGITAL™ instruction manual which is supplied in the thermostat box.

Note:

-Illustrations are not drawn to

scale

-For design purposes only

-Actual Installations may vary

Page 13

IV. Basic Regulations for Safe Operations

Standard Cautions:

CAUTION: ALWAYS HAVE WORKING CARBON MONOXIDE AND SMOKE

DETECTORS/ALARMS INSTALLED WHEN USING THIS APPLIANCE. ONE ON

EACH FLOOR AND BY SLEEPING ROOMS IS RECOMMENDED

CAUTION- Hot Surfaces WARNING-Risk of Fire

-Keep children away Do NOT operate with fuel or ash door open

-Do not touch during operation Do NOT store fuel or other combustible

material within marked installation clearances

DANGER-Risk of Fire/Explosion

- Burn Rice Anthracite Coal Only

-Do NOT burn garbage, gasoline, Do NOT connect this unit to a chimney flue

oil, or any other flammable liquids serving another appliance.

CAUTION WARNING

Use caution when opening loading door. Have chimney inspected. The chimney

Avoid opening loading door rapidly. This is a very important part of your heating

could cause flame to flash out door. This system. It must be the right size,

occurs when there is unburned gas at the properly constructed, and in good

top of the fire box. When the door is condition. Chimney must be at least 15’

opened, oxygen combines with gases high and exceed the roof a minimum of

and ignites. 3 feet, unless using Power Vent System

WARNING-Risk of Fire WARNING-Over Fire Unit

-Comply with all minimum clearances to Do NOT over fire your unit.

combustibles as specified. This will cause warping of fire box parts,

-Failure to comply may cause fire. damage the stove, and void all warranty.

Local Codes:

All local codes should be strictly followed and inspected by local officials. Please follow local building

codes, manufacture codes, and fire codes. Local codes vary depending on location and regulations.

Communication and inspection in accordance with local building and fire officials must be present and

installation must successfully pass the local professional inspection.

VI. Stove Start Up & Operation

Install Coal-Trol Thermostat:

Once appliance is placed in the desired location you can locate your Coal-Trol thermostat so that the

supplied control cable will reach it. The supplied cable is 25 feet long. Longer lengths can be ordered

Page 14

from your Hitzer dealer or directly from Hitzer. The maximum length that will work is 100 feet. The Coal-

Trol control box is located on the top of the blower housing. Connect control cable to thermostat on the

wall and to the control box on the furnace. Once the ductwork has been connected mount hi-temperature

cut out switch (set to 155°) in ductwork approximately 3 inches above the furnace top. Drill 1” hole in duct

and mount switch with sensor inside duct. Follow the instructions and set-up procedure included with the

Coal-Trol Thermostat.

Start Up:

Note: For the first fire in your new Hitzer Furnace, create a small hot fire to allow paint to cure to the

stove. This may create a slight odor as paint cures to the furnace. Let this small fire burn for at least 2

hours before you raise the Coal-Trol temperature setting to maximum heating potential.

CAUTION: NEVER USE GASOLINE, KEROSENE, CHARCOAL LIGHTER FLUID, OR

ANY OTHER TYPE OF FLAMMABLE LIQUID TO START YOUR FIRE.

First make sure you have coal in the hopper and the power vent on if applicable. In the center of the

grate build a fire with broken up self lighting charcoal, a big hand full of wood pellets, a coal stoker igniting

block (coal mouse), or kindling wood. Once the fire is started and established, sprinkle a very thin layer of

coal over it and turn the power on to the COAL-TROL DIGITAL™ control. This starts the combustion

blower and also the feed motor. As you see the coal start to glow sprinkle another layer of coal on. As this

coal starts to glow red the feed motor should now be feeding coal far enough onto the grate that it will

start. Once coal is started you can adjust the thermostat to the desired temperature and the automatic

system will take over from here.

Adjusting Chimney Draft:

With the coal fire burning and stabilized, drill a small hole in the back of the stovepipe a few inches above

your furnace. Attach a manometer to this hole to read the chimney draft. Adjust the barometric damper so

that your manometer reads between .03 and .06 (inches of water column) following the instructions

provided with the damper. Do not run at a draft above .06 (inches of water column) as this could cause

your stoker to over fire. Over firing can cause a dangerous fire hazard. It would be best to set it with a

manometer if available. The settings on the barometric damper are close but not completely accurate.

Measuring Furnace Compatibility:

Follow the instructions with your Coal-Trol to find the fan speed adjustment. Adjust this from automatic to

manual at 99. This is the max speed of the convection fan. At the same time adjust the thermostat on

your central furnace 8 to 10 degrees above the room temperature. This should in a few minutes have it’s

fan running at max. With both fans running at their maximum settings, Drill a small hole in the plenum of

each furnace and measure the static pressure in each with a manometer. The maximum static pressure

must not exceed the pressure listed on the nameplate of the furnaces. If these pressures are exceeded

your installation is incorrect and dangerous. Exceeding these pressures will void your warranties and

possibly damage either one or both of your furnaces. This problem can be easily fixed by enlarging your

duct work or possibly adding another line to your plenum. .

Notice: Always burn your stoker with the ash door, glass door, and hopper lid closed and the door

gaskets and seals in good condition. Failure to keep these doors closed can result in smoke and carbon

monoxide coming into your house creating a very dangerous situation

CAUTION: ALWAYS HAVE A WORKING CARBON MONOXIDE, AND SMOKE

DETECTOR INSTALLED WHENEVER USING THIS APPLIANCE

CARBON MONOXIDE

Actuation of your CO alarm indicated the presence of Carbon Monoxide. Turn off your coal stove

immediately and increase ventilation by opening windows and doors to help move the fresh air

throughout the house. Exit the area at once. Contact your installer or other local authorities to

determine the source of the carbon monoxide and solve the problem.

Page 15

VII. Maintenance

Failure to maintain or properly use this appliance may cause a house fire. At the beginning of each

heating season this appliance, the connector pipe, and chimney should be inspected to see that it is in

good working condition.

Daily:

Check ash pan and remove and dump if full. Failure to remove ashes will result in ashes blocking

up your grate and your fire will not burn correctly. Ash pan will fill within several days depending

on the burn rate. Ashes should be placed in a metal container with a tight fitting lid. The closed

container of ashes should be placed on a noncombustible floor or on the ground, well away from

all combustible materials, pending final disposal. The ashes should be retained in the closed

container until all cinders are out and have thoroughly cooled before final disposal.

Clean glass. Brush fly ash off as it will etch into glass if left on.

CAUTION: THE ASH PAN AND PARTS OF YOUR STOKER WILL BE HOT. ALWAYS

WEAR GLOVES AND PROTECTIVE CLOTHING WHEN EMPTYING ASH PAN OR

WORKING ON A HOT OR BURNING STOVE.

Weekly:

Pull small handle on the back of the flue collar out and push back in vigorously several times.

This will knock the fly ash off of the heat exchanger plates inside your stoker and down to the

bottom of the stoker.

Clean all ash and fly ash from floor inside of the stoker around ash pan.

Two months or after approximately 2 tons of coal: This cleaning time line will differ from other Energy

Master II owners depending on amount of coal burned, ash content of the coal, the burn rate, and draft of

the chimney.

Allow stoker to run out of coal, go out, and cool down.

Remove chimney connector pipes and check and remove any fly ash accumulation. This will

mainly be at the bottom of elbows and horizontal runs.

Remove all fly ash from heat exchanger plates inside and below the flue collar and on the floor of

the stoker around the ash pan.

Carefully remove or raise cast iron grate and vacuum coal fines and fly ash from under the grate.

Clean coal fines and dust from under feeder shovel

Clean glass thoroughly

End Of The Season:

Summertime moisture and high humidity can be absorbed by dust and fly ash and cause rust and

corrosion. A clean stoker helps reduce this.

Do all the 2 month items plus the following.

At the end of your heating season remove all coal from hopper. Letting hopper run out of coal

while burning is best as it will also remove any moisture left in stoker from damp coal.

Remove all ash and dust from inside stoker with vacuum and paint brush.

Carefully raise or remove cast iron grate and vacuum ash and dust from under it.

Disconnect stove pipes from stoker. Thoroughly clean all fly ash, soot, and dust out of pipe.

Especially elbows and horizontal runs.

Check and clean chimney if necessary.

Clean all fly ash and dust from heat exchanger plates through flue collar.

Remove hopper and clean all dust, and coal fines from feeder and under feeder plate. If rust or

corrosion is observed on feeder sand lightly and coat with spray paint or a rust inhibiter like WD-

40.

If using a power vent, it must be disassembled, cleaned, and lubricated according to the

instructions that came with the power vent.

Page 16

VI. Troubleshooting

Page 17

IX. Further Information:

POWER OUTAGES:

In event of a power outage a small generator or 12 volt battery and an inverter with a capacity of at least

550 watts may be used. The length of the burn time using the back-up system will be determined by the

capacity and condition of the battery and the amount of heat needed. Some generators will also work

however the output of either must be a pure sine wave. Other outputs can cause the Coal-Troll Digital™

to not work.

You may also contact your Hitzer dealer or Hitzer Inc., for questions or more information regarding stove

installation and operation.

Hitzer Inc.

269 E Main St.

Berne, IN 46711

(260) 589-8536

hitzer.com

Email: info@hitzer.com

Table of contents

Other Hitzer Furnace manuals

Popular Furnace manuals by other brands

Carrier

Carrier 59SC2D Installation, start-up, operating and service and maintenance instructions

ICP

ICP N9MSB0401410B Service and technical support manual

Whip Mix

Whip Mix Pro Press 100 Operation manual

VERDER

VERDER CARBOLITE GERO CWF 13/36 Installation, operation and maintenance instructions

J. A. Roby

J. A. Roby GRIZZLY owner's manual

Thermo Pride

Thermo Pride OC2-56 Installation and operation manual