HM Machinery SBM 28B User manual

Industrivej 3-9

9460 Brovst,

Denmark

Tel. + 45 98236088

Fax. + 45 98236144

MANUAL

GEARED HEAD DRILLING MACHINE

HM SBM 28B

EU declaration of conformity

HM MACHINERY A/S

Industrivej 3-9

9460 Brovst

DENMARK

Tlf.: + 45 98 23 60 88

Fax.:+ 45 98 23 61 44

hereby declares that

HM SBM-28F are manufactured in accordance with the provisions of the European

Parliament and Council Directive 2006/42 / EC of 17 May 2006

And also in accordance with:

·Low Voltage

·EUROPEAN PARLIAMENTAND COUNCIL DIRECTIVE 2014/35 / EU of 26

February 2014

·EMC

·EUROPEAN PARLIAMENT AND COUNCIL DIRECTIVE 2014/30 / EU of

26 February 2014

Vigtigt

Husk påfyldning af olie inden opstart

Important

Remember to fill oil in the gearbox before use of the machine.

Achtung

Bitte Öl auffüllen bevor die Maschine gestartet wird

Important

S'il vous plaît n'oubliez pas de mettre de l'huile dans

la boîte de vitesses avant d'utiliser la machine.

Importante

Recordar rellenar con aceite la caja de transmision antes de arrancar la maquina.

CONTENTS

1. NOTE

2. PASSPORT DATA

3. LIMITED WARRANTY

4. SAFETY AND GENERAL INFORMATION

ªSAFETY

ªFORESEEN USE OF THE MACHINE

ªCORRECT USE OF THE MACHINE

ªPIECE CLAMPING

ªTOOL FIXING

ªCHIPS DURING MACHINE

5. TEST REPORT

6. MAIN SPECIFICATIONS

7. INSPECTION

8. CLEANING

9. INSTALLATION

10.MACHINE OPERATION INSTRUTION

11.UNLOAD TOOL OPERATION MANUAL

12.SPEED LEVER PANEL

13.WIRING DIAGRAM

14.DRILL PROTECTON GUARD

15.ELECTRIC CONNECTION

16.MACHINE CARE AND MAINTENANCE

NOTE

This manual has been prepared for the owner and operators of this machine. Its purpose,

aside from machine operation, is to promote safety through the use of accepted correct

operation and maintenance procedures. Completely read the safety and maintenance

instructions before operation or servicing the machine. To obtain maximum life and

efficiency form your machine, and to aid in using the machine safety, read this manual.

Since we continually strive to incorporate latest developments in the construction of the

machine, it is quite possible at time, due to printing and shipping requirements, some data

may not correspond to the machine in question.

LIMITED WARRANTY

We make every effort to assure that our products meet high quality and durability

standards and warrants to the original retail consumer/purchaser of our products that each

product be free from defects in materials and workmanship as follow: ONE YEAR LIMITED

WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This warranty

does not apply to defects due directly or indirectly to misuse, abuse ,negligence or

accidents, normal wear and tear or alterations outside our facilities, or to a lack of

maintenance.

We shall in no event be liable for death, injuries to persons orfor incidental, contingent,

special, or consequential damages arising from the use of our products.

To take advantage of this warranty, the product or part must be returned for examination,

postage prepaid. Proof of purchase date and an explanation of the complaint must

accompany the merchandise. If our inspection discloses a defect, we will either replace the

product, or refund the purchase price,if we cannot readily and quickly provide a repair or

replacement. We will return repaired product or replacement at our expense, but if it is

determined there isno defect, or that the defect resulted from causes not within the scope

of our warranty, then the user must bear the cost of storing and returning the product.

SAFETY AND GENERAL INFORMATION

1. SAFETY

A drilling machine, due to its purpose, is considered an “open machine” Therefore, some

safety measures have to be taken to avoid accidents.

Bear in mind the following safety instructions:

FThe machine must always be operated for the purpose for which it was designed.

FDo not ever stand under a hanging machine or nearby, when it is being loaded for

transportation.

FConnect the machine to an exclusive electric connection, which includes differential

switch of protection. First plug in the green-yellow protection wire and then the others.

FThe piece must always be fastened with suitable devices. Do not ever handhold the

workpieces.

FSharpened tools in good condition must always be used.

FAppropriate tools must always be used, Do not ever adapt a tool for a use for which it

was not designed.

FUse the correct speeds and feeds for the material being machined as well as for the

tool being used.

FUse glasses to prevent small chips from getting into the eyes.

FInsert the tools correctly in the tool holder cone.

FFix the work piece fastening devices to the machine table.

FDo not wear baggy clothes, loose gloves, etc, which can be caught by the tool while

drilling.

FKeep the working place clean.

FGather the chips with suitable instruments (brush, gloves, etc.)

Before carrying out any operation which is not strictly drilling,

Ftapping etc. (like lubricating, changing of tools, etc,) turn the main switch to the

“0”position.

FBefore changing speeds, stop the machine and wait until all moving elements are

completely brought to a halt.

FDo not ever leave the machine on without supervision. When leaving the machine,

check that the general switch is in the “0”position and that moving elements are

stopped.

FCheck periodically the correct operating of all security controls and elements of the

machine.

FBefore pressing the starting pushbutton, set the drill protector guard in the working

position.

FConsider work area environment. Don’t use electric power driven tools in damp or wet

locations. Keep work area well lit. Don’t use electric power tools in presence of

flammable liquids or gases.

FKeep children away.

FUse only such accessories and attachments as are recommended in the operating

instructions or the catalogue for the power tool concerned.

2. FORESEEN USE OF THE MACHINE

The drilling machine was designed to be used with specific tools and for certain machining

operations.

The most common machining operation is the drilling of holes with helicoidal drills. The

drilling of holes is carried out by the combination of a drill turning movement and a feed

movement in the turning spindle direction.

Besides the helicoidal drill, other tools can be used to drill holes. There is a great variety of

drill types and shapes in the market,which can be used on this machine, provided that

they are designed for such a purpose and that can be fixed in the spindle

taper. They will usually be the Morse taper or ISO type. The drill shanks should have the

corresponding taper to the spindle in which they are to be fitted, or parallel shank if they

are going to be fitted by means of a tool holder. Contact the tool manufacturer for any

further information. Do not ever use tools which were not designed to be used in a drilling

machine.

A drilling machine can also perform other machining operations apart from the drilling,

such as tapping, reaming, chamfering, punch marking, countersinking, spot facing. To

perform such operations, it is necessary to have appropriate tools, specially designed for

this sort of jobs. In the tapping case, besides using correct tool, the machine has to be

provided with such a device that verses the turning direction of the tool when it reaches the

depth previously fixed.

3. CORRECT USE OF THE MACHINE

FNot exceeding its working capacity.

FOperating the machine by qualified and trained staff,and according to the points

mentioned in the instruction book.

FWorking under the safety systems provided with the machine, checking them and

keeping them.

FWatching the safety measures mentioned in the instruction book and notices on the

machine.

FWearing clothes which provide personal safety as mentioned in the instruction book.

FWatching the safety measures which may affect work on the machine,and that can be

lawfully expected, as well as those demanded in the workshops.

4. PIECE CLAMPING.

Tangential cutting forces and axial forces in the feed direction of the tool are mainly

produced during the drilling process. The tangential forces produce a moment of forces

which make the piece being drilled turn. Therefore, the pieces to be drilled (or to be

machined by one of the operations mentioned above) must be clamped in an appropriate

device, such as a drill chuck, and the drill chuck must be correctly clamped to the machine

table. For this reason the machine tables are provided with “T” slots.

The pieces must be clamped conveniently by some clamping device.

The clamping devices must be clamped to the machine table.

The machine table is provided with “T” slots for such purpose.

5. TOOL FIXING

The tools generally used in this machine will have parallel or taper shanks. Drill holders

are normally used to fix the main spindle of the machine to the parallel shank tools. This

fixing device is used for small drill diameters (max. up to dia.16mm). Bigger diameter drills,

usually have taper shank of Morse taper (the ones of smaller diameters than 16mm can

also have taper shanks).

The housing in the main spindle to insert the tool is of Morse taper type. It is very important

to insert the tool taper correctly in the main spindle taper to avoid the tool falling from its

housing when turning and provoke an accident. The coupling system itself of the tool male

taper in the female taper of the main spindle is auto-locking, but for it to work the surfaces

of the tool taper and spindle taper must be in contact. To get the best possible contact, the

surfaces of the tool taper as well as the spindle taper should be in good conditions.

Therefore, it is advisable to handle the tool as well as the spindle of the machine carefully.

6. CHIPS DURING MACHINE

The machining process removes material from the piece. This material is released in

chips, which can be of different shapes depending on the material itself. The most

common ones are of three types: fragmented chips in small bits, short helicoidal chips and

long helicoidal chips.

The chips fragmented in small bits can be rejected from the machining area and can be

dangerous if they reach the eyes of the operator. To avoid this, it is advisable to wear

safety glasses.

The long helicoidal chips tend to roll up the tool and gain considerable volume before

breaking, which is dangerous if they reach the operator,as they may produce injuries.

The reached volume may also displace the drill protector from its security position,

increasing the risk of an accident. It is advisable to use chip breaking tools to machine

materials which produce such chips. For further information contact the tool manufacturer.

TEST REPORT

No. Checking items Inspection item Tolerance Data

G1 Flatness of table and

base

0.12

G2 Spindle taper run out

a. At the end of

spindle nose

b. At the end of

200mm test bar

a.0.03

b.0.06

G3 Verticality of spindle

center line to table

a. Transverse direction

b. Longitudinal

direction

a.0.10/300

(α≤90°)

b.0.10/300

G4 Verticality of spindle

sleeve vertical travel to

table

a. Transverse direction

b. Longitudinal

direction

a.0.10/150

(α≤90°)

b.0.10/150

MAIN SPECIFICATIONS

Model GB 28 S

Max.drilling capacity mm 28

Spindle taper —MT3

Spindle stroke mm 130

Distance from spindle center to column surface

mm 250

Distance from spindle nose to worktable

mm 125-825

Distance from spindle nose to base mm 1220

Spindle speeds range rpm 75-3200

Number of speeds —12

Diameter of column mm 98

Worktable size mm 380×380

Dimensions of base mm 360×535

Width of T-slot mm 14

Distance of T-slot base mm 160

Main motor(2 speed motor)KW 0.85/1.1

Packing size(L×W×H) mm 2100×400×640

N.W/G.W KG 200/230

20'container Q'ty: sets 42

Transport

Insert an iron bar through the transversal hole in the machine head which with the aid of a

rope, will be used for lifting the machine.

INSPECTION

The machine should be carefully examined on arrival, to check that it is complete and in

good order, so that claims can be made, if necessary.

CLEANING

Remove all anti-rust compounds. Clean and lubricate all movable parts.

INSTALLATION

In order to guarantee the stable working of the machine.

Please tighten the foundation bolts before operating.

MACHINE OPERATION INSTRUCTION

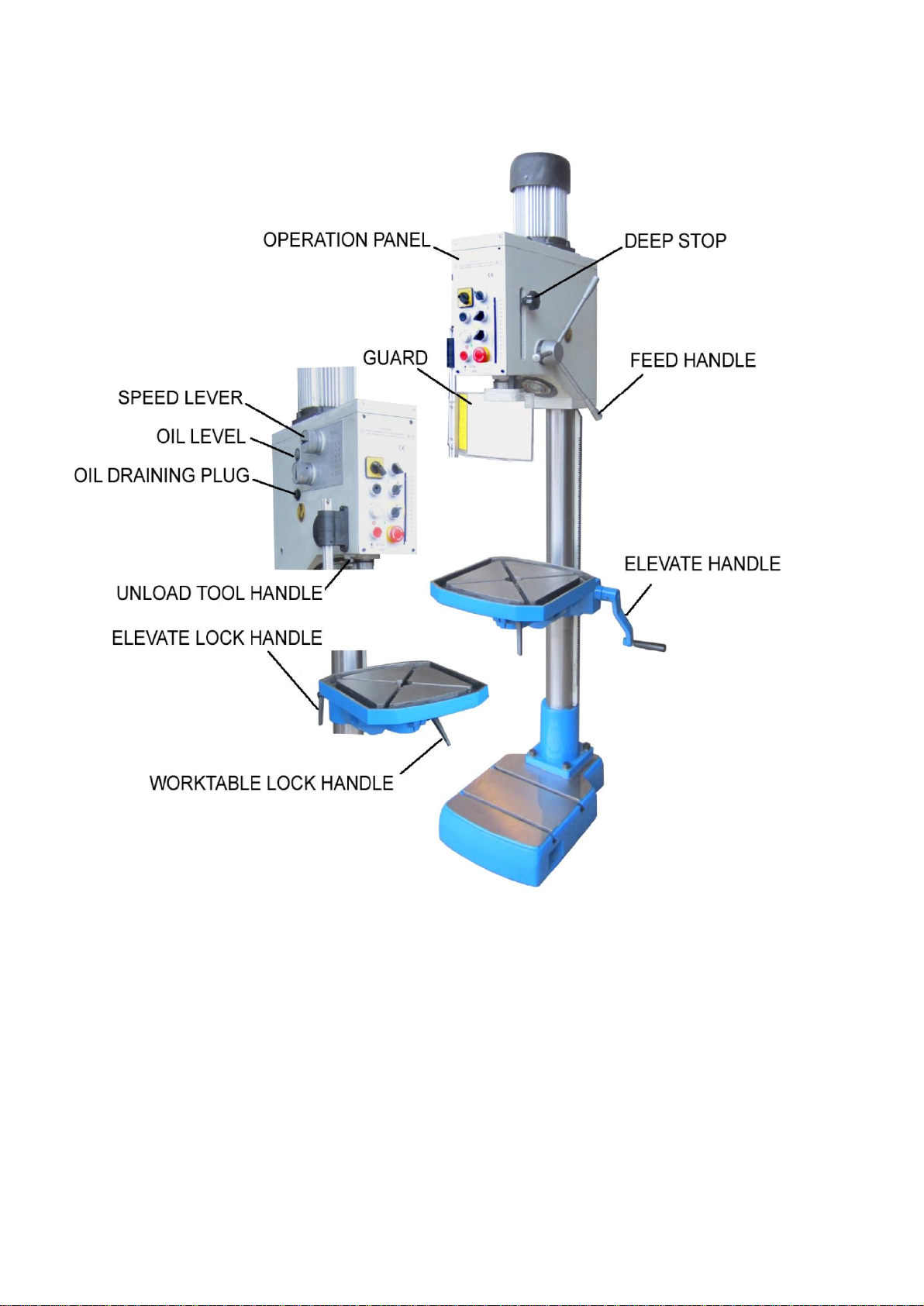

FIG.1

Table elevation

LoosenLOCK HANDLE, turning TABLE ELEVATE HANDLE, the table elevates vertically.

Fix the LOCK HANDLE when you reach the requested working position.

Table rotation

Loosenthe LOCK HANDLE, pull the table left or right to move around the axis of the

column. Fix the LOCK HANDLE when you reach the requested position.

Table turning

Loosenthe TABLE LOCK BOLT, pull the table up and down, fix the TABLE LOCK BOLT

after turning to the requested angle.

Inclined hole processing can be realized.

Spindle elevation

Press down the FEED HANDLE, spindle going down.

Tools installation and disassembling

Fig.2

OFF

ON

UNLOAD TOOL OPERATION MANUAL

1. According to the Fig.2, please pull out the UNLOAD TOOL HANDLE.

2. First the left hand should hold the tool, then the right hand push upward the FEED

HANDLE.

ATTENTION:

When using should put the handle in “OFF” position.

CAUTION: Tools installation and disassembling should be performed after machine is completely

stop running.

CAUTION: When installing and disassembling the tools, the emergency stop switch should be

pressed down.

Open the safety guard, install the tools in the spindle hole, make sure it is fixed

installing.

NOTE: Close the safety guard, loose the emergency stop switch then running machine.

SPEED LEVER PANEL

WIRING DIAGRAM

ELECTRIC COMPONENTS LIST

Code Name Model Specification Qty

HK Main switch JCH13-20/3

HZ Double speed

switch

3LBB-20 1

KM1-2 Contactor 3TB41-22

Coil voltage 24V

1

TC Transformer JBK5-63 1

SQ1 Microswitch LXW16-16/1C2 1

SQ2 Microswitch LXW16-16/1C2 1

HL SC-108E 24V,35W 1

SL Power indicator light

AD17-16 AC24V

1

SB1 Mushroom button YO90-01M 1

SB2,SB3 Button + pilot lamp

YO90-22 2

SA1 Switch YO90-20XB/3 1

SA2 Switch YO90-20XB/2 1

FU1 Circuit Breaker DZ47-63 D1 1P 1

M1 Main motor YD100L-8/4 0.85/1.5KW 1

Table of contents

Languages:

Other HM Machinery Drill manuals