Preface About This Document

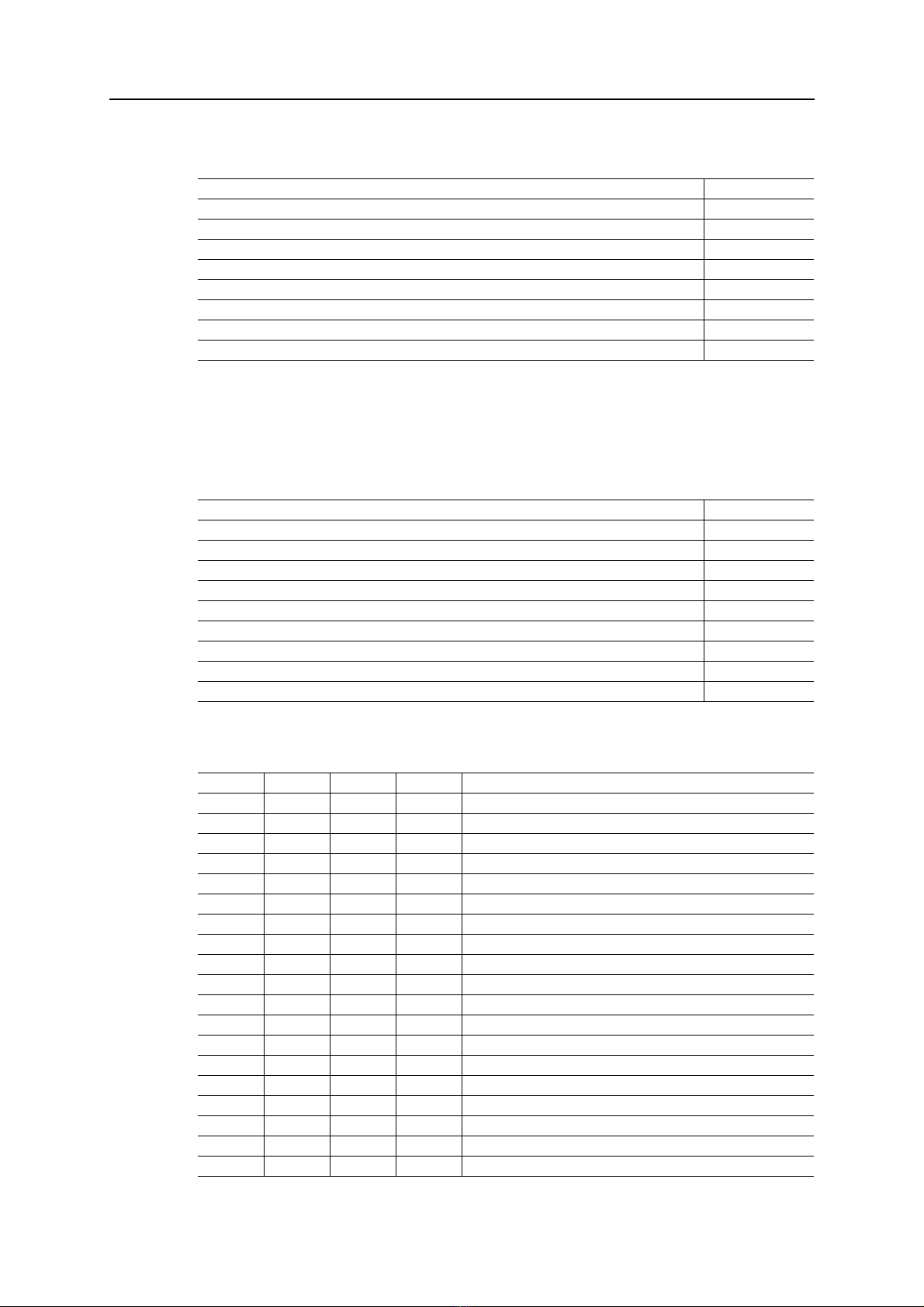

How To Use This Document ............................................................................................................ P-1

Important User Information .............................................................................................................. P-1

Related Documents.............................................................................................................................. P-2

Document History ............................................................................................................................... P-2

Conventions & Terminology.............................................................................................................. P-3

Glossary ................................................................................................................................................. P-3

Support .................................................................................................................................................. P-4

Chapter 1 About the Anybus Communicator for Modbus-RTU

External View ........................................................................................................................................1-2

Status LEDs ...........................................................................................................................................1-3

Configuration Switches ........................................................................................................................1-4

Node Address...............................................................................................................................1-4

Baudrate Configuration.................................................................................................................1-4

Parity & Stop Bits.......................................................................................................................1-4

Physical Interface...........................................................................................................................1-4

Hardware Installation ...........................................................................................................................1-5

Software Installation .............................................................................................................................1-6

ABC Config Tool.........................................................................................................................1-6

Chapter 2 Basic Operation

General....................................................................................................................................................2-1

Data Exchange Model ..........................................................................................................................2-2

Memory Map................................................................................................................................2-2

Data Exchange Example.............................................................................................................2-3

Sub-Network Protocol .........................................................................................................................2-4

Protocol Modes..............................................................................................................................2-4

Protocol Building Blocks ...............................................................................................................2-4

Master Mode ................................................................................................................................2-5

Generic Data Mode ......................................................................................................................2-5

Data Representation on Modbus RTU..............................................................................................2-6

General.........................................................................................................................................2-6

Supported Function Codes.............................................................................................................2-6

Coil & Register Map ...................................................................................................................2-6

Supported Exception Codes...........................................................................................................2-6

Chapter 3 Navigating the ABC Config Tool

Main Window ........................................................................................................................................3-1

Pull-down Menu ...........................................................................................................................3-2

Toolbar Icons ................................................................................................................................3-5

Table of Contents

Table of Contents