1

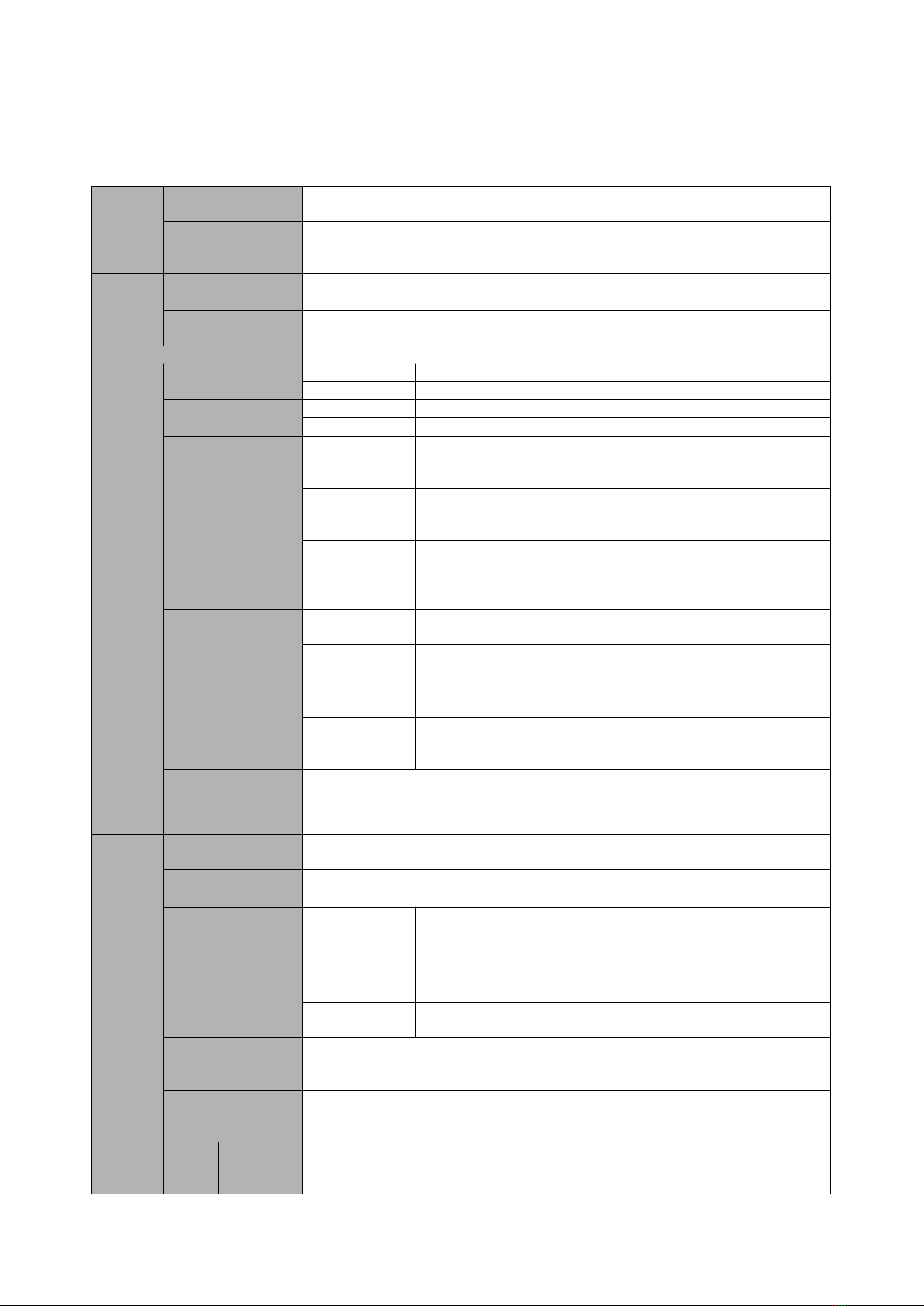

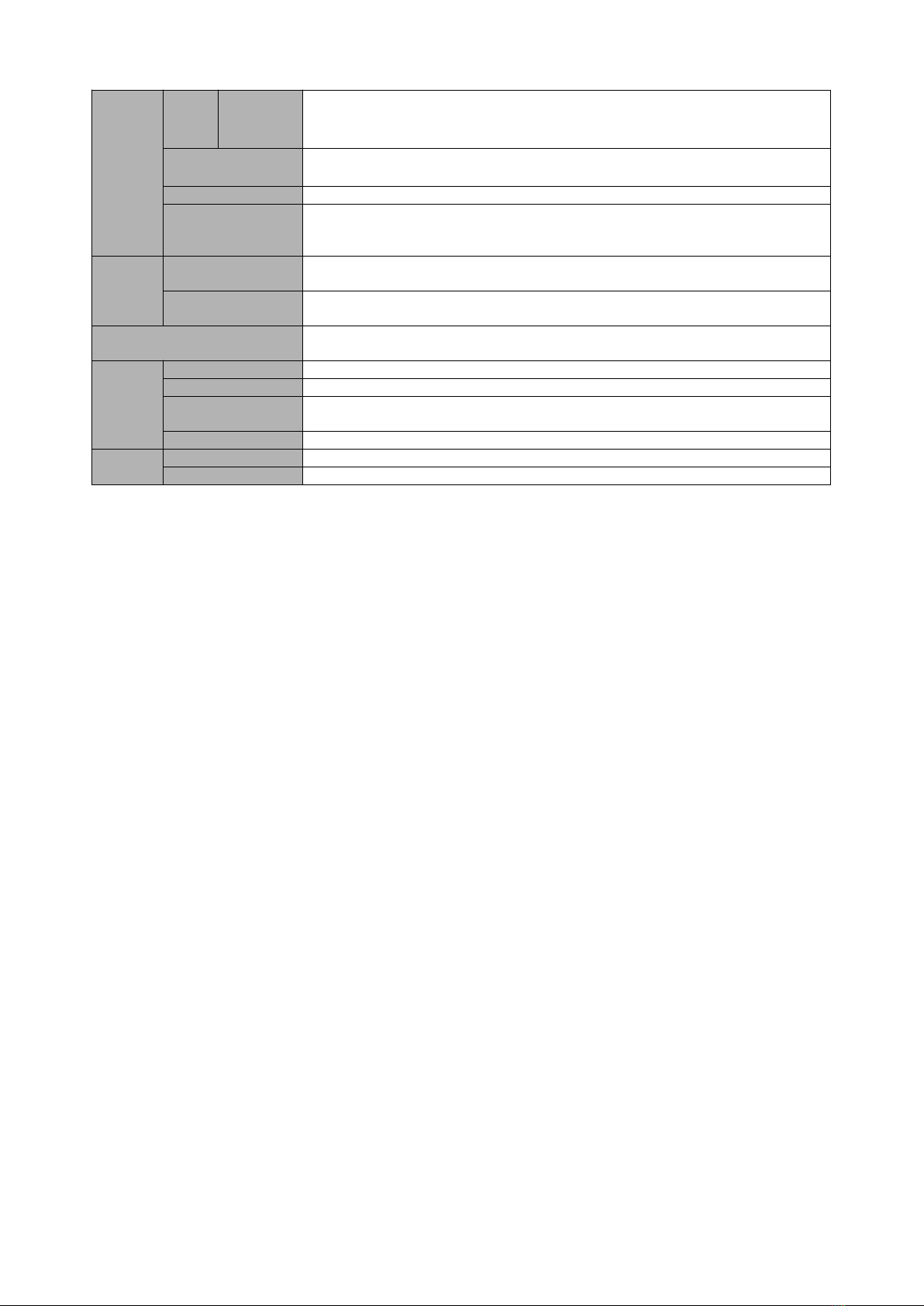

Content

I. Technical indicators and specifications of products................................................................................................2

II. Inverter Installation and Wiring............................................................................................................................. 4

2.1 Matters needing attention for Installation.....................................................................................................4

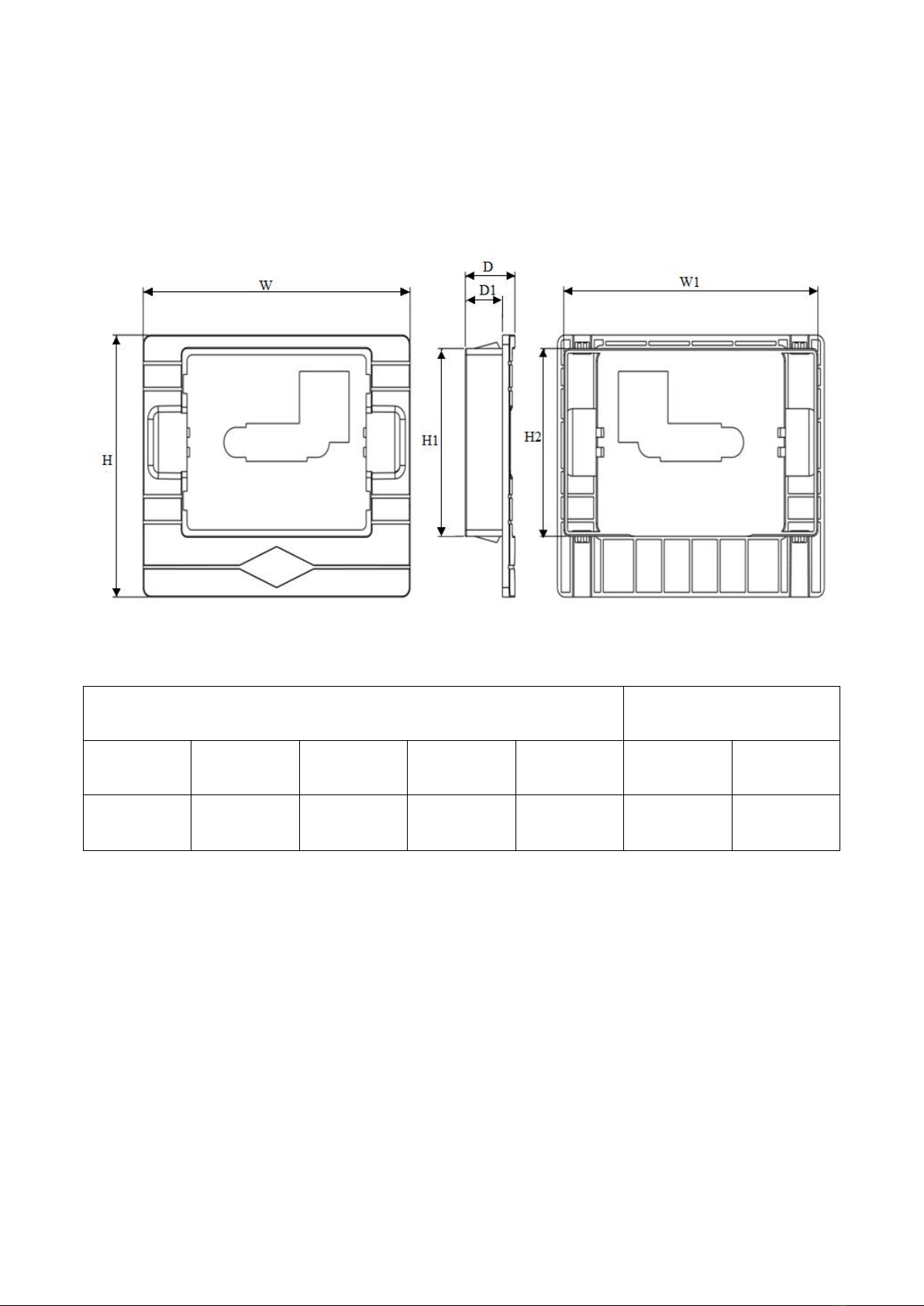

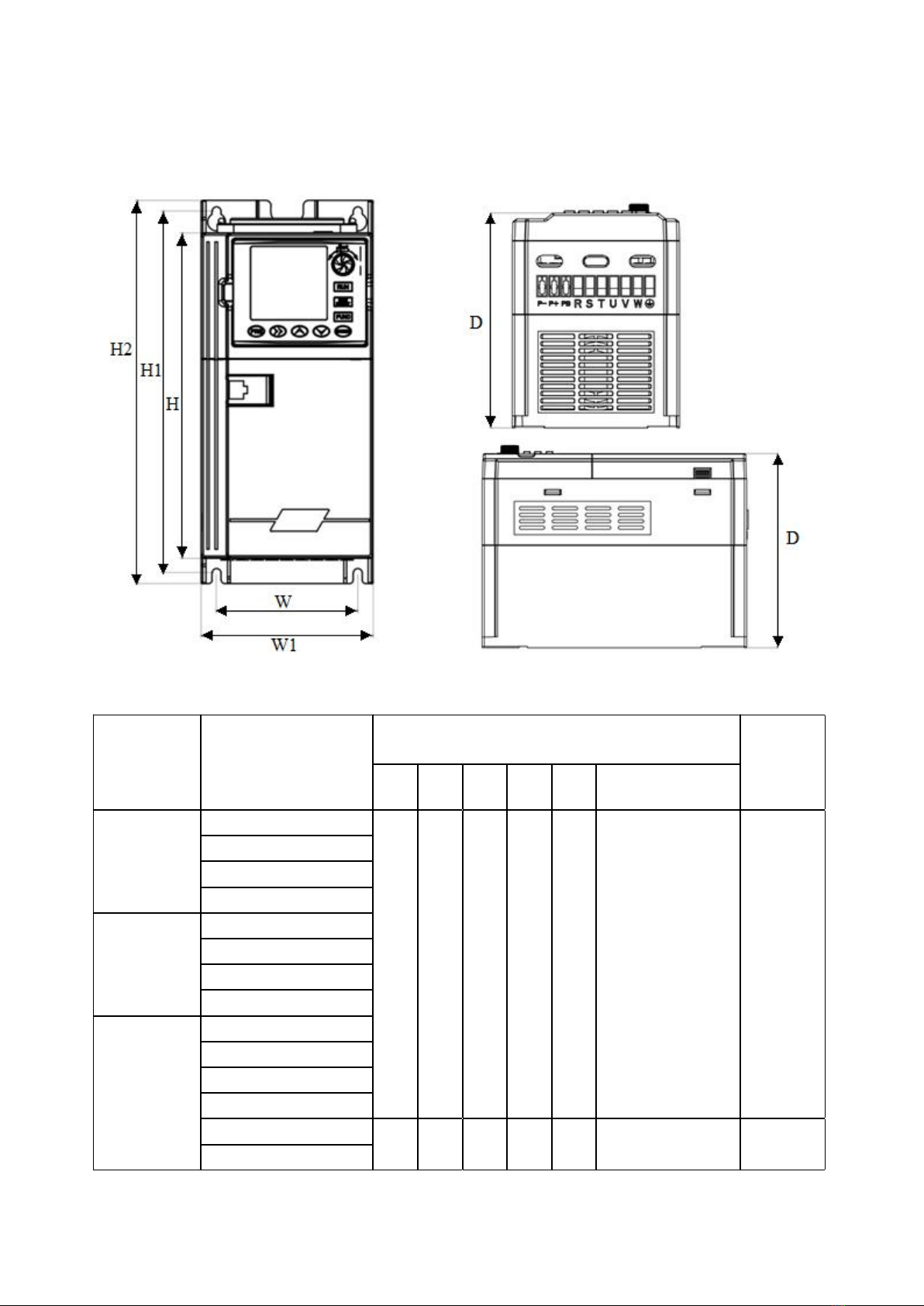

2.2 Outline drawing.............................................................................................................................................5

a. Overall dimensions of keypad base........................................................................................................ 5

b. Overall dimensions of the whole machine..............................................................................................6

2.3 Basic operation wiring.................................................................................................................................. 7

2.4 terminal for controlling loop.........................................................................................................................7

2.5 Matters needing attention for Wiring............................................................................................................9

III Communication protocol......................................................................................................................................10

1.RTU mode and format....................................................................................................................................10

2.Description of reading and writing function code:........................................................................................10

3.Register address............................................................................................................................................10

4.Description of parameter address of communication protocol:.................................................................... 10

5. 03H Reading function mode:........................................................................................................................ 12

6. 06H write function mode.............................................................................................................................. 13

IV. Exceptions and Handling.....................................................................................................................................15

V. Parameters instructions.........................................................................................................................................16

VI. Parameter description......................................................................................................................................... 31

00 group-basic operating parameters................................................................................................................31

01 group-auxiliary operating parameters..........................................................................................................36

02 group-analog and digital input and output parameters................................................................................ 42

03 group -PID parameters.................................................................................................................................49

04 group -advanced functions parameters........................................................................................................ 53

05 group- Protective Function parameters........................................................................................................56

06 group: communication parameters...............................................................................................................59

07 group- supplementary Function parameters................................................................................................ 61

08 group-manage and display parameters........................................................................................................ 63

Warranty agreement.................................................................................................................................................. 65