INSTRUCTIONS

(Refer to the illustrations in the parts list to identify the various parts mentioned below.)

TO FILL

1. Remove tank from case and check both stem and

wheels on the tank valve. The black wheel or air

valve and the red valve or fuel valve must be closed

by turning to the right as far as possible.

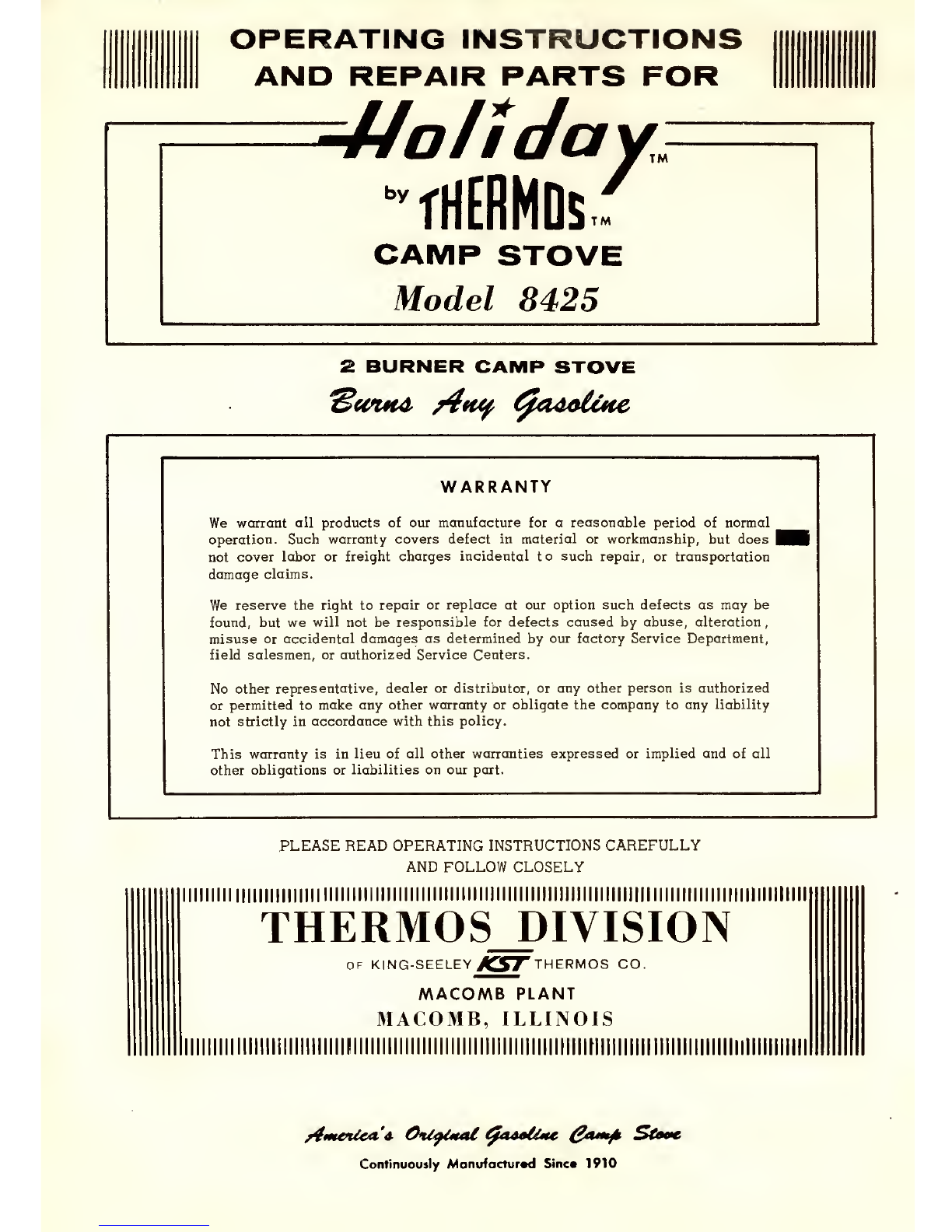

2. Remove the pump assembly from the tank and

fill with aGOOD GRADE OF CLEAN, FRESH

FUEL.

3. Replace pump assembly by turning down snuggly

with fingers.

4. Wipe off any gasoline that has been spilled

while filling.

ATTACH TANK

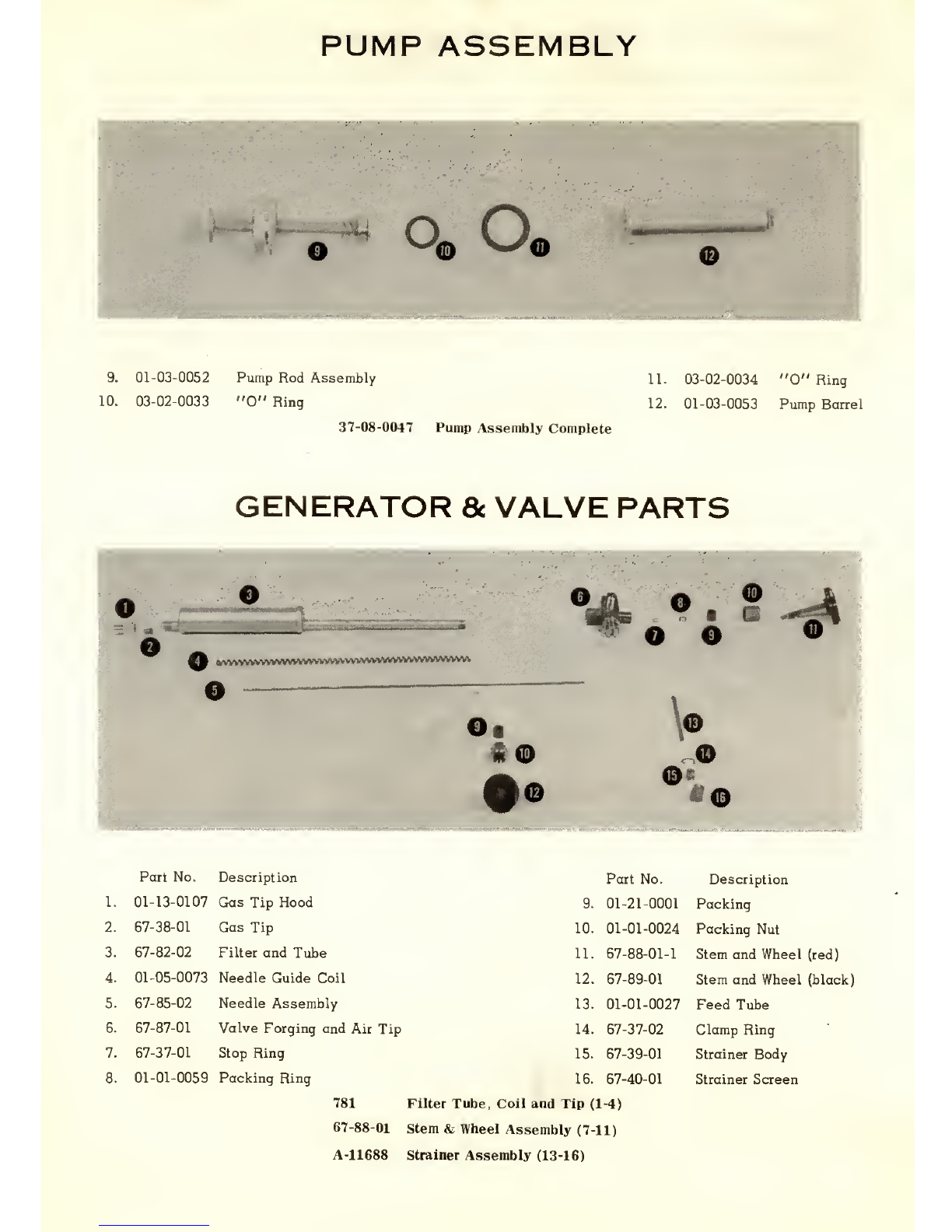

1. Place tank and generator on the stove by insert-

ing the air tip hood of the generator in the hole of

the outer shield on the manifold. This is behind and

above the first or master burner.

2. Hook the tank on the case tank shield and push

down to seat firmly.

AIR PRESSURE

1. Be certain both valves are closed.

2. Pump about 35 strokes.

3. If the gas tip hood fails to seat properly within

the opening in the air shield, it may be necessary

to loosen the screws that hold the manifold in

position, and move the manifold assembly either

forward or backward.

LIGHTING

1. Valve handle for other burners must be pushed

in. Open black valve about one turn. Light match

and open red valve slowly, holding match at burner

under generator until it lights. After burning about

two minutes, slowly close black valve as this sup-

plies air only for starting. In lighting, if the flame

goes down or dies out, pump in more air. IF BLACK

VALVE IS LEFT OPEN AFTER LIGHTING OPER-

ATION, PRESSURE WILL GO DOWN.

IMPORTANT LIGHTING INSTRUCTIONS

Do not rush the lighting operation with this stove

or you will have ahigh, yellow, smoky flame.

TO LIGHT OTHER BURNER

Slide valve handle out from case and light burner.

When two burners are used it is obvious that more

gas must be supplied. The flow of gas is regulated

by opening or closing the red valve.

TO EXTINGUISH

Close red valve tight. Alittle gas will continue to

escape from the generator for amoment or two after

valve is closed. This does not indicate that the

valve leaks. Be sure the red valve is closed tight.

IMPORTANT!

After appliance has been in use, the packing In

the valve stem nuts canshrink and cause aleak.

Tighten nut with wrench to stop leak. Be sure

to empty fuel from tank when appliance is to be

out of use for some time.

GENERAL INFORMATION.

If flame has atendency to go out when closing the

black valve, open red valve wider and then close

the black valve more slowly. Best results are ob-

tained by using alow flame for about two minutes,

until the generator is thoroughly heated. If stove

burns with ayellow flame there may be liquid gas-

oline in the manifold. With instant starting gasoline

pressure stoves some liquid gasoline will pass

into the manifold. As the manifold heats, this gas-

oline will vaporize and the burners will burn with

ablue flame. If flame blows away from burner,

there is too much air pressure in the tank, or black

valve has been left open.

This stove has an air adjustment located on the

top of the outer shield above the end of the gen-

erator. For more air, loosen screw and slide to the

left in the direction of the arrow.

Extreme changes in altitude may require achange

in this shutter from the factory setting.

After the stove has operated for at least ten minutes

and the flame tends to blow away from the burner,

it is an indication that the air adjustment is too

far open. Closing it too much will give ayellow

(rather than blue) flame.

If stove will not burn, or goes out while burning,

this may be due to lack of fuel or air pressure or

the gas tip on the generator may be clogged. To

remedy, close and open red valve quickly or re-

move and clean or replace gas tip. If needle point

is bent, replace. Air or fuel orifice in the tank

valve may be clogged. To remedy, unscrew valve

from tank and clean both orifices.

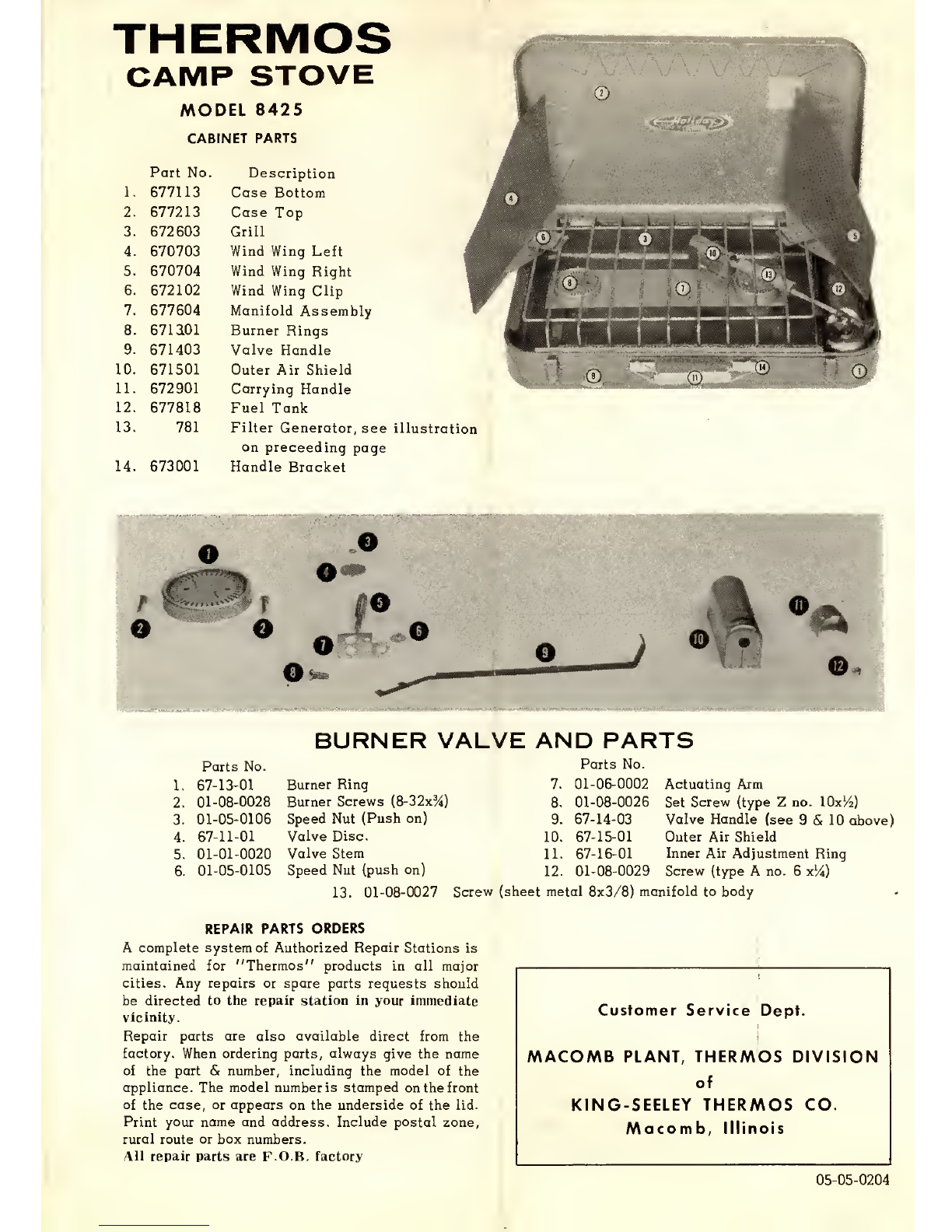

If stove pops and blows out, this is probably due

to burned out rings on the burners. Replace with

new burner rings.

Should generator leak gas while stove is not burn-

ing, tighten the red valve more. If leakage still

occurs, replace the gas tip, as the orifice may have

become enlarged by the action of the needle point.

CARE OF STOVE

1. Keep cabinet and parts clean.

2. Store in adry place.

3. Clean burner periodically by removing two

screws and lifting them off manifold.

4. Empty and dry out tank before putting in storage.

5. Keep packing nuts on the two valve wheels tight

to avoid gasoline leaks.

6. Replace gas tip on generator and needle valve

occasionally.

Needle points for repair are extra long be-

cause they do not screw into the stem the same

distance. They need to be cut off and trimmed

to atapered point that extends through the tip

about one-sixteenth of an inch.