2

DISTRIBUTOR INSTALL:

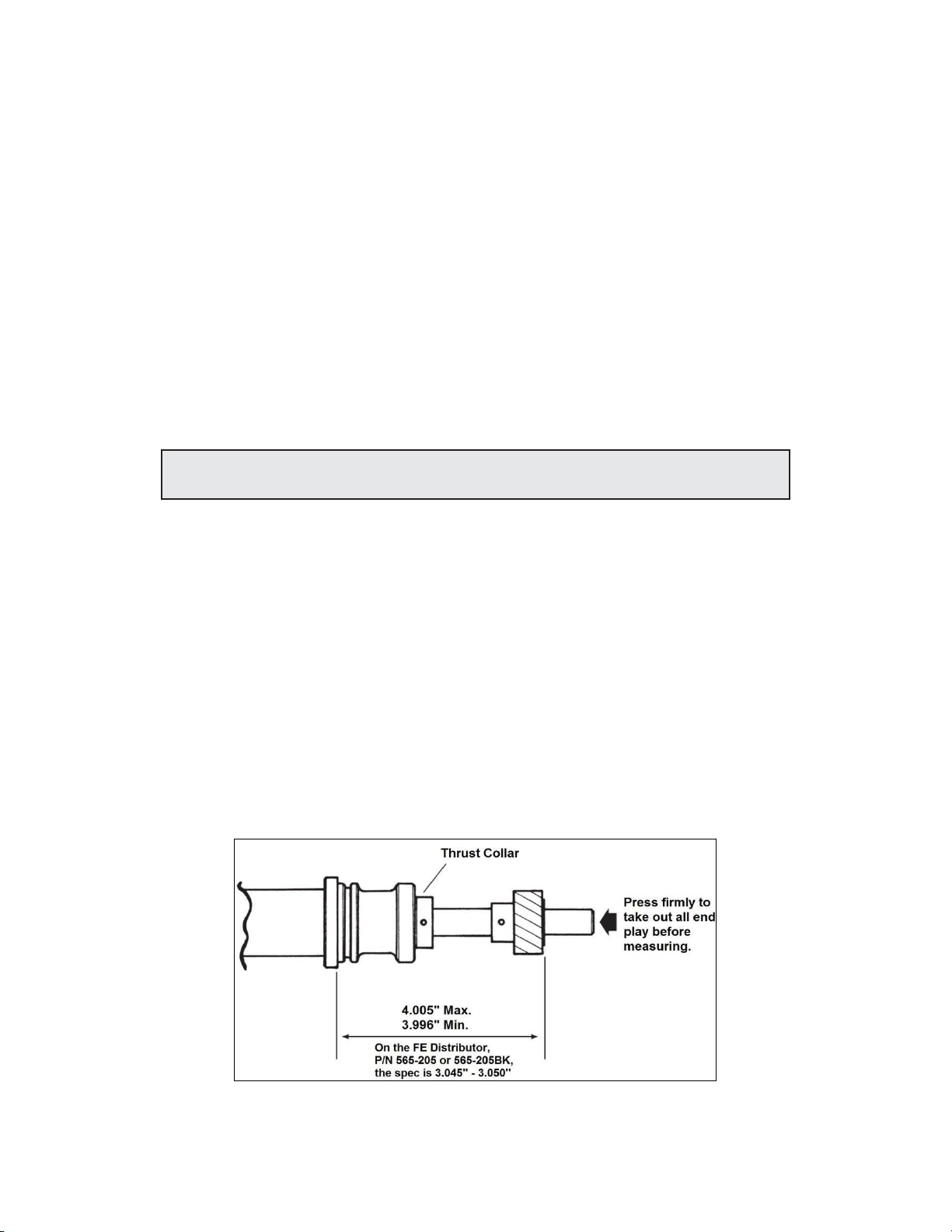

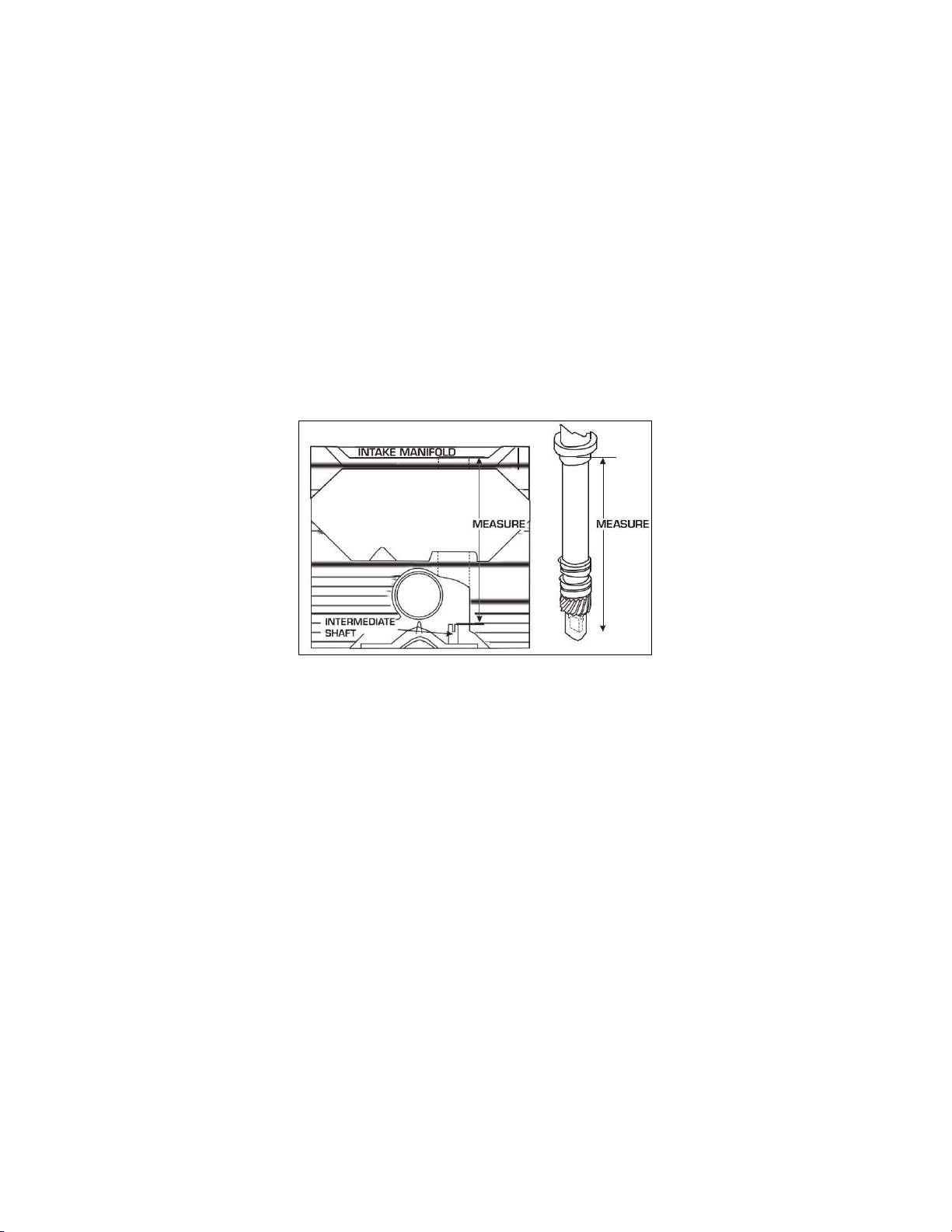

NOTE: If the engine block or heads have been milled, make sure that the distributor will fully seatand not bind or

bottom out on the oil pump drive. A quick check is to remove the distributor gasket, and make sure that the

distributor still fully seats on the mounting surface. If it does not, further investigation is needed.

1. Install the distributor gasket on the base of the distributor. If desired, apply adhesive between thegasket and

distributor to hold it in place.

2. If the engine has already been broken in/run previously and is about to be fired immediately after the distributor install,

coat the gear with motor oil. If the engine is new or will sit a while before it is fired, coat the distributor gear with a moly

paste or camshaft break-in lube. Ensure no synthetic oils are used during the installation or break-in period. We

recommend a standard 30 or 40 weight or Multi-Viscosity oil such as 10W-30 or 20W-50 to be used for the break-in

period. Engines that produce oil pressure over 70psi when COLD should utilize a racing grade mineral oil for break-in.

It is also recommended to monitor gear wear after the break-in period for several hours. Check the gear for proper

mesh, tooth alignment, andfor excessive tooth wear.

3. Position the rotor contact so it is pointing to the desired direction of the #1 spark plug wire. Insert the distributor into

the engine, ensuring that it is fully seated (see NOTE above). The rotor will rotate as you install the distributor. If it is

does not land in the location you desire, remove the distributor and back it up a tooth or two at a time until you are

satisfied with its location. You will need to make sure the oil pump drive shaft is turned in a direction that allows for the

distributor shaft to mesh with it. NOTE: An engine oil priming tool is an ideal alternative to aid in aligning the oil pump

drive shaft. Make sure that the drive shaft meshes andthe distributor fullyseats.

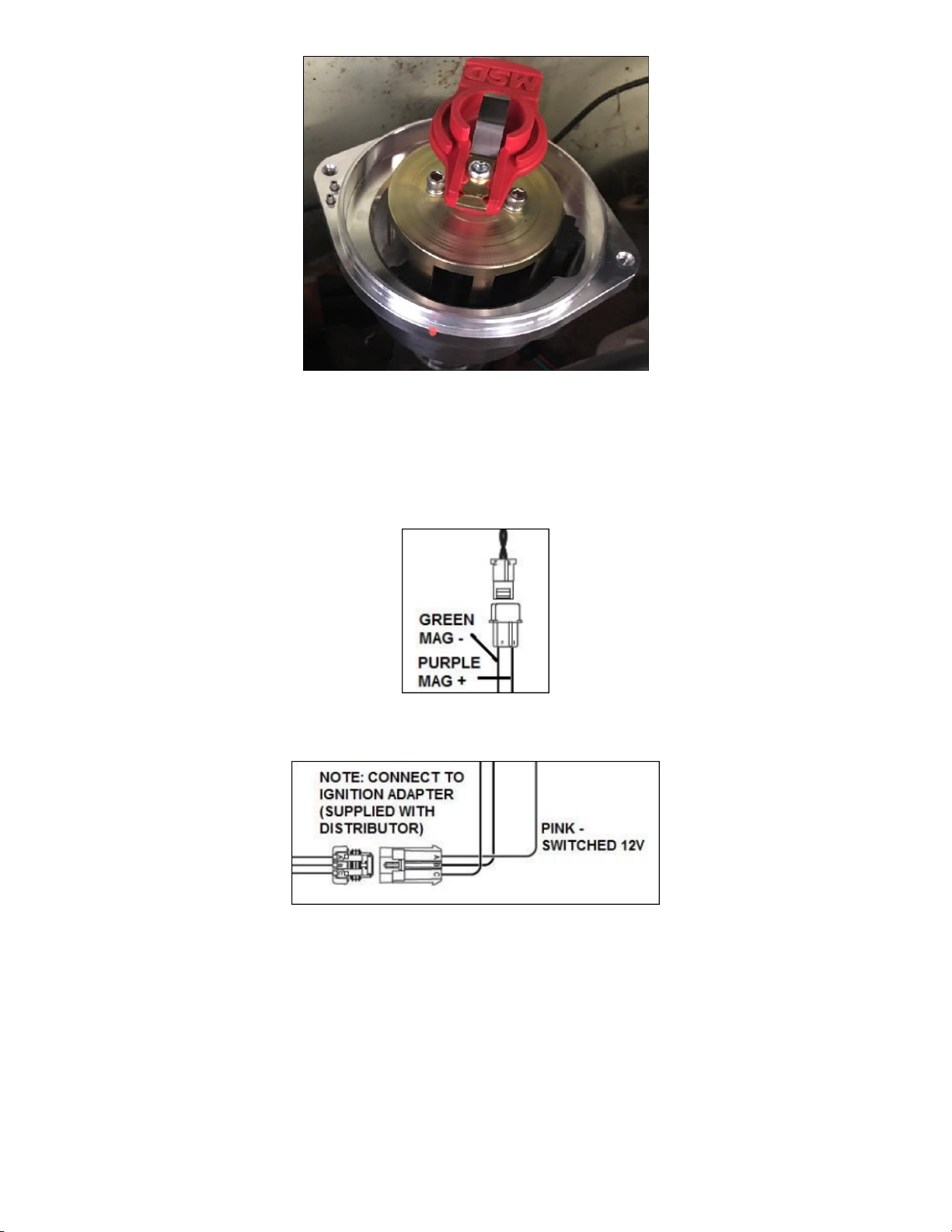

4. Next, place the provided clear distributor cap over the rotor, the cap is formed to accept the rotor, as seen below in

(Figure 1).

5. Now, rotate the distributor housing until the housing locks into the cap, this process phases the distributor housing.

The below image shows the cap and distributor housing in their “locked” position (Figure 2).

Figure 1 Figure 2

6. Tighten the distributor hold down bracket.

7. Once step 5 (Distributor Alignment) is completed, the rotor will be pointing to the cylinder #1 terminal on the

distributor cap. It can be useful to mark the distributor housing to indicate where the #1 terminal on the cap will be

(Figure 3). Note which position this is on the distributor cap. Install the cap and install the #1 plug wire. Install the rest

of the plug wires based on the engine’s firing order and rotor rotation.