HP FUEL PUMPS

P/N 12-700 & 12-890

Installation Instructions 199R10569

WARNING! THESE INSTRUCTIONS MUST BE READ AND FULLY UNDERSTOOD BEFORE BEGINNING INSTALLATION. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN POOR PERFORMANCE, VEHICLE DAMAGE, PERSONAL INJURY, OR DEATH.

IF THESE INSTRUCTIONS ARE NOT FULLY UNDERSTOOD, INSTALLATION SHOULD NOT BE ATTEMPTED. PLEASE CONSULT

HOLLEY TECH SERVICE OR A QUALIFIED MECHANIC.

NOTE: NOT FOR USE WITH METHANOL! Will work with E-85!

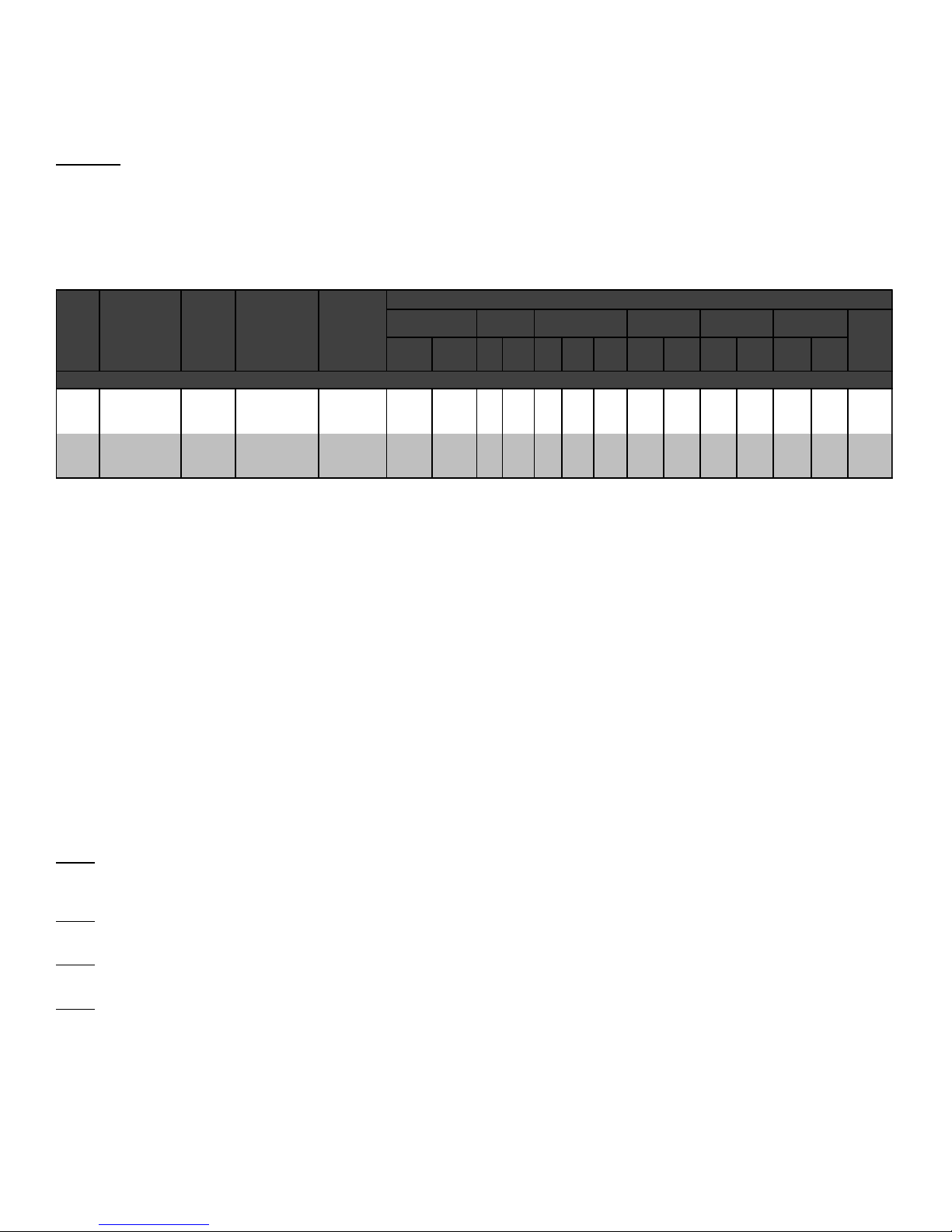

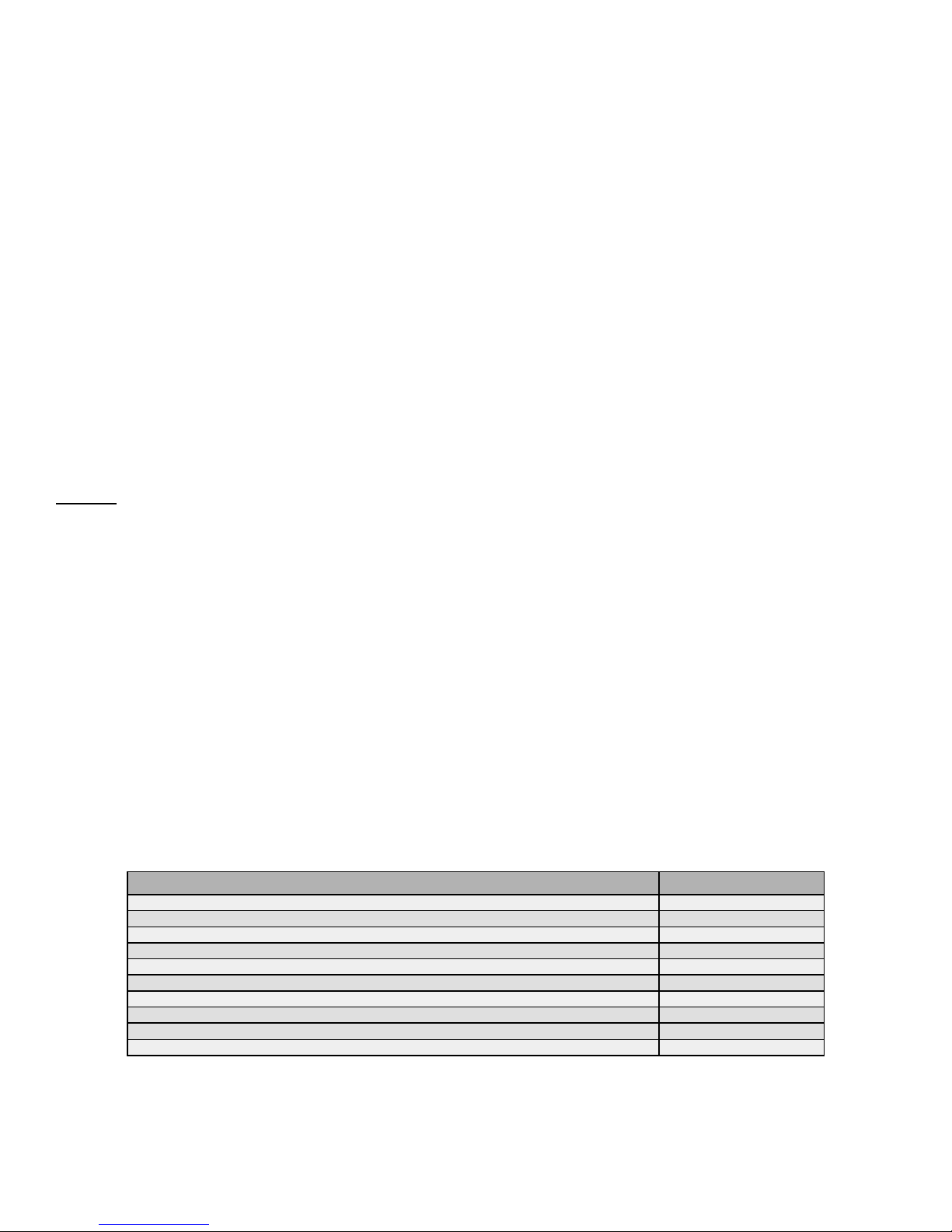

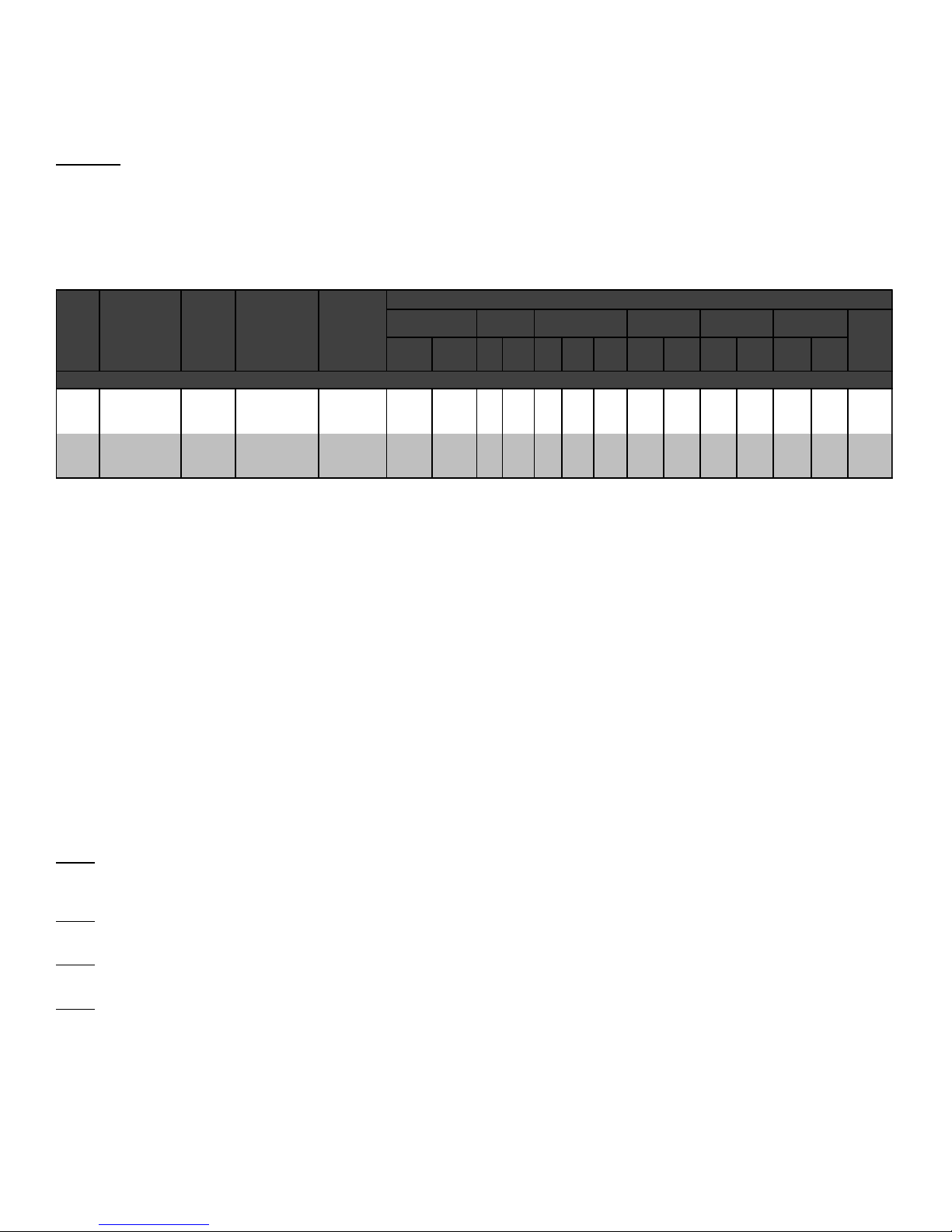

APPLICATIONS:

Inlet Outlet Inlet Outlet Return Pre Post Pre Post Carb EFI

75 @ 8PSI

57 @ 43PSI

47 @ 60 PSI

Street/Strip Gasoline / Diesel Yes

-8AN -8AN -6 AN -6AN -6AN 162-564 162-555 162-564 162-554 12-845 12-846 13 Amps

96 @ 8PSI

76 @ 43PSI

70 @ 60 PSI

Street/Race Gasoline / Diesel Yes

-8AN -8AN -8AN -6AN -6AN 162-564 162-555 162-564 162-554 12-845 12-846 18 Amps

The pumps below do not have an internal bypass. A bypass style regulator and return line are required.

Holley Recommendations for Peak Performance

Fuel Filter

(Fuel injected)

GPH Flow at Rated

PSI and 13.5V

PARTS REQUIRED FOR INSTALLATION:

Pre-Filter

Post-Filter

Relay Kit (30amp minimum) – Holley P/N 12-753 or equivalent

Safety Shutoff Switch (Holley P/N 12-810 or equivalent)

Fuel hose & fittings

Wire & connectors

Mounting hardware

NOTE: These pumps are not serviceable in the field. Contact Holley tech service for fuel pump service.

INTRODUCTION:

Congratulations on your purchase of the Holley HP Fuel Pump. This instruction sheet contains all the information needed to install this fuel pump.

Please read all the WARNINGS and NOTES. They contain valuable information that can save you time and money. Holley Performance Products

cannot and will not be responsible for any alleged or actual engine or other damage, or other conditions resulting from misapplication of the fuel pumps

and fuel pressure regulators described herein. However, it is our intent to provide the best possible products for our customer; products that perform

properly and satisfy your expectations. Should you need information or parts assistance, please contact Technical Service at 1-270-781-9741, M-F, 8

a.m. to 6 p.m. & Sat. 9 a.m. to 3 p.m. CST. Please have the P/N ready when calling.

NOTE: A screen type pre-filter (100 micron), a top quality post fuel filter, fuel hose and clamps, 12 gauge wire, fuel fittings, assorted terminals, a relay

kit (12-753), and an optional safety shut-off switch (12-810) is required to complete the installation of the Holley HP fuel pump. These parts

are not included with the fuel pump.

NOTE: These Holley HP fuel pumps require the use of a bypass style fuel pressure regulator (Part number 12-845 for carbureted applications and 12-

846 for EFI applications).

NOTE: The Holley HP fuel pump utilizes o-ring sealed inlet/outlet ports. The ports utilize ¾-16 O-ring (-8AN) threads. These ports are not pipe

thread, therefore Do not use thread sealant.

NOTE: Holley ALWAYS RECOMMENDS using our oil pressure safety shut-off switch, part number 12-810.

PUMP MOUNTING AND INSTALLATION:

The best location for mounting any electric fuel pump is the rear of the vehicle, near the fuel tank and in a position even with or below the bottom of the

tank, allowing the fuel to be gravity fed to the pump. The pump should be mounted on a solid member, such as the chassis, with the pump

outlet pointing forward or upward. Avoid exposure of the pump and fuel lines to moving parts and to any hot areas, such as the exhaust manifold.

The pump should not be mounted in an enclosed area, such as the vehicle’s trunk. Follow the steps below for mounting the pump.