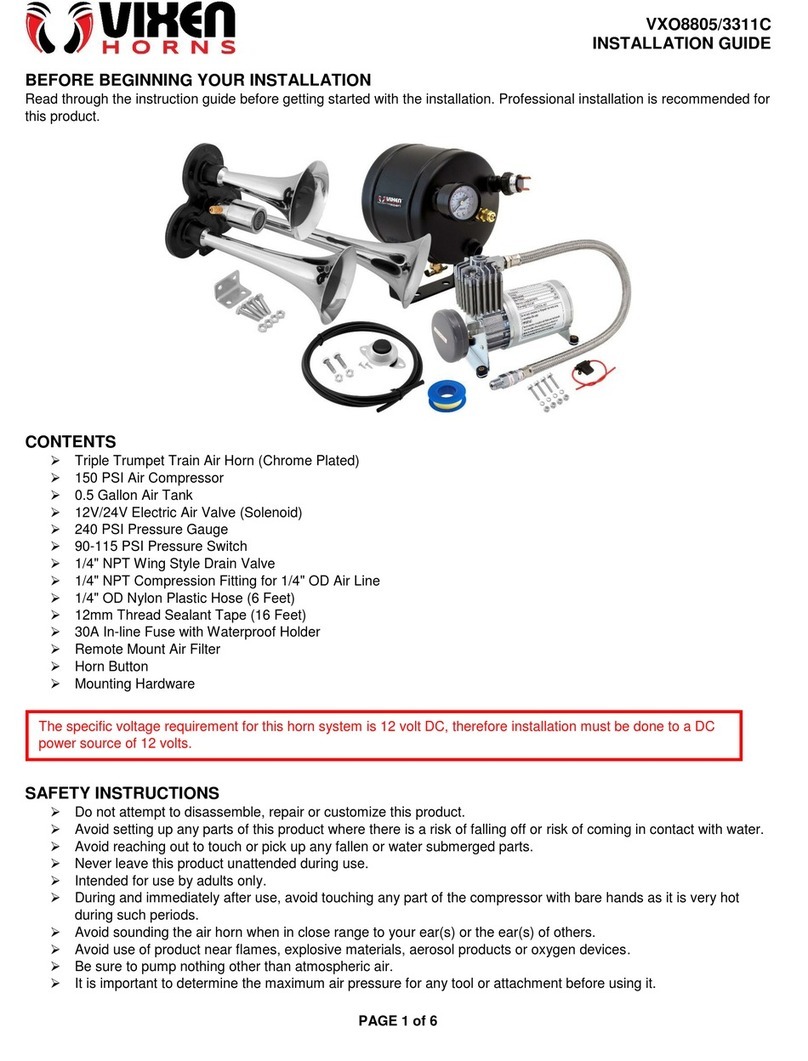

•

•

•

Troubleshooting

Compressor

•The compressor doesn't turn on.

oTry connecting the compressor to a car battery directly.

Take the red wire to the positive terminal and the black wire to the negative terminal.

Give us a call if the compressor doesn't run. If it does, go to the next step.

oDouble check the blue wire on the pressure switch.

If this blue wire is not hooked up or doesn't have +12v power, the compressor will never run.

This blue wire receives a signal from the vehicle to let the system know the car is on. This is to

prevent the system from running when the car is off.

oMake sure the fuse isn't blown

If the fuse is blown, this could be due to a short in your wiring. Before you put a new one in,

check and ensure your wire is not frayed or exposed anywhere.

•The compressor doesn't fill the tank

oMake sure the drain cock isn't open

The drain cock is fully closed when the wing nut is threaded OUTWARD. >>>

oMake sure the valve isn't open or backward

If the valve is open, the air from the compressor is escaping through it constantly. If the valve

is backward, air will escape through it constantly.

oCheck the compressor's air inlet

If the red plug from the inlet was not removed, the compressor cannot suck in air. Remove the

filter and remove the plug.

Make sure to check that you removed the red plug from the end of the compressor's leader

hose. If the plug is still present, the compressor will not be able to push air out of the hose.

•The tank loses pressure after a few hours

oSpray each fitting and air line with soapy water or Windex.

The liquid will bubble up anywhere a leak is present. Usually, fittings need to be tightened

further or more Teflon tape needs to be present on the threads. If you have a leak from the air

line connections, re-cut the lines and re-seat them.

oMake sure the compressor's check valve wasn't overtightened

If the check valve is overtightened, it will leak back to the compressor and the air will escape

from the filter. This may also lead to a blown fuse.