2© 2002 Directed Electronics, Inc. Vista, CA

Bitwriter™, Code Hopping™, DEI®, Doubleguard®, ESP™, FailSafe®, Ghost Switch™, Learn

Routine™, Nite-Lite®, Nuisance Prevention Circuitry®, NPC®, Revenger®, Silent Mode™, Soft Chirp®,

Stinger®, Valet®, Vehicle Recovery System®, VRS®, and Warn Away® are all Trademarks or Registered

Trademarks of Directed Electronics, Inc.

table of contents

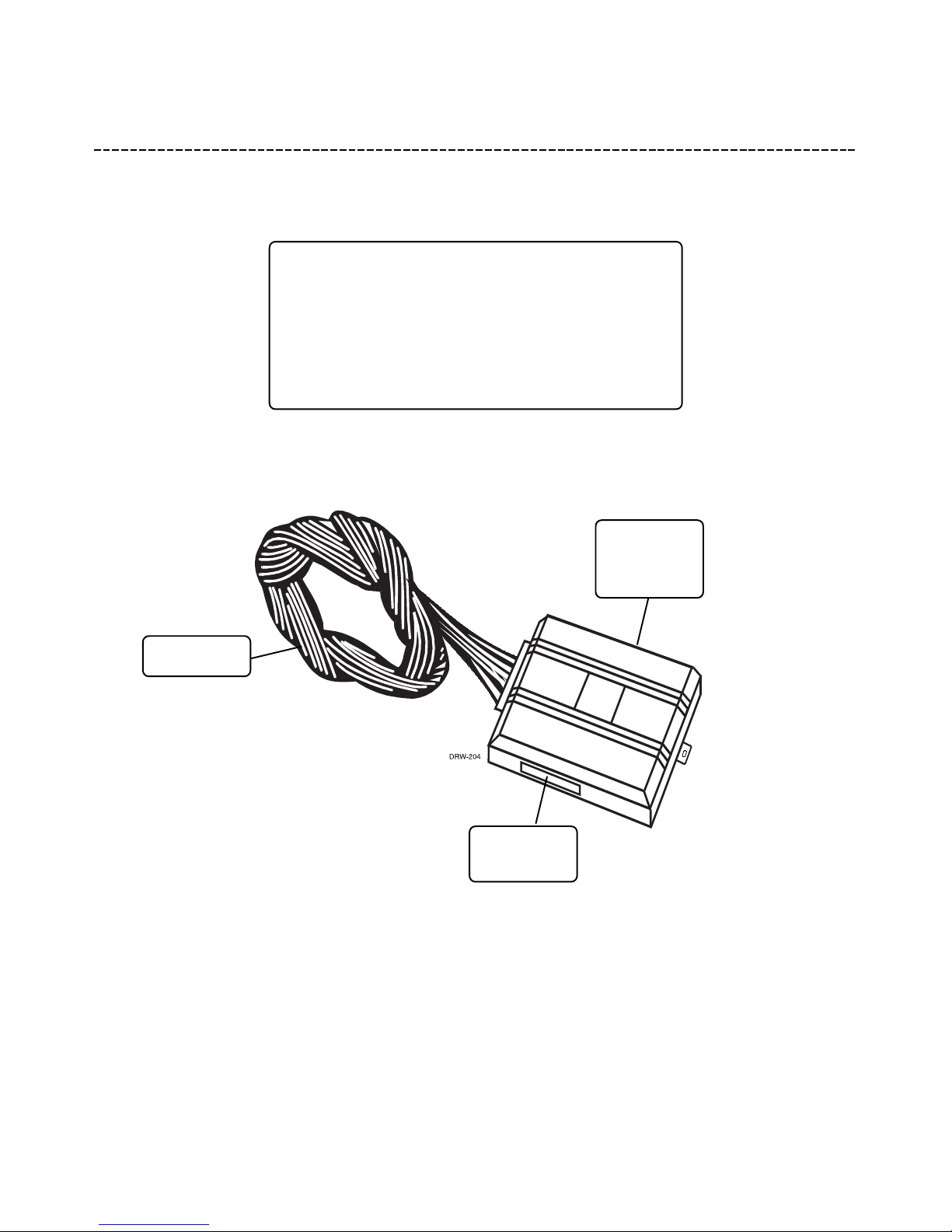

what is included . . . . . . . . . . . . . . . . . . . . . 3

installation points to remember . . . . . . . . . . 4

deciding on component locations . . . . . . . . . 4

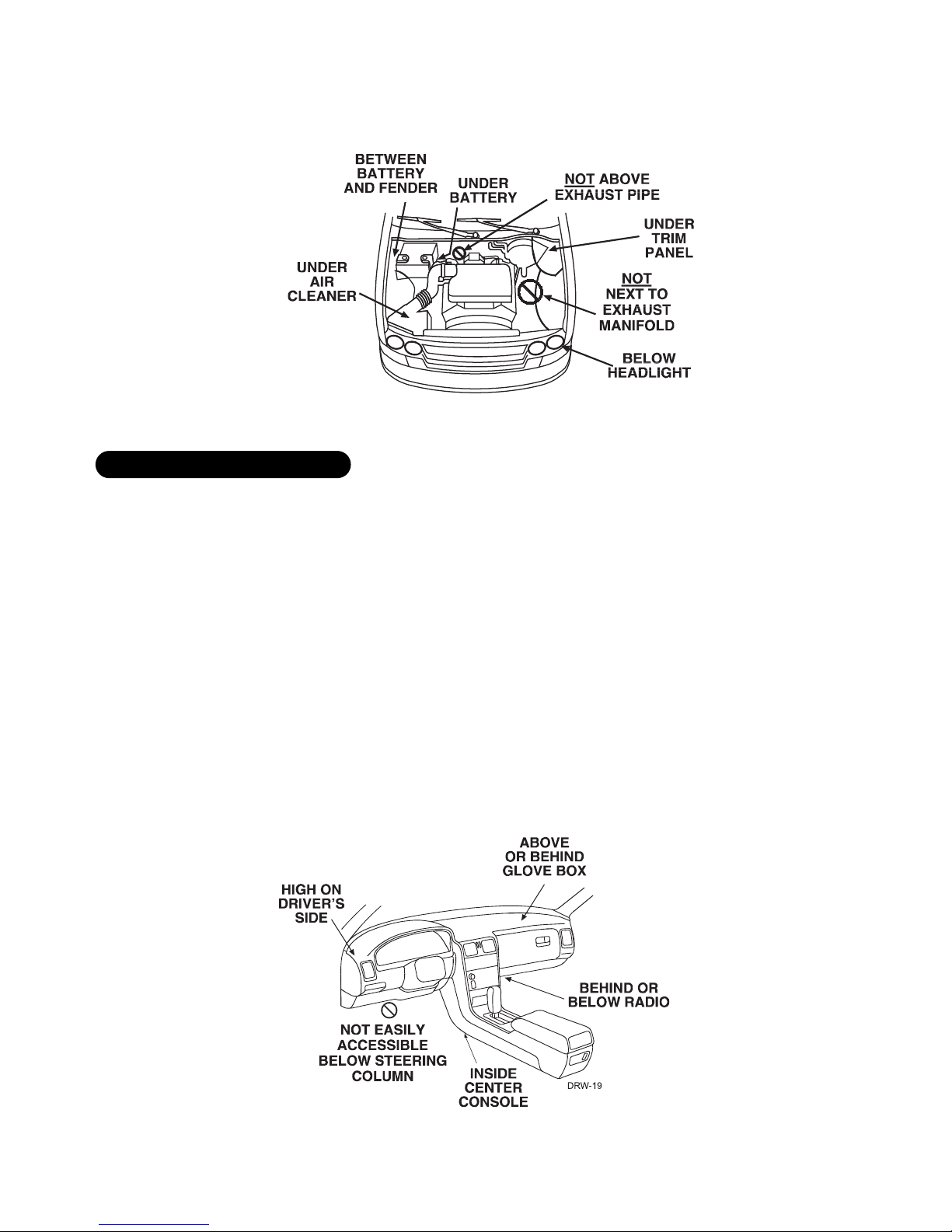

locations for the siren . . . . . . . . . . . . . . . . 4

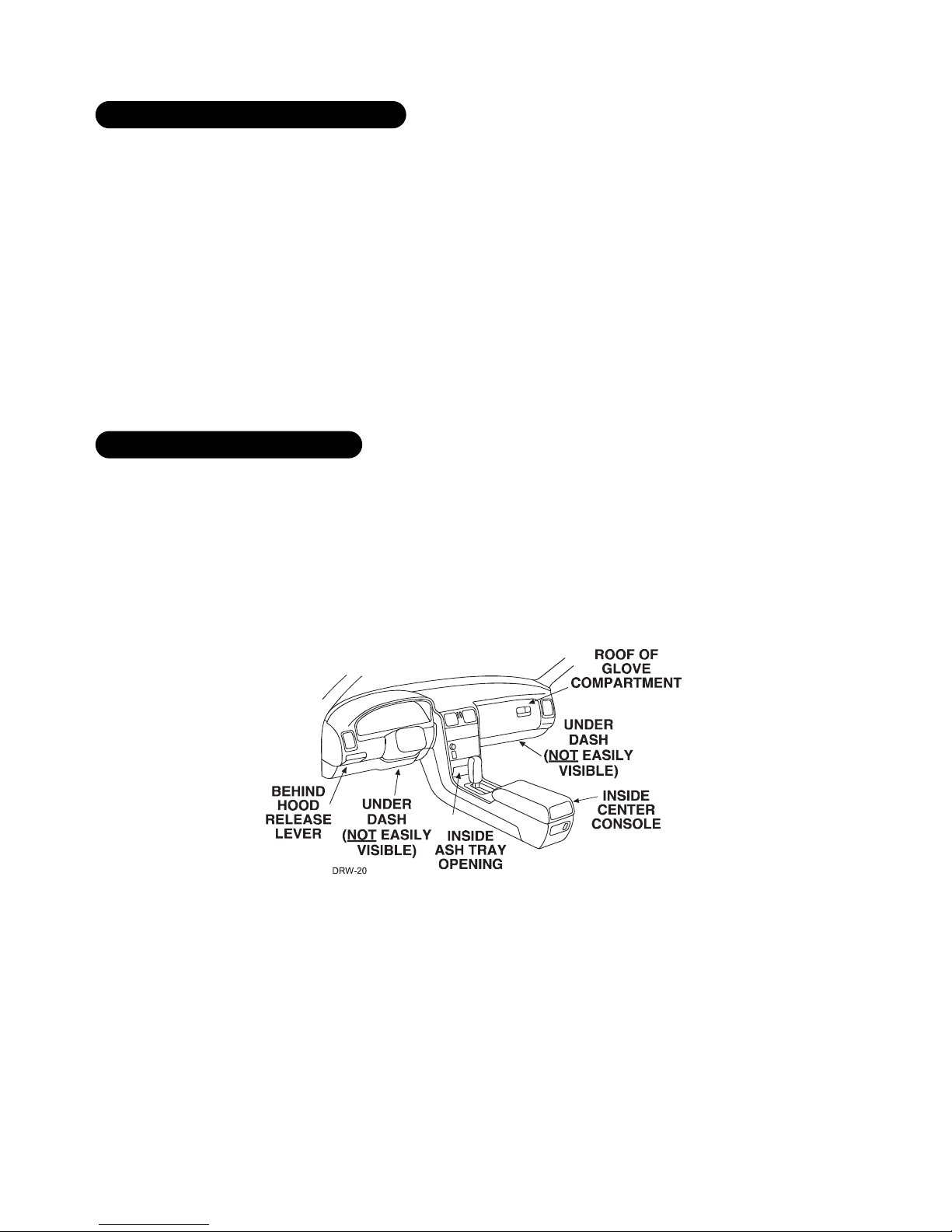

locations for the control module . . . . . . . . . 5

on-board stinger doubleguard shock sensor . . 6

locations for valet/program switch . . . . . . . . 6

locations for the status LED . . . . . . . . . . . . 6

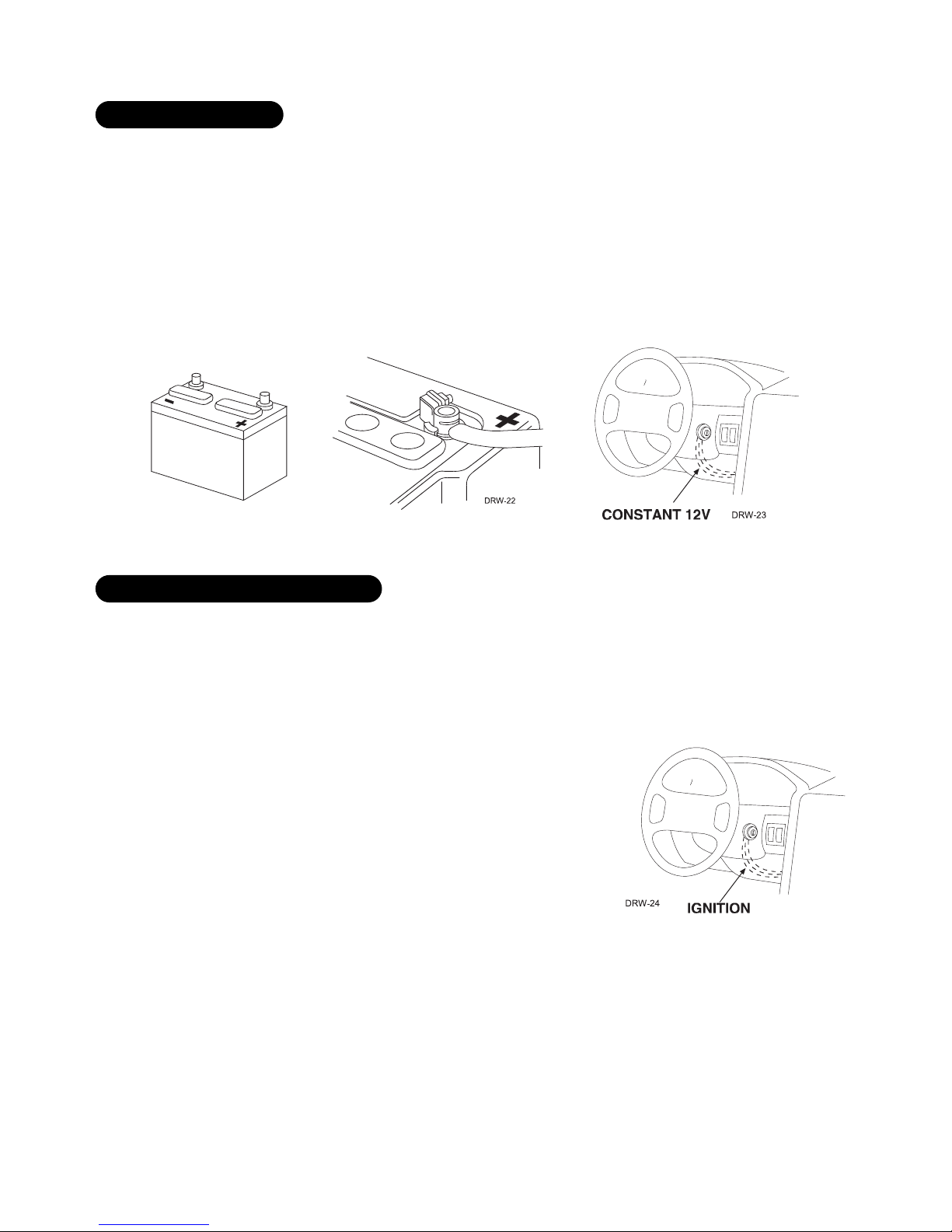

locations for the optional starter kill relay. . . 7

finding the wires you need . . . . . . . . . . . . . . 7

obtaining constant 12V . . . . . . . . . . . . . . . 7

finding the 12V switched ignition wire . . . . . 8

finding a (+) parking light wire . . . . . . . . . . 8

finding the door pin switch circuit. . . . . . . . 9

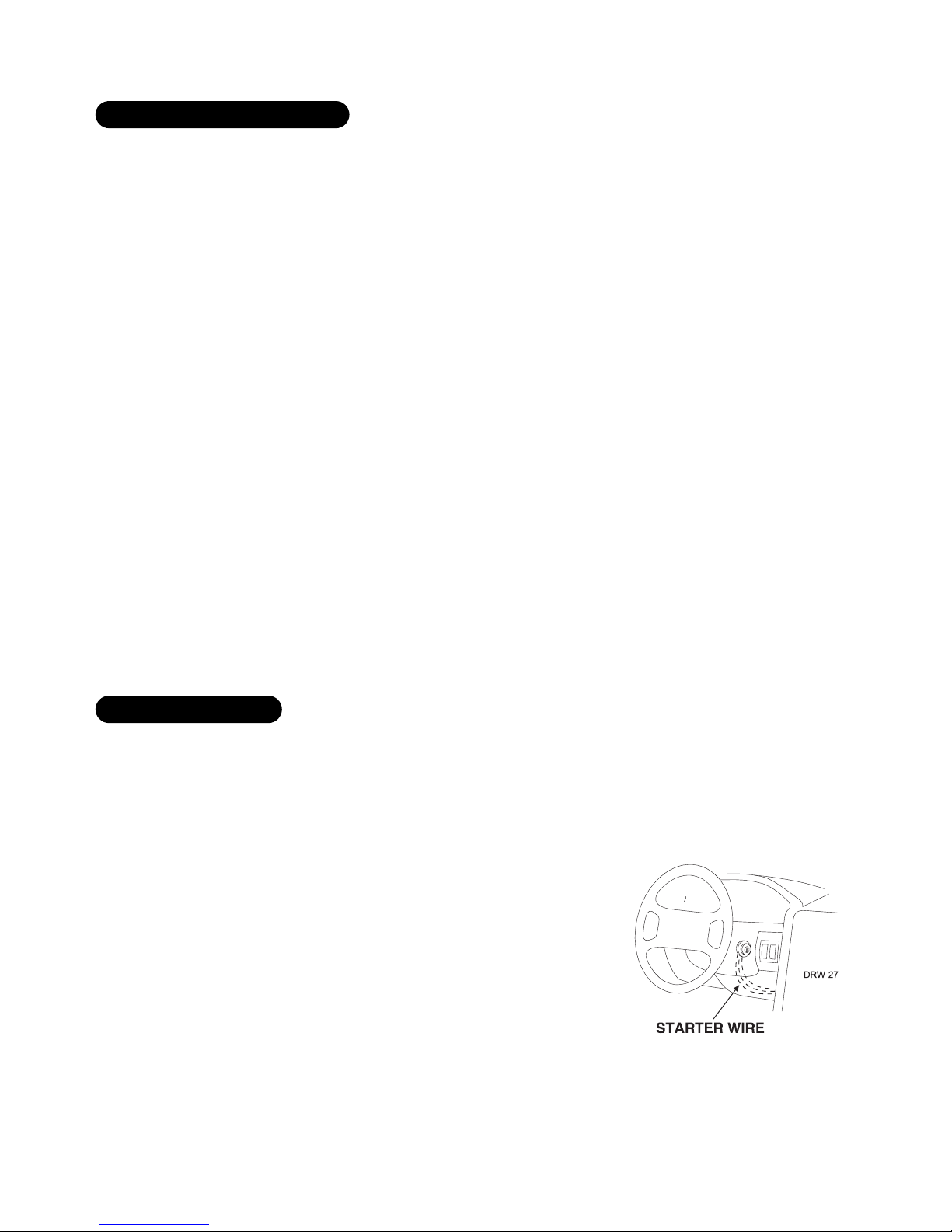

finding the starter wire . . . . . . . . . . . . . . 10

making your wiring connections . . . . . . . . . 10

primary harness (H1), 12-pin connector . . . . 11

primary harness wire connection guide . . . . . 12

on-board stinger doubleguard shock sensor . . 16

bypassing sensor inputs . . . . . . . . . . . . . . . 16

harness 2, (-) door lock outputs . . . . . . . . . 17

type A door locks . . . . . . . . . . . . . . . . . . 18

type B door locks . . . . . . . . . . . . . . . . . . 19

type C door locks . . . . . . . . . . . . . . . . . . 20

type D door locks . . . . . . . . . . . . . . . . . . 21

type E door locks . . . . . . . . . . . . . . . . . . 22

type F door locks . . . . . . . . . . . . . . . . . . 23

type G door locks . . . . . . . . . . . . . . . . . . 24

type H door locks . . . . . . . . . . . . . . . . . . 25

transmitter/receiver learn routine™ . . . . . . . 26

two-vehicle operation with single transmitter 27

operating settings learn routine™ . . . . . . . . 28

feature menu . . . . . . . . . . . . . . . . . . . . . . 29

feature descriptions . . . . . . . . . . . . . . . . . 30

nuisance prevention circuitry (NPC™) . . . . . . 31

valet mode . . . . . . . . . . . . . . . . . . . . . . . . 32

table of zones . . . . . . . . . . . . . . . . . . . . . . 32

troubleshooting . . . . . . . . . . . . . . . . . . . . 33