Hove ONE ver. 1 Manual 2021-03-01 Rev. 1.0 1 / 19

Table of Contents

General description of the machine ..............................................................................- 4 -

Manual dosing mode ................................................................................................- 4 -

Automatic dosing mode............................................................................................- 4 -

Intended use .............................................................................................................- 4 -

Safety rules.....................................................................................................................- 4 -

On delivery of the machine............................................................................................- 5 -

When using the machine for the first time....................................................................- 5 -

Cleaning the machine................................................................................................- 5 -

Assembly ...................................................................................................................- 5 -

Daily use.........................................................................................................................- 6 -

After use....................................................................................................................- 6 -

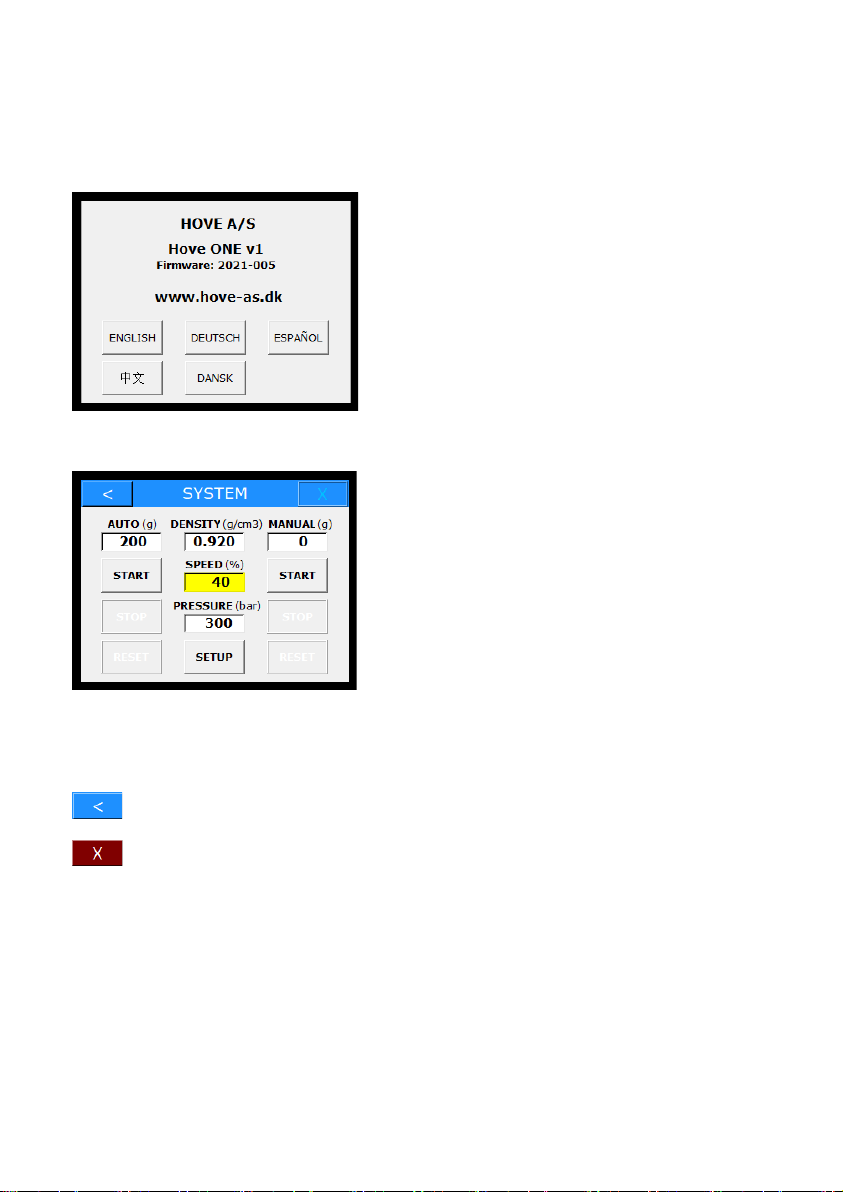

Operating the machine ..................................................................................................- 7 -

Control Panel..................................................................................................................- 7 -

General Buttons ........................................................................................................- 7 -

Change settings.........................................................................................................- 8 -

Set AUTO GRAMS.................................................................................................- 8 -

Set DENSITY..........................................................................................................- 8 -

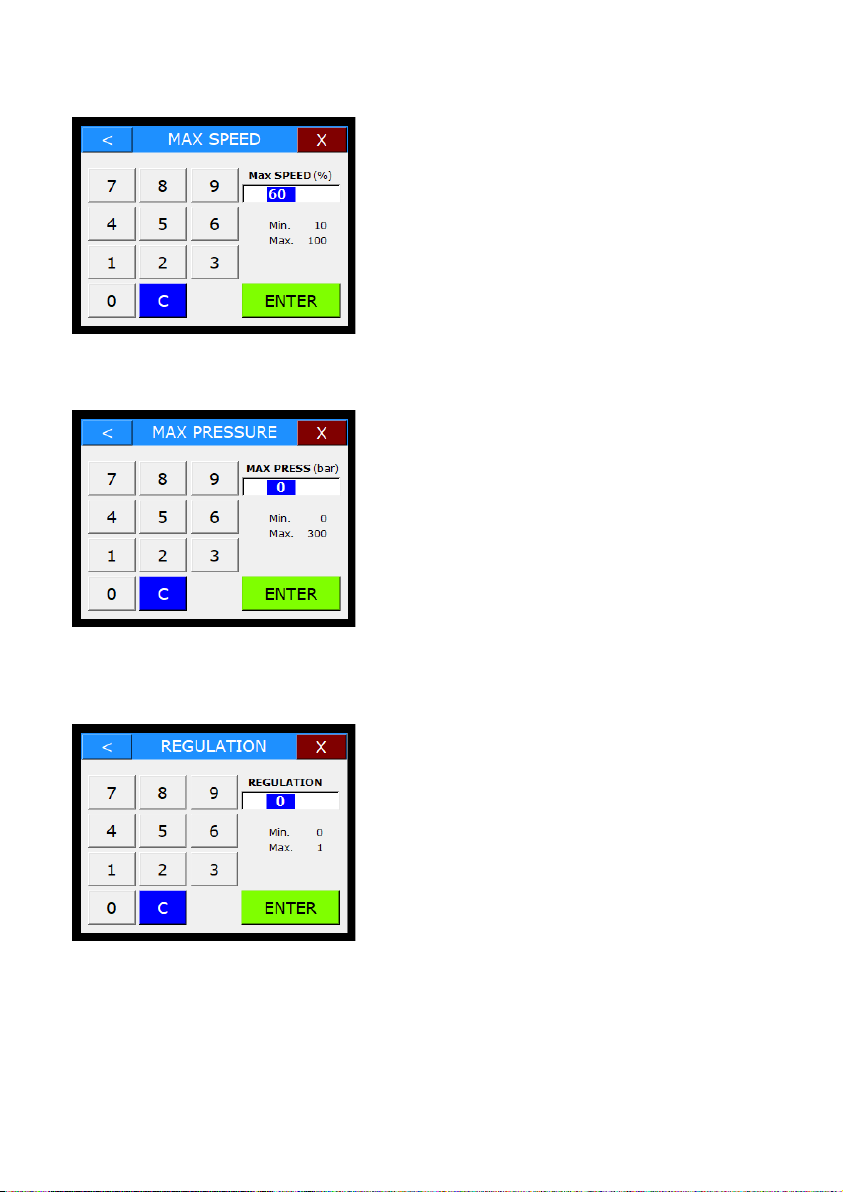

Set MAX SPEED.....................................................................................................- 9 -

Set MAX PRESSURE ..............................................................................................- 9 -

Set PRESSURE REGULATION.................................................................................- 9 -

Set MODEL #.......................................................................................................- 10 -

Running the machine...................................................................................................- 10 -

Start of automatic dosing........................................................................................- 10 -

Pausing/aborting................................................................................................- 11 -

Start of manual dosing............................................................................................- 12 -

Pausing/aborting................................................................................................- 12 -

Empty detection......................................................................................................- 12 -

Remote Control............................................................................................................- 13 -

Display.....................................................................................................................- 13 -

Push buttons ...........................................................................................................- 13 -