TABLE OF CONTENTS

1. Specifications ...... . ................... . ...... . ....... . . Page No.

1

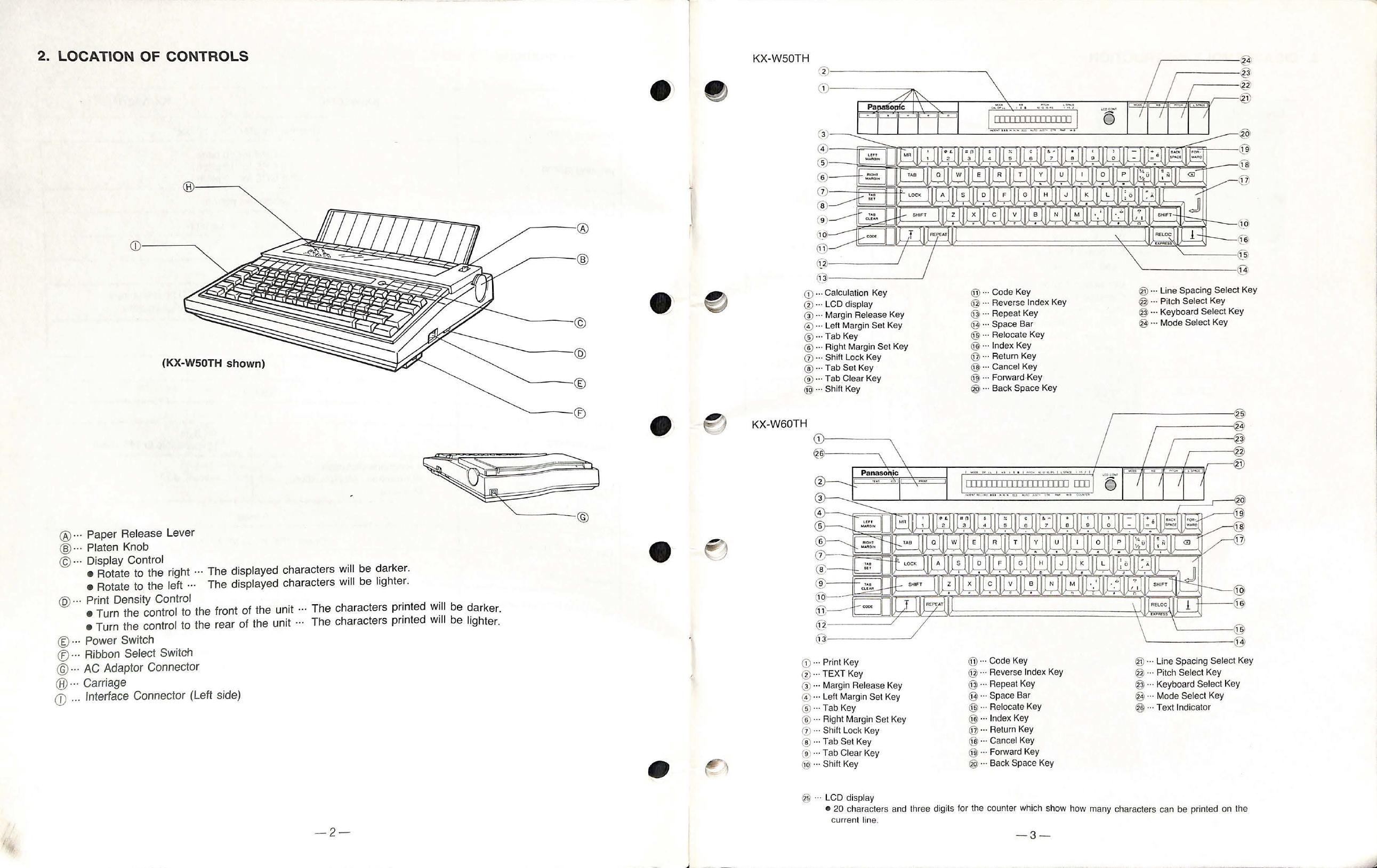

2 . Location of Controls ................. .. ... .... .. ... . . ... .

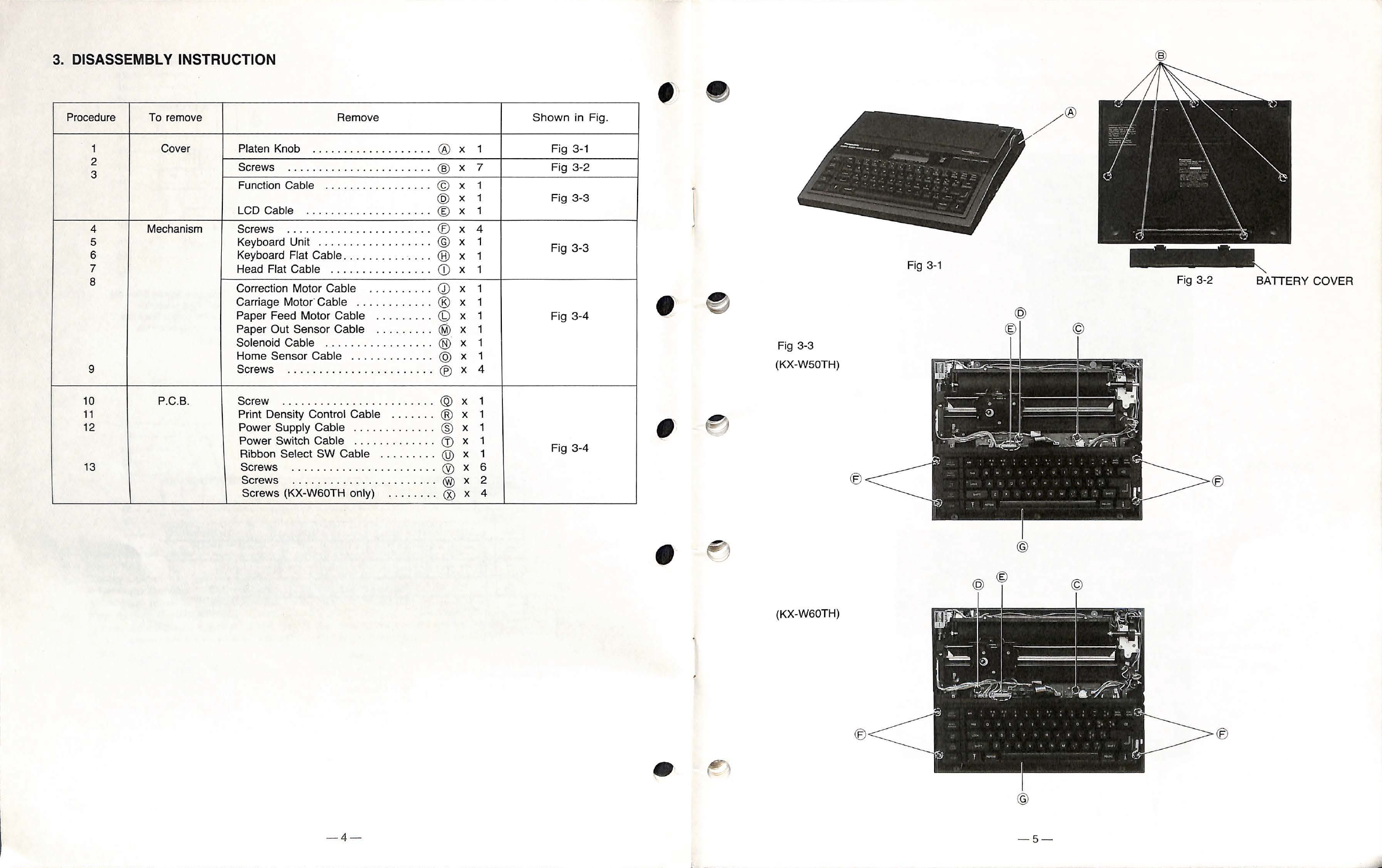

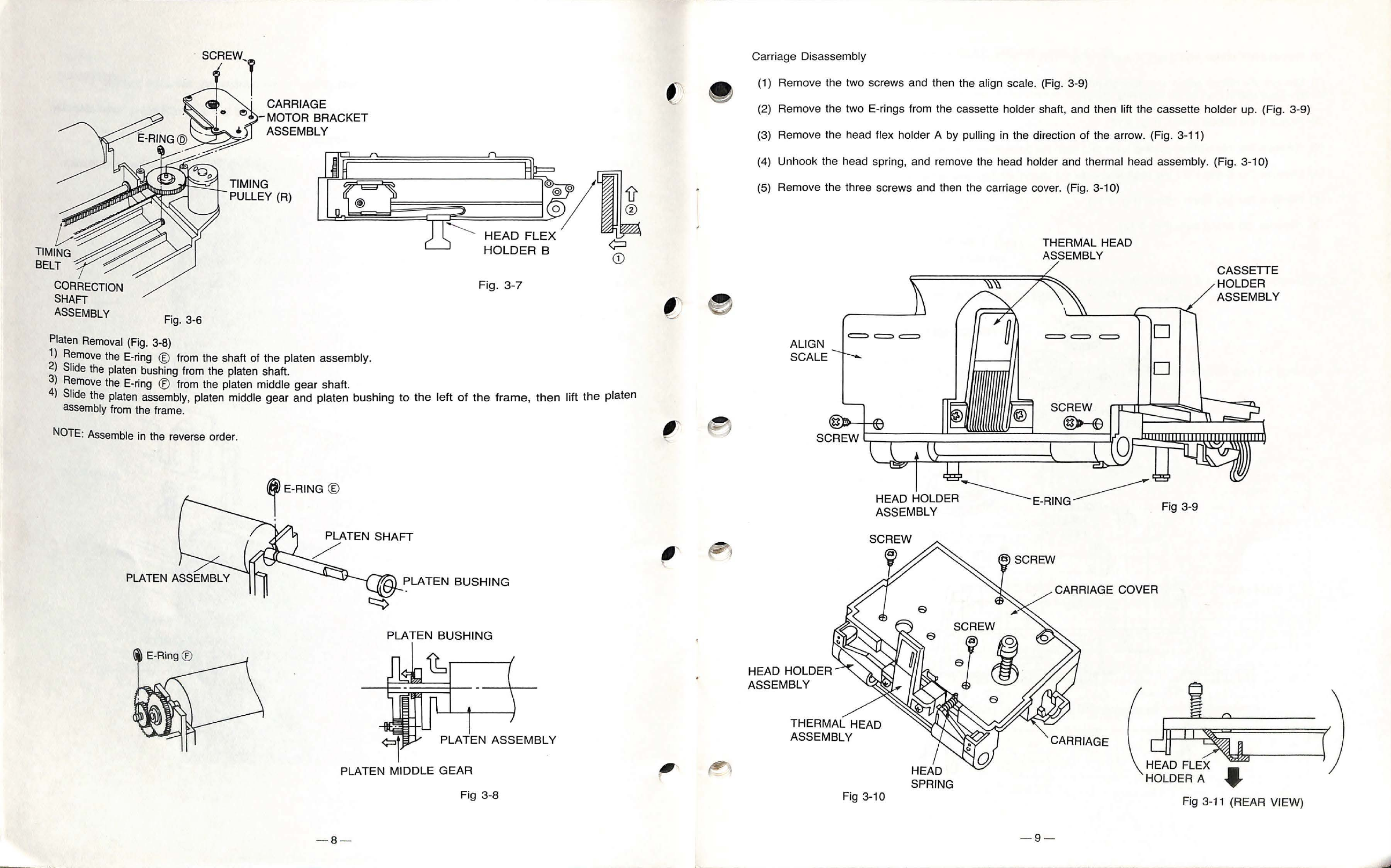

3. Disassembly Instruction ........... .. . . ....... . ....... .. .. .

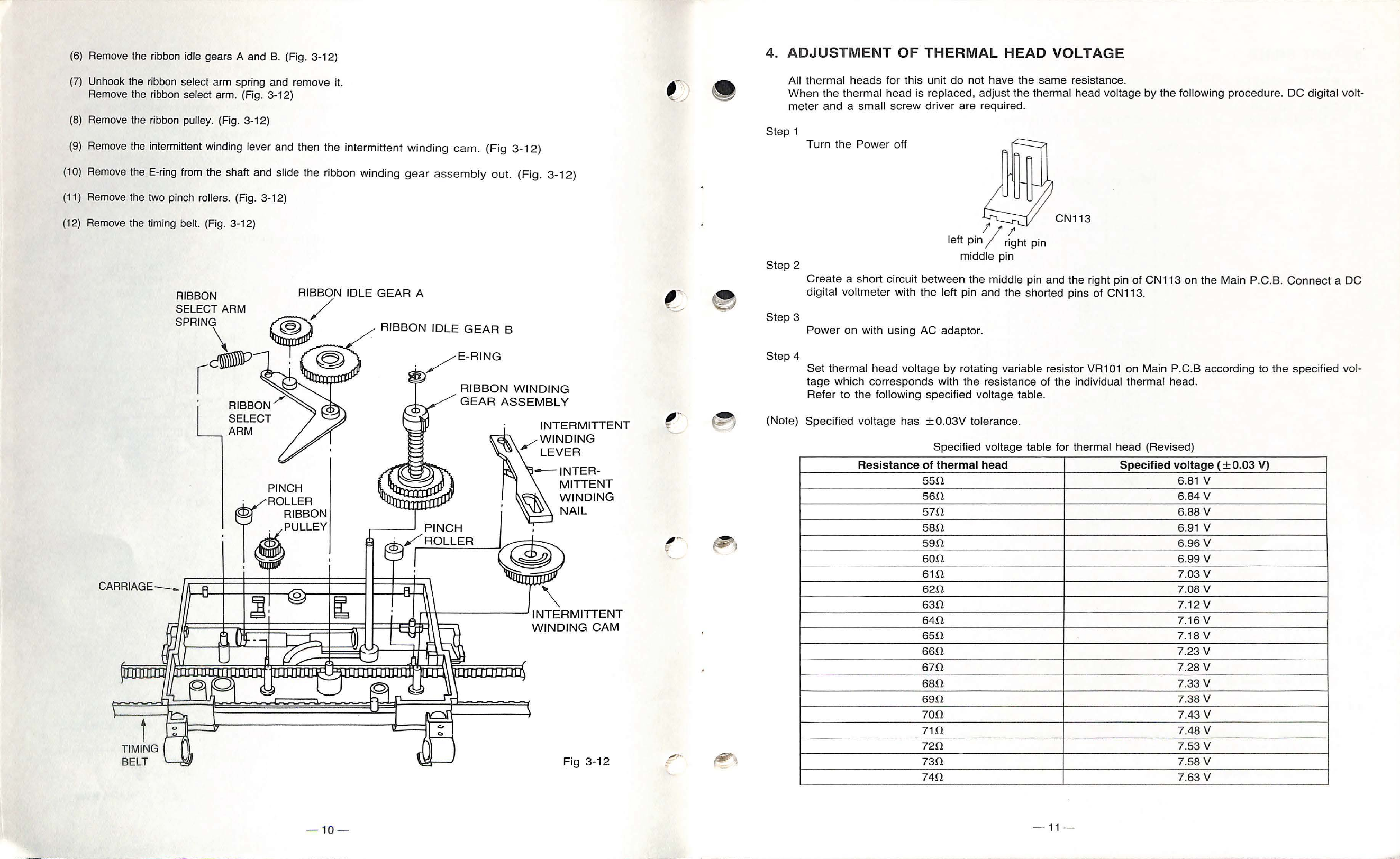

4. Adjustment of Thermal Head Voltage ............ .. . . ... .. .. .

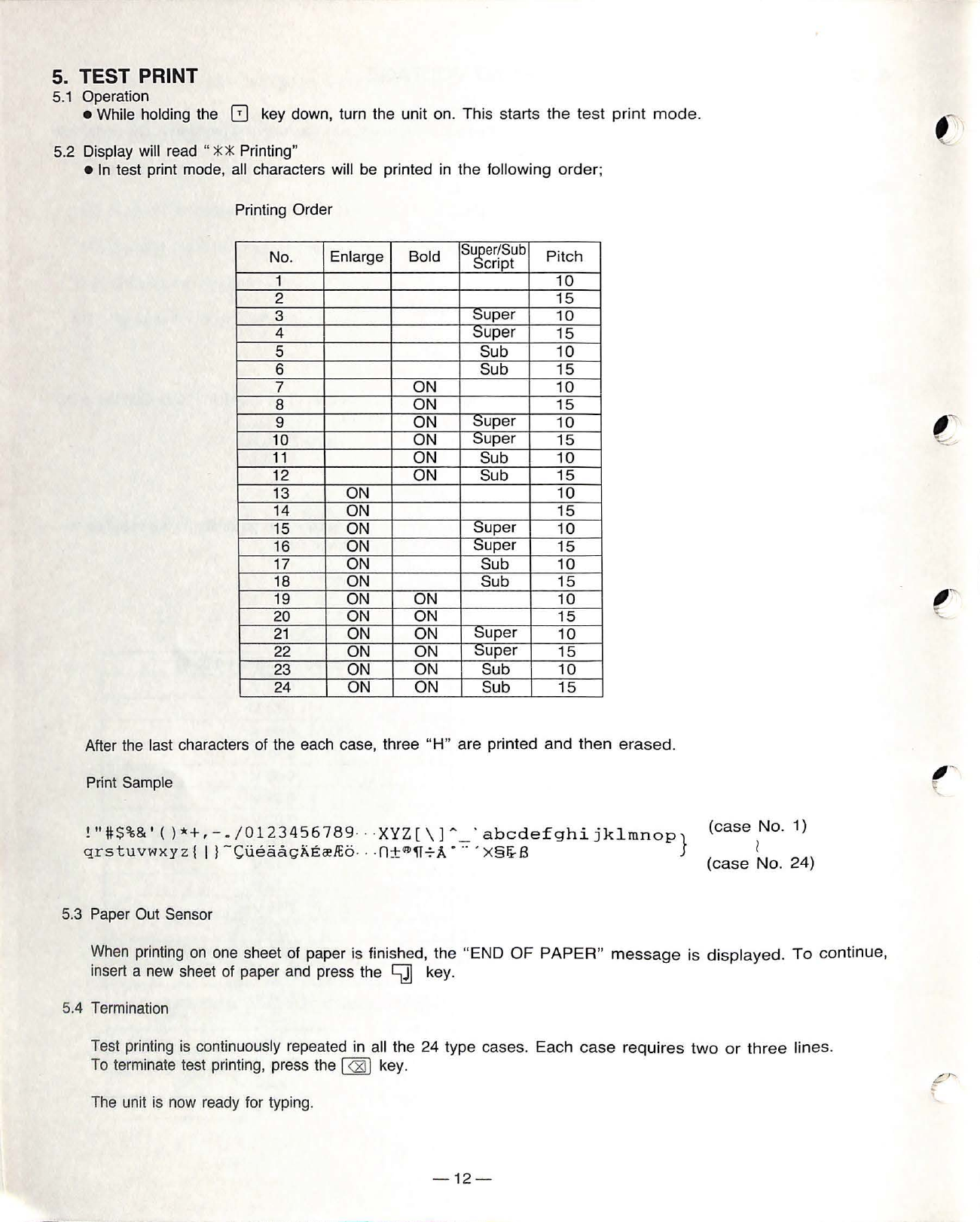

5. Test Print . .. ... .... . ............................ . .... . .

6. Schematic Diagram .. . ........ . ....... . ............ .. ... .

7. Print Circuit Boards .. . ... ............................ .. . .

8. Block Diagram ......... . .... . .......................... .

9. Explanation of Mechanism . ..... ... .......... ... . ..... . .. .

9.1 Printing Section ............................ . . .... . .

9.2 Ribbon Feed Section ... .. .. . .... ...... ..... ... . .... .

9.3 Carriage Spacing Section ... ..................... .

9.4 Paper Feed Section .. .... . . ... . . .. . .... .. .. ... . .... .

10. Explanation of Electronic Operation .. .. ....... ........ ..... .

10.1 Principle of Operation ..... . .. . . .. ... .. . .. . ... . . .. .

10.2 Circuitry . ......... . .. ......... . ... ........ . ... .. .

10.3 Explanation of Connectors . . . . . . . . . . . . . . . . . . . . . . . . . · ·

11. Troubleshooting .. . ..... ... . .......... ... ..... . .. ·. . . · · ·

11.1 Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . · · · · ·

11.2 Troubleshooting Flow Chart .. ... . . .... .. .... .... : : : :

12. IC Pin Configuration .. . ... . ... ....... ... . .. .. .... .

12.1 Logic Symbol Chart . . . . . . . . . . . . . . . . . ....

.. ..... .. .. . .. .

12.2 Pin Configuration . . . .. .. . ... . .. .. .. .... .. . . .. .... .

13. Parts Location and Parts List ................. ... . .. . . .. .. .

13.1 Covers .... . . .................. ... . ..... . . ..... ....

13.2 Chassis ... . ........ . .. .. . .. .. .. . . .. ..... ..... ...

13.3 Carrier .. . . . ........ .. . . ... . ... ... .... . . . . ... ... .

13.4 Keyboard ... . . . ............... .. . .. .... . .. ... ... .

13.5 Circuit Boards ................... . .. .. .... .

(Main-1/F·DensityControl-RAM Board) .. .. .. ...

13.6 Packing Materials ...... . .................. . .... . . .

2

4

11

12

13

15

17

18

18

19

20

21

22

22

22

41

46

46

49

58

58

58

61

61

64

66

67

70

73

•

•

•

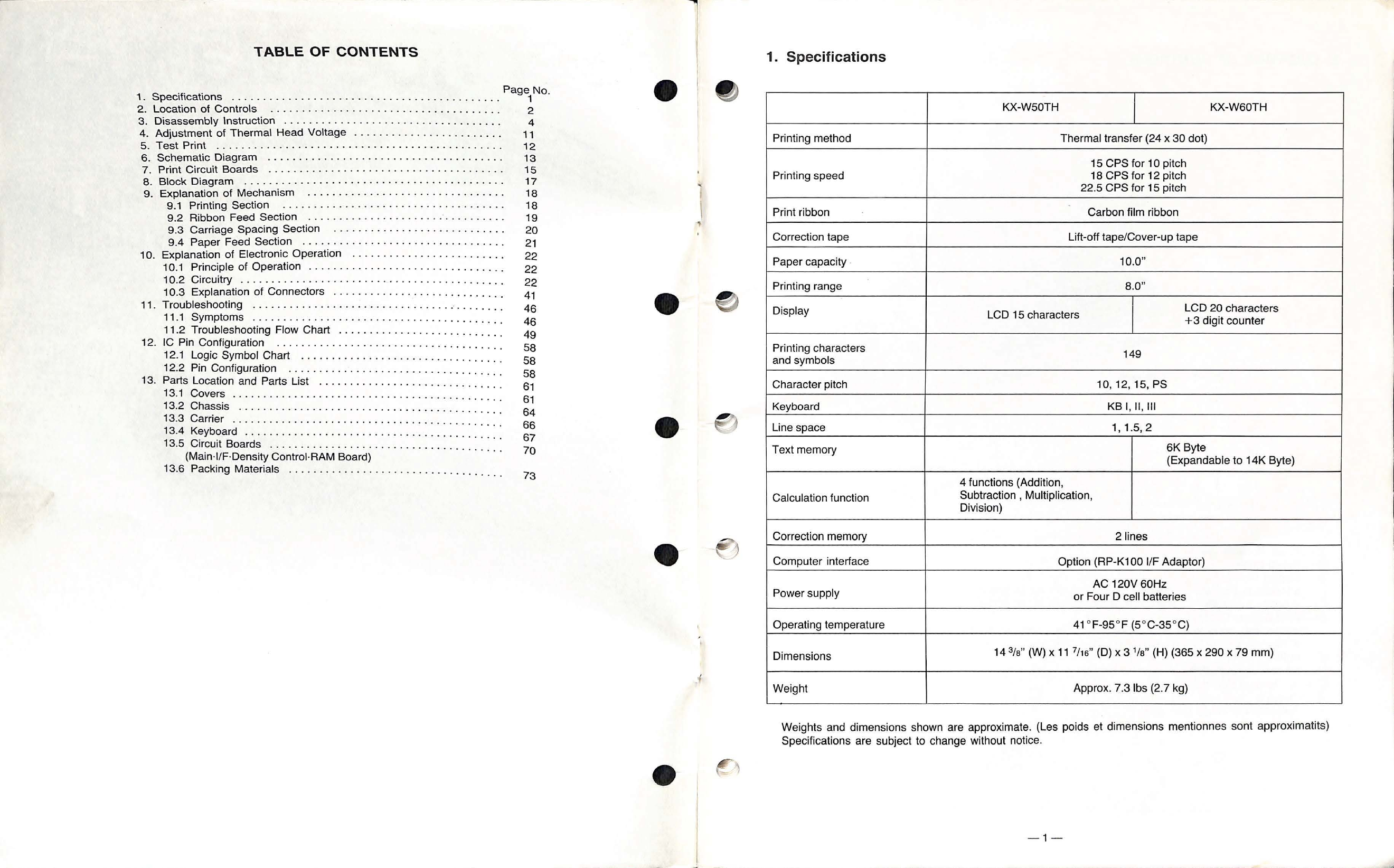

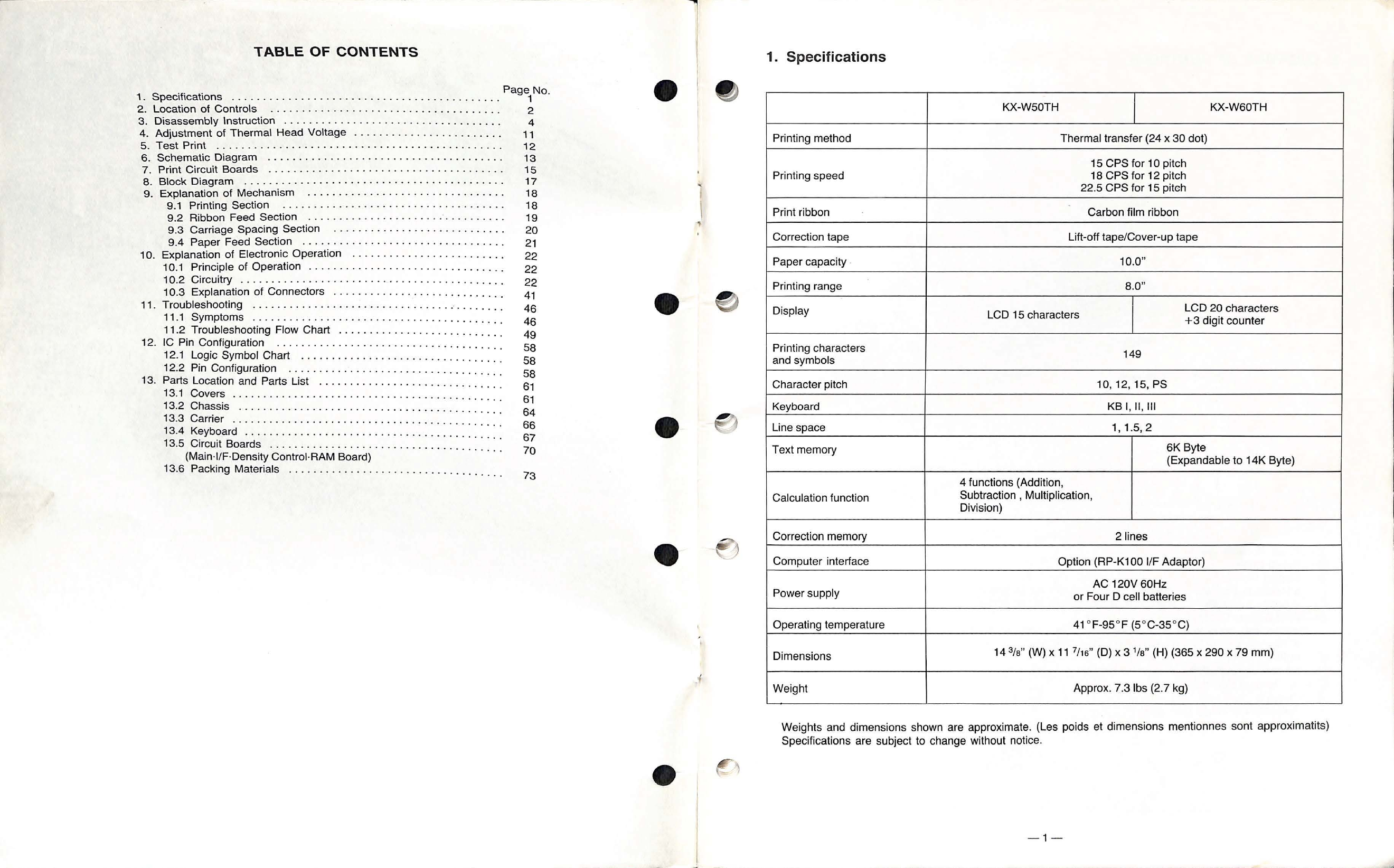

1. Specifications

KX-W50TH KX-W60TH

Printing method Thermal transfer (24 x 30 dot)

15 CPS for 10 pitch

Printing speed 18 CPS for 12 pitch

22.5 CPS for 15 pitch

Print ribbon Carbon film ribbon

Correction tape Lift-off tape/Cover-up tape

Paper capacity 10.0"

Printing range 8.0"

Display LCD 15 characters LCD 20 characters

+3 digit counter

Printing characters 149

and symbols

Character pitch 10, 12, 15, PS

Keyboard KB I, II, Ill

Line space 1, 1.5, 2

Text memory 6K Byte

(Expandable to 14K Byte)

4 functions (Addition,

Calculation function Subtraction , Multiplication,

Division)

Correction memory 2 lines

Computer interface Option (RP-K100 1/F Adaptor )

AC 120V 60Hz

Power supply or Four D cell batteries

Operating temperature 41°F-95°F (5°C-35 °C)

Dimensions 14 3/a"(W)x 11 7/ 16" (D) x 3 1/a" (H) (365 x 290 x 79 mm)

Weight Approx. 7.3 lbs (2.7 kg)

Weights and dimensions shown are approximate. (Les poids et dimensions mentionnes sont approximatits)

Specifications are subject to change without notice.

-1-