3

8/17/2016 850-EI

IMPORTANT: Fuel Supply for “Hi/Lo” Systems –It is necessary to supply your (Hi/Lo) fire feature with 1.5 times

the maximum rated BTU. This will ensure there is enough pressure for your high/low function to work properly. This

requirement does not increase the amount of fuel your appliance will consume during normal operation. (Example: A

200k BTU fire pit should be supplied with 300 k BTU fuel capacity).

IMPORTANT: Do not exceed maximum input pressures; low pressure will impact HI/LO model’s flame control.

IMPORTANT: Ensure any flex line that may be used from the permanent main fuel supply to the product is rated to

the stated max BTU of the product and certified to ANSI Z21.75*CSA 6.27.

2) Selecting the Location

WARNING: All fire pits, match lit kits, spark ignition, safety pilot and electronic ignition systems are designed and intended for

outdoor use only. Fire pits are not to be installed within 36”-48” of any structure depending on the size. See drawing in instructions.

WARNING: For electronic ignition models there must be an electrical shut off (wall switch or breaker) on the exterior of the fire

pit or on adjacent wall to allow for emergency shutdown and maintenance.

WARNING:All fire pits must have a gas shutoff on the outside of the exterior of the fire pit to allow for emergency shut off and

maintenance. The gas shutoff should not be used to adjust flame height.

WARNING: Select a location where the fire pit can be attended during operation. Never leave an operating fire pit unattended or

by someone not familiar with its operation or emergency shut off locations.

WARNING: Both children and adults should be alerted to the hazards of high surface temperatures and should stay away to avoid

burns and clothing ignition.

WARNING: Young children should be carefully supervised when they are in the area of fire pit.

WARNING: Clothing or other flammable materials should not be placed on or near fire pit.

WARNING: Fire pits create very high temperatures - Combustibles must be located far enough away that there is no risk of

ignition.

IMPORTANT: It is recommended that material such as granite, marble or other dense stone be kept away from heat and

especially flame due to risk of cracking. Manufacturer is not responsible for damage.

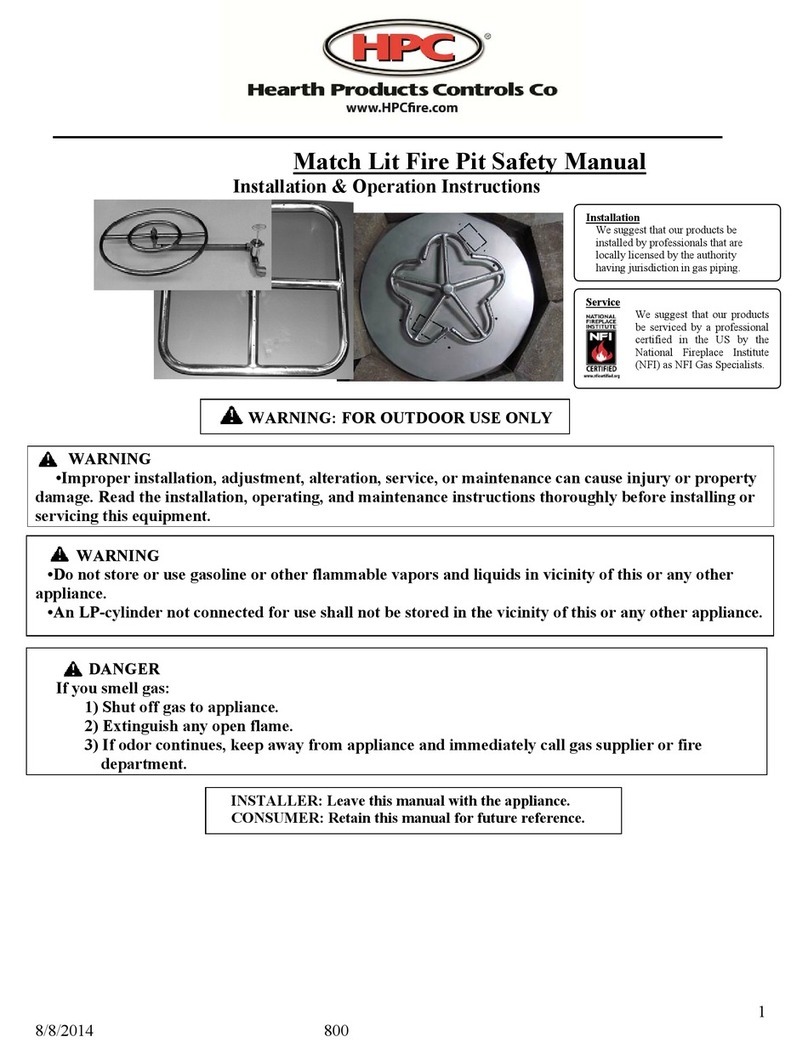

Fire Pit Clearances –See figures 1 and 2 on last pages

Under valve box when applicable for drainage

Sides surrounding fire pit from structure or combustibles

Overhead clearance above product

Noncombustible screen only

Select a location above ground with good drainage and allows easy access for installation and maintenance of the fire

pit.

Pick a location that allows sufficient horizontal room to enjoy the fire pit while allowing a safe distance from the heat

and flame.

3) Construction of the Enclosure

WARNING: For electronic ignition models there must be an electrical shut off (wall switch and breaker) on the exterior of the fire

pit or on adjacent wall to allow for emergency shutdown and maintenance. Verify correct 110VAC, 1 amp or 24VAC 4 amp supply.

All electronic applications should utilize a GFCI protected circuit.

WARNING: For 24V systems a Class II, 24VAC, 4 amps (14 gauge wires) must be supplied to the fire pit and able to be

switched on and off from a remote location to allow for easy access or emergency.

WARNING:All fire pits must have a gas shutoff on the outside of the exterior of the fire pit to allow for emergency shut off and

maintenance. The gas shutoff should not be used to adjust flame height. Refer to your local codes.

WARNING: Use noncombustible materials and construction for gas supply, power and enclosure. A metal outlet box should be

used inside the enclosure for electronic ignition models.

WARNING: We prefer the enclosure incorporate 4 vents total (minimum 18 sq. inches each side) to reduce the risk of thermal

shutdown on the EI Series- some enclosures may require more ventilation based on material, size and extended use. The minimum

requirement is the enclosure incorporate 1 vent on at least 2 sides (2 vents total) at a minimum size of 18 sq. inches of total free area

each (Example: 3”x 6” or larger) to ensure that heat and residual gas can escape. Installation of the vents in the mid to lower area of

the enclosure is recommended. Failure to properly vent enclosure may result in the fire pit overheating or explosion. Continuous

overheating could lead to heat damage to internal components. The vent may work as a drain as well when installed at bottom

sidewall to prevent water build up.

WARNING: The interior void space of the enclosure surrounding the valve box cannot be filled with any material (gravel, crushed

rock, concrete, etc.) - It is a requirement to have a minimum of 2” under the valve box for proper ventilation and drainage.

WARNING: The fire pit assembly should be recessed a minimum of 2.25” from the top of the enclosure to protect flame from

being blown out. Some areas may require more in the range of 4 to 6”.

WARRANTY REQUIREMENT: Do not daisy chain wiring for multiple fire pit installations. Each fire pit must have dedicated

wiring.