Precautions for use of EP Series products:

1. The installation manual should be read carefully before installation and use.

2. Any failure to comply with the content marked by safety warning marks may cause personal

injury, pump damage and other property loss, for which, the manufacturer shall not assume

any responsibility and compensation.

3. Installer, operator and user must comply with the local safety regulations.

4. The user must confirm that installation and maintenance of the product should be conducted

by staff proficient in the instructions and having professional qualification certificates.

5. Pumps must not be installed in damp environment or places that may be splashed by water.

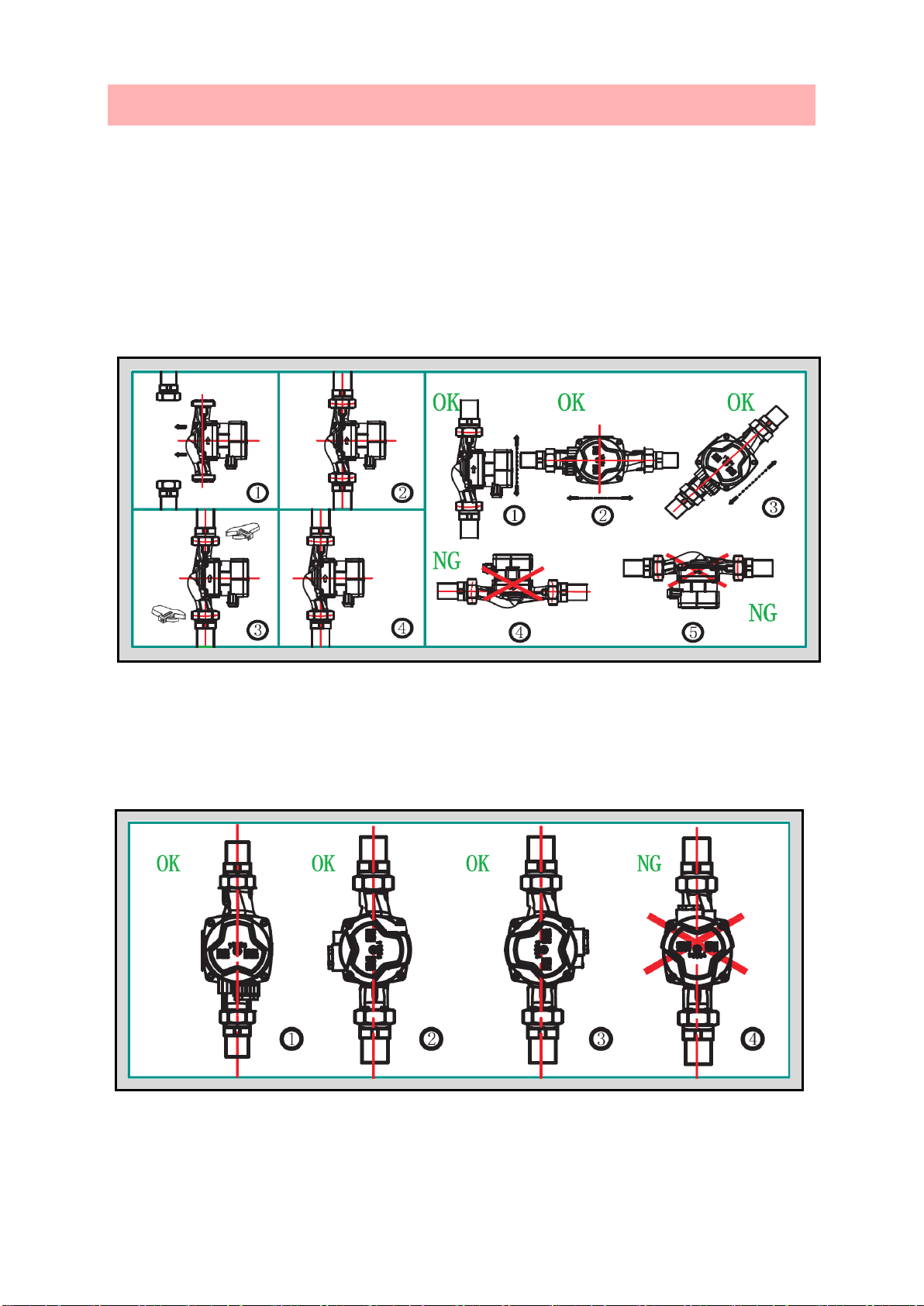

6. In order to facilitate maintenance, one stop valve should be installed on each side of the

pump inlet and outlet respectively.

7. The power supply of pump should be cut off during installation and maintenance.

8. Pump with copper or stainless steel body should be adopted to the domestic hot water

Circulation.

9. The heat feed pipeline should not be supplemented with non-softened water frequently to

avoid an increase in the calcium in the circulating water of pipeline so as not to clog

impellers.

10. It is prohibited to start the pump when there is no pumping liquid.

11. Some models can not be used for diet water.

12. Pumping liquid may be of high temperature and pressure, therefore, liquid in the system

should be drained off or stop valves on both sides of the pump must be switched off to avoid

burns before moving and removing pump.

13. In the summer or when the ambient temperature is high, attention should be paid to

ventilation so as to prevent moisture condensation and cause electrical fault.

14. In the winter, if the pump system does not operate or when the ambient temperature is

below 0℃, liquid in the pipeline system should be emptied to avoid causing frost crack to

the pump body.

15. If the pump does not use for a long time, please turn off the conduit valves on pump inlet

and outlet ends and cut off the power of pump.

16. If he flexible cord is damaged, please connect service center to have it replaced together

with the connector.

17. If it is found that the motor is burning hot and abnormal, immediately turn off the valve on

the pump inlet end and cut off the pump power, besides, immediately contact your local

dealer or service center.